7

INSTALLERUSER

MAINTENANCE TECHNICIAN

1.4 HYDRAULIC CONNECTION.

Attention: before connecting the water heater and

so as not to make the warranty null and void on the

DHW heat exchanger, wash the system thoroughly

(piping, etc.) in a way to remove any residue that

could compromise the good functioning of the

water heater. Hydraulic connections must be made

in a rational way following the set-up of the water

heater couplings.

Attention: to preserve the duration of appliance

eciency features, in the presence of water whose

features can lead to the deposit of lime scale, installa-

tion of the polyphosphate dispenser is recommended.

1.5 ELECTRIC POWER SUPPLY.

is water heater is powered by direct current via

one 1.5 V “LR 20” alkaline battery.

N.B.: The appliance is supplied by Immergas

with a battery in the packaging box and then not

connected.

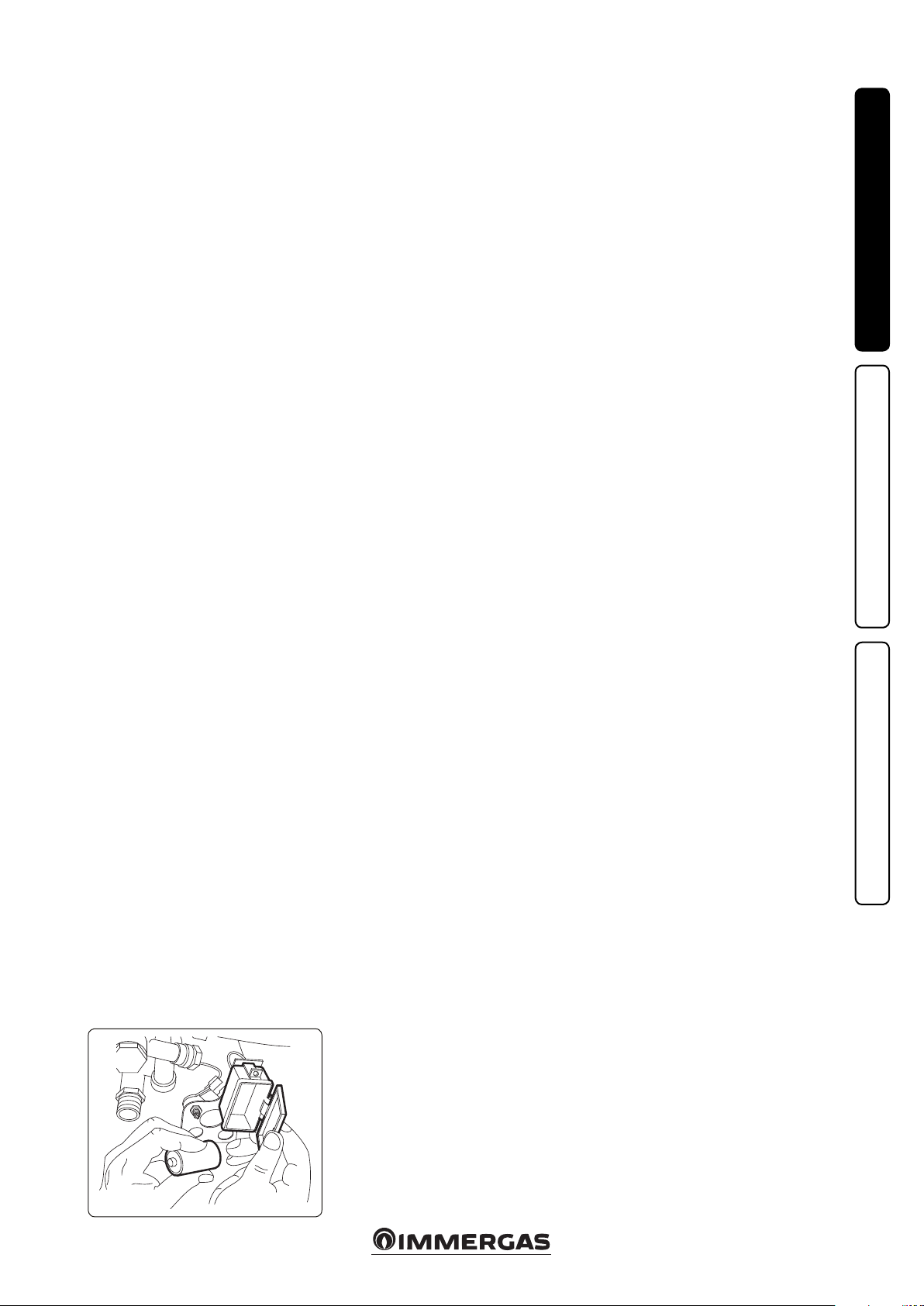

In the ignition phase, it is therefore necessary to

connect it, setting it up in the correct position.

e battery is housed in a relevant compartment

organised in the lower le area, near to the hydraulic

couplings (Fig. 1-3).

Attention: water heater pipes must never be used

to earth the electric or telephone lines. Ensure that

this does not occur before the battery is inserted.

1.6 VENTILATION OF THE ROOMS.

In the room in which the water heater is installed

it is necessary that at least as much air ows as

that requested for by normal combustion of the

gas and ventilation of the room. Natural air ow

must take place directly through:

- permanent openings in the walls of the room

to be ventilated that lead towards the outside;

- ventilation pipes, individual or branched type.

e air used for ventilation must be withdrawn

directly from outside, in an area away from

sources of pollution. Natural air flow is also

allowed indirectly by air intake from adjoin-

ing rooms. For further information relating to

ventilation of the rooms follow that envisioned

in the current technical regulations.

Evacuation of foul air. In the rooms where the

gas appliances are installed it may also be neces-

sary, as well as the intake of combustion agent air,

to evacuate foul air, with consequent intake of a

further equal amount of clean air.

is must be realised respecting the provisions

of the technical regulations in force.

1.7 FLUE DUCTS.

egasapplianceswithattachmentfortheue gasdis-

charge pipe must have direct connection to chimneys

or safely ecient ues. e combustion products can

bedischargeddirectly outsideonlyif thesearemissing,

aslongas thecurrenttechnical regulationsfortheue

terminal are respected as well as the existing laws.

Connection to chimneys or ues. e connection

of the appliances to a chimney or ue takes place by

means of ue ducts.

In the event of ttings with pre-existing ues, these

must be perfectly clean because the detachment of any

wastefromthewallsduringfunctioning,couldblockthe

passage of ue gases, thus causing extremely dangerous

situations for the user.

e ue ducts must be connected to the chimney

or ue in the same room in which the appliance is

installed or, at most, in the adjoining room and must

complywiththe requirements indicatedbythecurrent

technical regulations.

1.8 FLUES/CHIMNEYS.

For the appliances with natural draught individual

chimneys and branched ues can be used.

Individual chimneys. e individual ues must be

dimensioned with respect to the standard in force.

Branched ues. In buildings with lots of oors,

branched ues can be used for the natural draught

evacuation of combustion products. New ues must

be designed following the calculation method and

provisions of the current technical regulations.

Chimney caps. e chimney cap is a device po-

sitioned on the top of an individual chimney or

branched collective ue. is device facilitates the

dispersion of combustion products, even in bad

weather conditions, and prevents the deposit of

foreign bodies.

is must meet the requirements of the current

technical regulations.

In order to prevent the formation of counter-

pressures that prevent the discharge of combustion

products into the atmosphere, the outlet height

corresponding to the top of the chimney/ue, inde-

pendently of any caps, must be out of the “respect

area”. It is therefore necessary to use the minimum

heights indicated in the gures stated in current

technical regulations.

Direct exhaust outside. e natural draught ap-

pliances to be connected to a chimney or a ue can

discharge the combustion products directly to the

outside, through a pipe passing through the perim-

eter walls of the building. In this case discharge takes

place through an ue duct, which is connected to a

draught terminal at the outside.

Positioning the draught terminals. e draught

terminals must:

- be installed on external perimeter walls of the

building;

- be positionedaccordingtothe minimumdistances

specied in current technical standards.

Combustion products exhaust of natural draught

or fan assisted appliances in open-top closed

environments. In spaces closed on all sides with

open tops (ventilation pits, courtyards etc.), direct

combustion product exhaust is allowed for natural

draught or fan assisted gas appliances with a heat

input rangefrom4to 35kW, providedthe conditions

as per the current technical standards are respected.

Important: it is prohibited to put the fumes exhaust

control device out of order voluntarily. Every piece

of this device must be replaced using original spare

parts ifthey have deteriorated. Inthecaseof repeated

interventions of the fumes exhaust control device,

check the ue exhaust pipe and the ventilation of the

room in which the water heater is located.

1.9 GAS SYSTEM STARTUP.

To start up the system, refer to the technical stand-

ards in force.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from the pipelines;

- check that the internal system is properly sealed

according to technical regulations in force.

1.10 APPLIANCE STARTUP IGNITION.

To commission the water heater (the operations listed

below must only be performed by a qualied rm and

without any unauthorised persons):

- check that the internal system is properly sealed ac-

cordingto thespecicationsset forth by regulations

in force;

- ensurethatthe typeofgasusedcorrespondstowater

heater settings;

- check that there are no external factors that may

cause the formation of fuel pockets;

- switch the appliance on and check correct ignition;

- make surethatthegasowrateandrelevantpressure

values comply with those given in the manual (see

par. 3.11);

- check the correct ventilation of the rooms;

- checkthe existingdraughtduringnormalfunction-

ing of the appliance, e.g. a draught gauge positioned

at the exit of the appliance combustion products;

- check that there is no backflow of combustion

products into the room, even during functioning

of fans;

- ensure that the chimney safety device intervenes in

the event of gas supply failure and check the relative

intervention time;

e water heater must not be started up even if only

one of the checks should be negative.

1.11 KITS AVAILABLE ON REQUEST.

• Water/gas connection cock kit (on request).

e gas cock is indispensable and must be type-

approved for the pre-xed use.

• Flexible pipes connection kit. ey can be used for

the DHW circuit connection.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Fig. 1-3