Impact Subsea ISM3D User manual

www.impactsubsea.com

Innovative Underwater Products

ISM3D

Heading, Pitch & Roll Sensor

Installation & Operation

Manual

Revision: 1.2

Date: 09/01/19

Impact Subsea Ltd

T. +44 (0) 1224 460 850

E. info@impactsubsea.co.uk

W. www.impactsubsea.com

Contents

1.0 Introduction.................................................................................................................................3

2.0 Specification................................................................................................................................4

2.1 Unit Overview .................................................................................................................4

2.2 Unit Dimensions..............................................................................................................4

2.3 Attitude & Heading Reference System............................................................................5

2.4 Communications, Power & Physical...............................................................................5

3.0 Overview.....................................................................................................................................6

4.0 Installation .............................................................................................................................7

4.1 Location............................................................................................................................7

4.1.1 Magnetic Disturbers (For Heading Accuracy).....................................................7

4.1.2 Alignment with Vehicle (For Pitch/Roll Accuracy)...............................................7

4.2 Mounting .........................................................................................................................9

4.3 Electrical .......................................................................................................................10

4.3.1 Connector Pin Out..............................................................................................10

4.3.2 Power..................................................................................................................11

4.3.3 Serial Interface....................................................................................................11

4.3.4 RS232 Wiring.....................................................................................................11

4.3.5 RS485 Wiring.....................................................................................................12

4.3.6 Establishing Communications............................................................................13

4.3.7 Connector Mating...............................................................................................13

4.3.8 Connector Cleaning............................................................................................13

5.0 Operation ..................................................................................................................................14

5.1 Use With seaView Software...........................................................................................14

5.2 Integration With Systems...............................................................................................15

5.3 ISM3D Setup..................................................................................................................15

5.4 Magnetic Calibration......................................................................................................18

6.0 ASCII Output Strings ...............................................................................................................23

6.1 AHRS.............................................................................................................................23

7.0 Servicing....................................................................................................................................26

8.0 Warranty....................................................................................................................................27

9.0 Technical Support .....................................................................................................................28

Every effort is made to ensure that information within this document is up to date. However, information within this

document is subject to change without notice, in-line with our commitment to continuous product development and

improvement.

www.impactsubsea.com

Innovative Underwater Products

1.0 Introduction

The ISM3D sensor is a compact and highly accurate Attitude and Heading

Reference System providing Heading, Pitch & Roll.

Suitable for a large range of underwater applications, the ISM3D can be used with

ROVs, AUVs, Hydro-graphic Survey, Construction, Positioning and any other

application where accurate Heading, Pitch & Roll is required underwater.

The Heading, Pitch and Roll readings are provided from integrated Micro Electro

Mechanical Systems (MEMS) based Magnetometers, Accelerometers and

Gyroscopes. The outputs of each MEMs based device are fused together to provide

highly accurate and stable Heading, Pitch and Roll measurements.

Using the Inertial Heading mode, the ISM3D also provides a high resilience against

temporary magnetic interferers. This enables successful prolonged operation

alongside steel structures where required.

Housed in a compact and lightweight Titanium or Delrin® housing ensures that the

ISM3D is not only at the forefront of sensor technology; but is built to withstand the

most extreme underwater environments.

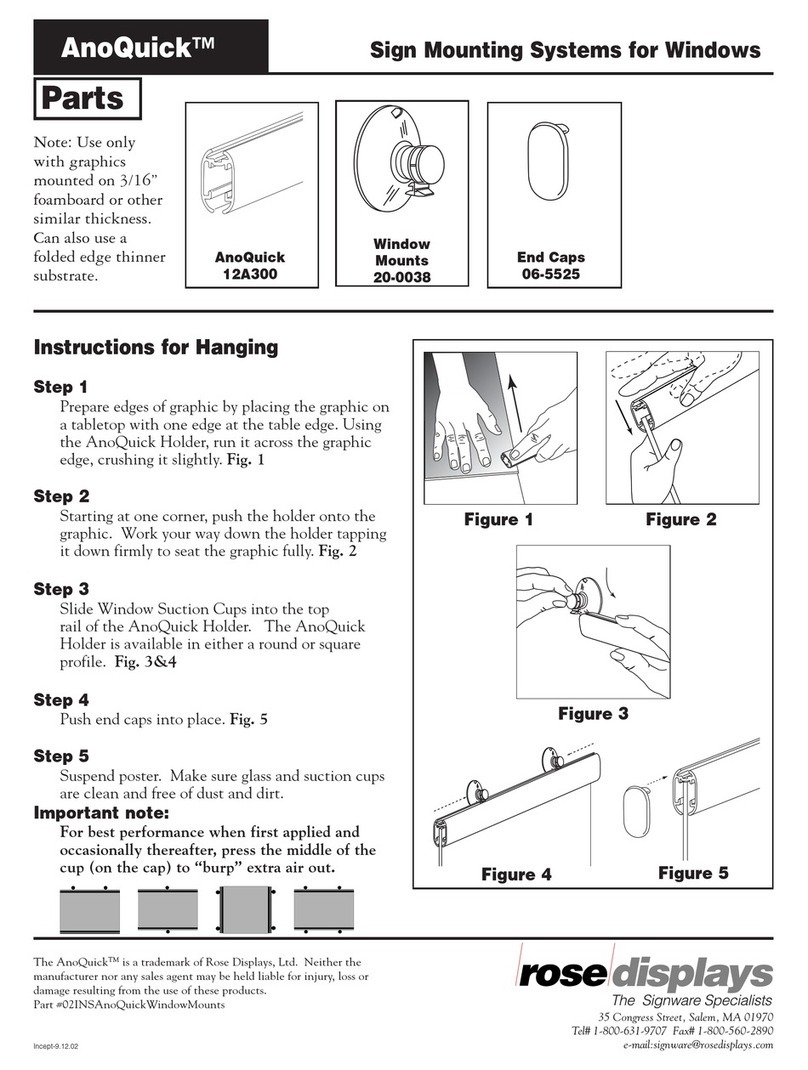

ISM3D Attitude & Heading Reference System (Titanium)

© Impact Subsea Ltd 3

www.impactsubsea.com

Innovative Underwater Products

2.0 Specification

2.1 Unit Overview

2.2 Unit Dimensions

All dimensions are in mm.

© Impact Subsea Ltd 4

www.impactsubsea.com

Innovative Underwater Products

2.3 Attitude & Heading Reference System

Heading Attitude

Accuracy ± 0.5° of Magnetic

North

Pitch ± 90°

Roll ± 180°

Resolution 0.01° Accuracy ± 0.07°

Resolution 0.01°

2.4 Communications, Power & Physical

Communications & Power Physical

Digital RS232 & RS485 Weight

(Air/Water)

Titanium: 0.33/ 0.225kg

Delrin: 0.20 / 0.10kg

Protocol 300 to 115,200

baud

Depth Rating Titanium: 6,000 meters

Delrin: 1,000 meters

Data Continuous or on

demand

Temperature Operating: -10 to 50°

Storage: -20 to 70°

Data Rate Up to 250Hz Connector Subconn MCBH8M-SS

fitted as standard

Input Voltage 7 to 32V DC

Power 29mA @ 24V DC

© Impact Subsea Ltd 5

www.impactsubsea.com

Innovative Underwater Products

3.0 Overview

The ISM3D is a highly compact, robust and accurate underwater Attitude & Heading

Reference System (AHRS).

The ISM3D is depth rated to 1,000 meters (Delrin®) or 6,000 meters (Titanium).

The Heading, Pitch and Roll readings are provided by a Micro-Electro-Mechanical

system (MEMS) based technology. MEMs based Gyros, Accelerometers and

Magnetometers are integrated within the unit.

The outputs from each MEMS based sensor are processed by an advanced fusion

algorithm to provide highly stable and accurate Heading, Pitch & Roll.

For optimal heading performance, a hard and soft iron calibration can be performed

on the unit once installed on the ROV, AUV or other underwater platform. This

ensures that a consistently accurate heading is provided at all times.

In areas where a large amount of steel or other magnetic disturber is present, the unit

can be switched to Inertial mode. Inertial mode operates using the Angular Rate

Gyroscopes and Accelerometers, without input from the Magnetometer. The low drift

rate of the MEMS based Gyroscopes enables navigation to be conducted in areas

where previously only a fibre or ring laser diode based heading sensor would suffice.

The ISM3D can be configured using the supplied seaView software. seaView allows

all settings to be configured (output strings, communications protocol, baud rate etc).

In addition to allowing the ISM3D to be configured, seaView also allows all outputs to

be viewed in real time and logged.

© Impact Subsea Ltd 6

www.impactsubsea.com

Innovative Underwater Products

4.0 Installation

4.1 Location

When evaluating the installation location of the ISM3D, there are several

factors to consider to achieve optimum operation from each part of the

unit:

–Magnetic Disturbers (Heading)

–Alignment with Vehicle (Pitch/Roll)

4.1.1 Magnetic Disturbers (For Heading Accuracy)

Where the heading output is to be used, the ISM3D should be mounted as

far as possible from sources of magnetic interference.

Electrical items which can cause magnetic interference include motors,

transformers and valve packs.

Ferrous metals, or any other magnetically active materials will also have

influence on the heading reading. Thus, where possible, the unit should be

installed as far as possible from magnetically active materials.

A magnetic calibration should be conducted using the seaView software once

the unit is physically installed.

4.1.2 Alignment with Vehicle (For Pitch/Roll Accuracy)

When mounting vertically, the ISM3D should be mounted with the

base (complete with mounting screw holes) facing downwards (to the

seabed) and the indentation in the connector end cap pointing forwards, in

the direction of forward vehicle travel:

© Impact Subsea Ltd 7

www.impactsubsea.com

Innovative Underwater Products

When mounting horizontally the ISM3D should be installed with the

indentation in the connector end cap pointing upwards:

© Impact Subsea Ltd 8

www.impactsubsea.com

Innovative Underwater Products

4.2 Mounting

The ISM3D should be mounted using four M5 Screws, screwed into the base

of the unit:

Alternatively the unit has a 31mm recess in the main body to enable a

clamp to be tightened securely around the unit:

Ideally a non-metallic clamp should be used, however in the event that this is

not possible, effort should be made to electrically isolate the clamp from the

ISM3D housing. This can be achieved by using rubber or plastic strips

around the body of the ISM3D.

The ISM3D has two flats, on either side of the body – these are to enable

the unit to sit tightly against another flat surface if available.

© Impact Subsea Ltd 9

www.impactsubsea.com

Innovative Underwater Products

4.3 Electrical

The ISM3D is fitted with a SubConn MCBH8M-SS connector as standard.

This will mate to a SubConn MCIL8F connector/cable assembly.

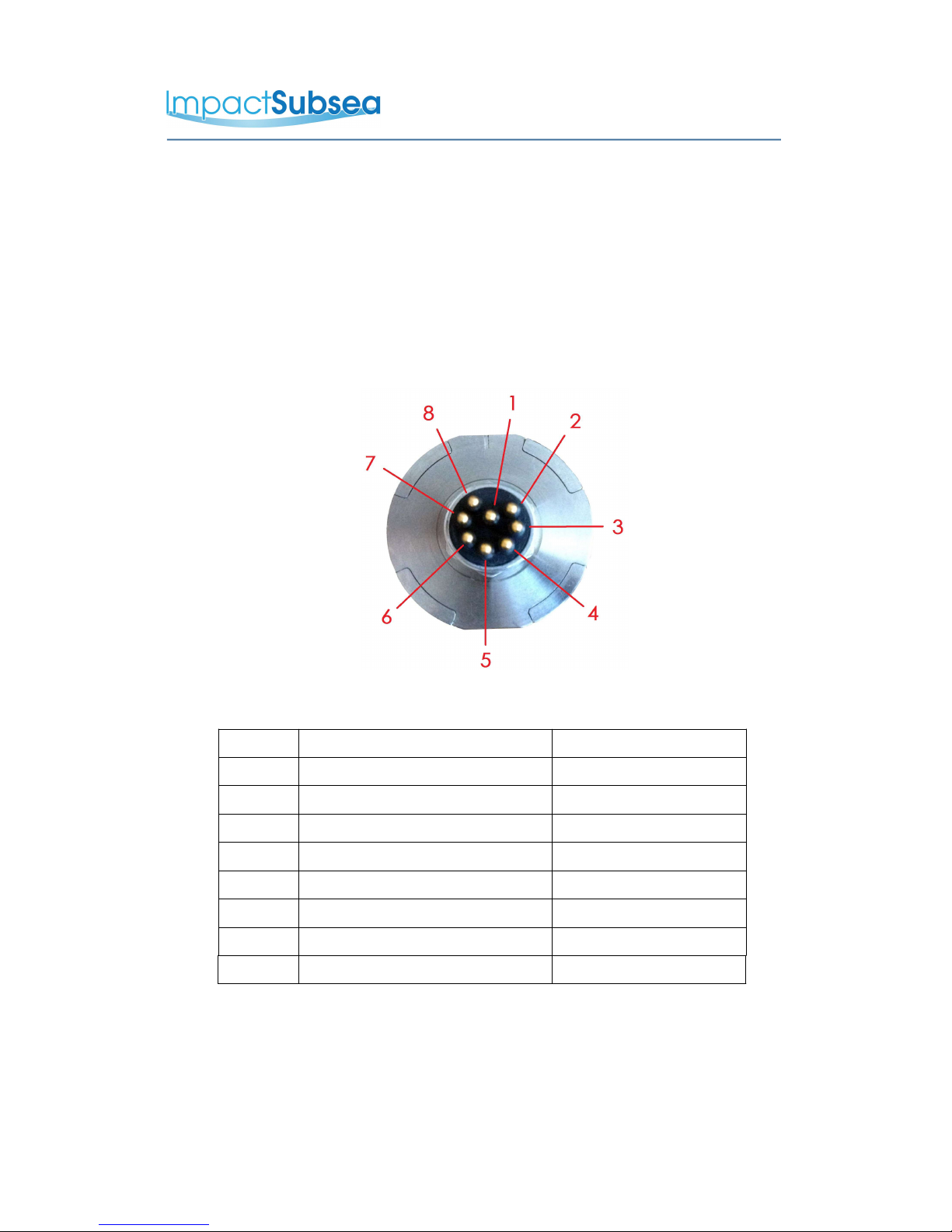

4.3.1 Connector Pin Out

The standard connector pin out is provided below:

Male Connector on ISM3D Unit

Pin Function Mating Wire Colour

1 0VDC Black

2 7-32VDC White

3 Not Used Red

4 Not Used Green

5 0V Digital Orange

6 Not Used Blue

7 RS232 TX & RS485 A+ White/Black

8 RS232 RX & RS485 B- Red/Black

© Impact Subsea Ltd 10

www.impactsubsea.com

Innovative Underwater Products

4.3.2 Power

The ISM3D is polarity protected and fused with a 400mA resettable poly

fuse. Internal circuitry isolates the supply from the outside environment

requiring the serial interface to use the digital 0V reference pin.

4.3.3 Serial Interface

The RS232 and RS485 interface is isolated from the supply and has in-line

fused protection on the serial lines. A prolonged transient voltage on these

lines will blow the surface mount fuses which will require replacement by

Impact Subsea or an approved distributor.

4.3.4 RS232 Wiring

© Impact Subsea Ltd 11

www.impactsubsea.com

Innovative Underwater Products

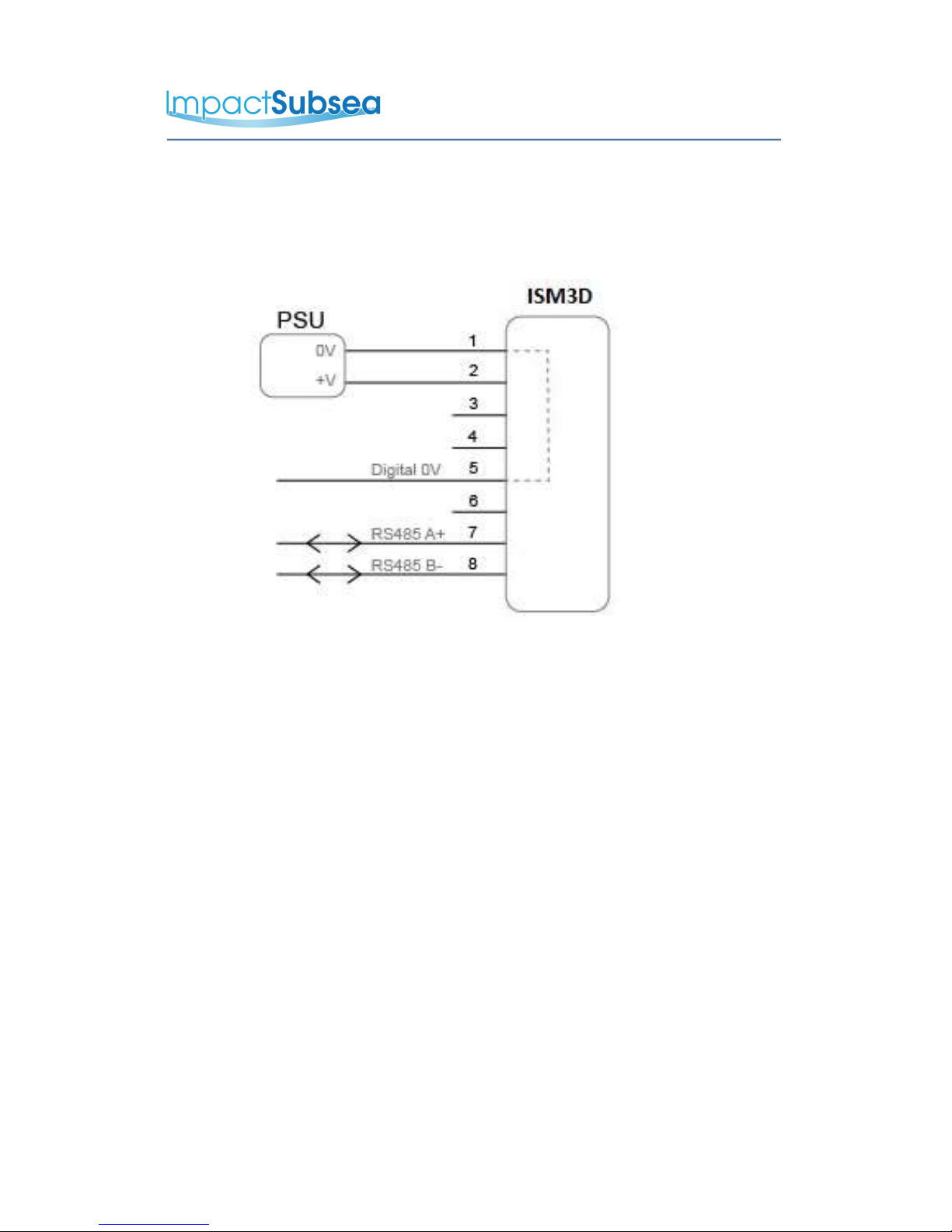

4.3.5 RS485 Wiring

The RS485 termination resistor is software selectable.

The digital 0V must be connected on an RS485 interfaces, otherwise

the voltage potential between one of the A+ or B- lines to ground could

reach a damaging level

© Impact Subsea Ltd 12

www.impactsubsea.com

Innovative Underwater Products

4.3.6 Establishing Communications

The default serial settings are RS232, 9600, N81

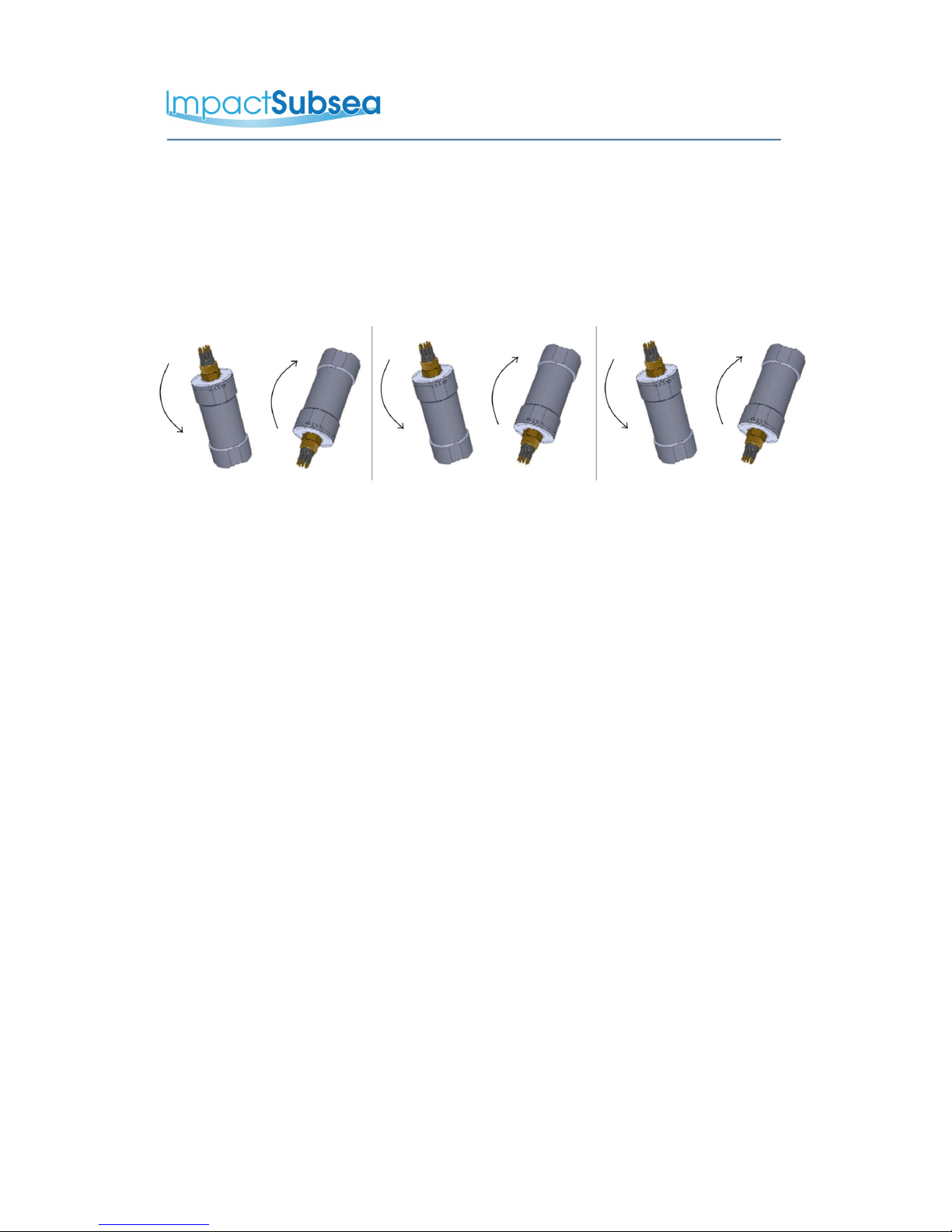

If the ISM3D is tilted from vertical to upside down 3 times within the first 10

seconds of power up then it will temporarily configure the serial interface to

the default and output an ASCII message with the settings.

Note: When the device is powered cycled the serial interface setting will

revert back to the last configuration.

4.3.7 Connector Mating

When mating the cable to the SubConn connector, to maximise the life of the

connector, it is important to observe the following:

–Always apply grease before mating. Molykote 44 Medium grease must be

used.

–Disconnect by pulling straight, not at an angle.

–Do not pull on the cable and avoid sharp bends at cable entry.

–Do not over-tighten the bulkhead nut.

Do not expose the connector to extended periods of heat or direct sunlight. If

a connector becomes very dry, it should be soaked in fresh water before use

4.3.8 Connector Cleaning

General cleaning and removal of any accumulated sand or mud on a

connector should be performed using spray based cleaner (for example

Isopropyl Alcohol).

New grease must be applied again prior to mating.

© Impact Subsea Ltd 13

www.impactsubsea.com

Innovative Underwater Products

5.0 Operation

5.1 Use With seaView Software

The ISM3D is supplied with the highly intuitive seaView software.

The latest version of seaView can be downloaded from

www.impactsubsea.com

seaView can be used with all Impact Subsea sensors. Single sensors can be

operated, or multiple sensors together.

seaView is designed for use with a PC running the Windows 7, 8 or 10

operating system and requires Microsoft's .net framework 4.5.2 or above to

be installed.

seaView uses an advance framed binary protocol to communicate to the

ISM3D and can do so over RS232 or RS485 at any standard baud rate.

The parity must be none, stop bits 1 and data bits 8. If the ISM3D

communication settings differ from this then perform the comms

reset as described in the 'Establishing Communications' section of this

manual.

All settings and offsets are saved to the ISM3D device flash memory.

Impact Subsea seaView Software

© Impact Subsea Ltd 14

www.impactsubsea.com

Innovative Underwater Products

5.2 Integration With Systems

Conceptually there are two modes of operation, Interrogated and

Autonomous.

Integration mode requires a master to request the ISM3D to make a

measurement and report this back.

The ISM3D can be interrogated by the user defined interrogation string.

Upon interrogation the ISM3D will make a measurement and report back

the result over the serial interface.

Autonomous mode will make a measurement and output the results at a

specified time interval.

The ISM3D can be configured to operate in one or both of these modes at

the same time.

5.3 ISM3D Setup

The ISM3D unit can be configured to output a variety of output strings,

at various output rates, autonomously or by interrogation.

Offsets can be applied to the Heading, Pitch & Roll, the reference point for

Pitch, Roll & Heading can be changed and Inertial Mode can be enabled and

disabled.

All settings can be viewed and adjusted by using the Impact Subsea seaView

software. To alter settings, the ISM3D application should be run and the

settings page opened.

Clicking the green tick 'Save' button at any time will save the configured

settings to the ISM3D firmware. These settings will then be held until the

ISM3D is next configured using the seaView software.

© Impact Subsea Ltd 15

www.impactsubsea.com

Innovative Underwater Products

5.3.1 Communication Protocol

The Serial Mode can be adjusted (RS232, RS485 or RS458 Terminated).

The baud rate, word length, parity and stop bits can also be adjusted to suit interface requirements.

5.3.2 ISM3D Setup

The second setup page allows configuration of the output string, which mode the ISM3D should work in

along with various offsets:

The settings on each line (1 to 4) shown above are detailed:

© Impact Subsea Ltd 16

www.impactsubsea.com

Innovative Underwater Products

Line 1:

Allows for the selection of the required output string:

Line 2:

Allows autonomous mode to be enabled and disabled. When enabled, the rate at which the output string

(defined in line 1) is set in times per second (Hz).

Line 3

Allows for an interrogation string to be enabled and disabled. When enabled the interrogation string (which

is used to trigger the output defined in line 1) can be configured to a command of the users choice. If this is

not altered, the default trigger command is #o<CR>.

Line 4

Allows an offset to be applied to the Heading, Pitch & Roll. If the difference between magnetic north and true

north is known, the offset can be applied here (either positive or negative degrees). This will enable the

ISM3D to report True North heading values.

Any inaccuracy in mounting (causing an offset to the pitch & roll) can be zero'd using the Pitch and Roll

offsets.

If the unit has been mounted Horizontally or Inverted, this can be set in the buttons of Line 4.

Line 4 also allows the Inertial Mode of the ISM3D to be enabled or disabled. The default and recommended

setting is to have the inertial mode enabled.

When inertial mode is enabled, the magnetometers are only used for the first ten seconds after power up to

find magnetic north. After ten seconds, the high grade MEMS Gyros take over as the primary heading

device and update the heading accordingly. In this mode the unit is highly resilient to magnetic interference

and can operate alongside sources of magnetic interference for several hours without significant drift in the

heading.

© Impact Subsea Ltd 17

www.impactsubsea.com

Innovative Underwater Products

5.4 Magnetic Calibration

Following final physical installation on the vehicle (or other structure) it is

critical that a magnetic calibration is conducted.

The magnetic calibration takes into account all local hard and soft iron

artefacts of the vehicle (or other structure the ISM3D is mounted to). This

enables the correction of any heading offsets that permanent magnetic

interferers may cause.

If the magnetic calibration is not conducted, the heading will not be

correct and will suffer from non linear movement when rotated. For example

when operating with inertial mode disabled, a 90° physical rotation may only

be recognised as a 80° rotation.

To conduct a good magnetic calibration, please complete the following

procedure. There is also a video demonstration of this procedure available

on the ISM3D product page of the Impact Subsea website.

5.4.1 Magnetic Calibration Procedure

Step1:

Ensure that the ISM3D has been physically installed in a location as free from magnetic interference as

possible (away from value packs, thrusters etc).

Step 2:

Check that the ISM3D is mounted securely to the structure ensuring the unit is not able to move

independently from the structure.

Step 3:

If conducting the magnetic calibration in a workshop, ideally hang the ROV from a crane away from magnetic

sources. If conducting the calibration at sea, deploy the ROV and move into open water, away from any

structures with a magnetic property (vessel, pipeline etc). Do not conduct the calibration with the ROV

on the vessel.

© Impact Subsea Ltd 18

www.impactsubsea.com

Innovative Underwater Products

Step 4:

Run the seaView software, select the ISM3D application and connect to the ISM3D unit:

Step 5:

Once connected to the ISM3D, go into the ISM3D settings (Gear Cog graphic)

Step 6:

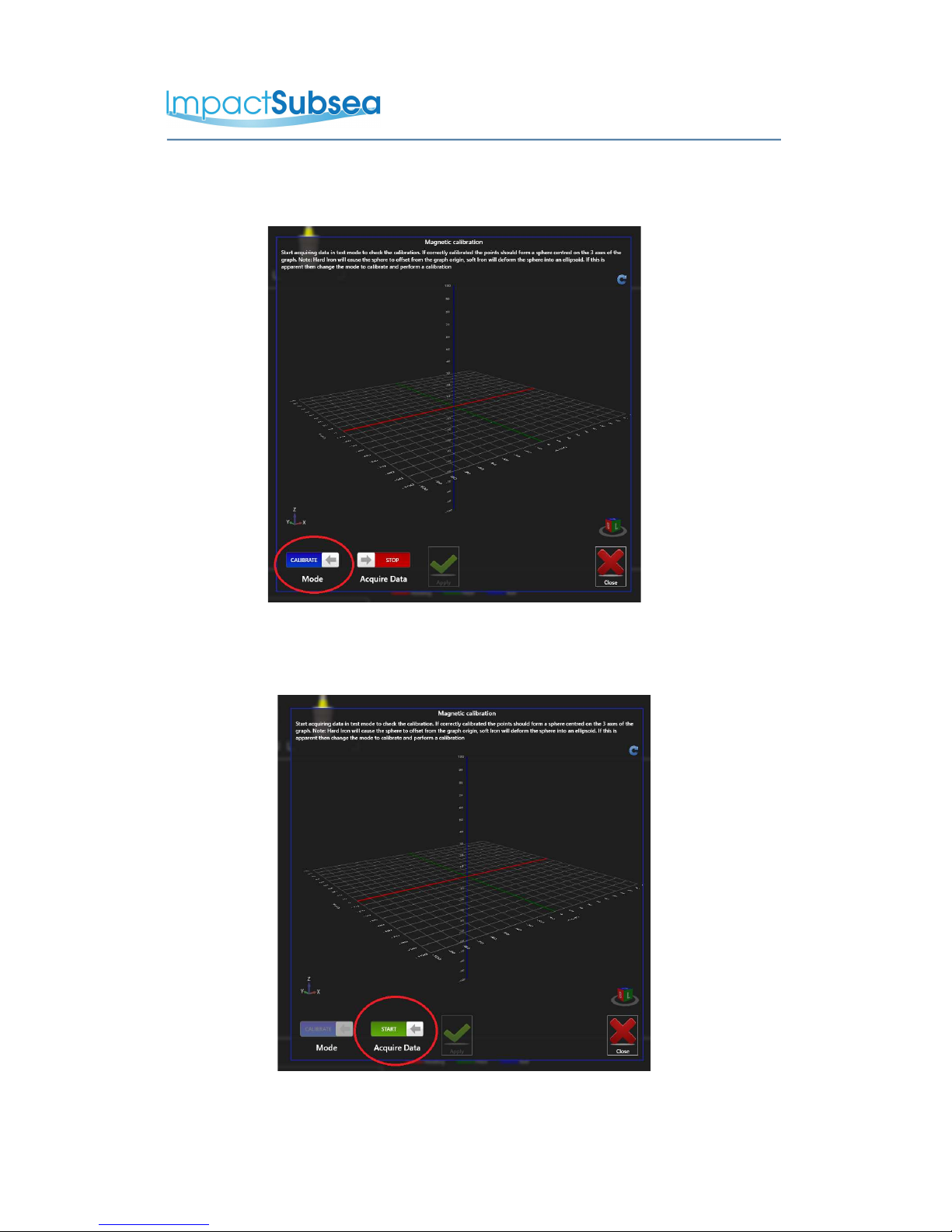

Click on the 'Calibrate' button to open the calibration window:

© Impact Subsea Ltd 19

www.impactsubsea.com

Innovative Underwater Products

Step 7:

On the 'Mode' button, click this to change it to 'Calibrate'

Step 8:

On the 'Acquire Data' button change to 'Start'. The calibration process has now begun.

© Impact Subsea Ltd 20

Table of contents

Other Impact Subsea Accessories manuals

Popular Accessories manuals by other brands

aldes

aldes Agito and Presence Assembly instructions

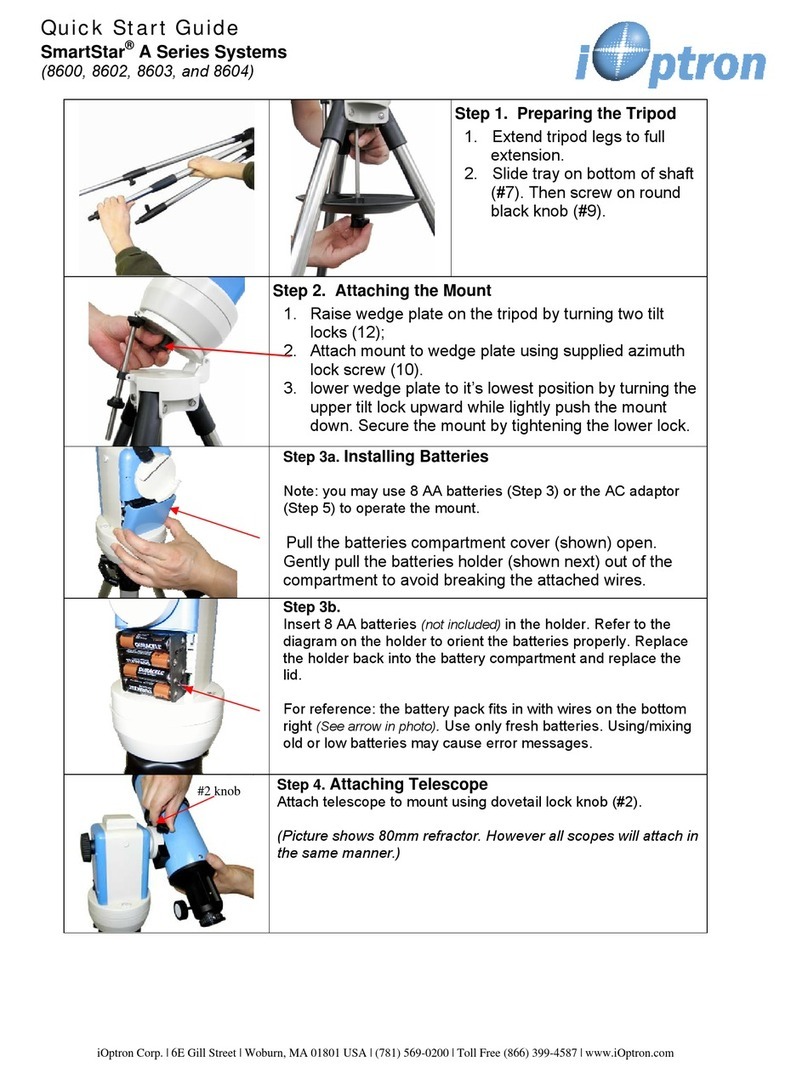

iOptron

iOptron SmartStar 8600A quick start guide

Clas Ohlson

Clas Ohlson SCW-6002 user manual

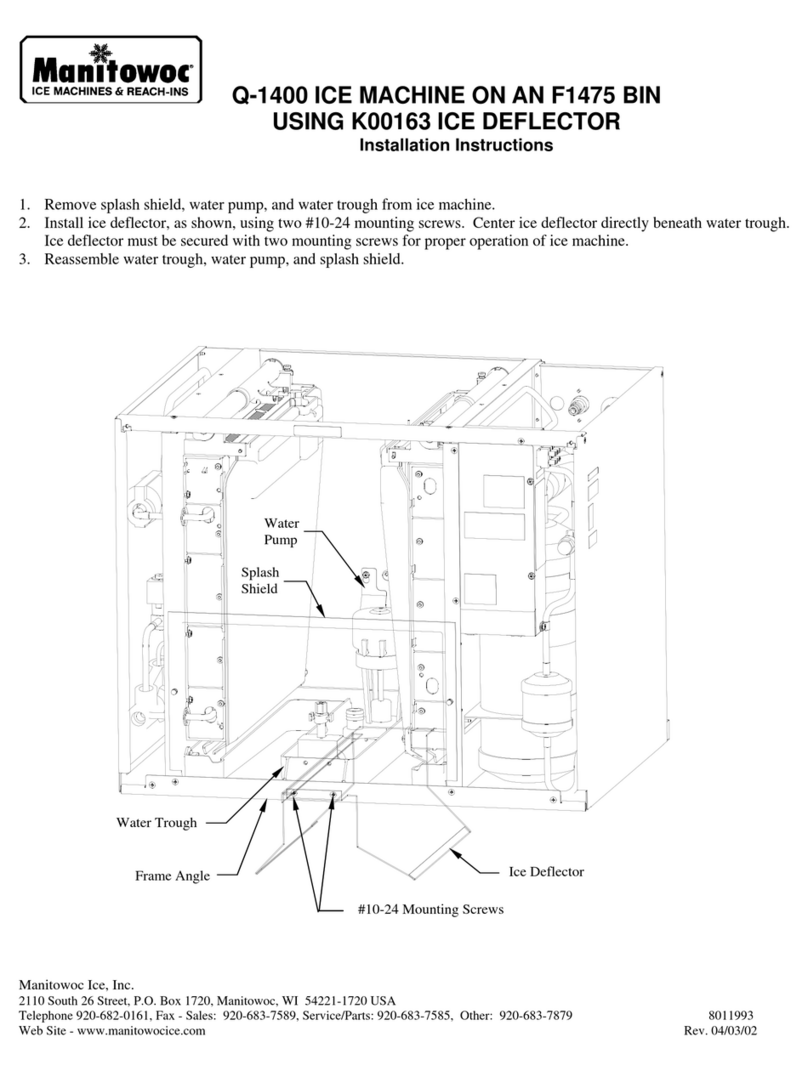

Manitowoc

Manitowoc Q-1400 installation instructions

Dahua Technology

Dahua Technology Wireless Door Detector Plus user manual

Mobicool

Mobicool MCG15 operating manual