IMS

E3T-

INSTRUCTION MANUAL

! WARNING

! CAUTION

Thank you for selecting IMS product.This sheet primarily describes precautions

required in installing and operating the product.Before operating the product,read

the sheet thoroughly to acquire sufficient knowledge of the product.For your

convenience,keep the sheet at your disposal.

Failure to follow these instructions may result in serious injury or death:

Fail-safe device must be installed when using the unit with machinery that may

cause serious injury or substantial economic loss. (e.g. nuclear power control,

medical equipment, ships, vehicles, railways, aircraft, combustion apparatus,

safety equipment, crime/disaster prevention devices,etc.)

Failure to follow these instructions may result in product damage:

Do not use this unit over rated voltage;

Do not use this unit where there is flammable or explosive gas;

Do not use this unit where there is vibration or impact;

In cleaning the unit, do not use water or an oil-based detergent.

Control box

Specifications

LED1:sensor output status

LED2:transmission power adjustment status

Key1:Increase the transmitting power

Key2:Reduce the transmitting power

Functions of indicators and keys

Operation instruction

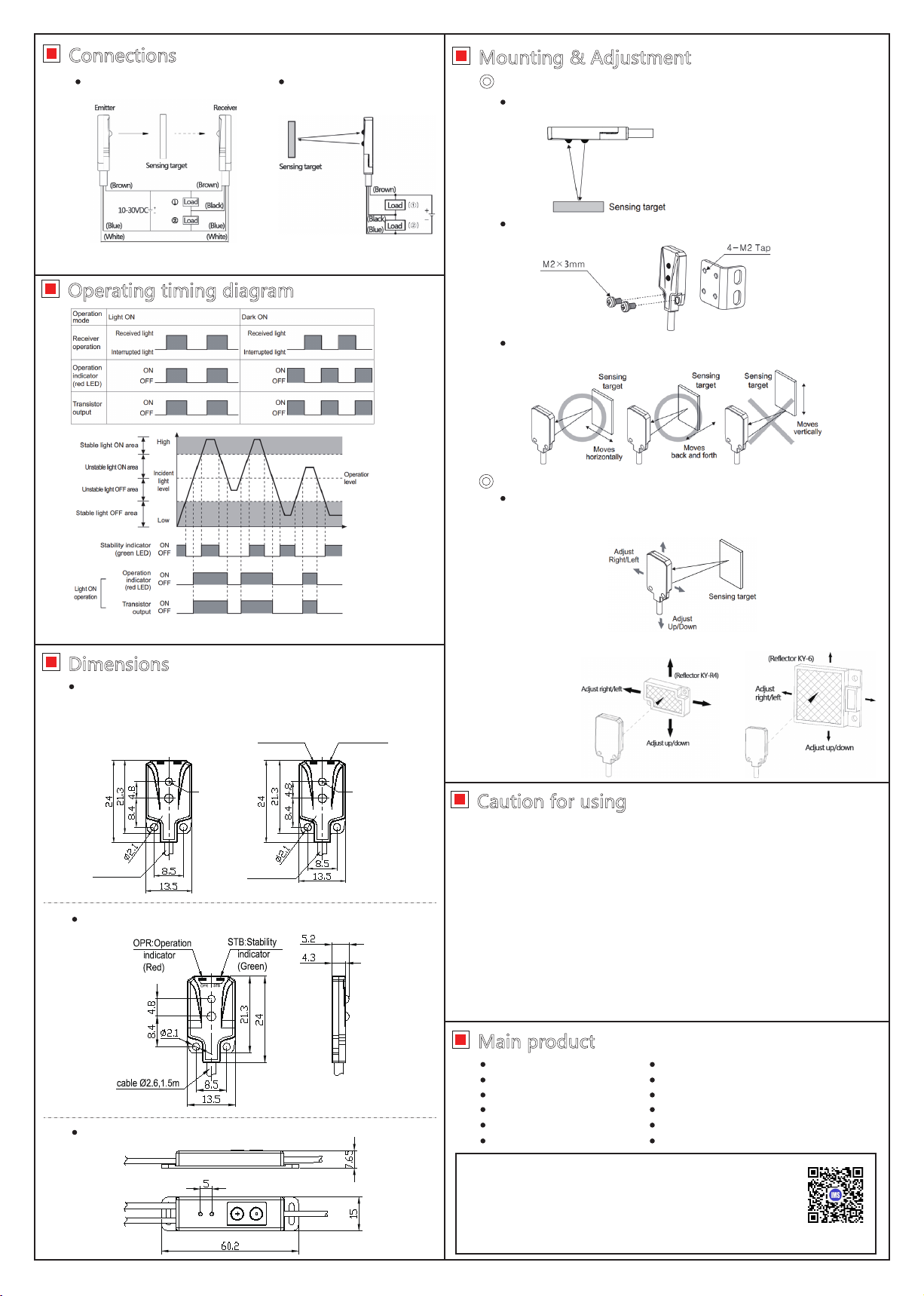

Control output circuit diagram

NPN open collector output

PNP open collector output

1ms

0.25ms

M

Ordering information

L

Cable type

Connector type

C

E3T D 1 M N L T C

Connection type

Tavailable

Fixed

Response time

Item E3T

Photoelectric sensor

Number Sensing distance

Output

Sensing distance unit

Sensing distance

(slot series use 30/50 to refer slot distance)

Sensing method(slot series is none)

Operation mode

Sensitivity

T

D

R

Through-beam

Diffuse reflective

Retro reflective

V

B

Convergent Reflective

Polarization opaquing

(

Light source code

)

Light on

Dark on

Selectable

D

S

L

N

P

O

D

C

A

NPN

PNP

NPN+PNP

5V

Relay

Analog

Unit:mm

Unit:m

M

(*1) Reflector:KY-R4

(*2) Reflector:KY-6

①

②

Sensing method

Sensing distance

Sensing object

Model NPN

PNP

Through-beam Diffuse reflective

E3TT -N

E3TT -P

E3TD -N E3TR -N

E3TD -P E3TR -P

0~500mm/1m 30/50/70mm(Non-glossy

white paper 50*50mm)

200mm(*2)100mm(*1)

Opaque materials of

max. φ2mm

Opaque materials of

φ2mm

φ0.5mm(sensing distance

10mm)

φ2mm(sensing

distance100mm)

Min. sensing target

Hysteresis

Response time

Power supply

Current consumption

Light source

Operation mode

Output

Insulation resistance

Noise strength

Dielectric strength

Vibration resistance

Shock resistance

Ambient illumination

Ambient temperature

Ambient humidity

Degree of protection

Cable

Material

Accessory

Weight

Indicators

Circuit protection

Max. 20% at rated sensing

distance

Max.1ms

Max. 20mA

10~30VDC(including ripple Max.10%(p-p))

Red LED(650nm)

Light ON/Dark ON

NPN or PNP open collector output

Max. 100mA

(

Residual voltage:Max. 3V

),Load voltage:Max. 26.4VDC

Reverse polarity protection、output short-circuit protection、

Over current protection

Operation indicator:Red,Output indicator:Green

Min. 20MΩ ( at 500VDC megger )

±240V the square wave noise(pulse width:1μs)by the noise simulator

1000VAC 50/60Hz for 1 minute

1.5mm or 300m/s² amplitude at frequency of 10 to 55Hz in each of

X,Y,Z direction for 2 hours

500m/s² in X,Y,Z directions for 3 times

Sunlight:Max. 11,000lx ,

Incandescent lamp:Max. 3,000lx (Receiver illumination)

Operation:-25 ~ 55 ℃,Storage:-40 ~ 70 ℃(with no icing)

Operation and storage:35 ~ 85 %RH(with no condensation)

IP64(IEC standards)

Case:PBT,Lens:PMMA

φ2.6mm,3P,Length:2m (Through-beam type:3P/4P,

Length:1.5m)

(AWG28,Core wire diameter 0.08mm,No. of core wire:16,Insulator

out diameter:0.8mm)

Fixing bracket,screw

Approx. 40g Approx. 25g

Retro reflective

Opaque materials Opaque materials

Load current

Key1

Key2

Short press key1 one time:Increase the transmitting power slightly. When the power

up to the maximum, LED2 will blink at an interval of 0.25s.

Short press key2 one time:Decrease the transmitting power slightly. When the power

down to the minimum, LED2 will blink at an interval of 0.5s.

Long press key1:When the long press time reaches 2s, the transmitting

power will continue to increase. The voltage will no longer change after release the

button. When the LED2 flashing, it means the power reaches the maximum.

Long press key2:When the long press time reaches 2s, the transmitting power will

continue to decrease. The voltage will no longer change after release the button.

When the LED2 flashing, it means the power reaches the minimum.

Save setting:The parameter will be automatically saved to EEPROM and does not

need to be set next power on.

Compact Photoelectric Sensor

Load

Over

current

protection

Blue(0V)

(Black)Output

(Brown)+V

10~30VDC

+

-

Max. 100mA

Stability

(green)

Main circuit

Load

Over

current

protection

Blue(0V)

(Black)Output

10~30VDC

+

-

Max. 100mA

(Brown)+V

Operation

(red)

Stability

(green)

Main circuit

Operation

(red)