Inawise TPMS-4WD series Manual

I

nawise

(

Australia

)

Pt

y

Ltd

Product features and installation instructions

for the TPMS-4WD-V2tyre pressure and

temperature monitoring system.

Document Number: 913-9001 Rev G 11/July/2012

User and installation

guide

TPMS-4WD series TyrePressure

MonitoringSystem

(TPMS)

PAGE II

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

TABLE OF CONTENTS

INTRODUCTION..................................................................................................................................1

PRODUCT APPLICATION AND FUNCTIONALITY.....................................................................1

1. TPMS-4WD-V2 PRODUCT OVERVIEW..................................................................................1

2. PRODUCT FEATURES................................................................................................................3

2.1 FEATURES SUMMARY ................................................................................................................3

2.2 THEORY OF OPERATION .............................................................................................................4

3. INSTALLATION ...........................................................................................................................5

3.1 INSTALLING DISPLAY UNIT........................................................................................................5

3.1.1 Mounting location ............................................................................................................5

3.1.2 +12V power source determination...................................................................................6

3.1.2.1 Cigarette lighter power option: ................................................................................................... 6

3.1.2.2 Hard wired power option: ........................................................................................................... 6

3.1.3 RF Antenna.......................................................................................................................7

3.1.3.1 Wire Antenna.............................................................................................................................. 7

3.1.4 Fixing display module into place......................................................................................8

3.1.5 Reconnect vehicle battery.................................................................................................8

3.2 INSTALLING SENSOR/TRANSMITTER MODULES..........................................................................9

3.2.1 Identify the ID-Keys..........................................................................................................9

3.2.2 Sensor Disassembly........................................................................................................10

3.2.3 Loosen Electronic module..............................................................................................10

3.2.4 Fix Sensor.......................................................................................................................11

3.2.5 Adjust head angle ...........................................................................................................11

3.2.6 Torque valve stem...........................................................................................................11

3.2.7 Mount tyre ......................................................................................................................12

3.2.7.1 Lubricate................................................................................................................................... 12

3.2.7.2 Position tyre.............................................................................................................................. 12

3.2.7.3 Position upper bead................................................................................................................... 12

3.2.7.4 Finish fitting tyre....................................................................................................................... 12

3.3 SETTING PRESSURE RANGE ......................................................................................................13

3.4 CHECKING CURRENT PRESSURE RANGE ...................................................................................13

3.5 TURNING ON THE SENSOR/TRANSMITTERS ..............................................................................14

3.6 CHECKING THE SYSTEM WORKS...............................................................................................14

4. TYRE REMOVAL.......................................................................................................................15

4.1 BREAKING UPPER AND LOWER BEAD. ......................................................................................15

4.2 UPPER AND LOWER BEAD DEMOUNT........................................................................................15

PAGE III

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

5. OPERATING PROCEDURE......................................................................................................16

5.1 GENERAL.................................................................................................................................16

5.2 TURNING ON LCD BACKLIGHT................................................................................................16

5.3 DISPLAYING TYRE TEMPERATURE...........................................................................................17

5.4 DISPLAYING SENSOR KEY ID..................................................................................................17

5.5 DISPLAYING CURRENT PRESSURE RANGE.................................................................................17

5.6 SETTING BASE PRESSURE........................................................................................................18

5.7 ROTATING TYRES ....................................................................................................................18

5.8 DISABLING MONITORING OF SPECIFIC WHEELS ........................................................................19

5.9 REPLACING SENSORS...............................................................................................................19

5.10 SPARE TYRES ..........................................................................................................................19

6. DISPLAYS AND WARNINGS...................................................................................................20

7. TROUBLE SHOOTING..............................................................................................................22

8. QUESTIONS AND ANSWERS ..................................................................................................23

9. WARRANTY AND SUPPORT...................................................................................................27

10. TECHNICAL SPECIFICATION...........................................................................................28

............................................................28

11. SAFETY WARNING...............................................................................................................29

12. REPLACING VALVE CAPS..................................................................................................29

13. FCC COMPLIANCE...............................................................................................................29

14. DISCLAIMER..........................................................................................................................29

PAGE 1

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

Introduction

Product application and functionality

1. TPMS-4WD-V2 Product overview

Thank you for choosing an Inawise Tyre Monitoring product. Not only will this

product make your vehicle safer, but you are also helping the environment by

using less fuel and increasing the life of your tyres. Such is the impact that this

type of device can have, that tyre monitoring systems have been made

mandatory in the USA as of September 2007 for all new vehicles manufactured

and brought into the USA. It is speculated that many if not most other countries

will follow this lead.

This TPMS-4WD-V2 is one of a series of products in our TPMS range. This

model is specifically designed for 4WD vehicles catering to the unique

requirements imposed by 4WD applications.

One of the features of this model is a Low and High range pressure selector

switch on the back of the display module. This feature allows the system to

recalibrate to a new set of parameters with the flick of a switch, once the

vehicle’s tyres have been deflated for off road driving.

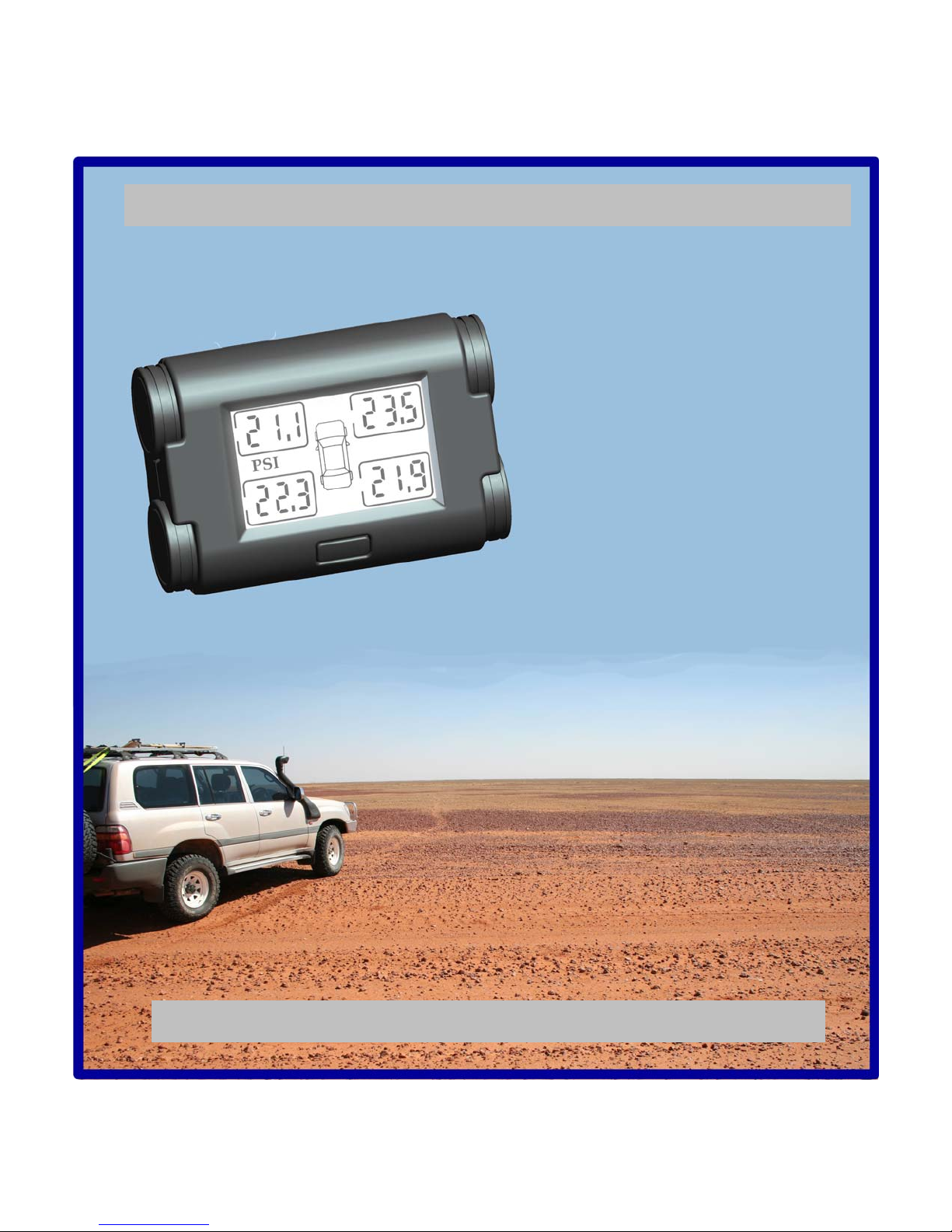

The TPMS-4WD-V2 is a realtime Tyre Pressure (and temperature) Monitoring

System (TPMS). “Realtime” meaning the actual temperature and pressure at

that moment in time. The system is designed to constantly monitor vehicle tyre

pressure and temperature whenever the display unit is powered up.

The kit consists of a display unit, 4 sensors,

a power cord, a cigarette lighter adaptor and

an integrated dual wire antenna.

Since the display unit consumes very little

power, it is recommended that the display

unit be hardwired to the vehicle’s 12V

electrical system. The 12V supply should be

live irrespective of the position of the

ignition key switch. This will enable the

TPMS-4WD-V2 to monitor the tyres not

only when the vehicle is being driven, but

also when it is parked.

PAGE 2

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

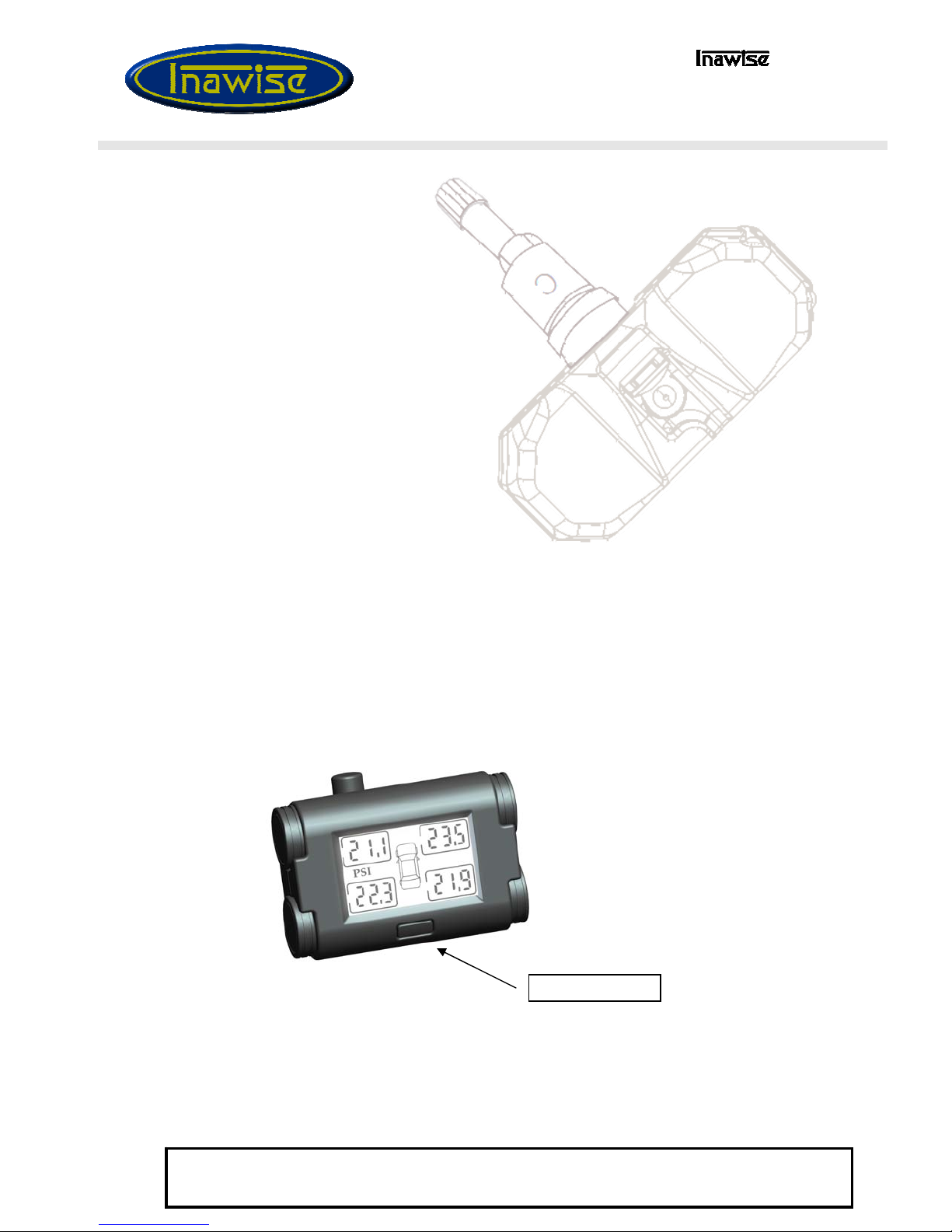

The TPMS-4WD-V2 is designed to monitor 4 wheels and

hence is designed for 4 wheel vehicles only. The kit is

supplied with 4 sensor assemblies which need to be fitted

to each wheel of the vehicle. Each of the sensors consists

of a valve stem, incorporating the new tyre valve and an

electronic assembly which is encapsulated within a

plastic/silicon housing.

The actual electronics within the sensor consist of a low power 433.92Mhz RF transmitter, a

microprocessor with embedded temperature and pressure transducers, a motion detector and a

lithium battery as a power source. None of the electronic components, including the lithium

battery are serviceable or replaceable. In the event of a failure the whole valve sensor assembly

can be replaced.

The sensors need to be fitted in place of the existing tyre valves. To do this the tyre needs to be

removed from the rim, the sensor fitted and then the tyre re-fitted. Normally this work is carried

out most efficiently by a specialised tyre fitter or tyre retail outlet. Only rims with a tyre valve

mounting hole of 11.3mm are supported. This is the standard size for most OEM and after

market rims.

The battery life of the sensors has been designed to last for 7 years (typical) or 250,000km of

driving. The concept being that if a set of sensors is fitted to a vehicle at the time that a new set

of tyres are fitted, the sensors will outlast the life of the tyres. As that set of tyres is replaced, it

can then be determined whether the sensors should be replaced or whether they can be utilised

for another tyre cycle.

The valve stem section of the sensor assembly is manufactured from high grade aluminium with

a propriety finish to prevent corrosion. Aluminium is utilised to ensure the sensor assembly

weight is kept to a minimum, while at the same time providing mechanical strength essential for

4WD applications. This low weight ensures that wheel balancing can be easily achieved. Under

certain environmental conditions electrolysis can occur if a steal valve cap is fitted to the valve

stem. This electrolysis will cause the valves stem to corrode. As a result it is recommended that

only the supplied plastic or an aftermarket aluminium valve cap be used.

The encapsulated electronics will ensure reliable operation even in dirty, muddy and humid off

road environments. In addition the encapsulation will also ensure the sensor can withstand

heavy vibration and shock typically encountered on rough 4wd tracks. As all the electronics are

environmentally and mechanically insulated and isolated, including the lithium battery, the unit

is not serviceable in any way, nor can the battery by replaced.

Additional sensors can be purchased and fitted to spare tyres, however only 4 wheels can be

monitored at any one time. Tyres can be easily rotated along with spare tyres due to Inawise’s

unique sensor ID technology. (See section on Tyre Rotation)

PAGE 3

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

2. Product Features

2.1 Features summary

Display and monitor tyre pressure and temperature of 4 wheels simultaneously

“On-Road” and “Off-Road” selector switch on back of display module

Unique patented sensor ID technology

Simple “set and forget” operation, or can be used as a performance driving aid

informing the driver of real time tyre pressures and temperatures

Reduces the risk of catastrophic tyre blowouts due to low pressure or over

temperature

Notifies driver of low tyre pressure before any noticeable affect is felt, particularly

on dirt roads and rough tracks

Audible and visual alert on over pressure

Audible and visual alert on under pressure

Audible and visual alert on fast leak detection (over 3.7 PSI within a 15second

period)

Audible and visual alert on over temperature

Display unit powered from vehicle 12V supply, no need for batteries

LCD display with white LED backlight.

Front panel “function” button to switch between pressure and temperature display.

Rear On/Off power switch

Compatible with vehicles which have tinted windows containing metallised film

Intelligent power saving technology enables battery life of sensors to last a typical

life of 7 years or 250,000km.

Sensor electronics and tyre valve all in one assembly

Electronic module located inside rim and protected from external damage

Sensor electronics encapsulated in silicon, creating environmental isolation,

ensuring long life and reliability in harsh environments.

Aluminium valve stem with proprietary protective coating to guard against

corrosion in harsh environments.

Virtually immediate driver alert when problem detected

1 year warranty.

Low power consumption.

CE/FCC/E-Mark standards certification

PAGE 4

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

2.2 Theory of operation

The Sensor/Transmitter modules are mounted inside each wheel rim and are held in position by a

special aluminium stem tyre valve, which replaces the existing tyre valve. The sensors monitor

the tyre pressure and transmit this information at predetermined intervals via RF (Radio

Frequency) to the display module. These transmissions occur every few seconds when the vehicle

is moving and only every few minutes when the vehicle is stationary, in order to conserve the life

of the lithium battery located within each sensor.

Whenever the display is powered up it receives this information via an RF signal. The display

module’s first step is to ascertain whether the information is from a valid sensor, and if so which

wheel it relates to. This is done via the ID-Key technology. Each sensor has a unique ID. No two

sensors have the same ID. Each sensor’s ID is associated with an “ID-Key” which is a device

which looks like a button and plugs into the side of the display module. This ensures only

information from the correct sensors is read and displayed.

The display unit, on qualifying the identity of the data from the RF signal, then evaluates the data

to ensure it is within valid parameters. The new data is displayed onto the LCD screen and if a

problem is detected the data is highlighted and an alarm is sounded.

Since tyre pressure can vary significantly due to variation in tyre temperature, it is the actual

sensor which carries out the determination of whether air is leaking from the tyre, while the

display unit determines whether the pressure is within defined limits. The microprocessors

within the sensors cross reference changes in tyre pressure with changes in tyre temperature. An

algorithm determines whether the change in tyre pressure is due to a leak or simply due to a

change in tyre temperature.

The sensor modules incorporate a motion detector to determine if the vehicle is parked or

moving. When the vehicle is parked the sensors conserve power by monitoring the tyre at greater

time interval provided the tyre is within a normal pressure range. If the vehicle is moving, or the

tyre pressure is outside a normal range, the sensors update the display every 4 seconds.

PAGE 5

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3. Installation

Installation instructions for the TPMS-4WD-V2

Premise: The Display unit does not require professional installation, however it

is recommended that the Display unit be “hard wired” to the vehicles electrical

systems (rather than the 12V Cigarette lighter output), as such a general

aptitude with the ability to identify, cut, strip and join wires is required.

The sensors need to be installed in each wheel in place of the standard existing

tyre valve stem. While this can be done by a non professional, it is time

consuming and hard work without the correct equipment. In addition, on

completion the wheels need to be dynamically balanced which can only be done

with the appropriate tyre balancing equipment. Any tyre shop or corner service

station will be able to provide this service cheaply and efficiently.

3.1 Installing Display unit

3.1.1 Mounting location

Identify a suitable location to mount the display unit. The unit should be located

in a position where the display can be easily read while driving, but not in a

location where it obscures driver view. Within a compartment in the console

(right), or on top of the dash are all suitable locations.

Once a location has been identified consider where the power cables will be

run. It may be necessary to slightly move the mounting location or find a new

location so that the power cables can be hidden or at least run where they

cannot be interfered with, or be accidentally pulled by the driver or any of the

passengers.

PAGE 6

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3.1.2 +12V power source determination

At this stage you now need to determine if you intend to hard wire the 12V

power (recommended), or use the 12V Cigarette lighter adaptor. If you are

going to use the Cigarette lighter go to Step 3.1.2.1 if you are going to hard

wire the 12V supply, go to Step 3.1.2.2

3.1.2.1 Cigarette lighter power option:

With the ignition turned off, plug the cigarette adaptor cable into the power

cable connector running to the display. Locate the display module in the

approximate location you intend to mount it (but do not mount it as yet). Run

the power cable from the display unit to the cigarette lighter outlet so that it is

supported by the surrounding trims or console and if possible hidden out of

sight. If possible run the cable behind or under the dash, so as to hide it

wherever possible. Plug in the cigarette lighter connector to the cigarette lighter

output and ensure the cable is long enough and not stretched at any point. Now

proceed to Step 3.1.3

3.1.2.2 Hard wired power option:

Locate the closest and most convenient location where you can tap into the

+12V supply. Remember the supply must be permanently on even when the

ignition is turned off. Normally the vehicles stereo system uses such a supply

for the clock function. Next disconnect the vehicle’s primary lead acid battery

by removing the negative (Black) terminal from the battery.

NOTE! Many modern vehicles have stereo systems equipped with an anti theft

security feature. This feature requires a security code to be entered into the

stereo system before it can be powered up once the 12V supply is removed. If

you have such a system, ensure you have access to this security code.

Locate the display module in the approximate location you intend to mount it

(but do not mount it as yet). Next plug the hard wired power connector cable

into the socket of the power cable for the display unit and run the cable neatly,

and if possible out of view, to the location where you have identified as the

most convenient location to tap into the +12V supply. Join the red wire (+) you

have just run to the 12v source. Then join the black (-) wire to any ground

connection point. The wires can be joined using any conventional technique

such as “wire joining crimp connectors” or by cutting, stripping and soldering

the wires together. On completion ensure the wires are not exposed or shorting.

If they are exposed, use isolation tape to cover the joint. Finally use the cable

ties supplied to hold the cable firmly in place. Ensure the cable is well

supported and does not hang in any area where it can be pulled on, or caught

onto anything. Now go to Step 3.1.3

PAGE 7

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3.1.3 RF Antenna

The Antenna is used to receive the RF signal from the four individual

sensors/transmitter modules fitted to each wheel rim. The TPMS-4WD-V2 is

equipped with two long coaxial wire antennas hard wired into the display

module. These antennas need to be positioned so that a reliable level of signal

reception is obtained.

3.1.3.1 Wire Antenna

Run the two wire antennas in opposite directions across the dash (or preferably

hidden under the dash) and around the vehicle. Where ever possible hide the

wires behind trimming. Try to ensure the last 100mm end of the wire antennas

are left “Free standing” and away from other wires and metal objects. This is

the primary point where the RF signal is picked up. In absolute extreme

situations the wire antennas can be run through the fire wall, into the engine

compartment, and then run down to the bottom of the chassis where the

reception ends of the wire antenna will be located close and in direct “line of

site” to the RF transmitters mounted within the rims.

PAGE 8

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3.1.4 Fixing display module into place

Fix the display module into place using the double sided adhesive supplied.

Ensure both surfaces are clean and if necessary clean with methylated spirits.

3.1.5 Reconnect vehicle battery

The vehicle battery can now be reconnected. The display module will power up

once the rear On/Off switch is switched to ON. As the display module powers

up, the unit will beep and all of the displays will read “000” as the sensors are

yet to be fitted to the wheels.

PAGE 9

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3.2 Installing Sensor/Transmitter modules

The sensor/transmitters need to be installed to each of the 4 wheels. The modules

include a new tyre valve, meaning that the existing tyre valve needs to be removed and

discarded. In order for the sensors to be installed the wheels need to be removed from

the vehicle and the tyres then removed from the rims.

(NOTE: With some tyre/rim combinations, it is possible to fit the sensor by breaking

the tyre bead and pressing the tyre wall away from the location of the valve hole on

the rim, in order to create working clearance suitable to install the sensor module.

This method reduced the time required, as the tyre does not have to be completely

removed from the rim. Care must be taken to ensure the tyre wall does not

unexpectedly spring back into place and cause human injury. )

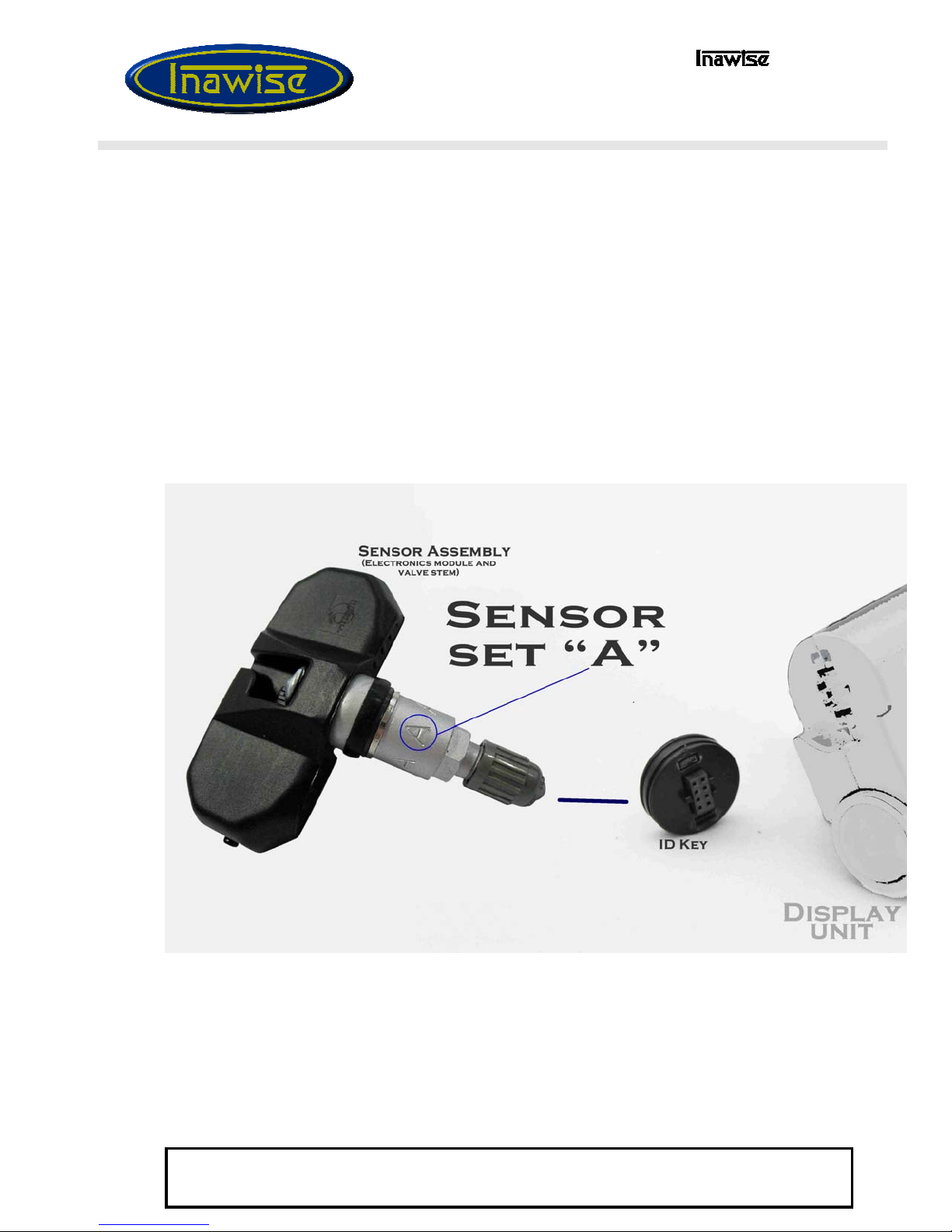

3.2.1 Identify the ID-Keys.

Each sensor is labelled with a letter “A”, “B”, “C” or “D” on its valve stem. The letters

correlate to the same letters on the identifier buttons plugged into the side or the

display module.

By default the Left Side front tyre is allocated Sensor “A”. The Right Front is sensor “B”. The Left

Back is sensor “C” and the Right Back is sensor “D”. These positions relate to the representation of

the wheel on the LCD display. The ID-Keys can be unplugged from the display module and relocated

as required. In order to unplug the ID-Keys the “release” button must first be de-pressed. This then

allows the ID-Key to be unplugged. It is recommended that the sensors be fitted in the default order to

avoid the ID-Keys requiring rotation during this initial installation.

PAGE 10

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

Once the ID codes for the sensor/transmitters have been identified they can be fitted to the rims.

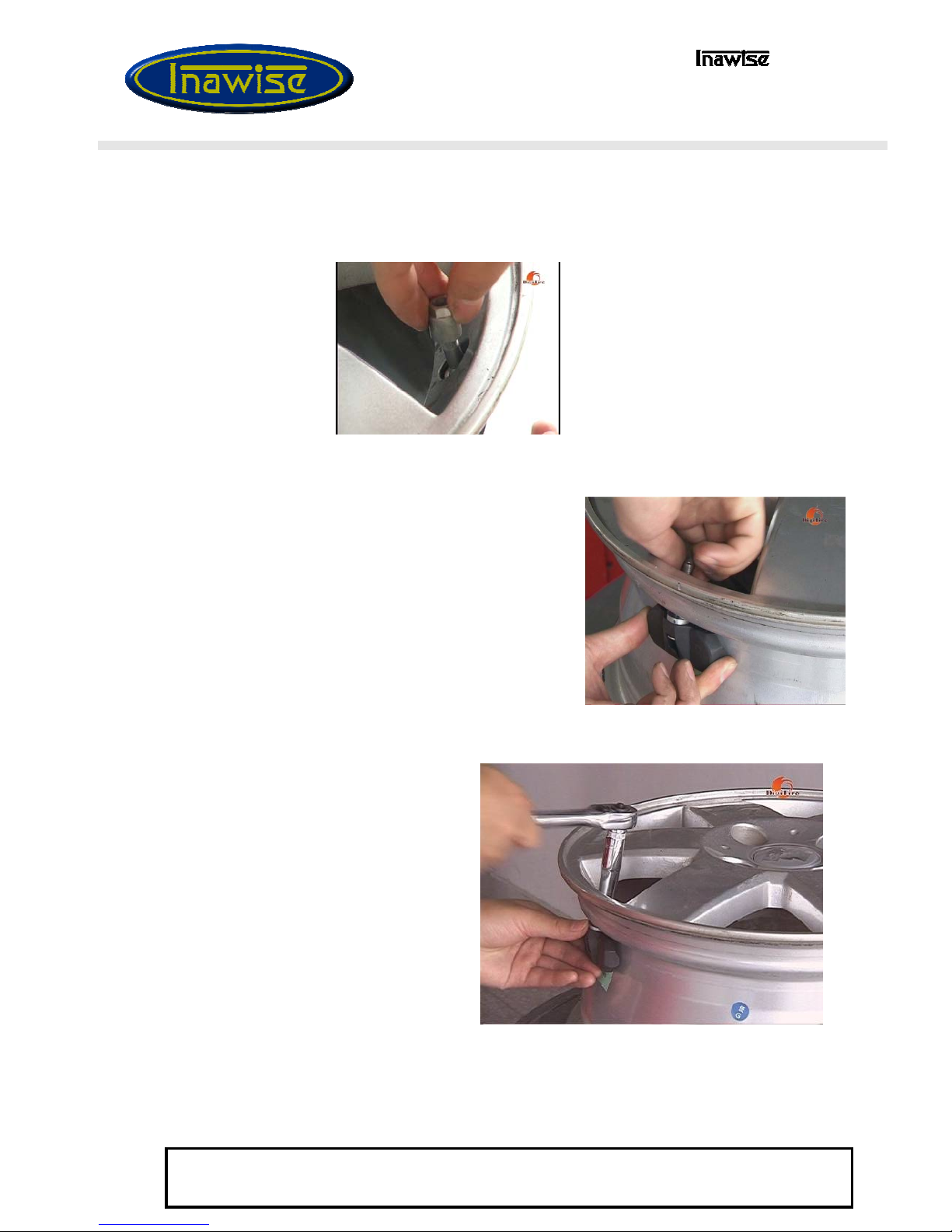

3.2.2 Sensor Disassembly

Remove the Valve Cap and the Retaining Nut

from the valve stem. The Retaining Nut has a

plastic washer pressed into its seat.

3.2.3 Loosen Electronic module

Loosen the self-locking screw to allow the Electronics module to be adjusted to

fit the rim. Clean the rim around the valve hole both on the inside and out.

Insert the valve stem through the valve hole, from the inside of the rim.

PAGE 11

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3.2.4 Fix Sensor

The valve stem fixing nut incorporates a self retained plastic washer. Fit the nut to the valve stem and tighten only

by hand, ensuring the washer is in place on the nut.

3.2.5 Adjust head angle

Now adjust the angle of the electronics module so it

sits as close as possible to the rim surface,

preferably hard against it, then tighten the Self

locking screw to lock the electronics module into

that position.

3.2.6 Torque valve stem

Tighten the valve stem NUT (6)

with 3.5 to 4.6Nm (2.6 – 3.4 foot

pounds) of torque.

(Note: Correct torque setting is

critical. Under tightening will cause

air to leak. Over tightening will

cause the “valve stem air seal

rubber washer” to fail causing air

to leak. The nut can be tightened

without the use of a torque wrench.

The correct torque is reached when

the “valve stem air seal rubber

washer” is compressed to 60-70% of

its original thickness, and is not seen

to be overly bulging).

PAGE 12

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3.2.7 Mount tyre

The tyre can now been mounted back onto the rim.

3.2.7.1 Lubricate

Apply lubricant to both the tyre bead and the rim.

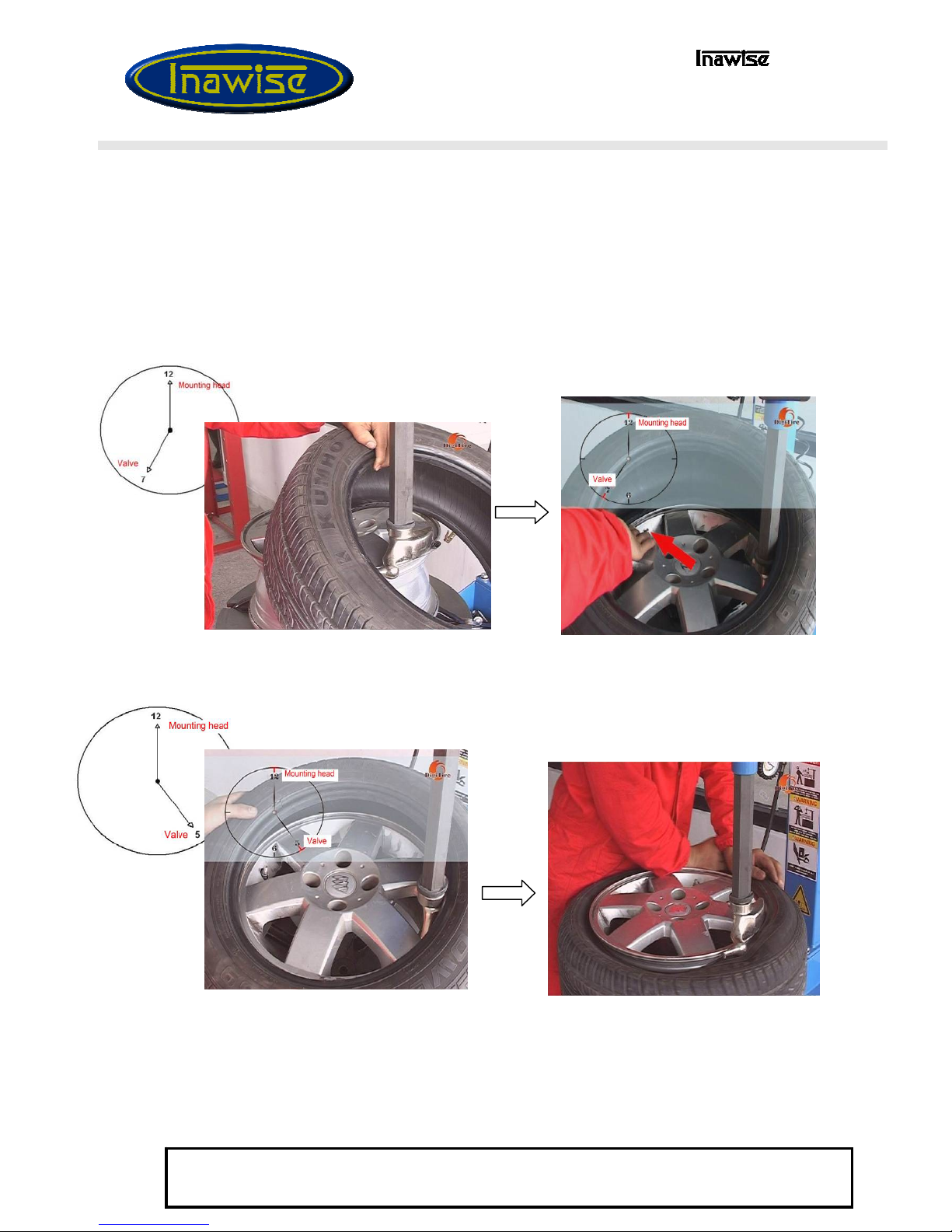

3.2.7.2 Position tyre

The lower bead must be mounted with the mounting head of the changer

located at 12o’clock while the position of the tyre valve is at 7 o’clock. This is

done to ensure the electronic module will not be damaged.

3.2.7.3 Position upper bead

The upper bead must be mounted with the mounting head of the tyre changer

positioned at 12 o’clock and the valve at 5 o’clock

3.2.7.4 Finish fitting tyre

The tyre can now be inflated to the vehicles recommended specified cold tyre

pressures and dynamically balanced. Repeat procedure for all other wheels and

then refit wheels to vehicle.

PAGE 13

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

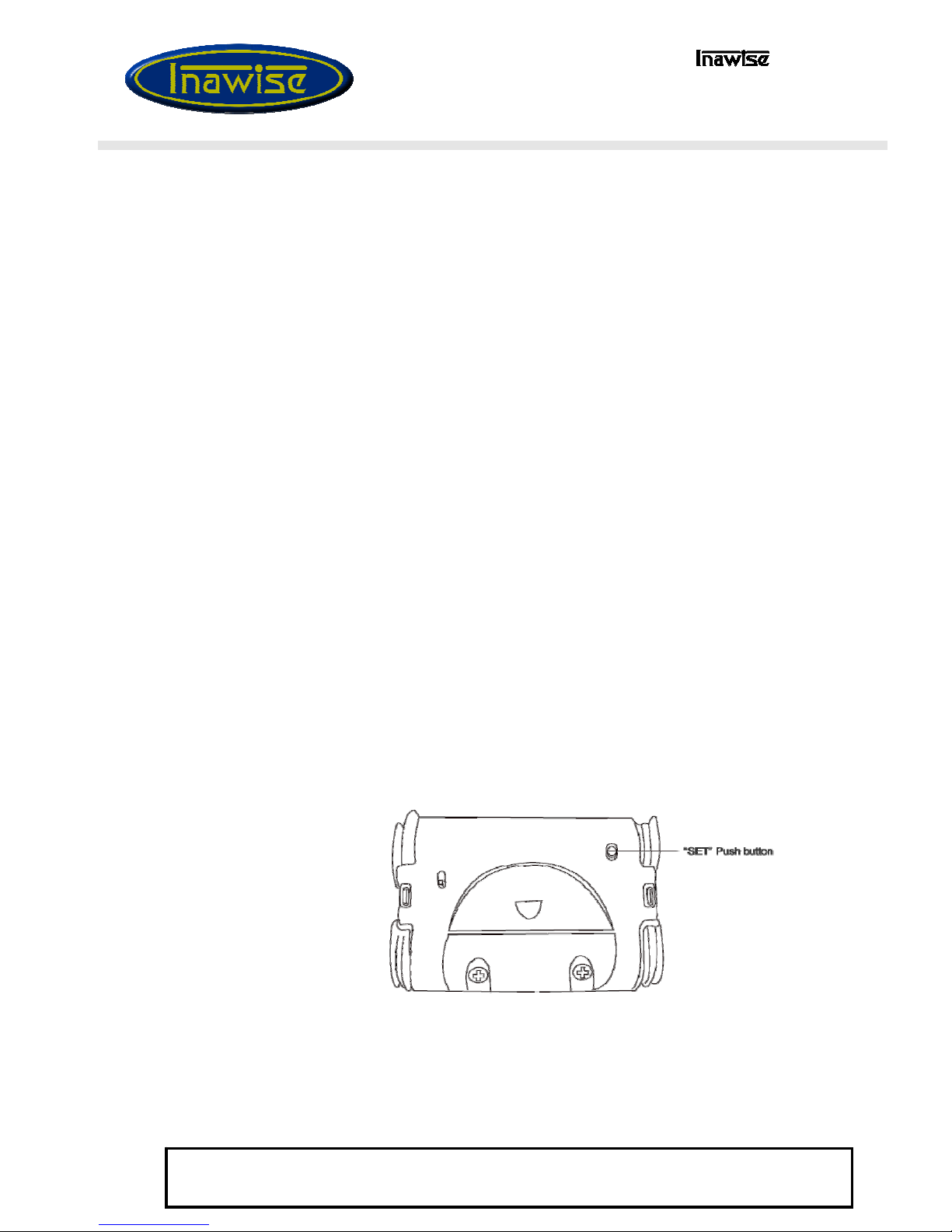

3.3 Setting pressure range

The final step is to set the pressure range for your tyres. On this model the

pressure range is set using the “Road” / “Off Road” push button switch at the

back of the display module.

Press and hold the switch for aproximatly 6 seconds to toggle betweeon “ON-

road” and “OFF-road” modes. The screen will momentarily display the word

“on” in the 4 positions to signify ON-road mode. “off” will be momentarily

displayed in the 4 positions when in OFF-road mode.

3.4 Checking current pressure range

Momentarily pressing the set button will cause the display to show the

current pressure range mode (ON-road or OFF-road) without changing

any setting.

“OFF” road mode selected

“ON” road mode selected

PAGE 14

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

3.5 Turning on the Sensor/Transmitters

The sensor units are shipped in a powered down sleep mode to conserve battery

life and ensure maximum battery life once they are put into service.

The sensors are activated from the “power down shipping mode” by

pressurising the sensor or driving the vehicle with the sensors installed on the

wheels at a speed of 25km/h or more for a few minutes.

As the sensors come on-line the display will change from displaying “000” to

displaying the data for that wheel.

3.6 Checking the system works

The system should now be up and fully functional. All four readings on the

displays should be showing the correct tyre pressure for all four tyres.

By pressing the “function” button located at the front of the display, the display

should first turn on the LCD backlight. A second press will cause the display to

toggle from pressure display to temperature.

The LCD backlight will stay on for only a few seconds and then automatically

turn off again to preserve power.

“Function” Button

PAGE 15

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

4. Tyre Removal

If the rim is already fitted with a sensor/transmitter module, a specific

procedure is required to break the bead and remove the old tyre from the rim, in

order to avoid the sensor/transmitters being damaged.

4.1 Breaking upper and lower bead.

The upper and lower beads must be broken with

the bead breaker head located AT LEAST 90deg

of arc away from the tyre valve sensor /

transmitter module.

This will ensure the sensor/transmitter is not

damaged as the bead separates from the rim.

4.2 Upper and lower bead demount.

With the demounting head located at a 12.00

o’clock position, ensure the tyre valve

sensor/transmitter module is located at 11.00

o’clock. This will ensure that the sensor

/transmitter will not be damaged by the head. In

addition it is important that the sensors be located

on the opposite side to where the tyre bead is

stretched into the rim cavity.

PAGE 16

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

5. Operating Procedure

5.1 General

The typical operating mode of the TPMS-4WD-V2 is “set and forget”. The system will

monitor the tyres and in the event of a problem, will sound an alert, turn on the LCD

backlight and highlight the tyre with the problem.

In the event the TPMS issues an alert, as soon as it safe to do so, the driver should slow

down, turn on the hazard lights, pull over to a safe location, and investigate the problem.

During normal operating mode, the driver can at any time read the individual tyre

pressures of all 4 tyres. The location of the pressure or temperature readings on the LCD

display relates to the physical location of the tyre.

When going “Off Road”, it is simply a matter of depressing the “set” push button switch

on the back of the display and holding down for 6 seconds until you hear a beep,

indicating the pressure mode has been changed. The tyres can then be deflated to the

required pressure determined by the terrain. When going back onto a sealed road the

display module can be switched back to “Road” mode and the tyres re-inflated.

While the vehicle is parked the sensors will measure and transmit the tyre pressure and

temperature to the display unit every 4 minutes. The display will always display the

most recent reading.

Once the vehicle starts to move, the sensors measure the tyre pressure and temperature

every 4 seconds and transmit this information every 30 seconds to the display module. In

the event the sensor detects a problem, the information is transmitted immediately,

which will cause the display module to display the problem and give out an audible

alarm.

5.2 Turning on LCD Backlight

The LCD backlight can be turned on manually by pressing the function button on the

front of the display panel once.

The LCD will remain backlit for a pre-programmed period of time (around 12 seconds)

and then turn off again. The backlight cannot be manually turned off or be configured to

permanently remain on, or programmed to stay on longer.

“Function” Button

PAGE 17

Pty Ltd

TPMS-4WD-V2 User and installation guide

Document 913-9001 Rev G 11/July/2012

Copyright 2009 @ll rights reserved

This document is not to be reproduced or copied in ^ny w^y unless the express permission in writing h^s been obt^ined

from

In^wise Pty Ltd

(@ustr^li^)

5.3 Displaying Tyre Temperature

Tyre temperature can be displayed by pressing the function button twice. The

first press turns on the backlight the second press causes the display to swap to

the temperature display.

Pressing the function button again will cause it to swap back to the pressure

display.

5.4 Displaying Sensor Key ID

In addition to the labels “A”, “B”, “C” and “D” each transmitter/sensor has a

unique 6 digit identifier. Pressing and holding down the “Function” button on

the font of the display module for 8 seconds will cause the display to enter the

ID-Key display mode.

Each display will first show the first three digits of the 6 digit ID and then after

a few seconds display the last three digits.

If the display shows “---” it indicates that the ID-Key is not plugged in correctly

for that tyre or the system is faulty.

To turn off the sensor key ID display, hold the “Function” button on the front

of the display down for 8 seconds.

5.5 Displaying current pressure range

Momentarily pressing the set button at the back of the display will cause

the display to show the current pressure range mode (ON-road or OFF-

road) without changing any setting.

Table of contents