Inciner8 i8-75a User manual

Leading Provider of Thermal Treatment Solutions

+44 (0) 1704 884020

i8-75a Incinerator

Installation & Operation Manual

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

General Responsibility

PLEASE READ THIS INFORMATION:

We don’t accept responsibility for any damages or injuries caused by neglecting these instructions.

Purchased equipment is in compliance with existing regulations for safety measures .Treatment and

Handling of equipment is end-user’s responsibility.

Our incinerators are made from existing technology and regulations of safety measures.

Nevertheless, because of improper usage and handling some serious injures for user or other

person, as well as physical damage to equipment or other goods may occur.

These incinerators are intended for incineration of waste products and for energy recycling from

exhaust heat. (This is optional equipment). Any usage of incinerator beside mentioned is considered

as improper, and end-user takes full responsibility for possible damages and injuries.

Proper usage of incinerator also considers installation, maintenance and service of equipment as

described in this manual.

Installation and calibration of incinerator, as well as service and maintenance procedures can be

done only by approved professionals.

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Read and Understand this Manual

WARRANTY

INCINER8's exclusive warranty is that the products are free from defects in materials and

workmanship for a period of one year (or other period if specied) from date of sale by INCINER8.

INCINER8 MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. INCINER8 DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

INCINER8 SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall the responsibility of INCINER8 for any act exceed the individual price of the

product on which liability is asserted.

IN NO EVENT SHALL INCINER8 BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS INCINER8’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Safety

PLEASE ADHERE TO THESE GUIDELINES

Use appropriate lifting equipment when installing incinerator. Failure to do so may cause injury or damage the machinery

Use appropriately qualied personnel for the fuel and electrical connections.

Ensure the incinerator is cured prior to rst use. Failure to do so will void the warranty.

Do not modify the incinerator or any of its parts in any way. Doing so will void the warranty.

Wear suitable Personal Protection Equipment (PPE) when operating the incinerator to prevent injury during loading of

waste into chamber. Please check the PPE requisites for your country.

Ensure ash has cooled down before removal to avoid injury.

Do not overll the incinerator.

Ensure the loading door is closed and locked during operation to prevent un-authorised entry to the chamber whilst burn

cycle is in process.

In case of loss of electricity, shut down the burner immediately to prevent damage to the burner by heat transferring back

for the main chamber.

Ensure installation and layout is compliant with local building regulations.

Regularly check the condition of your incinerator to ensure it is in good condition. Service every 1 year/1000 hours

(whichever comes rst).

Do not use cleaning agents containing chlorine, acid or other aggressive materials on your incinerator. This can remove

the paint and lead to corrosion.

If any signs of corrosion do appear, treat immediately with high temperature paint to prevent the corrosion spreading.

Ensure the incinerator has constant electrical supply when in use. If power supply is susceptible to failures, consider the

use of a generator.

If power does fail during the burn cycle, remove burners immediately to prevent damage to them.

Ensure the incinerator is used in the manner for which it was intended – waste incineration (including following this

instruction manual). Using this product in any other way is considered improper, and the end user accepts full responsi-

bility for any possible injuries/damage.

Ensure explosive/ammable materials are not stored in close proximity to the incinerator.

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Preface

Thank you for purchasing an i8-75a incinerator.

This manual describes how to use the i8-75a. Read this manual thoroughly and be sure you understand it before

attempting to use the Incinerator and use the incinerator correctly according to the information provided. Keep this

manual in a safe place for easy reference.

©INCINER8, 2015

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of INCINER8.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

INCINER8 is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless,

INCINER8 assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

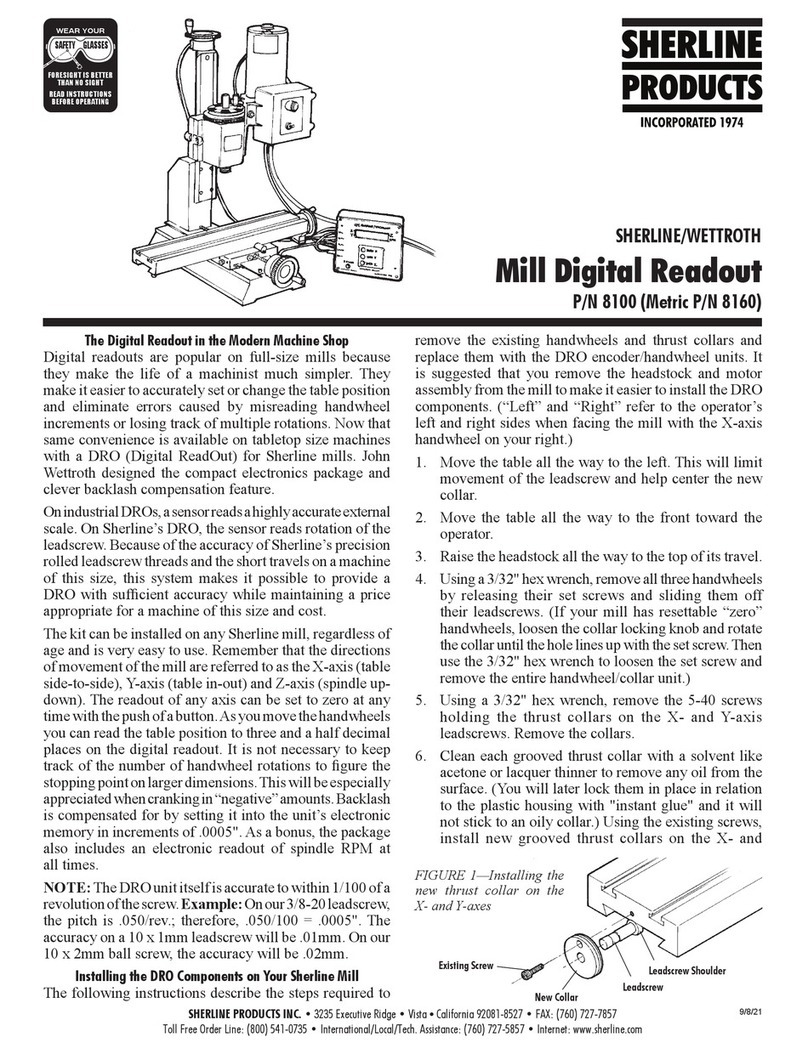

Package Contents

MODEL: i8-75A

Please remember

We take great care in ensuring all parts are included ifor the assembly of your product. Please check the package

contents against the list above and contact us immediately should anything be missing.

Main Chamber

Secondary Chamber

Chimney

Stack Cap

Control Panel

Locking Handle

M8 x 20mm hex bolt

Control Panel

Locking Handles

Stack CapSecondary Chamber

Primary Chamber Chimney

Fire RopeMastic Burners

M8 x 20mm hex bolt x 8

M10 x 20mm serrated ange bolt x 16

M10 serrated ange nuts x 16

8mm tech screw x 4

Fire Rope & Mastic

Primary Burner Max 1 / Azur 60

(x8)

M10 serrated flange nuts

M10 serrated flange bolts

8mm tec screw

(x16)

(x16)

(x4)

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Site Preparation

Summary

We recommend a 4m x 4m concrete slab that is level and at. Floor must be solid, at and levelled. The concrete base is

a standard reinforced concrete slab 20cm thick. We recommend replacing the material at a depth of at least 50cm

(applying gravel and compacting to the compressibility modulus M = 80.0 MN/m2.

If being sited in a building/shelter, this to be 4m x 4.2m. Inside installation is acceptable if 15 or more air changes per

hour are provided. The room must be positive pressure as well. This prevents internal combustion products from entering

the room. The room should be designed not to exceed 120°F (50°C) or damage may occur to electrical components.

Local re and building codes are to be met by the installer.

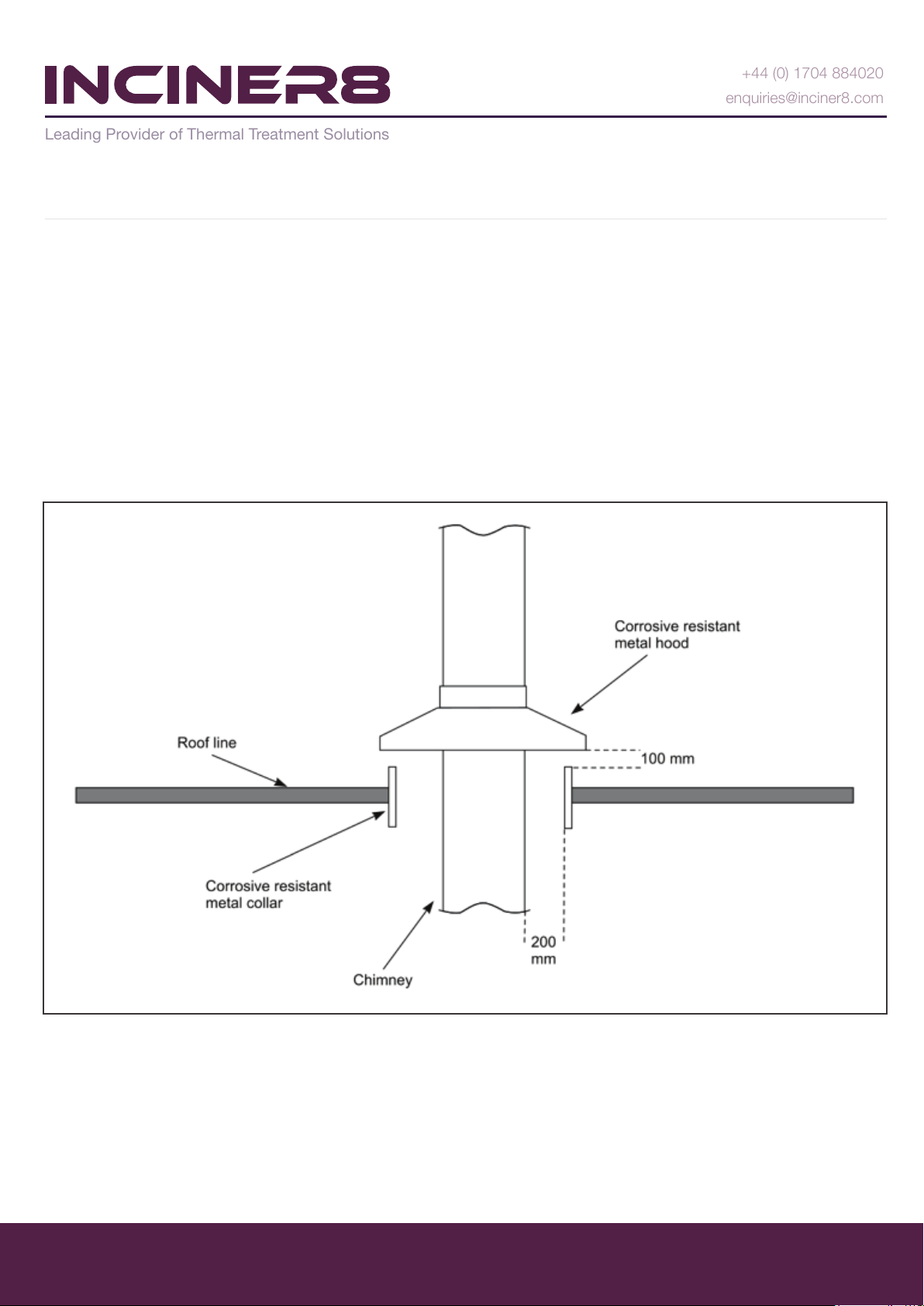

If the building has a roof, provision will need to be made to allow the chimney to pass through with weather protection as

shown on next drawing: (See APPENDIX 1 for more drawings)

All the fuel (gas or oil) supply installations must be done by approved professionals, in accordance to local regulations.

The control panel has a thermocouple attached via a 3m lead. The control panel will need siting in a suitable position

based on this 3m length. This is where power needs to go to – 230V 50Hz 10amp (if not ordered with power specica-

tions). It is the client’s responsibility to supply power and a qualied electrician to make this connection in line with local

regulations.

It is also the clients responsibility to provide suitable lifting equipment and operator to place the primary chamber and lift

the secondary chamber into place, either a forklift truck, crane or similar, suitable for 2,000 kgs can be used.

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

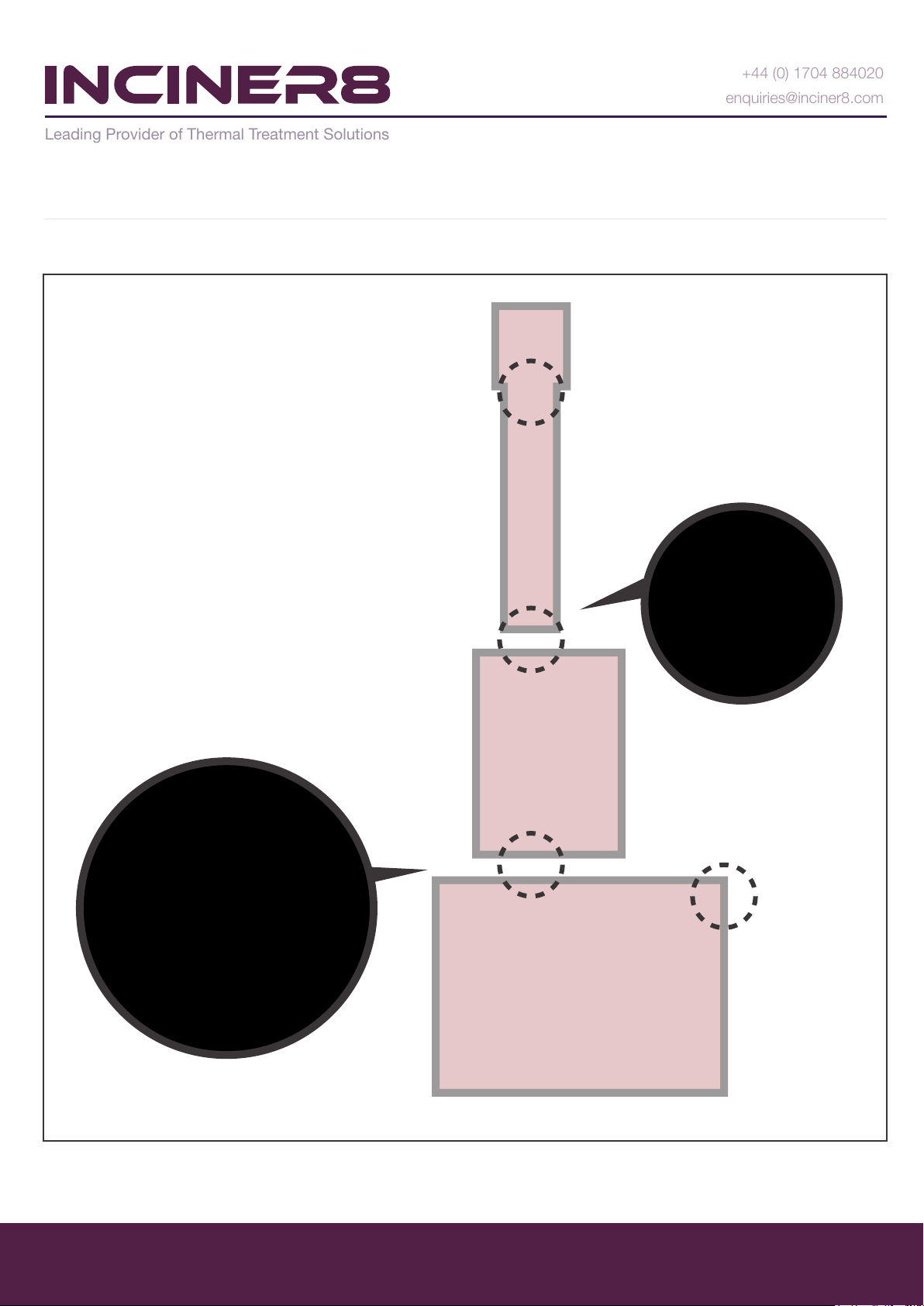

STEP 1 - Connection of Main Parts

a). Find suitable location for the primary chamber.

b). Attach the stack cap to the chimney using the 4 tech

screws supplied.

c). Using the Fire Cement supplied put a thick beads of

the gasket sealant around the refractory lining on the

outlet of the secondary chamber.

d). Insert chimney and stack cap on the secondary

chamber outlet at securely fasten with 8 M10x20

anged bolts and nuts.

e). Using the re cement put a thick bead of sealant

around the outlet of the primary chamber.

f). Lift the secondary chamber on the primary chamber

ensuring the burner mount is facing the same direction

as the primary burner mount.

g). Use the 8 m10x20 anged bolts and nuts to securely

fasten the secondary chamber to the primary.

h). Attach latch handle with 4 bolts (M8x20)

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

STEP 2 - Connecting the Burners

a). In the primary burner box take out the 4 studs and insert in the 4 holes in the primary burner mount.

b). Repeat the above process for the secondary burner.

c). Remover the mounting plate and gasket from the burner and attach to the studs using the 4 nuts in the burner box.

d). Repeat the above process for the secondary burner.

e). With the burner mount attached the burner can be slotted back on the mount and tighten the retainer nut.

f). Repeat the above process for the secondary burner.

g). On both burner pumps remove the bolt labelled P and insert the pressure gauges supplied in the burner boxes using

sealant tape which is not supplied.

h). Connect the fuel pipes to both primary and secondary burner following the piping diagram found in the manual.

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

STEP 3 - Connecting the Control Panel & Thermocouple

Thermocouple Port

This is located near the rear of the

chimeny stack.

a). Choose location for control panel and ensure there is enough cable length to reach each burner and the

thermocouple can reach the thermocouple port.

b). Attach the cable from the control panel to the burners, the primary cable is labelled PRIM and should go to the

primary burner and the secondary cable is labelled SEC and will go to the secondary burner. Insert and tighten the

thermocouple to the thermocouple port.

c). Make sure the control panel has a power supply and follow the instructions for the curing process.

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

STEP 3: Control Panel Model: CE2

Thermocouple.

This is to be screwed into the port

located at the top of the secondary

chamber just beneath the chimney

ange.

Ensure the end of the thermocouple

is centrally located in the chimney

and not touching the concrete.

Electrical connection.

Single phase 10amp connection

required. Connection to be made by

a qualied electrical engineer.

Burner connection port.

Use appropriate burner plugs from

the control panel to connect primary

and secondary burner.

Burner plugs are marked as

PRIMARY (for primary chamber

burner) and SECONDARY (for

secondary or afterburner)

Please remember

All our products are designed to operate on 240v mains supply. Please ensure you use the right voltage when operating

this equipment.

Make sure the control panel has a power supply and follow the instructions for the refractory

curing process.

Choose location for control panel and ensure there is enough cable length to reach each

burner and the thermocouple can reach the thermocouple port.

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

STEP 3 - Gas Connections

Please consult an experienced and qualied gas engineer before attempting any gas installations.

ONLY A QUALIFIED GAS

ENGINEER CAN CARRY OUT

THIS STEP. DO NOT ATTEMPT

THIS IF YOU ARE

IN-EXPERIENCED

Please note

You will need to connect these hoses to the fuel supply using 1/4” BSP (British Standard Pipe) male ttings, the supplied

hoses have 1/4” BSP female ttings. Ensure fuel supply is sufcient to give fuel pump feeding pressure of 12-15 bar

when using light oil.

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

STEP 3 - Oil Connections

Please consult an experienced and qualied engineer before attempting any fuel installations.

ONLY A EXPERIENCED

ENGINEER CAN CARRY OUT

THIS STEP. DO NOT

ATTEMPT THIS IF YOU

ARE IN-EXPERIENCED

Please note

You will need to connect these hoses to the fuel supply using 1/4” BSP (British Standard Pipe) male ttings, the supplied

hoses have 1/4” BSP female ttings. Ensure fuel supply is sufcient to give fuel pump feeding pressure of 12-15 bar

when using light oil.

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

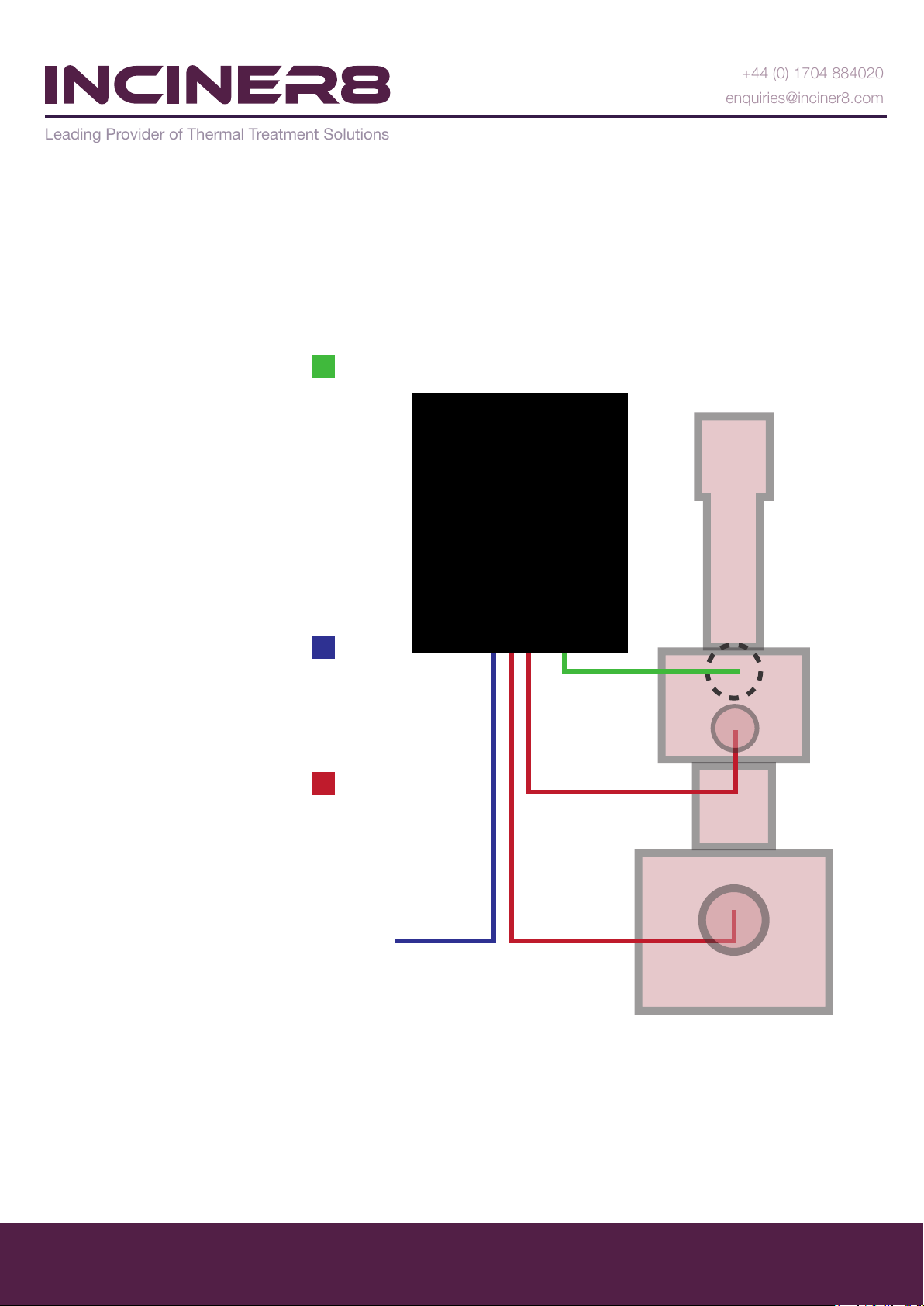

STEP 4 - Fuel Connections

Connect the 2 – Flexible PTFE fuel hoses (within the burner box), 1 for ow, 1 for return. Light oil ow return setup - Two

pipe system example for 2 burners

Please note

Flow & Return

example

You will need to connect these hoses to the fuel supply using 1/4” BSP (British Standard Pipe) male ttings, the supplied

hoses have 1/4” BSP female ttings. Ensure fuel supply is sufcient to give fuel pump feeding pressure of 12-15 bar

when using light oil.

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Assembly

STEP 4 - Fuel Connections

Connect the 2 – Flexible PTFE fuel hoses (within the burner box), 1 for ow, 1 for return. Light oil ow return setup -

Single pipe system example for 2 burners

Please note

Flow & Return

example

You will need to connect these hoses to the fuel supply using 1/4” BSP (British Standard Pipe) male ttings, the supplied

hoses have 1/4” BSP female ttings. Ensure fuel supply is sufcient to give fuel pump feeding pressure of 12-15 bar

when using light oil.

It is imperative that the refractory concrete within the unit is cured prior to use. Failure to do so will void the warranty and

may damage the machine. Please ensure that the air/fuel ow settings on the burner are set correctly (the ame should

be clean without any black smoke) and fuel pipework is free from leaks. During this process, it is normal to have

steam/water coming out of the incinerator.

Burners can be turned on/off from control panel. To start curing process, set primary airow to 3.5 and secondary airow

to 1. Please note that only primary burner should be turned on and secondary burner must be permanently off during this

exercise.

Curing is carried out using the following temperature set points as ordered in the procedures below;

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Refractory Curing

YOU MUST FOLLOW THIS PROCESS

Advice

Following the curing process, you will see hairline cracks and minor scaling in the concrete which is completely normal.

Cracks wider than 2 mm should be treated using High Temp Black Mastic.

Congratulations, your incinerator is now cured.

Set Temperature 100°C Primary Burner ON 5 Minutes Primary Burner OFF15 Minutes

Set Temperature 100°C Primary Burner ON 5 Minutes Primary Burner OFF15 Minutes

Set Temperature 200°C Primary Burner ON 15 Minutes Primary Burner OFF15 Minutes

Set Temperature 200°C Primary Burner ON 15 Minutes Primary Burner OFF15 Minutes

Set Temperature 300°C Primary Burner ON 30 Minutes Primary Burner OFF15 Minutes

Set Temperature 300°C Primary Burner ON 30 Minutes Primary Burner OFF15 Minutes

Set Temperature 400°C Primary Burner ON 60 Minutes Primary Burner OFF15 Minutes

Set Temperature 400°C Primary Burner ON 60 Minutes Primary Burner OFF15 Minutes

Set Temperature 400°C Primary Burner ON 120 Minutes Primary Burner OFF15 Minutes

Set Temperature 450°C Primary Burner ON 60 Minutes

Set Temperature 500°C Primary Burner ON 60 Minutes

Set Temperature 550°C Primary Burner ON 60 Minutes

Set Temperature 600°C Primary Burner ON 60 Minutes

Set Temperature 650°C Primary Burner ON 60 Minutes

Set Temperature 700°C Primary Burner ON 60 Minutes

Set Temperature 750°C Primary Burner ON 60 Minutes

Set Temperature 800°C Primary Burner ON 60 Minutes

Set Temperature 850°C Primary Burner ON 60 Minutes

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Fault Finding

Please check before contacting us about any issues

Black scorch marks on the

incinerator body

Thermocouple failure

Steam from the incinerator

during the curing process

Small cracks within the

refractory concrete

Large cracks

Burner ame appears to turn

up the chimney

Flames from the chimney

"Booming" noise from the

incinerator during operation

Smooth appears from the

joint of the incinerator body

and top

Control Panel displays

"0000"

Grey/white smoke

Black smoke

Burner issues

Leakage from damaged re

rope or misaligned door

Excessive temperature or

corrosion from waste gases or

uids

Water within the refractory

concrete

Expansion/contraction whilst

heating/cooling

Wear & tear

Too much draw from chimney

Too much ammable waste in

the main chamber

Main chamber overlled or air

setting too high

Mastic sealing joint is

damaged

Thermocouple failure resulting

from loose connection

Temperature is too low

Insufcient oxygen in main

chamber

Replace re rope or realign door

Replace thermocouple

This is completely normal

This is completely normal

Repair with high temperature cement or

mastic

If chimney has been extended, this is too high

Reduce waste batch size

Reduce waste batch size or lower air setting

Reseal the joint with high temperature mastic

Check wiring or replace thermocouple

Increase temperature or ensure unit is

pre-heated

Reduce waste batch size. It is sometimes

better to burn smaller batches more regularly

Please refer to fault nding section in

enclosed burner manual

PROBLEM CAUSE SOLUTION

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

General Operation

Incineration

Like in every combustion process in incineration it is all about providing optimal conditions for clean combustion.

Most important factors you can control are:

Air

Black smoke normally indicates lack of the oxygen in combustion process, so there is a lot of unburned carbon in the

smoke, and this is what makes it black.

Increasing air settings on the air dumper on the side of the burner will provide better air / fuel ratio, which will also

increase burn rate, but this will only help providing there is not too much waste loaded in the chamber.

Fuel (both diesel oil and waste)

You are supplying fuel to a process through burners (pumping diesel oil), and also through waste loaded into a chamber.

It is very important to have primary burner on, only for a short time, to ignite waste. Once waste starts to burn itself, turn

primary burner off. This will help you to obtain better combustion conditions, and also to save fuel.

Temperature

In case of very ammable waste, lower preheating temperature is suggested, as this will prevent all the waste material to

ash instantly, and too much energy to be released in a very short time.

Burn procedure

Please follow these instructions to define optimal batch size, air settings etc:

Repeat steps 2 - 6 above gradually increasing batch size, in order to dene maximum batch size, temperature and air

settings for a clean combustion for each waste type you are dealing with.

Most important is to have main burner on for as short time as possible (only for preheating, and waste ignition - if

needed).

Preheat incinerator using both burners with lower air settings during the preheating (main burner air dumper on 3 –

3,5) to 500 – 850 deg C. For highly ammable waste use lower preheating temperature (I.E. 350 - 400 deg C)

Stop primary burner and load small quantity of waste for a start (i.e. 5-15 kg – depends on waste type)

Start primary burner only for a short period of time (i.e 1 minute), but only if waste hasn’t ignited itself - in most

cases you will not need primary burner at all after preheating (if burning ammable waste), and increase air settings

positioning air dumper on main burner to between 6 and 8 (depends on waste type).

Turn main burner off, and If needed, add more air (increase air dumper setting on main burner).

Once waste is ignited, temperature will increase to a certain pick (depending on waste amount and caloric value)

and then, it will start decreasing (indication that it has been mostly burned).

You can now load another batch of waste (a bit more waste than in rst batch) etc ...

1

2

3

4

5

6

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

General Operation

The Controller: Omron E5CC

To change set point value

Press up (5) or down (4) arrows as required, left arrow (3) moves digit position

Digit being changed will ash, after 3 seconds change is made

To Change Hysteresis

Hysteresis is the the variable allowance that the burn will burn or stop

Press button 1

Adjust hysteresis value as required.

Preset value is 25°C

To return to home page, press button 1

PV = Present temperature value from the thermocouple

SV = set point value for desired burn temperature

PV

SV

22

800

PV

SV

HYS

25.0

PV

SV

WIoN

40.0

PV

SV

WIoN

40.0

PV

SV

1 2 3 4 5

Press button 1 ( HYS displayed )

Press button 2 (WloN displayed) –

adjust burn time here

Using arrow keys (4,5) adjust

desired burn time

Once the ashing stops the

control panel needs to be reset for

the new time to start. Turn

SYSTEM to OFF and then ON, the

new time will now start.

When heater output is activated,

“OUT1” is displayed in yellow.

When burn time is complete,

“STOP” is displayed in yellow.

ONOFF

SYSTEM

To Change Burn Time

Parameter

Inciner8 Limited. Company Registered in England & Wales - REG: 04866401

VAT Registration: 855999544

Enter the world of:

www.inciner8.com

+44 (0) 1704 884020

Leading Provider of Thermal Treatment Solutions

Maintenance

Pre-start checks

Ensure re rope, loading door and ash removal door seals are in good condition.

Check the condition of the refractory concrete lining. Repair any large cracks/holes.

Check fuel supply is clear and not restricted. Electrical connections are safe and secure.

Check exterior metal work. Treat any corroded sections immediately.

Check the thermocouple is working correctly.

Monthly checks

To keep your unit in good working condition, please carry out the following checks each month:

Damage to the re rope under the lid

Visible damage to the chimney

Visible damages to the outside body of the incinerator

(corrosion of metal parts, discolorations, leaks)

Condition of temperature probe

Condition of fuel and electrical installation

Service procedures (every 1 year or 1000 working hours)

Your unit must be routinely serviced to stay in good working condition. Servicing should take place

once a year (or after 1000 hours usage, whichever comes rst). The following checks and mainte-

nance should be carried out:

Replace re rope under the lid

Do parallel measurement of temperature probe (if regulated by law)

The burner should be serviced by an approved professional

Check sealing between each individual part of chimney (including secondary chamber)

Clean metal parts of incinerator, and re-spray if needed

All burners should also be routinely serviced by an approved professional

Please remember

You (the customer) must keep logs of all service procedures carried out, with

detailed comments where applicable.

Table of contents

Popular Industrial Equipment manuals by other brands

Interroll

Interroll SH 1210 Installation and operating instructions

ALENCON

ALENCON SPOT BOX v2 user manual

Belmash

Belmash SDM-2000 operating manual

PAW

PAW MB3.10 Assembly, installation and operation instructions

Busch-Jaeger

Busch-Jaeger Busch-Wachter DualLINE 6813/11 Series operating instructions

Precision Rated Optics

Precision Rated Optics OFS-943V Operation guide