4 5

Important Information and Warnings

Terms and Summary

Thismanualprovidesimportant informationforpersonnel involved with the installation,operation

and maintenance of this product. Although you may be familiar with this or similar equipment,

it is strongly recommended that you read this manual before installing, operating or maintaining

the product.

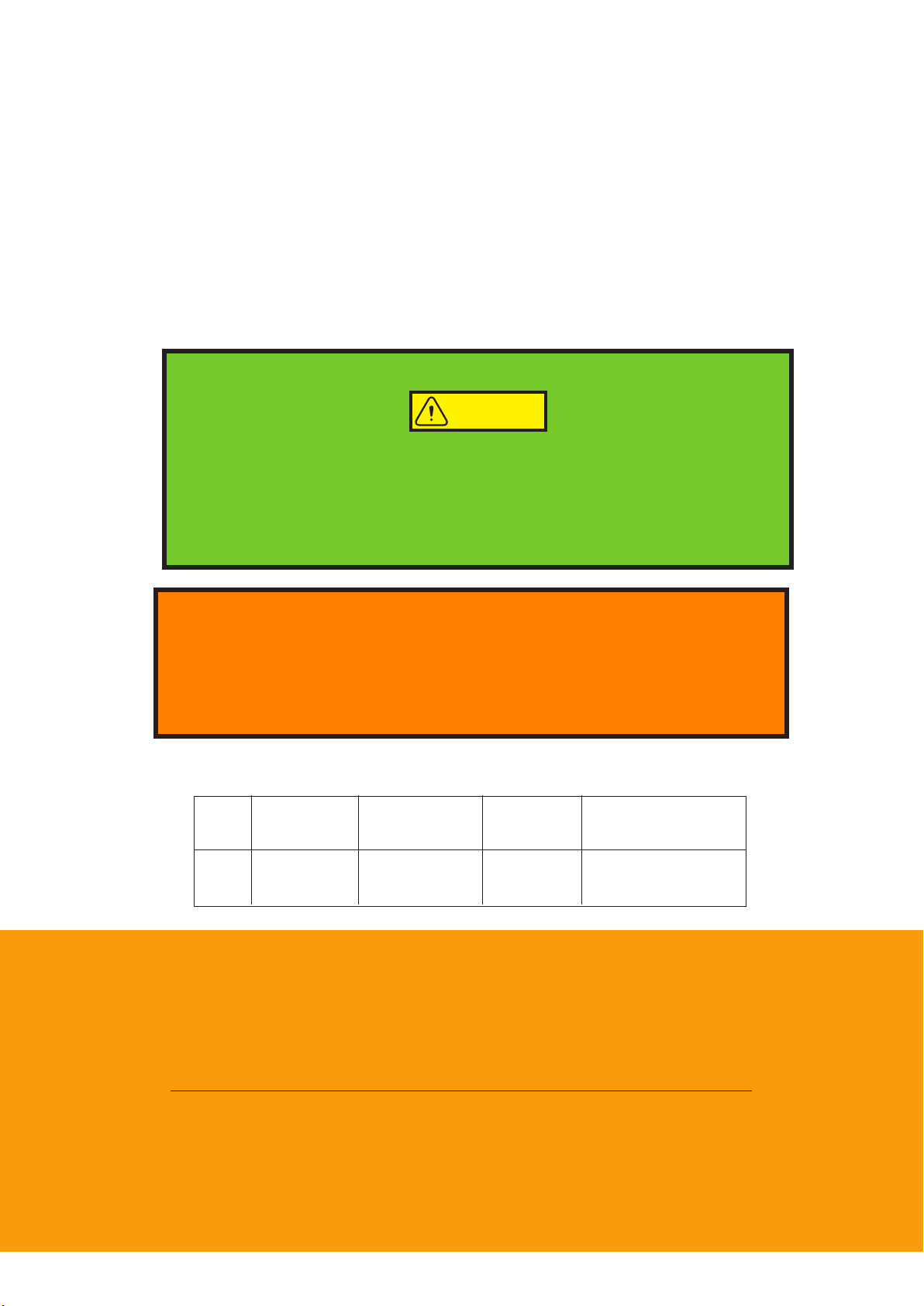

Danger, Warning, Caution and Notice - Throughout this manual there are steps and procedures

that can present hazardous situations. The following signal words are used to identify the degree

or level of hazard seriousness.

DANGER :- Danger indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury, and property damage

WARNING :- Warning indicates an imminently hazardous situation which, if not avoided, could

result in death or serious injury, and property damage.

CAUTION :- Caution indicates a potentially hazardous situation which, if not avoided, may result

minor or moderate injury or property damage.

NOTICE :- Notice is used to notify people of installation, operation, or maintenance information

which is important but not directly hazard-related.

CAUTION

These general instructions deal with the normal installation, operation, and maintenance

situations encountered with the equipment described herein. The instructions should not be

interpreted to anticipate every possible contingency or to anticipate the final system, crane,

or configuration that uses this equipment. For systems using the equipment covered by this

manual, the supplier and owner of the system are responsible for the system’s compliance

with all applicable industry standards, and with all applicable federal, state and local

regulations/codes.

This manual includes instructions and parts information for a variety of trolley and hoist

types. Therefore, all instructions and parts information may not apply to any one type or size

of specific trolley or hoist. Disregard those portions of the instructions that do not apply.

Record your hoist and trolley’s Product Code and Serial Number on the front cover of this

manual for identification and future reference to avoid referring to the wrong manual for

information or instructions on installation, operation, inspection, maintenance, or parts

Use only Indef authorized replacement parts in the service and maintenance of this trolley.

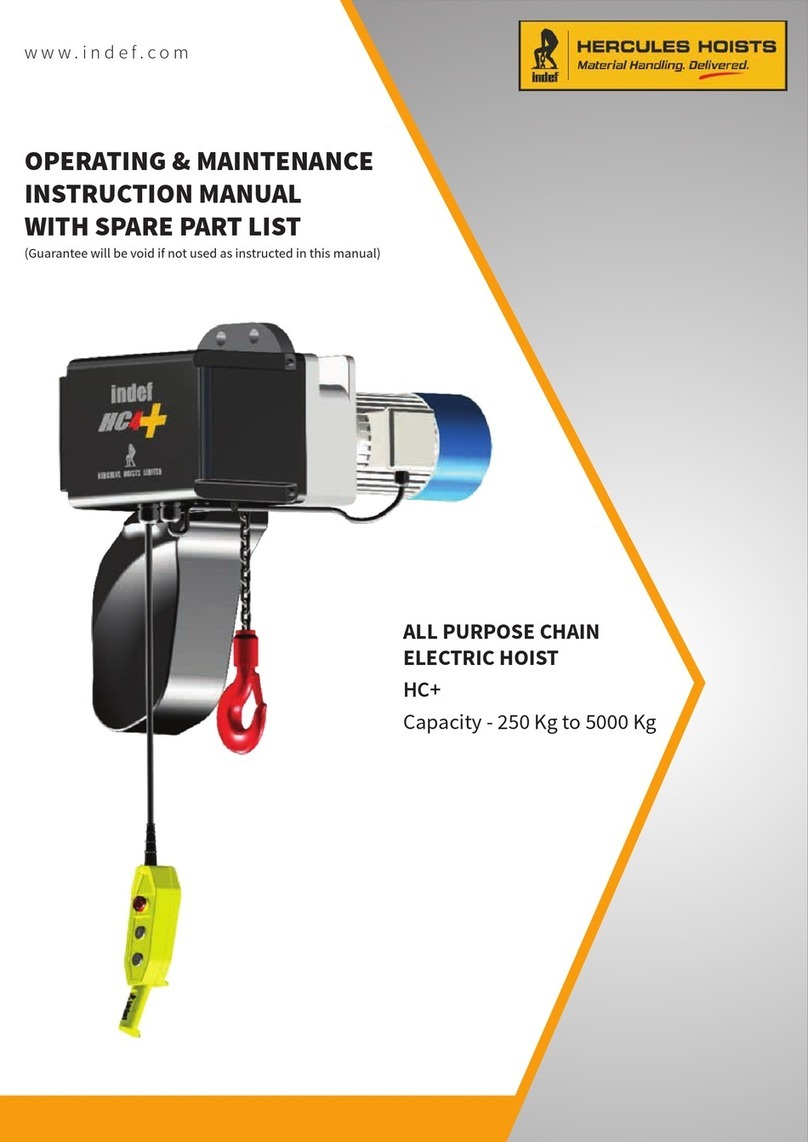

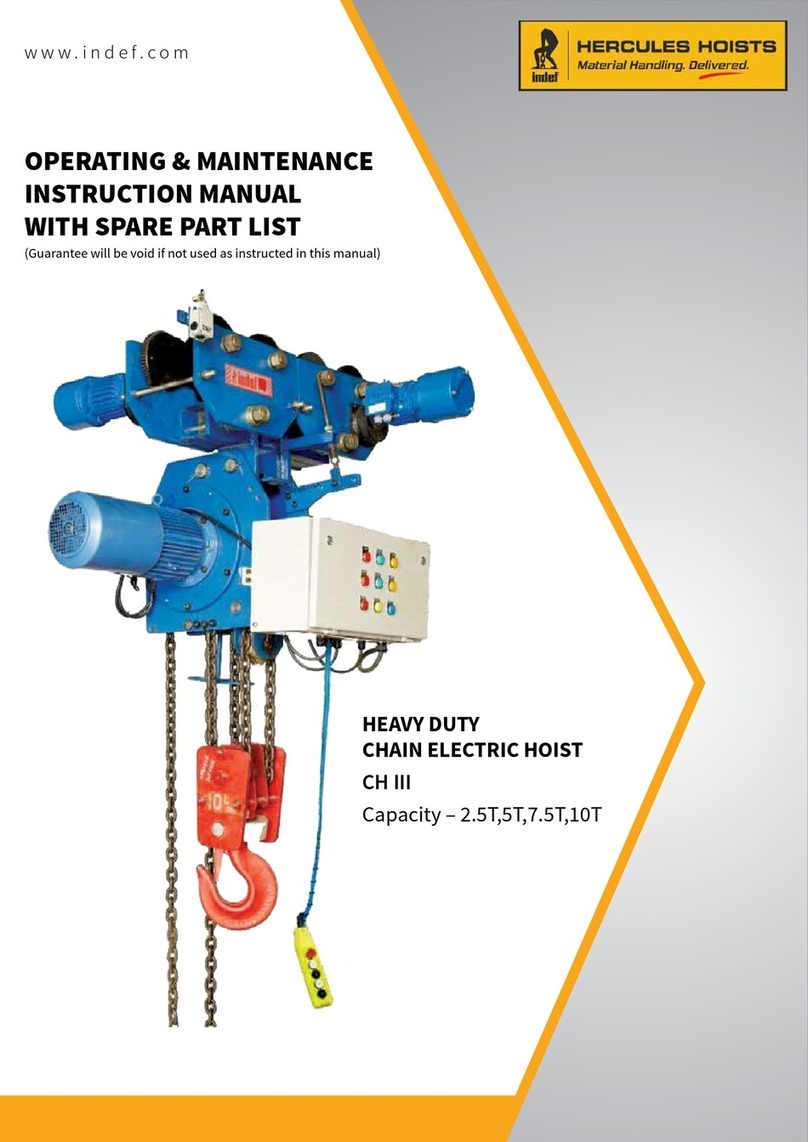

Indef CHAIN ELECTRIC HOIST

Hercules Hoists Limited ©2020

Note :- Due to continuous development and improvement specification listed above may be changed without notice

CAUTION

Equipment described herein is not designed for and MUST NOT be used for liing, supporting,

or transporting people, or for liing or supporting loads over people.

Equipment described herein should not be used in conjunction with other equipment unless

necessary and/or required safety devices applicable to the system, crane, or application are

installed by the system designer, system manufacturer, crane manufacturer, installer, or user.

Modifications to upgrade, rerate, or otherwise alter this equipment shall be authorized only

by the original equipment manufacturer.

Failure to read and comply with any one of the limitations noted herein can result in serious

bodily injury or death, and/or property damage.

The angle between rope and plane perpendicular to the axis of the drum shall not exceed 5°

(As per IS 3938 6.1.1.2).

Hoists shall not be operated unless the hoist unit is centered over the load, except when

authorized by a qualified person who has determined that the components of the hoist

and its mounting will not be overstressed. Should it be necessary to pick a load that is not

centered under the hoist unit, precautions should be taken to control the swing of the load

when it is picked clear of its support.

DANGER

HAZARDOUS VOLTAGES ARE PRESENT IN THE CONTROL BOX, OTHER ELECTRICAL

COMPONENTS, AND CONNECTIONS BETWEEN THESE COMPONENTS.

Before performing ANY mechanical or electrical maintenance on the equipment, de-energize

(disconnect) the main switch supplying power to the equipment; and lock and tag the main

switch in the de-energized position.

Only trained and competent personnel should inspect and repair this equipment.

Information

This symbol indicates tips and useful information.

Hercules Hoists Limited ©2020

Note :- Due to continuous development and improvement specification listed above may be changed without notice

Hercules Hoists Limited ©2020

Note :- Due to continuous development and improvement specification listed above may be changed without notice

Indef CHAIN ELECTRIC HOIST