11

Wire Rope

Attention !

Conditions and limits of rope use:

Less than 10% of the elementary strands are broken following twisting (1 step).

The diameter of the wire rope must be reduced by less than 7%.

There must be no bends (folded or twisted rope) or corrosion.

When the wire rope is replaced, fix the end with a stop sleeve.

The stop sleeve (fixed to one end of the rope to prevent the rope and load slipping off the pulley

due to an excessive load) must be complete, without damage, and there must be no risk of the

wire rope sliding or becoming separated from it.

Pulley

Wear in the pulley groove is caused by the wire rope, so the wire rope must also be inspected.

Methods for recognizing the limit values for the pulley groove with the naked eye:

1. After production and heat treatment, the surface of the pulley groove is coated with electric black.

2. When holding the load, the electric black coating becomes worn away to the point when the wire

rope no longer moves at the bottom of the groove.

3. When the equipment is used continuously, the score line moves to the bottom of the groove.

4. There are two reasons for this:

The wire rope diameter is reduced: the wire rope is worn and must be replaced.

The pulley groove is worn: if a new rope touches the bottom of the groove, it is time to replace

the pulley.

※Worn wire rope touching the bottom of pulley groove.

1. Replace the wire rope.

2. Mark the groove with an indelible marker.

※New wire rope touching the bottom of the pulley groove.

1. Replace the pulley.

12

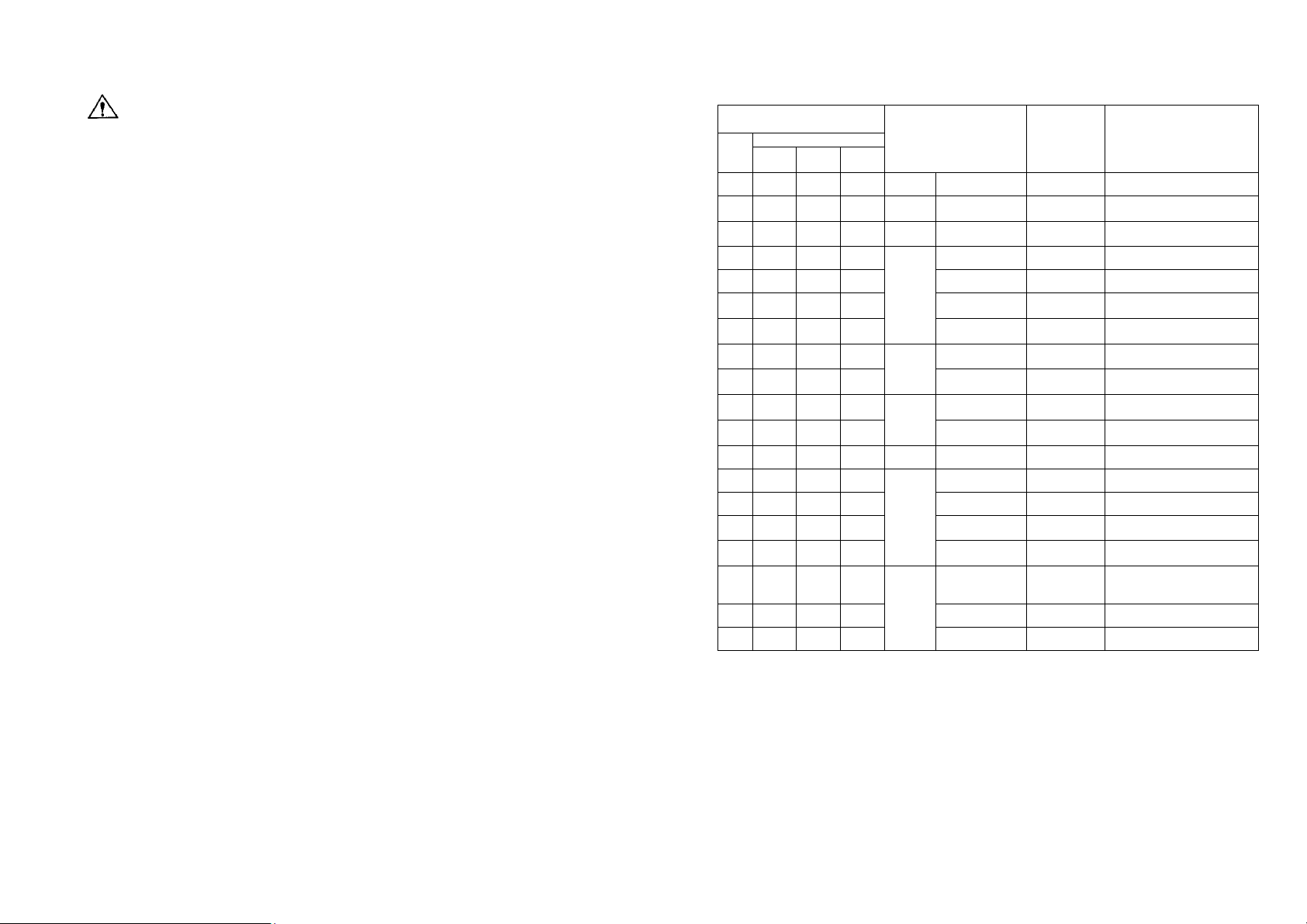

Checking

Classification of checks

Checking Item Checking Method Checking Reference

Daily Periodical

One

month Three

month One

yea

◎ Marking Label and the like Visual Existence of label

◎ Easylift

hoist Exterior Visual No cracks, breaks or significant

deformation

◎ Installation Functional operating

mechanisms Visual To be properly adjusted and free from

unusual sounds when operation

◎

Control/

Switch

Working Function Reasonable actuation

◎ Housing Visual To be free from cracks

◎ Wiring Visual To be free from remarkable loose or

damaged

◎ Cord Visual, electricity To be free from exposure of

conductive wire

◎

Motor

Condition

of insulation

Measure with

resistance tester 1MΩmin

◎ Staining damage Decomposition

chec

To be free from abnormalities

◎

Gear

Damage , wearing Decomposition

check

To be free from remarkable wear and

damage

◎ Lubrication condition Lubricating Have an abnormal sound to be

opened and checked

◎

Drum Exterior Visual No wear or corrosion

◎

wire rope

Broken strands Visual, measuring Less than 10%

◎ Wear Visual, measuring Less than 7% diameter reduction

◎ Deforming or

corrosion Visual Existence of abnormalities

◎ stop sleeve Visual It must be solidly fixed to the end of

the wire rope

◎

Hook

Housing and

mechanical

components

Visual, function To be free cracks, rupture and harmful

deformation

◎ Length stretching Measuring size deformation by 5% maximum

◎ Safety catch Visual To be free from deformed