HYDRAULIC MOTORISED COMPACT PIPE BENDER WITH FRAMEOPEN

SAFETY INSTRUCTIONS

WARNING : When using tools, the following safety instructions must be observed to

reduce the risk of personal injury and property damage.

Please read and observe the following instructions before use.

1. Keep work area clean : An untidy and cluttered work area increases the risk of accidents

2. Use eye protection : Always use safety glasses or goggles. A face mask should also be worn

when dust is generated.

3. Wear suitable work clothes : Don't wear loose fitting clothes or jewellery. They can be caught

in moving parts and may cause injury. For outdoor work rubber gloves and non-stick footwear

are advised. Wear a protective hair net to contain long hair.

4. Guard against electric shock : Avoid any body contact with grounded surfaces e.g. bars,

radiators, stoves, and refrigerator enclosures.

5. Keep children away : Children should be kept away from the work area. Do not permit them to

handle the tool or tool cable.

6. Secure the work pieces : Use clamps or a vice to hold work. This will free up both hands to

operate the tool, which is safer.

7. Don't overreach when working : Keep a balanced footing at all times.Avoid abnormal stances

and awkward body positioning.

8. Do not overload or force tools : Tools operate better in the specified performance ranges.

Forcing the tool may cause motor damage.

9. Check for damage : Before further use always check the protection guards carefully to ensure

proper operation and performance. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mountings and any other condition that may effect the tools operation.

An authorised service dealer should properly repair all damaged parts unless otherwise

indicated elsewhere in the instruction manual. Do not use the tool if the switch does not turn it on

and off.

10. Pull out power plug : When changing accessories or when the tool is not in use.

11. Avoid unintentional starting : Do not carry tools by the switch. Always check that the switch is

in the off position before connecting to power source.

12. Don't abuse power cable : Never carry the tool by the power cable. Do not use the power cable

to pull the plug out of the power point. The cable should also be protected from heat, oil and

sharp objects.

13. Storage : When not in use your power tools should be stored in a dry area, which is not

accessible to children.

14. Stay alert : Do not use the tool when you are tired. Use common sense and watch what you are

doing.

15. Remove keys and spanners : Do not forget to remove any adjustment keys, spanners and

wrenches before switching on the tool.

16. Voltage warning : Before connecting the tool to the power source ensure the voltage specified

on the nameplate is the same as the voltage supply. A power source with voltage greater than

specified on the tool can cause serious injury and damage to the tool. Using a power source with

voltage less than the tool rating can cause damage to the motor. Do not plug in tool if you are in

doubt.

17. Recommended use : Please note the use of tools other than those described in instruction

manuals or in the product catalogues can result in a risk of personal injury.

Page # 3 - M:282

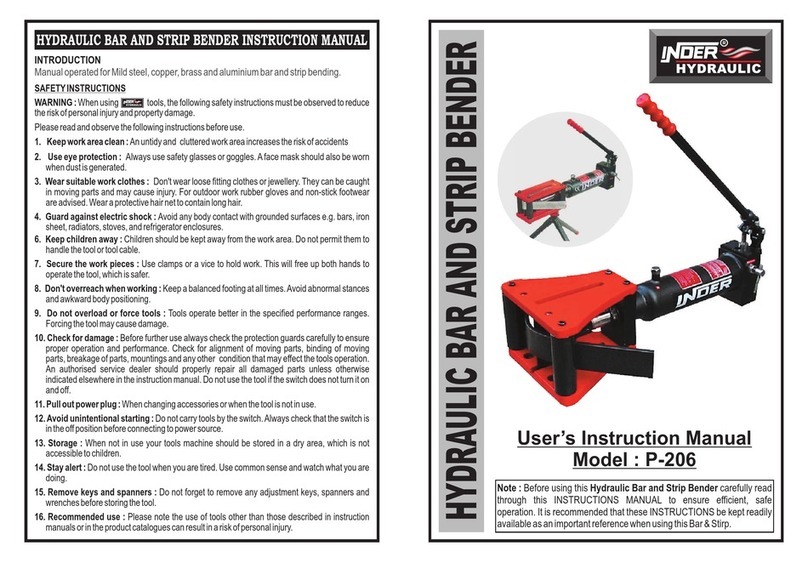

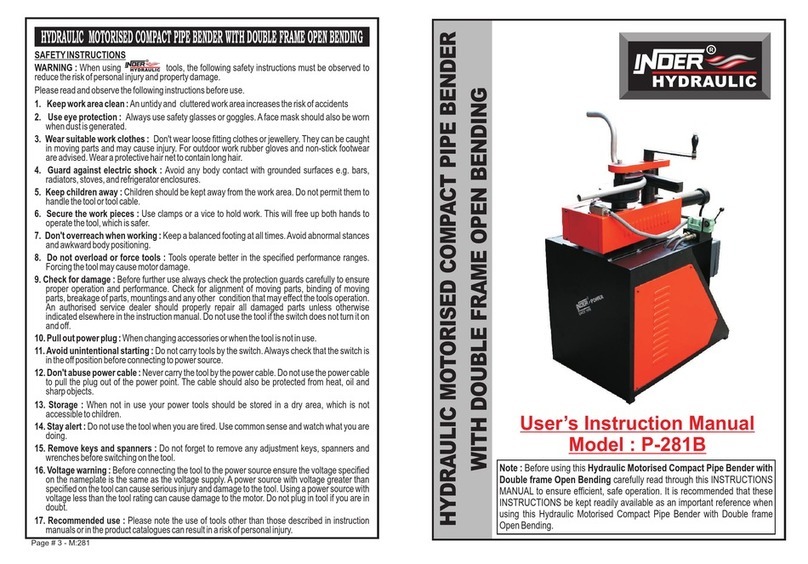

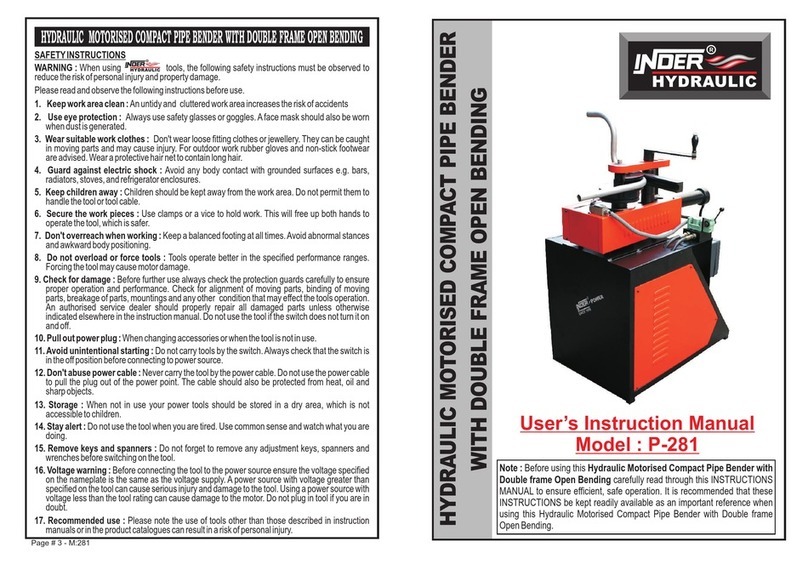

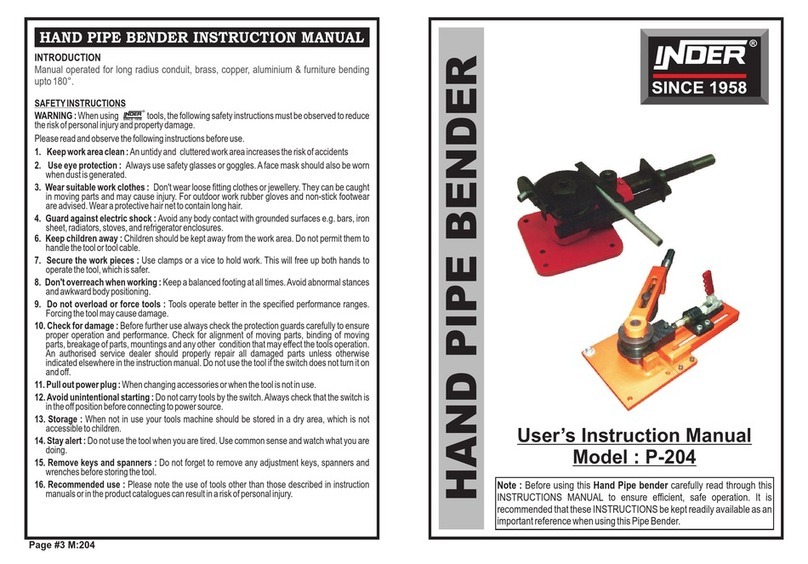

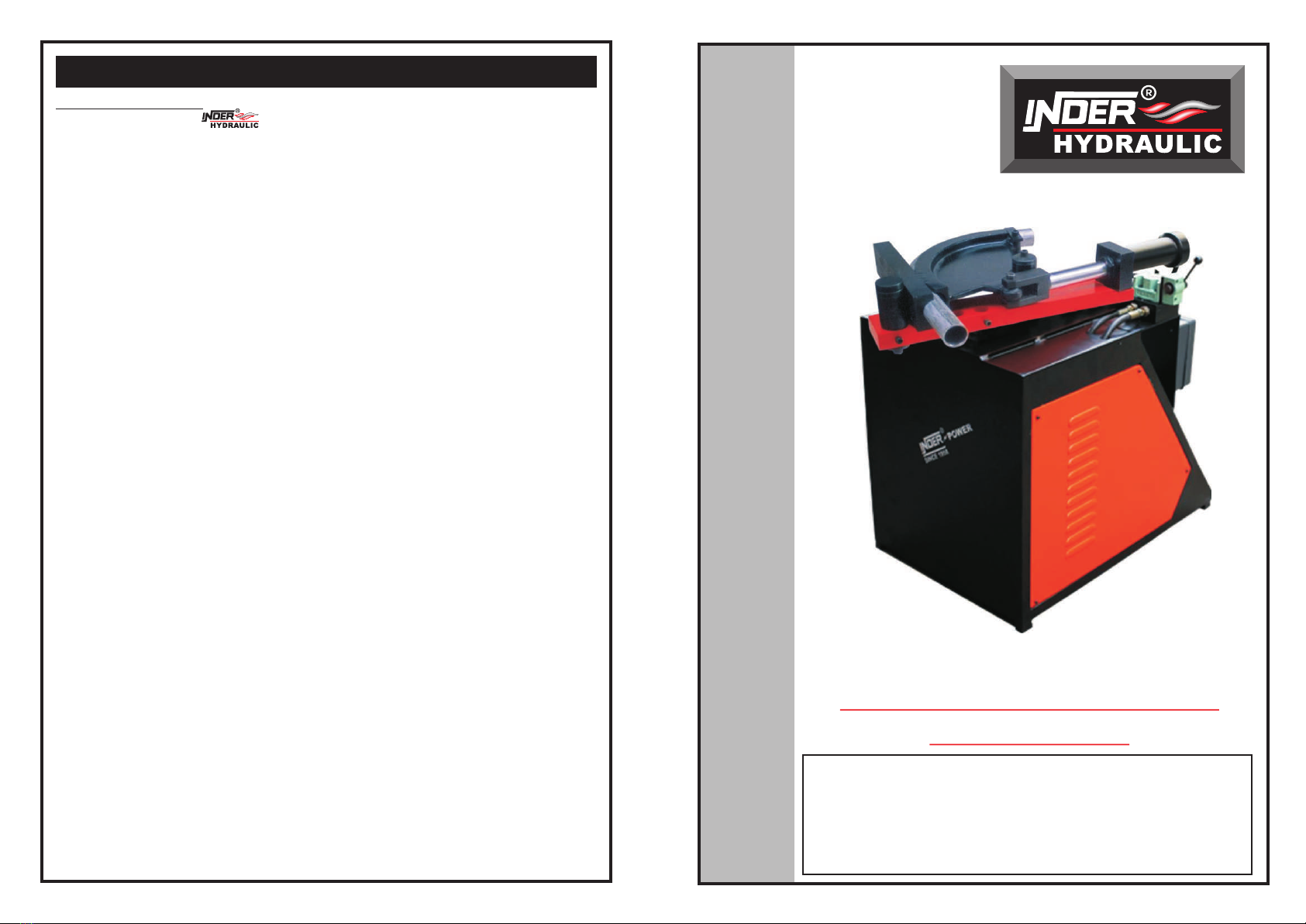

HYDRAULIC MOTORISED COMPACT

PIPE BENDER WITH OPEN FRAME

User’s Instruction Manual

Model : P-282

Note : Before using this Hydraulic Motorised Compact Pipe Bender with

Open frame carefully read through this INSTRUCTIONS MANUALto ensure

efficient, safe operation. It is recommended that these INSTRUCTIONS be

kept readily available as an important reference when using this Hydraulic

Motorised Compact Pipe Bender with Double frame Open Bending.