IContents

© 2011 Enter your company name

Table of Contents

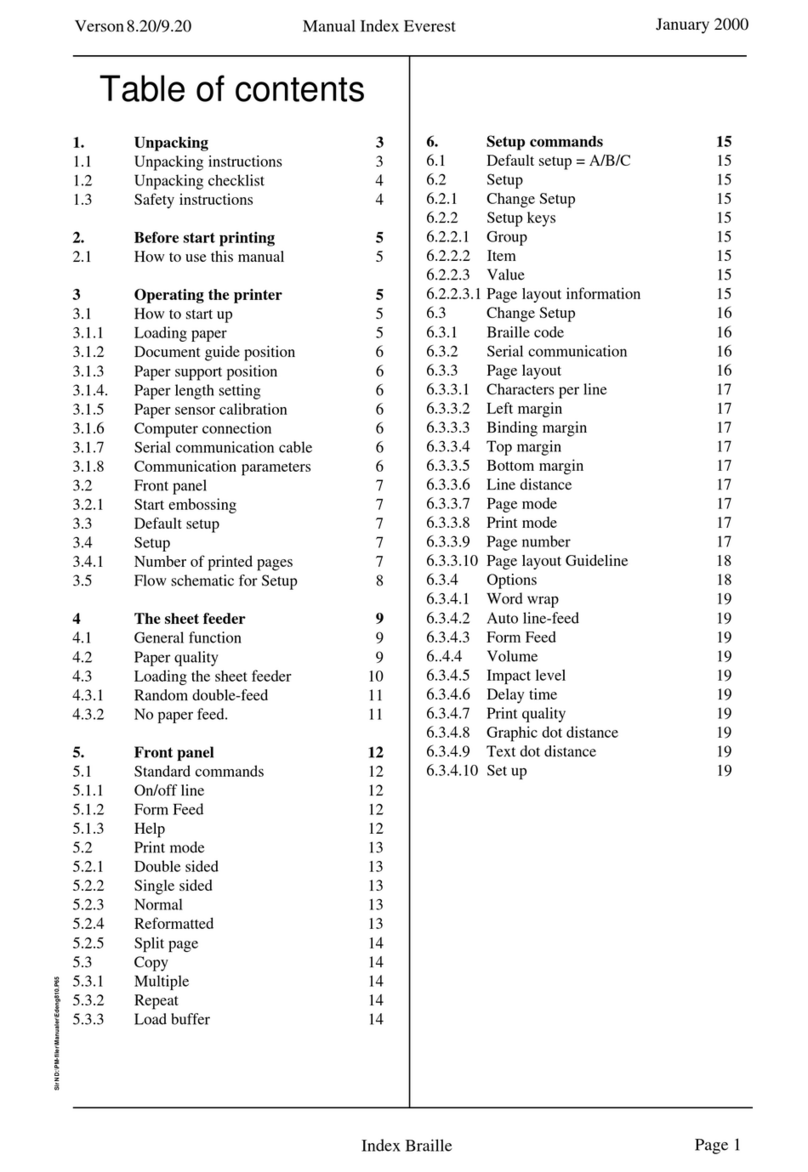

Model Disassembly instructions 1

................................................................................................................................... 11 Electronic modules Everest and Basic

................................................................................................................................... 12 Basic D

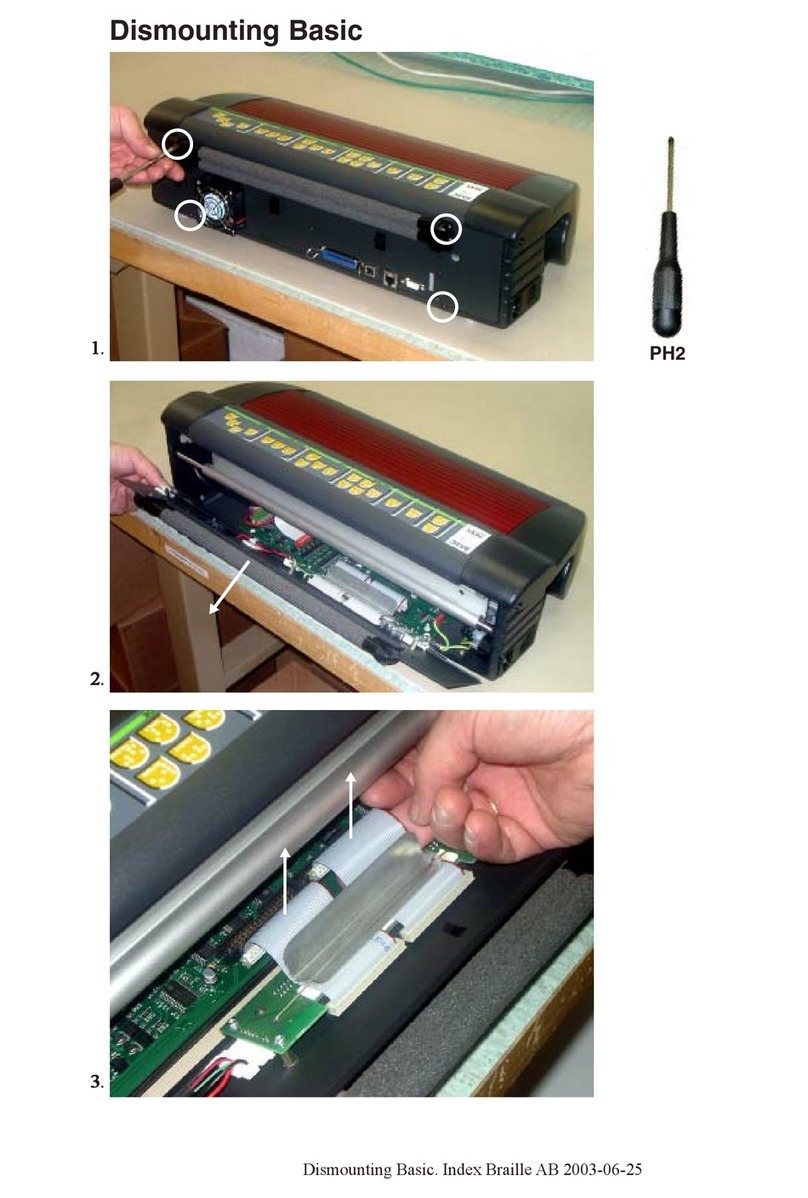

......................................................................................................................................................... 1Remove back plate

......................................................................................................................................................... 1Remove side covers

......................................................................................................................................................... 1Replace embossing head

......................................................................................................................................................... 1Replace Main Board

......................................................................................................................................................... 2Replace Paper Tractors

......................................................................................................................................................... 2Replace motor module

......................................................................................................................................................... 2Remove the fan

................................................................................................................................... 23 Everest D

......................................................................................................................................................... 3Clear major paper jam

......................................................................................................................................................... 3Remove front glass

......................................................................................................................................................... 3Remove back plate

......................................................................................................................................................... 3Remove side covers

......................................................................................................................................................... 3Replace sheet feeder

......................................................................................................................................................... 3Replace main board

......................................................................................................................................................... 4Replace embossing head

......................................................................................................................................................... 4Replace roller module

................................................................................................................................... 44 Braille Box

......................................................................................................................................................... 5Open the Service door

......................................................................................................................................................... 5Remove Braille tray

......................................................................................................................................................... 5Dismounting Braille Box

.................................................................................................................................................. 5Plates

........................................................................................................................................... 5Top plate

........................................................................................................................................... 5Mid plate back

........................................................................................................................................... 5Mid plate le t

........................................................................................................................................... 6Technical corner plate

........................................................................................................................................... 6Right lower cover plate

........................................................................................................................................... 6Inner ront plate

........................................................................................................................................... 6Braille tray cover plate

........................................................................................................................................... 6Braille tray guides

.................................................................................................................................................. 6Mechanical modules

........................................................................................................................................... 6Front glass door

........................................................................................................................................... 6Embossing tower

........................................................................................................................................... 7Replace embossing head

........................................................................................................................................... 7Replace roller module

........................................................................................................................................... 7Replace paper out lip lop

........................................................................................................................................... 7Replace ventilation module

......................................................................................................................................................... 8Sheet feeder

.................................................................................................................................................. 8Replace pick up roller

.................................................................................................................................................. 8Replace sheet eeder

......................................................................................................................................................... 8Electronic modules

.................................................................................................................................................. 8Replace CPU BCP V4

.................................................................................................................................................. 8Replace Driver PCB V4

.................................................................................................................................................. 8Replace Sheet eeder PCB V4

.................................................................................................................................................. 8Replace LED PCB V4

.................................................................................................................................................. 9Replace Power supply

.................................................................................................................................................. 9Replace an