5 6

CO2, Nitrogen or Compressed Air Usage

The BKO comes with a male quick-disconnect adapter on the bottom of the

regulator. The BKO can be set up to use a nitrogen or compressed air system.

Although it may be used, CO2 is not recommended for use as the propellant.

Generally the CO2 that we use as an industry is industrial grade CO2. It is dirty,

pumped fromlarge tanks full of contaminates including rust and metal flakes. CO2

can be used successfully if used with anti-siphon systems and filters. Be aware that

under the conditions of CO2 the results may not be as expected. Consult the place

where you purchased your BKO, or a recognized and competent airsmith, for

instruction in the safe handling of compressed-air cylinders before purchasing or

connecting one to your BKO.

Adjustable regulator compressed air systems:

The input pressure from your compressed air system should be regulated down to

350-500 PSI output pressure. Note: on MOST systems, there is a large difference

between the setting pressure and the actual output operating pressure. If your

compressed air system does not have an output pressure gauge on its regulator we

do not recommend its use.

Fixed output regulated compressed air systems:

Fixed output regulated tanks (preset) will work just fine with the BKO, however it

will not perform as well as an adjustable regulated tank. VERIFY the output

pressure from the regulator. If your compressed air system does not have anoutput

pressure gauge on its regulator we do not recommend its use.

CO2 usage:

Although it may be used, CO2 is not recommended for use as the propellant.

Generally the CO2 that we use as an industry is industrial grade CO2. It is dirty,

pumped from large tanks full of contaminates including rust, metal flakes and dirt.

CO2 can be used successfully if used with anti-siphon systems and filters. Be

aware that under the conditions of CO2 the results may not be as expected.

REMEMBER: CO2, compressed air or nitrogen systems can be extremely

dangerous if misused or improperly handled. Use only D.O.T. certified tanks.

Before pressurizing your BKO, check to make sure that you have a barrel plug or

barrel sock in place and there is no paint in the gun. The on-off switch should be

OFF. Air can now be applied, the gun will become pressurized and the gauge on

the regulator system adapter will show the air pressure regulated thru the input

regulator.

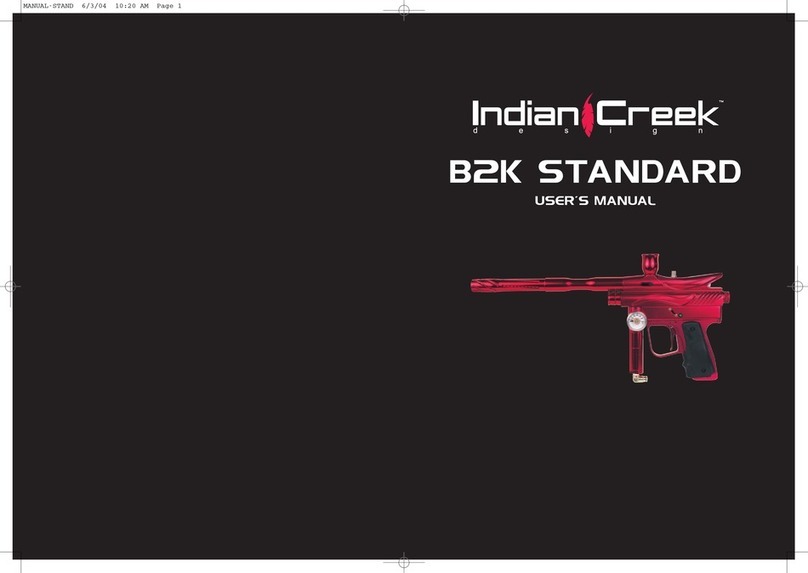

Paintball and Loader Usage

The BKO comes equipped to accept 1.03" OD standard-gravity feed loaders. Fit

the loader directly into the vertical feed tube. Always twist it down in a

CLOCKWISE direction. Always twist it off in a CLOCKWISE direction as well.

The BKO uses .68 caliber, water-soluble paint pellets. The pellets are gravity fed

from the loader through the direct vertical feed nipple and into the breech of the

gun.

Firing the BKO

Keep your finger out of the trigger guard and away from the trigger; point the

muzzle of your gun in a safe direction at all times during this process. Be sure your

goggles are securely in place. Push the on-off switch into the off position.

Always keep your BKO pointed in a safe direction!

1. Place the empty loader onto the gun. Be sure that it is securely mounted in

place.

2. Apply the compressed gas, pressurizing the gun.

3. Put the paintballs into the loader.

4. Remove the barrel plug.

5. Aim the gun at the target.

6. Push the on-off switch to the ON position, the LED will light up.

7. Place your finger on the trigger.

8. Pull the trigger with a smooth squeezing motion. BANG. . . .

UNLOADING THE BKO

Keep your finger out of the trigger guard and away from the trigger; point the

muzzle of your gun in a safe direction during this entire process. Alwayskeepyour

BKO pointed in a safe direction!

1. Push the on-off switch to the off position. The LED will be off.

2. Remove the pressurized gas from the marker carefully.

3. Place the barrel plug into the end of the barrel.

4. Tilt the marker so that the loader is lower than the body of the gun.

5. Remove the paintball loader from the directvertical-feed tube,turningthe

loader in a clockwise direction.

6. Inspect the inside of the direct vertical-feed tube to be sure that aball does