Industrial Controls MC-2120 Operating instructions

MC-2120 controller Operating

and Maintenance Manual

REV.00

2

CHAPTER 1: CUSTOMER INFORMATION

THANK YOU FOR PURCHASING AN INDUSTRIAL CONTROL PRODUCT

These instructions have been published by INDUSTRIAL CONTROL and are not subject to any

guarantee. The instructions may be withdrawn or revised by INDUSTRIAL CONTROL at any time and

without further notice.

Corrections and additions will be added to the latest version of the instructions. Always download the

installation instructions from our website, www.incontrol-co.com, for the latest available version.

Keep the safety instructions for future reference.

IMPORTANT! These instructions are intended for end users.

They can be printed and handed to end users. The installation instructions containing information

about the installation and configuration of the radio Controller unit on the machine is not intended to

be passed on to the end user. Only such information that is needed to operate the machine correctly

by radio controller may be passed on to the end user. INDUSTRIAL CONTROL MC controller are often

built into wider applications. Always refer to the applicable local regulations for installation and safety

requirements relating to cranes, hoists or other material handling and/or lifting equipment’s using

INDUSTYRIAL CONTROL products, e.g.: n applicable local and industrial standards and requirements,

n applicable occupational health and safety regulations, n applicable safety rules and procedures for

the factory where the equipment is being used, n user and safety manuals or instructions of the

manufacturer of the equipment where INDUSTRIAL CONTROL MC controller systems are installed.

INDUSTRIAL CONTROL instructions do not include or address the specific instructions and safety

warnings of the end product manufacturer.

INDUSTRIAL CONTROL products are covered by a guarantee/warranty against material, construction

or manufacturing faults, see § "GUARANTEE, SERVICE, REPAIRS AND MAINTENANCE" on page 11

www.incontrol-co.com

Info@incontrol-co.com

ABOUT SYSTEMS

The RC & MC product range is composed of transmitters and receivers intended for use together as a

system in complex control applications as an industrial firefighting monitor remote control.

Read all instructions and warnings carefully before mounting, installing and configuring the

products.

REV.00

3

ABOUT THIS DOCUMENT

Every care has been taken in the preparation of this manual. Please inform INDUSTRIAL CONTROL of

any inaccuracies or omissions. These End user instructions cover general safety issues, main technical

specifications, standard installation, operating instructions, general troubleshooting information and

regulatory information. Images shown in this document are for illustrative purposes only.

Term and symbol definitions

The capitalized terms and symbol used herein shall have the following meaning:

-WARNING! indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

-CAUTION! indicates a hazardous situation which, if not avoided, will result in minor or

moderate injury.

-IMPORTANT! is used for information that requires special consideration.

-NOTE! is used to address practices not related to physical injury.

This symbol is used to call attention to safety messages that would be assigned the signal words

"WARNING" or "CAUTION".

WARNINGS & RESTRICTIONS

Carefully read through the following safety instructions before proceeding with the installation,

configuration, operation or maintenance of the product. Failure to follow these warnings could result

in serious injury and property damage.

RC & MC products must not be operated without having read and understood the End User

instructions, specific technical documentation (when provided), and having received the appropriate

training. The purchaser of this MC product has been instructed how to use the system safely.

Operation

-This radio system should not be used in areas where there is a risk of explosion unless you put it in an

explosion-proof housing. (For Antenna it is recommended explosion proof type with related barrier)

-Only qualified personnel should be permitted to access the controller and operate the

equipment.

-Always follow operating and maintenance instructions as well as all applicable safety

procedures and requirements.

-Do not open the controller housing unless you are qualified.

-You must satisfy the age requirements in your country for operating the equipment.

-It is strictly prohibited to operate the equipment under the influence of drugs, alcohol

and/or medications.

-Always test the stop button before operating it. Press the stop button on console then

twist and pull it out. This test should be done on each shift, without a load.

-Never use a MC if the stop button is mechanically damaged. Contact your supervisor/representative for

service immediately.

-Never let the transmitter unattended.

-Always switch the transmitter off when not in use. Store in a safe place.

-Keep a clear view of the work area at all times.

-Avoid registering transmitters in receivers where they are not being used.

REV.00

4

Maintenance

-Keep the safety instructions for future reference. Always download the End user instructions

from our website for the latest available version.

-Always contact your representative for service and maintenance work on the product.

-If error messages are shown, it is very important to find out what caused them. Contact your

representative for help.

-The functionality of the stop button should be tested at least after every 200 hours’ use. Test

the stop button by pressing it and pulling it out.

-If the stop button is mechanically damaged, do not use the transmitter. Contact your

representative for service immediately.

-Before maintenance intervention on any remote-controlled equipment:

A- always remove all electrical power from the equipment.

B- always follow lockout procedures.

REV.00

5

CHAPTER 2: PRODUCT DESCRIPTION

CONTROLLER FRONT VIEW

1: Input / Output Terminal

4: I/O Card Indicator Status

2: Ethernet connector

5: RF Module / CPU Indicator Status

3: SMA Antenna connector

TERMINAL DESCRIPTION

Port Description

I/O

Signal type

Terminal

No.

1

Left Command

Out

+24Vdc Up to 500mA output to

Relay, Contactor, or Solenoid

Valve control command

1

2

Right Command

Out

2

3

Up Command

Out

3

4

Down Command

Out

4

5

Motor Fog Command

Out

5

6

Motor Jet Command

Out

6

7

Water MOV Open Command

Out

7

8

Water MOV Close Command

Out

8

9

Foam MOV Open Command

Out

9

10

Foam MOV Close Command

Out

10

①

②

③

④

⑤

①

REV.00

6

Port Description

I/O

Signal type

Terminal

No.

11

Left Status

In

+24Vdc Optocoupler protected

input

11

12

Right Status

In

12

13

Up Status

In

13

14

Down Status

In

14

15

Motor Fog Status

In

15

16

Motor Jet Status

In

16

17

Water MOV Open Status

In

17

18

Water MOV Close Status

In

18

19

Foam MOV Open Status

In

19

20

Foam MOV Close Status

In

20

21

Left Joystick Command Station

In

+24Vdc Optocoupler protected

input

21

22

Right Joystick Command Station

In

22

23

Up Joystick Command Station

In

23

24

Down Joystick Command Station

In

24

25

Motor Fog Joystick Command Station

In

25

26

Motor Jet Joystick Command Station

In

26

27

Water MOV Open Joystick Command Station

In

27

28

Water MOV Close Joystick Command Station

In

28

29

Foam MOV Open Joystick Command Station

In

29

30

Foam MOV Close Joystick Command Station

In

30

31

Emergency Stop Command Station

In

A

32

Enable / Disable Command Station

In

B

33

Oscillating

In

C

34

Com. Fault

In

D

35

Left Indicator Command Station

Out

Up to 500mA open collector

output

31

36

Right Indicator Command Station

Out

32

37

Up Indicator Command Station

Out

33

38

Down Indicator Command Station

Out

34

39

Motor Fog Indicator Command Station

Out

35

40

Motor Jet Indicator Command Station

Out

36

41

Water MOV Open Indicator Command Station

Out

37

42

Water MOV Close Indicator Command Station

Out

38

43

Foam MOV Open Indicator Command Station

Out

39

44

Foam MOV Close Indicator Command Station

Out

40

45

sensor off

Out

E

46

Enable / Disable Indicator Command Station

Out

F

47

Oscillating indicator command station

Out

G

48

Fault Indicator Command Station

Out

H

49

Input supply Positive Voltage

-24Vdc

GND

50

Input supply Negative Voltage

GND

51

Input supply Positive Voltage

24Vdc

+24V

52

Input supply Negative Voltage

+24V

53

RS485

A

54

B

55

CAN BUS

L

56

H

REV.00

7

CHAPTER 3: CONFIGURATION

This section will show you how to configure your new MC controller using the web-based

configuration utility.

Web-based Configuration Utility

If you wish to change the default settings or optimize the performance of the MC-2120, you may use

the web-based configuration utility.

After power on, connect Ethernet cable from PC to MC-2120

Go to control panel -> network and sharing center -> Ethernet properties and setup TCP/IPv4 as

manual.

REV.00

8

To access the configuration utility, open a web browser such as Internet Explorer or Firefox and

enter http://192.168.1.110 in the address field.

Note: our recommendation is Firefox browser.

RF Configuration

RF Activation: Check the box to enable the wireless function. If

you do not want to use wireless, uncheck the box to disable all

the wireless functions.

Point type: The MC2120 network is a MESH network. A network

consists of a Coordinator (master) and N routers (routers, slave

modules). All nodes have the same channel and PAN ID.

Note: always the RC remote control is set to coordinator as

factory set.

REV.00

9

PAN ID: MC-2120 networks are called personal area networks (PANs). Each network is defined with a unique

PAN identifier (PAN ID), which is common among all devices of the same network. MC-2120 devices are either

preconfigured with a PAN ID to join, or they can discover nearby networks and select a PAN ID to join.

MC-2120 supports 00 01-FF 00 PAN ID. Both PAN IDs are used to uniquely identify a network. Devices on the

same network must share the same PAN IDs. If multiple MC-2120 networks are operating within range of each

other, each should have unique PAN IDs.

Channel: Users can change the channel (2405 MHz~2480 MHz), the corresponding channel 11 ~ 26 optional.

Note: If the gateway is used as a data node for the positioning system, it needs to be set to: PAN ID = 0xDEBF,

channel = 15

Select Antenna: Users can switch between on bored antenna or external.

User defined address: self-address ranges from 0001 ~ to FF00

Receiver Ch.: this setting is related to Channel RC remote control selection. can be set 1 to 4

Note: each RC remote control can be full control 4 No. MC-2120 controller.

Clock Configuration

To set RC remote control time & date use this setting.

Server Configuration/Hardware & software version

Users can change the IP address with this setting.

Extension Module

Check the box to enable the module No.1 to 3. If you do not want

to use extension module, uncheck the box to disable all the

functions.

This mode to use network 4 No. MC2120 via CANBUS with one

antenna.

REV.00

10

RS485 Configuration

Check the box to enable the RS485. If you do not want to use

extension module, uncheck the box to disable all the functions.

This mode to use connect MC2120 to RC remote control or HMI via

RS485 Modbus. In this mode disable RF function.

Note: In this function the MC-2120 set to slave & RC remote is

master by factory set

Maser

controller

Module 01

controller

Module 02

controller

Module 03

controller

Coaxial cable

RS485 cable

CANBUS cable

REV.00

11

CHAPTER 4: OPERATION

To control a receiver, the transmitter must be registered and logged in to the receiver. If another

transmitter is already logged in to the receiver, it must be logged out before a different transmitter

can be logged in. If no transmitter is logged in to a receiver, any registered transmitter will

automatically log in when sending radio signals to the receiver. The transmitter will remain logged in

until it is manually logged out.

NOTES!

-More than one transmitter can be registered in the receiver, but only one transmitter can be logged in

at a time. (by factory setting is applicable for transmitter)

-Up to 4 No. MC receiver can be register in one RC transmitter

START THE TRANSMITTER (RC portable remote control)

IMPORTANT! To be able to control a receiver with the transmitter, the transmitter must be registered in the

receiver.

If no receiver is registered, the display will show [Offline] after the stop button has been pulled out.

NOTE! By default, all the receivers & transmitter register by factory.

1- Make sure that the stop button is pressed.

2- Press the [POWER ON] button. transmitter starts the lamp test. after lamp test the selection

receivers (monitors) appear on the display [figure No.01].

3- Select a receiver (monitor). Move CH +/- toggle switch to step between the registered

receivers. Move UP Angle+/- toggle switch to select the requested receiver. One of a

receiver has been selected.

4- Pull out stop button. the status on the display shows [RUN]. if the transmitter be registered

in the receiver, LED indicator status will light if active on main controller.

5- Move CH +/- toggle switch up /down to step between the registered receivers. If no receiver

is registered, the display will show [STATUS: offline].

6- In this case the LED indicator on Fix console [POWER ON] button stays on/off each 1 sec.

If not successfully completed, the display will show [offline & disconnect].

If no button press or joystick move is established within 30 seconds, the transmitter goes to standby.

If stop button push in operation condition, the LED indicator on RC transmitter goes off & STOP logo

appear on display [figure No.04].

REV.00

12

START THE FIX console (MC receiver located on Fix console)

IMPORTANT! To be able to control a receiver with the transmitter, the transmitter must be registered in the

receiver.

NOTE! By default, all the receivers & transmitter register by factory.

1- Make sure that the stop button is pressed.

2- Press the [POWER ON] button. Fix console starts the lamp test. In this case the LED indicator

on Fix console [POWER ON] button stays on.

3- Pull out stop button. The monitor is ready for operation

In this case the Fix console never goes to standby.

If stop button push in operation condition, the LED indicator on RC transmitter goes off & STOP appear

on display [figure No.04].

Disable & Enable RC transmitter when the fix console is activated

When the fix console is running the LED indicator on Fix console [POWER ON] button stays on. In this

case if you pressed [POWER ON] button on transmitter and select relevant monitor on display appear

“FIX CONSOLE ACTEVATED” [figure No.07].

To enable RC transmitter, press the [POWER ON] button one time on fix console. In this case the LED

indicator on Fix console [POWER ON] button stays on/off each 1 sec.

SWITCH THE TRANSMITTER OFF

NOTE! When the transmitter is switched off, it remains logged in to the receiver(s). To logout, see §

"Logout" on page 09

Press the stop button. The display shows [Stopping]. The transmitter switches off. All relays/contactor

deactivate inside fix console.

To switch off the fix console with RC transmitter, push [CH +] & [Angle +] together. the fix console goes

off and the RC transmitter goes to standby mode. press [POWER ON] button to switch off the

remote control.

REV.00

13

LOGOUT

A transmitter already logged in to the receiver has to be logged out before any other transmitter can

be logged in.

NOTE! If a transmitter has been lost or seriously damaged, use the replace procedure whenever

possible. It is possible to log out a transmitter directly from the receiver. However, this is not

recommended. Contact your representative for assistance.

NOTE! Logout can only be performed when the transmitter is on and a radio link with one or more

receivers has been established. The receiver must be powered up for the logout procedure to be

successful.

SWITCH CHANNEL

For radio systems operating on frequency band 2.4GHz, it is possible to switch channels.

To switch frequency bank on radio systems operating on frequency band 2.4Ghz MHz, contact your

representative for assistance.

AUTOMATIC SHUTDOWN

Automatic shutdown helps prolong battery capacity by automatically switching the transmitter off after a

preset period of inactivity.

the preset period on RC transmitter is 30 Min.

OSCILLATING MODE

Certain fire hazards require the cooling of large hazard areas using water application. Similarly, it may be

required to apply foam over a large area in some situation, instead of specific point application. This can be

achieved by using oscillating monitors, as the monitor oscillates in the horizontal plane, providing coverage to a

large area instead of a specific location. Oscillating Foam/ Water remote Monitors use electro mechanical means

to oscillate the monitor in a preset or selectable angle. The power for movement can be an external power

source. These are also recommended where unmanned operation is necessary in view of severe fire hazards.

it can be turned on remotely by Press the [Oscillating] button on RC remote control or Fix console. On

the fix console the monitor Oscillate 100% of calibration angle but on the RC remote control percent

of angle can be selected by push up / down [Angle +/-] toggle switch.

NOTE!

When the Oscillating mode is activated, no function can be controlled.

For Deactivate oscillating mode push [Oscillating] button.

REV.00

14

CHAPTER 5: GUARANTEE, SERVICE, REPAIRS AND MAINTENANCE

INDUSTRIAL CONTROL products are covered by a guarantee/warranty against material, construction,

and manufacturing faults. During the guarantee/warranty period, INDUSTRIAL CONTROL may replace

the product or faulty parts. Work under guarantee/warranty must be carried out by INDUSTRIAL

CONTROL or by an authorized service center specified by INDUSTRIAL CONTROL.

The following are not covered by the guarantee/warranty:

1- Faults resulting from normal wear and tear.

2- Parts of a consumable nature.

3- Products that have been subject to unauthorized modifications.

4- Faults resulting from incorrect installation and use.

5- Damp and water damage.

Maintenance:

1- Repairs and maintenance must be carried out by qualified personnel.

2- Only use spare parts from INDUSTRIAL CONTROL.

3- Contact your representative for service or any other assistance.

4- Keep the product in a clean, dry place.

5- Keep contacts and antennas clean.

6- Wipe off dust using a slightly damp, clean cloth.

CHAPTER 6: TECHNECAL DATA

MC-2120 size / protection

L:100mm W:90mm H: 120mm

IP20

Frequency Band / receiver sensitivity

2.4GHz / -98dBm

Area classification

Safe area

Operating Temperature

-40 to 60°C

Power supply / consumption

Normal 24Vdc (18 ~28Vdc) / Max 600mA

Reaction Time

< 0.1 Sec

operation & indicator

Left / Right –Up / Down joystick

Water actuator valve open/close

Foam actuator valve open / close

Oscillating mode pushbutton

On/off switch

FOG/JET

Distance

Visual distance 500 meter in open area with 5dB antenna

FREQUENCY BAND 2.4GHz

For radio systems operating on frequency band 2.4 GHz, the frequency band is divided into 11

channels (channel 11-26). Once the channel has been selected on the transmitter, the receiver will

automatically detect and switch to the same channel.

REV.00

15

CHAPTER 7: ANTENNA RULE

1. Antenna gain

A high antenna gain does not automatically mean a better connection. The high gain generates a

small angle of radiation, which requires a more precise alignment.

2. Antenna selection

Think about selecting the correct antenna characteristics, particularly on the receiver side. While

doing so, pay attention to the correct polarization.

3. Assembly height

An antenna, particularly outside, should be positioned as high as possible. This allows you to

improve the range. This keeps the Fresnel zone clear –the higher, the better.

4. Antenna cable as short as possible

The antenna cable should be as short as possible to keep signal loss on the cable as low as possible.

Bring the radio module closer to the antenna, e.g. in a small box.

5. Correct protection of antenna connections

Always protect connections on the outside cables, junctions and antennas with protective tape.

6. Antennas are not lightning arresters

Antennas on buildings are not used as lightning arresters. Select the position of the antenna

carefully, use surge protection and do not route the antenna cable parallel to the lightning

arrester.

7. Correct mounting

In the case of insufficient stability, the quality of your antenna alignment

can be reduced. When mounting the antenna, also think about wind and

other outside influences.

8. The right distance

Install the antenna in an open area, as far away as possible from any

obstacles such as buildings, trees, other antennas, or metal objects.

9. Connection to antenna from below

Outdoor antenna cables should always be connected to the antenna

from below. Also use a conduit, if necessary.

10. Weather influences

Fog and rain have nearly no influence on the wireless path. In the case of

ice and snow, on the other hand, you must make sure that the antennas

are not covered with ice.

⑧

⑨

⑤

⑤

③

④

REV.00

16

Explanations

- Antenna selection:

Areas of application for omnidirectional

antennas

• Numerous devices in different directions (Repeater or

mesh networks)

• Versatile applications

• Applications without visual communication (in the case

of a reflective environment, the signal can be received via

alternate lines)

Areas of application for directional antennas

• Bridging large distances

• Point-to-point connections

• Stationary or linear applications

• Decoupling due to directivity and different polarization

planes in the case of multiple point-to-point paths

Note: Make sure the antennas have a uniform polarization plane.

- The assembly height (Fresnel zone)

The wireless path may also work if obstacles are within the

Fresnel zone (house, tree, etc.). The decisive factor is the

number of obstacles and the area they occupy in this zone.

In practice, lower frequencies (e.g. 868 MHz) are better at

penetrating obstacles.

Note: Use antennas with circular polarization in a strongly reflective

environment. This type of antenna prevents polarization loss, allowing

you to achieve higher gain in this environment. To improve the signal

strength, you can also combine circularly and vertically polarized

antennas.

Wireless path

distance (d)

Antenna height(r)

868/900Mhz

2.4GHz

5GHz

200 m

4.0 m

2.5 m

1.5 m

500 m

6.5 m

4.0 m

2.5 m

1000 m

9.0 m

5.5 m

4.0 m

2000 m

13.0 m

8.0 m

5.5 m

d

r

REV.00

17

-The right distance

An omnidirectional antenna must always be installed at

a sufficient distance from obstacles (poles, building walls

or metal walls).

If multiple radio modules are used, you have to make

sure, the antennas are spread out at sufficient distances

from one another.

Frequency

Minimum distance

(Vertical and horizontal)

868/900 MHz

1.5 ~ 2.5 m

2.4GHz

0.5 ~ 1.0 m

5 GHz

0.5 ~ 0.8 m

-Surge protection

Antennas on buildings are not used as lightning arresters. Select the position of the antenna

carefully, use surge protection if antenna install outdoor.

Surge

protectio

n

Outdoor

Antenna

Coaxial cable

Coaxial cable

Table of contents

Popular Controllers manuals by other brands

Metso

Metso Neles ValvGuard VG9000F Installation maintenance and operating instructions

Mitsubishi

Mitsubishi FX3U Series Handbook

Zennio

Zennio MAXinBOX FC 0-10V FAN Technical documentation

Orbit

Orbit JETRONIC-BOX manual

Genie

Genie UNIVERSAL REMOTE Alternate Instructions

Siemens

Siemens PXC00-U Mounting instructions

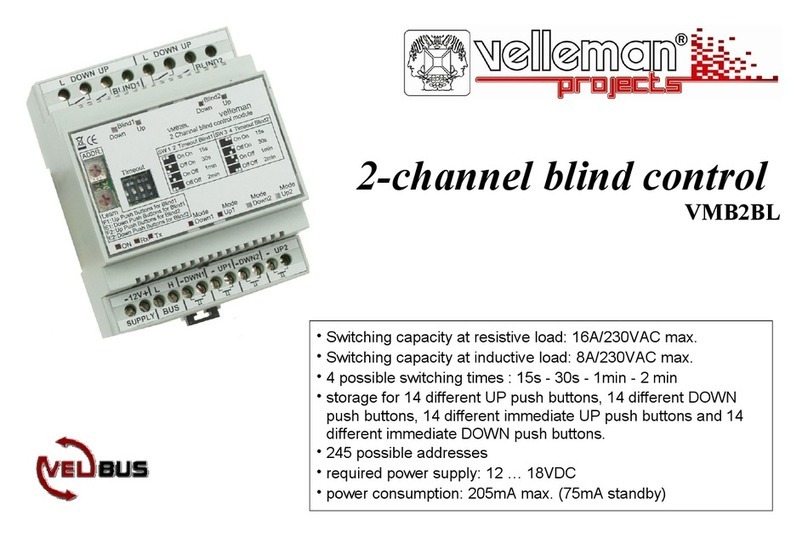

Velleman

Velleman VMB2BL manual

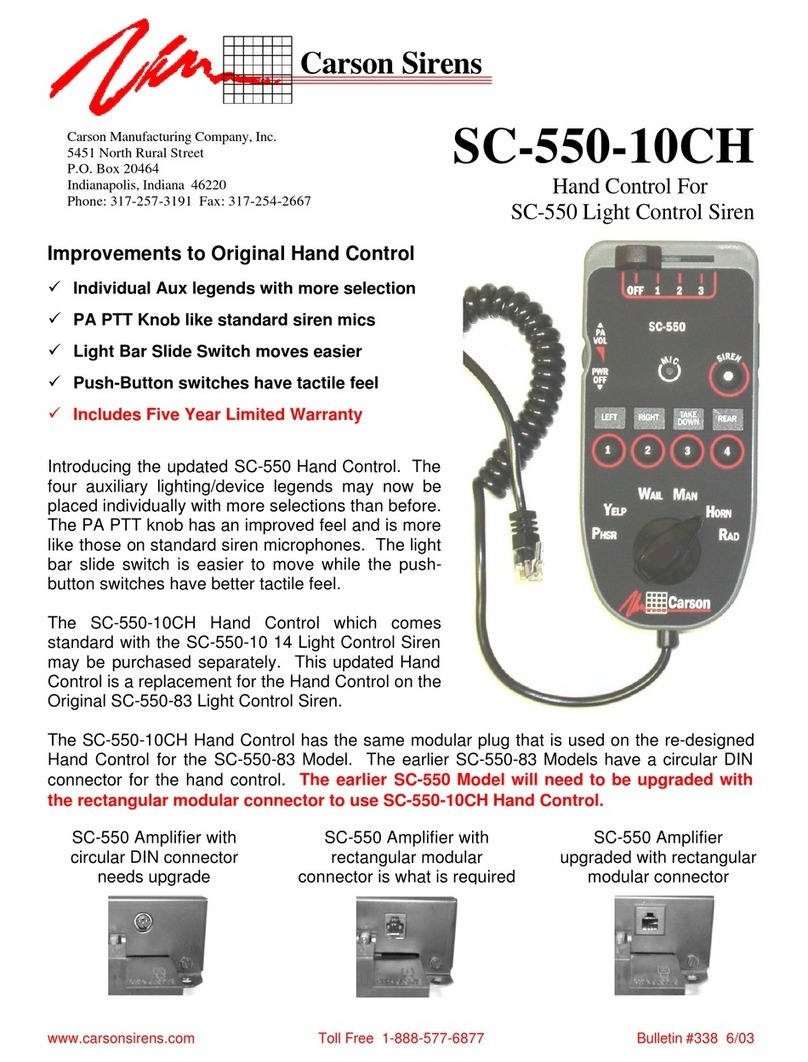

Carson

Carson SC-550-10CH Specification sheet

PR electronics

PR electronics 2286 product manual

Cirrus Logic

Cirrus Logic Crystal LAN CS8900A Reference manual

Aiphone

Aiphone LEM-1DL/C manual

Camozzi

Camozzi PRE Series Additional Installation, Operation and Maintenance Instructions