16 7 VG9F 70 en

❑To conclude press the ?key when the desired

value is shown on the display.

NOTE: If nothing else is defined, please select type 1 in

any class.

❑Select parameters as follows:

4.4.5 Actuator size, ACTS

This parameter defines the actuator size.

❑Look at e.g. the type code on the machine plate

in the Neles B1-series actuators to check the

size. If 3rd party actuator is used, please check

the actuator stroke volume.

❑After selecting ACTS on the display, press the ?

key to enter the edit state and ACTS starts to blink.

❑Select between the following values:

S 1 = Neles B1J8 actuator

(or stroke volume <1 dm3/ <61 in3)

S 3 = B1J10 (1-3 dm3/ 61-183 in3)

S10 = B1J12-16 (3-10 dm3/ 183-610 in3)

S30 = B1J20-25 (10-30 dm3/ 610-1831 in3)

L30 = B1J32- (>30 dm3/ >1831 in3)

Use the +and -keys to change the value.

❑To conclude press the ?key when the desired

value is shown on the display.

4.4.6 Spool type, STYP

This parameter defines the spool type and size in

VG9000F.

❑Look at the machine plate in the device to check

the typecode.

❑After selecting STYP on the display, press the ?

key to enter the edit state and STYP starts to blink.

❑Select between the following values:

15 = VG9_15

35 = VG9235

37 = VG9237

Use the +and -keys to change the value.

❑To conclude press the ?key when the desired

value is shown on the display.

4.4.7 Language selection, LANG

❑Select between three languages EnG, GEr or FrE

(English, German or French) using the +and -keys.

❑To conclude press the ?key when the desired

value is shown on the display.

4.5 Valve travel calibration

Select CAL from the menu by using +or -keys and

press the ?key.

NOTE: When device usage is hybrid the valve needs to

be in the normal position (not fail safe) for calibration to

be started.

4.5.1 AUTO CAL calibration function

During calibration process a blinking text "CAL run" will

be show on the display. If calibration ends successfully,

a text "CALIBRATION SUCCESSFUL" will be shown. Cali-

bration can be cancelled with the =key, which will

show a text "CALIBRATION CANCELLED". If calibration

fails, the reason will be shown, eg. "CALIBRATION

START FAILED", "POSITION SENSOR RANGE TOO

SMALL", "CALIBRATION TIMEOUT" or "CALIBRATION

FAILED". After calibration the device will return to the

main menu (measurement monitoring).

4.6 Testing, TESt

❑Select between two tests Partial Stroke Test

(PARt tst) or Pneumatics test (PNEU tst).

❑To conclude press the ?key when the desired

value is shown on the display.

4.6.1 Partial Stroke Test, PARt tst

Table 4 Selecting extra pneumatics instrumentation

parameters

Instrumentation type Parameter (EXTI)

Volume booster (VB) Booster type 1 (bo1)

Quick exhaust (QEV) Quick exhaust 1 (qE1)

Combination of VB and QEV Combination type 1 (co1)

NOTE:

When QEV or volume booster is used, VG with small

spool valve (VG_15_) is required.

NOTE:

When QEV or volume booster is used, VG with small

spool valve (VG_15_) is required.

CAUTION:

It is important to select the correct actuator size

because this parameter is used in device control.

Erroneous value may cause instability.

CAUTION:

It is important to select the correct spool type

because this parameter is used in device control.

Erroneous value may cause instability.

WARNING:

Automatic calibration drives the valve against the

mechanical open and closed travel limits of the

valve-actuator assembly and a tuning procedure is

performed. Make sure that these procedures can

be safely executed.

NOTE:

Make sure to run the pneumatics test before the auto-

matic travel calibration.

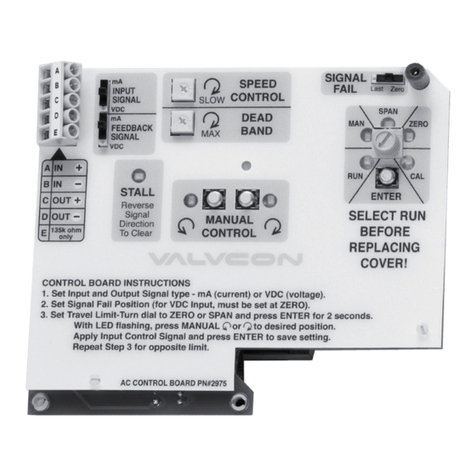

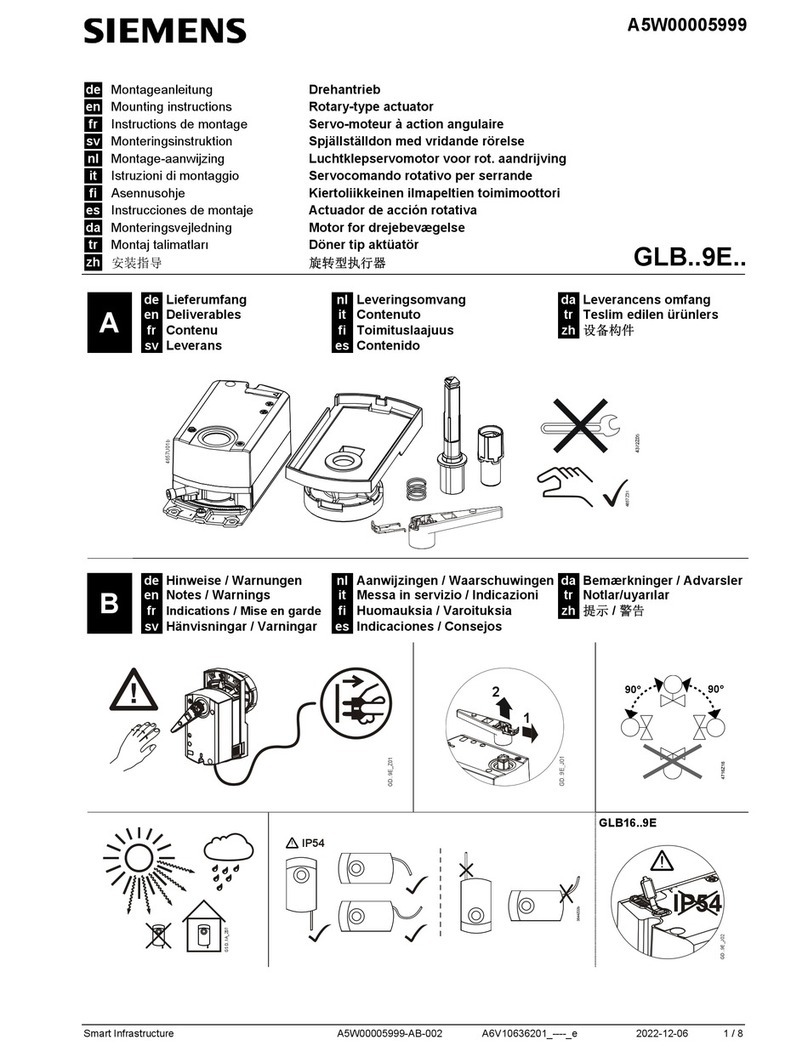

Fig. 14 Calibration selection

NOTE:

Valve position needs to be in the normal operating

position, supply pressure needs to be in valid range,

no supply pressure drop is allowed and any test can-

not be active when calibration is started.

Pneumatics test needs to be performed succesfully

before the calibration.

WARNING:

Partial Stroke Test moves the valve according to

the stroke size. Make sure that this procedure can

be safely executed.