Industrial Scientific Solar Power Supply User manual

Solar

Power Supply

Product

Manual

The Essential Guide to

Assembly, Operation,

and Disassembly for

the Safety Team and

Equipment operators.

Edition: 2

Part number: 17159773-1

November 20, 2020

Industrial Scientific Corporation, Pittsburgh, PA USA

Industrial Scientific Co., Ltd. Shanghai, China

© 2020 Industrial Scientific Corporation

All rights reserved. Published 2020

Revision 1

www.indsci.com/

i

Contents

General Information .......................................................................................................................................................1

Warnings and Cautionary Statements.......................................................................................................................1

Certification ...............................................................................................................................................................2

Compatibilities...........................................................................................................................................................3

Operational Roles......................................................................................................................................................3

Product Information........................................................................................................................................................5

Overview ...................................................................................................................................................................5

Key Features.............................................................................................................................................................5

Versatility...............................................................................................................................................................5

Variable output.................................................................................................................................................5

Durability ...............................................................................................................................................................5

Extensive runtime ............................................................................................................................................5

Portability...............................................................................................................................................................6

Connected safety ..................................................................................................................................................6

Specifications............................................................................................................................................................7

Hardware Overview...................................................................................................................................................8

Deployment..................................................................................................................................................................15

Overview .................................................................................................................................................................15

Site considerations..............................................................................................................................................15

Setup supplies.....................................................................................................................................................15

Unpack....................................................................................................................................................................16

Battery Installation...................................................................................................................................................17

Assembly.................................................................................................................................................................17

Operation ................................................................................................................................................................20

Maintaining the SPS battery charge....................................................................................................................20

Redeploy and Storage .................................................................................................................................................23

Overview .................................................................................................................................................................23

Relocation ...............................................................................................................................................................23

Disassembly............................................................................................................................................................24

Battery Removal......................................................................................................................................................26

Storage....................................................................................................................................................................26

Folding and storing the stand ........................................................................................................................26

Additional storage recommendations.............................................................................................................27

Service ....................................................................................................................................................................27

Warranty ......................................................................................................................................................................28

Limitation of Liability................................................................................................................................................28

Appendix......................................................................................................................................................................29

Applicable Certification Standards ..........................................................................................................................29

Contact Information......................................................................................................................................................31

ii

Tables and figures

Table 1.1 Solar Power Supply hazardous location certification .....................................................................................2

Table 1.2 Solar Power Supply compatibilities................................................................................................................3

Figure 2.1 Solar Power Supply and Connected Safety..................................................................................................6

Table 2.1 Solar Power Supply specifications.................................................................................................................7

Table 2.2 Solar Power Supply output parameters..........................................................................................................7

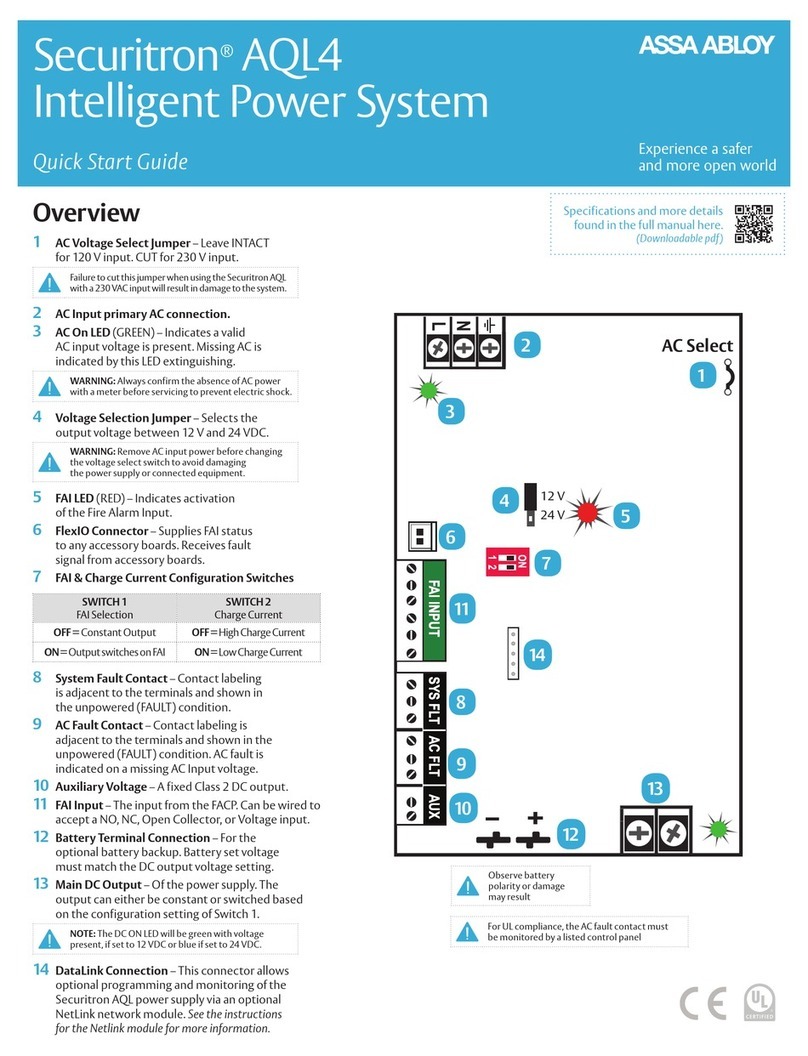

Figure 2.2 SPS Hardware Overview ..............................................................................................................................8

Figure 2.3 Solar Power Supply system diagram..........................................................................................................10

Table 2.3 Solar Power Supply parts list .......................................................................................................................11

Figure 2.4 Insert enclosure diagrams...........................................................................................................................12

Figure 2.5 Enclosure wiring diagram............................................................................................................................13

Table 3.1 SPS standard package contents..................................................................................................................16

Figure 3.1 Installing the Battery ...................................................................................................................................17

Figure 3.2 Assembling the SPS ...................................................................................................................................18

Figure 4.1 Disassembling the SPS ..............................................................................................................................24

Figure 4.2 Removing the SPS battery..........................................................................................................................26

Figure A.1 Supported equipment and connections......................................................................................................30

1

1

General Information

Warnings and Cautionary Statements

Certification

Compatibilities

Operational Roles

Warnings and Cautionary Statements

IMPORTANT: Failure to perform certain procedures or note certain conditions may impair the performance of the

product. To ensure safe and proper operation read and follow the procedures and conditions listed below.

WARNING –EXPLOSION HAZARD. DO NOT OPEN THE ENCLOSURE UNLESS THE AREA IS FREE OF IGNITIBLE

CONCENTRATIONS.

AVERTISSEMENT –RISQUE D'EXPLOSION. NE PAS OUVRIR LE BOÎTIER À MOINS QUE LA ZONE SOIT EXEMPT

DE CONCENTRATIONS IGNITIBLES.

WARNING: When the Solar Power Supply (SPS) is located in a hazardous-classified area NEVER open the SPS

enclosure to install or remove, or to connect or disconnect the SPS battery.

WARNING –EXPLOSION HAZARD. DO NOT REMOVE OR REPLACE FUSE WHEN ENERGIZED.

AVERTISSEMENT –RISQUE D'EXPLOSION. NE PAS ENLEVER OU REMPLACER LE FUSIBLE LORSQU’IL EST

ÉNERGÉTIQUE.

WARNING: Substitution of components may impair intrinsic safety and may cause an unsafe condition.

AVERTISSEMENT: La Substitution de composant peut ameliorer la Securite Intrinsique et peut entraîner un condition

non susception.

IMPORTANT: There are no user serviceable parts contained inside.

IMPORTANT: Always set the SPS power switch to off before connecting or disconnecting the SPS battery.

IMPORTANT: When a compatible Industrial Scientific product powered by the SPS is placed in a hazardous-classified

location, ensure that any unused ports are capped.

IMPORTANT: Read and understand this manual before operating the equipment.

IMPORTANT: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. The instrument complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

This device may not cause harmful interference.

2

This device must accept any interference received, including interference that may cause undesired operation

IMPORTANT: This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2)

l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

IMPORTANT: Refer to Control Drawing 18109634-200 for approved Industrial Scientific accessories for hazardous

location installation parameters.

IMPORTANT: Reportez-vous au dessin de contrôle pour les accessoires scientifiques industriels approuvés pour les

paramètres d'installation de localisation dangereuse.

CAUTION: For safety reasons, this equipment must be operated and serviced by qualified personnel only. Read and

understand the instruction manual completely before operating or servicing.

ATTENTION: Pour des raisons de sécurité, cet équipment doit étre utilesé entretenu et réparé uniquement par un

personnel qualifié. Étudier le manuel d'instructions en entire avant d'utiliser, d'entretenir ou de réparer l'équipement.

If it appears that the SPS or a device powered by the SPS is not working correctly, contact Industrial Scientific.

IMPORTANT: Only clean using a damp cloth.

The Magnet Mount Kit for use with the RGX Gateway and individual kit items can cause injury. To avoid injury, Industrial

Scientific recommends the following.

•Persons with a pacemaker or implantable cardio defibrillator (ICD) should maintain a minimum separation distance

of 90 cm (36 ″) between the pacemaker or ICD and the magnet. Please consult your physician or pacemaker or ICD

manufacturer for additional guidance and recommendations.

•Neodymium magnets have a strong attractive force. Each can attract quickly when in close proximity to another

magnet or metal surface and cause injury. The magnet material is brittle; it can crack or splinter on impact to cause

injury and potentially become a flying hazard. Use protective gloves and eyewear to avoid a potentially severe pinch

injury, cut, or splinter.

•Keep magnets away from electronic devices, identification cards, and credit cards that use microchips, magnets, or

magnetic fields.

Fully charge the batteries of compatible Industrial Scientific products before the first use of such products with the SPS.

Certification

Table 1.1 Solar Power Supply hazardous location certification

Certifying Body

Classificationa

Approved temperature range

cCSAusa

Class I, Division 2, Groups A, B, C, and D; T4 (with

IS output for Division 1).

-20 °C to +45 °C (-4 °F to +113 °F)

aTo determine the hazardous-classified areas for which a unit is certified, refer to its label.

3

Compatibilities

The Solar Power Supply (SPS) is compatible with the Industrial Scientific products and resources listed

below. Refer to each product manual for safety and usage guidelines and other related information.

Table 1.2 Solar Power Supply compatibilities

Industrial Scientific products

Related resources

Part number

Radius®BZ1 Area Monitor

Radius BZ1 Area Monitor Product Manual

17155915

Standard 1.52 m (5 ') Intrinsically safe (IS) cable

17159898

Extended length 50 m (54 yd) IS cable

17156261

RGX®Gateway

RGX Gateway Product Manual

17158071

Standard 0.61 m (2 ') IS cable

17159904

Extended length 35 m (38 yd) IS cable

17159948

The SPS can support one Radius BZ1 or RGX Gateway or any one of the following combinations:

•one Radius BZ1 and one RGX Gateway simultaneously

•two Radius BZ1 instruments simultaneously

•two RGX Gateway units simultaneously

The SPS insert assembly supports the mounting of one compatible device of each type. When two

compatible devices of the same type are supported, one can be mounted on the SPS and one can be

placed elsewhere. While two RGX units powered by a single SPS may be an unlikely combination, this

configuration is fully supported and serves a specific application, e.g. supporting two separate, but adjacent

LENS networks in a remote location that lacks other power sources.

Important: The SPS was designed for use with these compatible products from Industrial Scientific, do not

attempt to power other products using the SPS.

Operational Roles

To ensure the safe operation of the Solar Power Supply and compatible devices from Industrial Scientific,

this manual recognizes the following roles related to operating the equipment.

SPS operators include onsite personnel or users of the SPS who can operate, relocate, and partially

disassemble the SPS for relocation or storage. Operators should never need to open the enclosure.

The safety team consists of qualified onsite personnel who can set up the SPS including installation and

removal of the battery and connecting and disconnecting the battery within the enclosure in nonhazardous

locations only. Safety team members can also operate the equipment.

Service technicians are qualified personnel at an authorized Industrial Scientific service center who perform

service and repair procedures on the SPS or compatible products beyond those authorized for operators or

the safety team.

2

Product Information

Overview

Key Features

Specifications

Hardware Overview

Overview

The Solar Power Supply (SPS) is a stand-alone power supply that uses solar input to generate power for

the operation of compatible Industrial Scientific products. The SPS can operate in specific hazardous-

classified areas for which it is certified, supports applications such as fence lines, pipelines, and tank farms,

and can be used in locations where electrical power sources are limited or nonexistent. The SPS is

portable, easy to setup, and disassemble and is suitable for applications that require its ready relocation.

Key Features

Versatility

The SPS enables compatible products from Industrial Scientific to operate in areas lacking electrical power

or where these resources are limited. The SPS supports different compatible device configurations based

on a customer’s portable power needs. The stand’s telescoping legs and adjustable feet allow deployment

of the SPS across a variety of terrain types including uneven surfaces, hard surfaces, soil, and sand.

Variable output

Both SPS output connections can safely support either the Radius®BZ1 or RGX®Gateway. Each product

will function properly regardless of which connection is used.

Durability

The SPS can tolerate extreme environmental conditions and remain operational. It can withstand exposure

to fungus and salt fog (up to 96 hours of salt fog). Unanchored, the SPS can withstand up to 60 mph side or

headwinds.

Extensive runtime

Compatible Industrial Scientific products can run indefinitely when powered by the SPS as long as its

battery remains charged. Industrial Scientific recommends a daily minimum of four (4) hours of direct

sunlight to maintain the battery’s level of charge.

6

Portability

The modular design of the Solar Power Supply (SPS) enables its rapid disassembly for repositioning,

storage, or redeployment in another location. Once the SPS is unpacked and assembled, operators can

reposition or move the unit a short distance, as needed. The solar panel can be reoriented (360° rotation)

to improve solar exposure.

Connected safety

The SPS supports the Industrial Scientific connected safety system by enabling compatible connected

safety equipment items to operate in locations where electrical power sources are limited or nonexistent.

Figure 2.1 Solar Power Supply and Connected Safety

Deployment scenario 1: SPS + Radius BZ1 + RGX Gateway

Deployment scenario 2: SPS + two Radius BZ1 units

Deployment scenario 3: SPS + two RGX Gateway units

LENS group A

LENS group B

Support area monitoring of tank

farms, fence lines, and pipelines.

Deploy your connected safety

instruments wherever needed.

Support two adjacent, but separate,

LENS groups at a remote location.

Each RGX Gateway can support up

to 25 connected safety instruments.

Mount your compatible

connected safety equipment

items on the SPS itself.

Or deploy connected safety

devices at a distance using

longer IS cables available from

Industrial Scientific.

7

Specifications

The data supplied in tables 2.1 and 2.2 and figure 2.2 are provided to support the successful setup and

operation of the Solar Power Supply (SPS).

Table 2.1 Solar Power Supply specifications

Item

Description

Size (height x width x depth)

Approximately 0.84 x1.22 x 1.07 m (33 x 48 x 42 ″) when packaged, prior to assembly.

Weight

63.27 kg (139.48 lb)a

Materials

Aluminum stand and bracket assembly with stainless steel enclosure.

Performance

Ingress protection

NEMA 4X (enclosure) for outdoor usage

Power cables

Input (1)

Cable from solar panel to enclosure.

Outputs (2)

Intrinsically safe (IS) cables supplying DC power from enclosure to compatible devices.

Buttons or switches

One (power on and off)

Indicators

None –A compatible product will indicate that it is receiving power from the SPS.

Operating conditions

Ambient temperature

-20 °C to +45 °C (-4 °F to +113 °F)

EMC

Meets requirements for Electromagnetic Compatibility (EMC) for Class A equipment and

meets EMC requirements while connected as a system to a Radius BZ1 instrument.

Humidity

20-90% relative humidity (RH) noncondensing

Storagebtemperature

-40 °C to +75 °C (-40 °F to +167 °F)

aFor ease of handling, no subassembly (solar panel assembly, stand, battery, insert assembly, etc.) weighs more than 27.21 kg (60 lb).

Table 2.2 Solar Power Supply output parameters

Item

Value range

Output a parameters

Uo

14.7 VDC

Io

300 mA

Cob

0.58 pF

L0b

0.32 mH

Notes:

aFor corresponding input parameters, see the product manual for each compatible Industrial Scientific product.

bWhen added together, the Li and Ci entity parameters of the Industrial Scientific Solar Power Supply plus the total from the IS Cable

must not exceed the power supply entity parameters for L0 and Co. Refer to control drawing 17159827-350 referenced in Figure 2.6.

The SPS output connections provide the appropriate output entity parameter ratings to support the

compatible Industrial Scientific products listed in Table 1.2 Solar Power Supply compatibilities.

8

Hardware Overview

The main components of the SPS are shown below and referred to throughout this manual.

Figure 2.2 SPS Hardware Overview

Solar panel

Solar panel cable

Solar assembly

Solar panel mount

Adjusting knob (x 2)

Legs (x 4)

Stand top

Intrinsically safe (IS)

cable (Radius)

Stand assembly

Enclosure

Insert shelf

Insert peg & leg

pocket (x 4)

Insert assembly

IS cable (RGX)

Foot (x4)

(Right side view; shown with Radius BZ1 and RGX Gateway)

9

Figure 2.2 SPS Hardware Overview

Insert shelf

(Rear view, insert assembly; shown with RGX Gateway)

Cable pass through

IS cable port (x 2)

IS cable

Solar panel cable port

Power switch

IS port caps (x 2)

IS cable

Solar converter

(Close-up view, inside enclosure)

Fuse

IS barrier

Positive terminal

Negative terminal

Battery

Enclosure

fasteners (x 4)

Note: There are no user serviceable parts inside the enclosure; all components for Industrial Scientific use only.

10

Figure 2.3 Solar Power Supply system diagram

11

Table 2.3 Solar Power Supply parts list

Item

SPS component

Qty

Orderable

P/N

Description

1

50 W solar panel

1

17159602

Photovoltaic module, 83.56 x 53.59 x 5 cm (32.9 x 21.1 x 2 ″),

harvests sunlight for conversion to DC electrical power.

2

2 ″Solar panel mount

1

—

Connects solar panel to stand, allows 360° rotation of panel.

3

Adjusting knob

2

17159897

Secures solar panel mount to stand, hand tighten.

4

Stand assembly

1

—

—

5

Leg unit

4

17159607

Adjustable length with a pocket to hold an insert assembly peg.

—

Upper leg

4

17159604

Upper portion of leg, bolted to top of stand.

—

Lower leg

4

17159925

Lower, telescoping section of leg, attached to foot.

6

Adjustable foot

4

17159926

Flat or pointed configuration, toolless adjustment.

7

Pin with clip

4

17159933

Sets length of adjustable, telescoping legs on stand.

8

Insert assembly

1

—

Support structure that holds Radius BZ1, RGX, and enclosure.

9

Radius clamp

2

17159890

Corner clamp, hand tightened with screw knob to secure Radius.

10

IS power cablea

1

17159904

Supplies DC power for RGX Gateway, 0.61 m (2 ') shown.

11

IS power cablea

1

17159898

Supplies DC power for Radius BZ1, 1.52 m (5 ') shown.

12

Solar panel cable

1

17159911

Connects solar panel to enclosure, 3.70 m (12 ').

13

Enclosure, stainless steel

1

17159606

Enclosure with door; 50.80 x 40.64 x 15.24 cm (20 x 16 x 6 ″};

Prewired and mounted to insert assembly at factory.

14

Hex nut (7/16 ″)

2

17159934

Secures battery holder inside enclosure.

15

Battery holder

1

—

Bracket that secures SPS battery within the enclosure.

16

Battery, 12 volt

1

17159850

55 amp hour, sealed, lead-acid battery charged by solar panel.

17

IS barrier

1

—

IS buffer prevents incoming or outgoing current overload.

18

Solar converter

1

—

Converts harvested solar input into usable DC output.

19

Fuse

1

—

Provides overcurrent protection of the electrical circuits.

20

IS cable ports

2

—

IS connection - supplies DC power from battery.

21

IS cable port caps

2

17159532

Plastic caps with built-in tethers for output ports.

22

Solar panel cable port

1

—

Input connection from solar panel to enclosure.

23

Solar cable port cap

1

17159842

Tethered metal cap for solar panel cable port.

24

Power switch

1

—

Controls flow of power from battery to Radius and RGX units.

—

Magnet mount kit for RGXb

1

18109564

Attaches to the back of the RGX to allow mounting on the SPS.

—

J-hook Stakesb

4

17159992

Anchors the SPS feet to the ground, 30.48 x 1.59 cm (12 x 5/8 ″).

Notes:

aThe following cables are also compatible with the SPS: Part number 17156261 –50 m (54 yd) IS cable for Radius BZ1 and part number

17159948 –35 m (38 yd) IS cable for RGX Gateway.

bThese items are included with every SPS but not depicted in figures 2.3, 2.4, or 2.5.

12

Figure 2.4 Insert enclosure diagrams

3-D diagram of Insert enclosure internal components

Insert enclosure (back) with connection details

13

Figure 2.5 Enclosure wiring diagram

Wiring

Key

Positive (non-ground)

Negative (non-ground)

Ground

3

Deployment

Overview

Unpack

Battery Installation

Assembly

Operation

Overview

The Solar Power Supply (SPS) is designed for ease of setup including unpacking, assembly, deployment,

and the mounting of compatible Industrial Scientific products. Set up should be completed by a member of

the safety team, all other deployment steps can be completed by an operator.

Site considerations

Prior to unpacking and assembling the SPS, give careful consideration to site selection. Ensure that the site

selected for deployment achieves the following:

•Supports the assembly and connection instructions provided below in Figure 3.2.

•Meets all Specifications such as operating temperature and relative humidity.

•Allows the SPS solar panel to be properly oriented to harvest available solar energy.

•Location, terrain, and ground surface considerations:

oPlace the SPS in an open, outdoor location with abundant sunshine.

oAvoid natural or man-made obstacles (e.g. trees or nearby buildings) that might block access to

sunlight for a significant portion of the day.

oAvoid flood plains or areas subject to frequent flooding to reduce the risk of exposing the SPS

internal electrical components to water.

oOn uneven terrain, the length of the telescoping legs can be adjusted to level the stand.

oThe configuration of the stand feet (flat or pointed) can be changed for different site surfaces (hard

surface, soil, sand, etc.). The pointed feet can also be planted in certain surface types.

oThe legs of the SPS stand can also be anchored to the ground with the included j-hook stakes.

Setup supplies

For unpacking and assembly

•Utility knife

•Compass or compass app on smartphone

•Level (optional)

•Mallet for driving stakes (optional)

For battery installation or removal

•Flathead screwdriver

•Adjustable wrench

•Socket set with 6 ″ extension

16

Unpack

The Solar Power Supply (SPS) is shipped partially assembled in two corrugated cardboard boxes strapped

to a 1.22 m x 1.07 m (48 ″x 42 ″) fiber pallet. The total height of the assembled pallet and boxes is 0.84 m

(33 ″). The combined weight of the pallet and both boxes is 81 kg (178.5 lb). For transportation, the pallet

will fit into the back of most pickup trucks or the boxes can be removed from the pallet.

Box one is labelled “Legs”: This box contains only the four stand legs bolted to the stand top. Box two,

labelled “All other equipment”, contains the remaining standard components: the solar assembly (panel,

mount, and cable), insert assembly with enclosure, battery, and a set of four J-hook stakes.

Every SPS will ship with the standard IS cables for the Radius BZ1 and RGX Gateway and the Magnetic

mount kit for the RGX. Additional items, including Radius BZ1, RGX Gateway, and extended length IS

cables can be ordered separately.

Each item below should be accounted for during the unpacking process. Industrial Scientific recommends

unpacking the shipping boxes prior to onsite assembly. If any item is missing or appears damaged, contact

Industrial Scientific (see back cover) or an authorized distributor of Industrial Scientific products.

Table 3.1 SPS standard package contents

Quantity

Item

Description

1

Stand assembly

Stand top

4 telescoping legs

Flat, square, top plate with connector for solar panel mount, sockets for legs.

Adjustable aluminum legs, each bolted to stand top, terminating in a foot.

1

Insert assembly

Bracket assembly

Enclosure

Aluminum bracket structure with shelf for Radius, steel discs to mount RGX.

Stainless steel enclosure with door; contains all wiring, electronics and battery.

1

Solar panel assembly

Solar panel

Harvests sunlight to charge the SPS battery.

Solar panel mount

Connects solar panel to stand and permits 360° rotation of panel.

Solar panel cable

3.66 m (12 ') cable providing solar panel input to enclosure.

1

Battery

Sealed, lead acid battery charged by solar panel.

4

J-hook stakes

Steel stakes used for anchoring SPS feet to the ground.

1

Setup Guide

Solar Power Supply Set-up / Quick Guide

Other manuals for Solar Power Supply

1

This manual suits for next models

1

Table of contents