Industrial Shields M-DUINO PLUS series User manual

Ref. IS.MDUINO.XXX

M-DUINO PLUS FAMILY

M-Duino PLUS Family User Guide:

Ref. IS.MDUINO.XXX

Ref. IS.MDUINO.XXX

Ethernet PLC User Guide

Revised March 2018

Ref. IS.MDUINO.XXX

Preface

This User Guide is been implemented by Boot & Work, S.L. working

under the name Industrial Shields.

Purpose of the manual

The information contained in this manual can be used as a reference to operating, to

functions, and to the technical data of the signal modules, power supply modules and

interface modules.

Intended Audience

This User Guide is intended for the following audience:

Persons in charge of introducing automation devices.

Persons who design automation systems.

Persons who install or connect automation devices.

Persons who manage working automation installation.

Warnings:

Unused pins should not be connected. Ignoring the directive may damage the

controller.

Improper use of this product may severely damage the controller.

Refer to the controller’s User Guide regarding wiring considerations.

Before using this product, it is the responsibility of the user to read the product’s User

Guide and all accompanying documentation.

Ref. IS.MDUINO.XXX

Application Considerations and Warranty

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your

comments or questions to Industrial Shields before using the product.

Application Consideration

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED.

THEY SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR

PROTECTIVE DEVICE FOR ENSURING SAFETY OF PERSONS, AS THEY ARE

NOT RATED OR DESSIGNED FOR SUCH PURPOSES.

Please know and observe all prohibitions of use applicable to the products.

FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESSIGNED

TO ADDRESS THE RISKS, NEVER USE THE INDUSTRIAL SHIELDS PRODUCTS.

NEVER USE THE INDUSTRIAL SHIELDS PRODUCTS BEFORE THEY ARE

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Industrial Shields shall not be responsible for conformity with any codes, regulations or

standards that apply to the combination of products in the customer’s application or use

of the product.

The following are some examples of applications for which particular attention must be

given. This is not intended to be an exhaustive list of all possible uses of the products,

nor is it intended to imply that the uses may be suitable for the products:

Systems, machines, and equipment that could present a risk to life or property.

Nuclear energy control systems, combustion systems, railroad systems,

aviation systems, medical equipment, amusement machines, vehicles, safety

equipment, and installation subject to separate industry or government

regulations.

Outdoor use, uses involving potential chemical contamination or electrical

interference, or conditions or uses not described in this document.

At the customer’s request, INDUSTRIAL SHIELDS will provide applicable third party

certification documents identifying ratings and limitations of use that apply to the

products. This information by itself is not sufficient for a complete determination of the

suitability of the products in combination with the system, machine, end product, or

other application or use.

Ref. IS.MDUINO.XXX

Disclaimers

Weights and Dimensions

Dimensions and weights are nominal and they are not used for manufacturing

purposes, even when tolerances are shown.

Performance Data

The performance data given in this manual is provided as a guide for the user in

determining suitability and does not constitute a warranty. It may represent the result of

INDUSTRIAL SHIELDS’s test conditions, and the users most correlate it to actual

application requirements. Actual performance is subject to the INDUSTRIAL SHIELDS

Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on

improvements and other reasons.

It is our practice to change model numbers when features are changed, or published

ratings or when significant construction changes are made. However, some

specifications of the products may be changed without any notice. When in doubt,

special numbers may be assigned to fix or stablish key specifications for your

application on your request. Please consult with your INDUSTRIAL SHIELDS

representative at any time to confirm actual specifications of purchased products.

Errors and Omissions

The information in this document has been carefully checked and is believed to be

accurate; however, no responsibility is assumed for clerical, typographical, or

proofreading errors, or omissions.

Ref. IS.MDUINO.XXX

Warranty and Limitations of Liability

Warranty

Industrial Shields’s exclusive warranty is that the products are free from defects in

materials and workmanship for a period of one year (or other period if specified) from

date of sale by Industrial Shields.

INDUSTRIAL SHIELDS MAKES NO REPRESENTATION OR WARRANTY,

EXPRESSED OR IMPLIED, REGARDING MERCHANABILITY, NON-

INFRINGEMENT, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE

HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE

REQUIREMENTS OF THEIR INTENDED USE. INDUSTRIAL SHIELDS DISCLAIMS

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED

Limitations of Liability

INDUSTRIAL SHIELDS SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT,

OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

IN NO EVENT SHALL INDUSTRIAL SHIELDS BE RESPONISBLE FOR WARRANTY,

REPAIR OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS INDUSTRIAL

SHIELDS’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY

HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPIATE MODIFICATION OR

REPAIR.

Ref. IS.MDUINO.XXX

Table of Contents

General Description M-DUINO FAMILY product.......................................................10

1.1 Zone - Nomenclature ...................................................................................................... 10

1.2 Zone Distribution............................................................................................................. 10

1.3 A Zone Features............................................................................................................... 12

1.4 Mechanical dimension .................................................................................................... 13

1.5 General Features............................................................................................................. 14

Technical Specifications: ...........................................................................................15

2.1 General Specifications:.................................................................................................... 15

2.2 Performance Specification:............................................................................................. 15

Precautions................................................................................................................ 16

3.1 Arduino Board ................................................................................................................. 16

3.2 Intended Audience.......................................................................................................... 16

3.3 General Precautions........................................................................................................ 16

Software interface..................................................................................................... 16

How to connect PLC Arduino to PC........................................................................... 19

How to connect PLC to power supply .......................................................................20

M-duino Family Pinout.............................................................................................. 21

7.1 A Zone connection .......................................................................................................... 21

7.2 B Zone.............................................................................................................................. 23

7.2.1 Analog Shield....................................................................................................... 23

7.2.2 Relay Shield ......................................................................................................... 24

7.3 C Zone.............................................................................................................................. 25

7.3.1 Analog Shield (C Zone) ........................................................................................ 25

7.3.2 Relay Shield C Zone ............................................................................................. 26

7.4 D Zone ............................................................................................................................. 27

7.4.1 Analog Shield (D Zone) ........................................................................................ 27

7.4.2 Relay Shield D Zone............................................................................................. 28

Switch Configuration.................................................................................................29

8.1 A Zone: Communications ................................................................................................ 29

8.2 Analog Shield................................................................................................................... 31

Ref. IS.MDUINO.XXX

8.3 Relay Shield ..................................................................................................................... 31

M-Duino Arduino I/Os 5V pins .................................................................................32

9.1 I2C pins –SDA/SCL .......................................................................................................... 32

9.2 Serial 0 –RX0/TX0 ........................................................................................................... 33

9.3 Serial 1 –RX1/TX1 ........................................................................................................... 33

9.4 SPI –MISO/MOSI/SCK ..................................................................................................... 33

9.5 Pin 2/Pin 3 ....................................................................................................................... 34

A Zone Features: Communications & RTC & uSD..................................................34

10.1 RS-232 ............................................................................................................................. 34

10.2 RS-485 ............................................................................................................................. 34

10.3 I2C.................................................................................................................................... 35

10.4 SPI.................................................................................................................................... 35

10.5 TTL ................................................................................................................................... 36

10.6 Ethernet........................................................................................................................... 36

10.7 RTC................................................................................................................................... 36

10.8 uSD .................................................................................................................................. 37

I/O technical details: .............................................................................................38

Typical Connections .............................................................................................. 40

........................................................................................................................................... 40

Connector details: .................................................................................................44

Mechanical Characteristics ................................................................................... 45

Ref. IS.MDUINO.XXX

General Description M-DUINO FAMILY product

1.1 Zone - Nomenclature

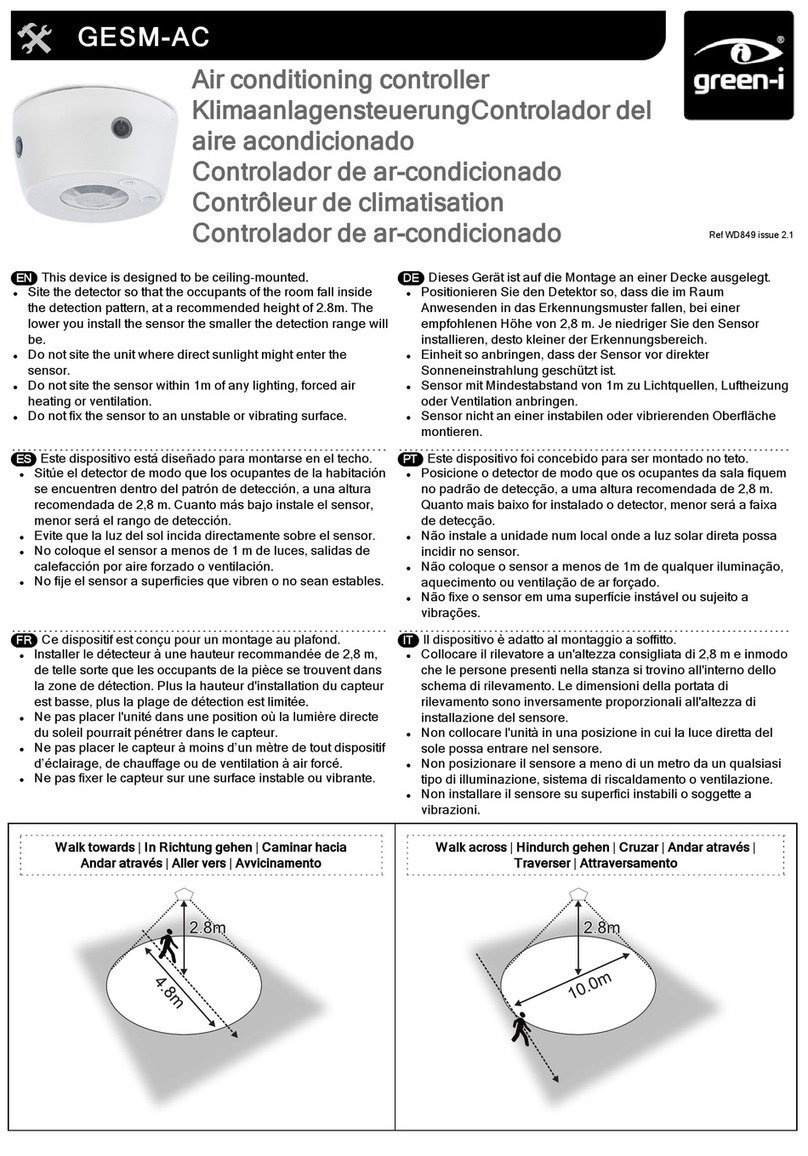

The nomenclature shown in this point will be used in the whole User Guide, so it is

important to understand this nomenclature.

The nomenclature to differentiate the zones is based on the Alphabet, being A the

shield from below and D the shield from above. Having a B and a C in the middle of

them. It can have a minimum of 2 zones (A, B) and a maximum of 4 (A, B, C, D). The

nomenclature is represented on the picture below:

The inputs in the zone B are named I0.X, being X any number suitable in the

Shield. Outputs are named as Q0.X and relays as R0.X

The inputs in the zone C are named I1.X, being X any number suitable in the

Shield. Outputs are named as Q1.X and relays as R1.X

The inputs in the zone D are named I2.X, being X any number suitable in the

Shield. Outputs are named as Q2.X and relays as R2.X

1.2 Zone Distribution

A zone is completely common for every single M-Duino Family PLC. The rest of zones

can have two different shields. The two shields that can be in every Zone (except for A

Zone) are the Analog Shield or the Relay Shield. Only 1 Shield is allowed per Zone.

Depending on the combination that is made to build the PLC it can provide more

Analog Inputs/Outputs or Relays Outputs. All the zones (B, C, D) can be one of the two

Shields:

A ZONE

B ZONE

C ZONE

D ZONE

D ZONE

C ZONE

B ZONE

A ZONE

D ZONE

C ZONE

B ZONE

A ZONE

Ref. IS.MDUINO.XXX

The distribution of the different features that provide the M-Duino Family is the

following one:

Shield

B Zone

C Zone

D Zone

Analog Shield

13 Inputs

(13 Digital inputs,

6 of which can

work as Analog

Input)

8 Outputs

(8 Digital Outputs,

3 of which can

work as Analog

Output)

13 Inputs

(13 Digital inputs,

6 of which can

work as Analog

Input)

8 Outputs

(8 Digital Outputs,

3 of which can

work as Analog

Output)

11 Inputs

(11 Digital Inputs,

4 of which can

work as Analog

Input)

6 Outputs

(6 Digital Outputs,

2 of which can

work as Analog

Outputs

Relay Shield

6 Inputs

(6 Digital Inputs,

4 of which can

work as Analog

Input)

11 Outputs

(8 Relay Outputs,

3 Digital Outputs,

3 of which can

work as Analog

Output)

6 Inputs

(6 Digital Inputs,

4 of which can

work as Analog

Input)

11 Outputs

(8 Relay Outputs,

3 Digital Outputs,

3 of which can

work as Analog

Output)

6 Inputs

(6 Digital Inputs,

4 of which can

work as Analog

Input)

9 Outputs

(7 Relay Outputs,

2 Digital Outputs,

2 of which can

work as Analog

Output)

Ref. IS.MDUINO.XXX

1.3 A Zone Features

Shield

A Zone

Communication

Shield

(1x) Ethernet

(1x) USB

(1x) I2C

(3x) TTL

(1x) RS-232

(1x) HALF/FULL Duplex RS-485

(1x) SPI external Port

(1x) RTC

(1x) uSD Socket

This is the list of our products depending on the combination of the shields. As it is

already said above the A Zone is totally common for all the M-Duino Family.

The nomenclature of the M-Duino Family products consists on placing the name of the

Shield/s after the total number of I/Os of the product.

For example M-Duino53ARR+ is a PLC with the 3 extra Zones (B, C, D), which are

Analog, Relay, Relay respectively. It has 53 I/Os.

M-Duino

B Zone

C Zone

D Zone

M-Duino53ARR+

A

R

R

* There are 2 different exceptions. M-Duino38R+/M-Duino57R+ should be called with this nomenclature M-

Duino38RR+/M-Duino57RRR+, as everything is Relay it is omitted. Also for the M-duino21+/42+/58+ as

they are all Analog they are not represented with this nomenclature. With the nomenclature represented in

the User Guide they would be: M-Duino21A+/M-Duino42AA+/M-Duino58AAA+

M-Duino

B Zone

C Zone

D Zone

Analog

Relay

Analog

Relay

Analog

Relay

M-Duino 19R+

X

M-Duino 21+

X

M-Duino 38R+

X

X

M-Duino 38AR+

X

X

M-Duino 42+

X

X

M-Duino 50RRA+

X

X

X

M-Duino 53ARR+

X

X

X

M-Duino 53ARA+

X

X

X

M-Duino 57AAR+

X

X

X

M-Duino 57R+

X

X

X

M-Duino 58+

X

X

X

Ref. IS.MDUINO.XXX

1.4 Mechanical dimension

M-Duino 1 BLOCK I/Os

M-Duino 2 BLOCKS

I/Os

M-Duino 3 BLOCKS

I/Os

Ref. IS.MDUINO.XXX

1.5 General Features

CONECTABLE PLC ARDUINO 24Vcc M-DUINO

MODEL TYPE

B Zone

B+C Zone

B+C+D

Zone

Input Voltage

12 to 24Vdc

Fuse protection (2.5A)

Polarity protection

I max.

1.5A

Size

101x119.5x70.1

101x119.5x94.7

101x119.5x119.3

Clock Speed

16MHz

Flash Memory

256KB of which 8KB used by bootloader

SRAM

8KB

EEPROM

4KB

Communications

I2C –Ethernet Port –USB –RS485 –RS232 -- SPI

–(2x) Rx, Tx (Arduino pins)

Max232-Max485-

W5500

USB consideration!

Only meant for uploading or debugging, not

always connected as a serial in a project!

Cannot be working in

a final application

An/Dig Input 10bit

(0-10Vcc)

0 to 10V

Input Impedance: 39K

Separated PCB ground

Digital Isolated Input

(24Vcc)

7 to 24Vdc

I min: 2 to 12 mA

Galvanic Isolation

* Interrupt isolated

Input HS (24Vcc)

7 to 24Vdc

I min: 2 to 12 mA

Galvanic Isolation

Analog Output 8bit

(0-10Vcc)

0 to 10Vdc

I max: 20 mA

Separated PCB ground

Digital Isolated

Output (24Vcc)

5 to 24Vdc

I max: 70 mA

Galvanic Isolation

Diode Protected for Relay

Imax 24Vdc: 410 mA

Digital Isolated

Output Relay

220V Vac

I max: 5A

Galvanic Isolation

Diode protected for Relay

PWM Isolated Output

8bit (24Vcc)

5 to 24Vdc

I max: 70 mA

Galvanic Isolation

Diode Protected for Relay

Relay Output

I max: 5A

V max: 24VDC / 230VAC

Expandability

I2C - 127 elements - Serial Port RS232/RS485

* By using this type of signal can no longer use Digital signal

(24Vdc)

Ref. IS.MDUINO.XXX

Technical Specifications:

2.1 General Specifications:

Item

M-DUINO B ZONE

M-DUINO B+C ZONE

M-DUINO B+C+D ZONE

Power supply

voltage

DC power supply

12 to 24Vdc

Operating

voltage range

DC power supply

11.4 to 25.4Vdc

Power

consumption

DC power supply

30VAC max.

External

power supply

Power supply

voltage

24Vdc

Power supply

output capacity

700Ma

Insulation resistance

20MΩ min.at 500Vdc between the AC terminals and the protective earth terminal.

Dielectric strength

2.300 VAC at 50/60 Hz for one minute with a leakage current of 10mA max. Between all

the external AC terminals and the protective ground terminal.

Shock resistance

80m/s2in the X, Y and Z direction 2 times each.

Ambient temperature (operating)

0º to 45ºC

Ambient humidity (operating)

10% to 90% (no condensation)

Ambient environment (operating)

With no corrosive gas

Ambient temperature (storage)

-20º to 60ºC

Power supply holding time

2ms min.

Weight

445g max.

542g max.

850g max.

2.2 Performance Specification:

Arduino Board

ARDUINO MEGA 2560

Control method

Stored program method

I/O control method

Combination of the cyclic scan and immediate refresh processing methods.

Programming language

Arduino IDE. Based on wiring (Wiring is an Open Source electronics platform composed of a

programming language. “similar to the C”. http://arduino.cc/en/Tutorial/HomePage

Microcontroller

ATmega2560

Flash Memory

256KB of which 8KB are used by the bootloader

Program capacity (SRAM)

8KB

EEPROM

4KB

Clock Speed

16MHz

Clock Speed

16MHz

Ref. IS.MDUINO.XXX

Precautions

Read this manual before attempting to use the M-Duino PLC and follow its descriptions for

reference during operation.

3.1 Arduino Board

All M-Duino family PLCs include Arduino Mega Board as controller.

3.2 Intended Audience

This manual is intended for technicians, which must have knowledge on electrical systems.

3.3 General Precautions

The user must operate M-Duino according to the performance specifications described in this

manual.

Before using M-Duino under different conditions from what has been specified in this manual

or integrating M-Duino to nuclear control systems, railroad systems, aviation systems, vehicles,

combustion systems, medical equipment, amusement machines, safety equipment and other

systems, machines, and equipment that may have a serious influence on lives and property if

used improperly, consult your INDUSTRIAL SHIELDS representative. Ensure that the rating and

performance characteristics of M-Duino are sufficient for the systems, machines, and

equipment, and be sure to provide the systems, machines, and equipment double safety

mechanisms. This manual provides information for programming and operating the M-Duino.

Software interface

Industrial Shields PLC are programmed using Arduino IDE, which is a software based on the C

language. They can also be programmed using directly C but it is much easier working with

Arduino IDE as it provides lots of libraries that helps in the programming.

Industrial Shields provides boards for programming the PLCs much easier. Basically it is no

needed to define the pins and if that pins are inputs or outputs. Everything is set up

automatically if using the boards.

In order to install Industrial Shields boards, these are the steps that must be followed.

Requirements:

Arduino IDE 1.8.0 or above (better to have always the latest version).

Ref. IS.MDUINO.XXX

Steps:

1. Open Arduino IDE and go to: “File -> Preferences”located in the top left corner.

2. In Additional Boards Manager URLs write the following:

http://apps.industrialshields.com/main/arduino/boards/package_industrialshields_index.json

3. Press OK to save the changes.

4. Go to: Tools -> Board: … -> Boards Manager

Ref. IS.MDUINO.XXX

5. Search for “industrialshields”on the browser.

6. Click install (selecting the latest version).

Following these steps you will be able to see now the Industrial Shields Boards:

Once it is selected the Ardbox Family or M-Duino family an extra option will appear on Tools:

There, it can be selected the exact model for every family.

Ref. IS.MDUINO.XXX

Also there are some examples of programming in File -> Examples -> M-Duino Family.

Furthermore there are some extra libraries that can be found in Industrial Shields github.

https://github.com/IndustrialShields/

How to connect PLC Arduino to PC

-Connect USB port from PLC to PC.

NOTE:

M-Duino Family uses USB-B cable.

-Open Arduino IDE interface:

-Select Industrial Shields boards -> M-Duino Family

Ref. IS.MDUINO.XXX

-Select the correct M-Duino Board.

-Select correct port.

How to connect PLC to power supply

-M-Duino Family PLCs are 12-24Vdc supplied. IMPORTANT: The polarity IS NOT

REVERSAL!

-Make sure that the live and GND connector of the power supply match the PLC.

-Make sure that the power supply mains output is not higher than 24Vdc.

Table of contents

Other Industrial Shields Controllers manuals

Popular Controllers manuals by other brands

FujiFilm

FujiFilm FRONTIER 350 instruction manual

KMS

KMS UEGO CAN manual

NetApp

NetApp FAS2050 Installation and setup

EcoFlow

EcoFlow APP for Smart Home Panel user manual

Stamford

Stamford MX341 Specification, Installation and Adjustments

Specialty Concepts

Specialty Concepts MARK-15 Installation and operation manual