Part No. 4801-5309 rev 1-15 Evolution Back-Up 4 of 17

®

Back-Up

Sta

e

Indicators

Main Display Display Indicator

Control

Buttons

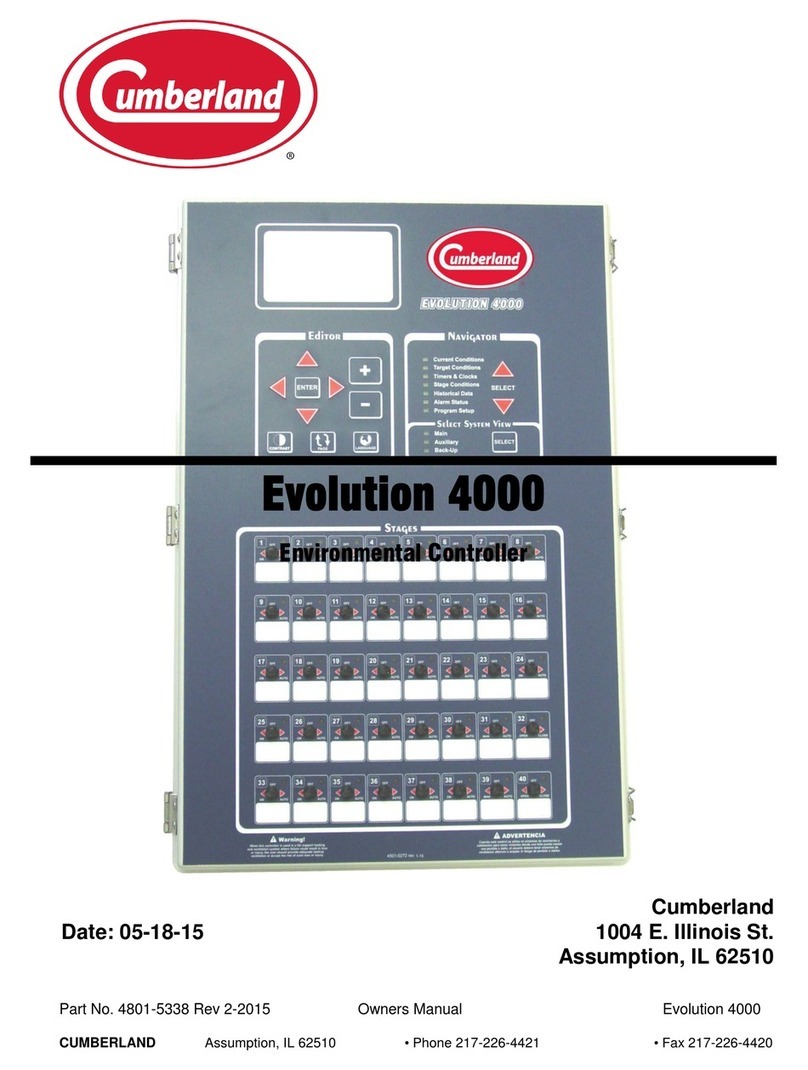

64 68 72 ………. 83 84 85 86 87 88 89

Heat

Cool 3 - Tunnel

Cool 2

Cool 1- Vents

Temperature (ºF)

Graph 1 Cool 1, 2, 3 and Heat

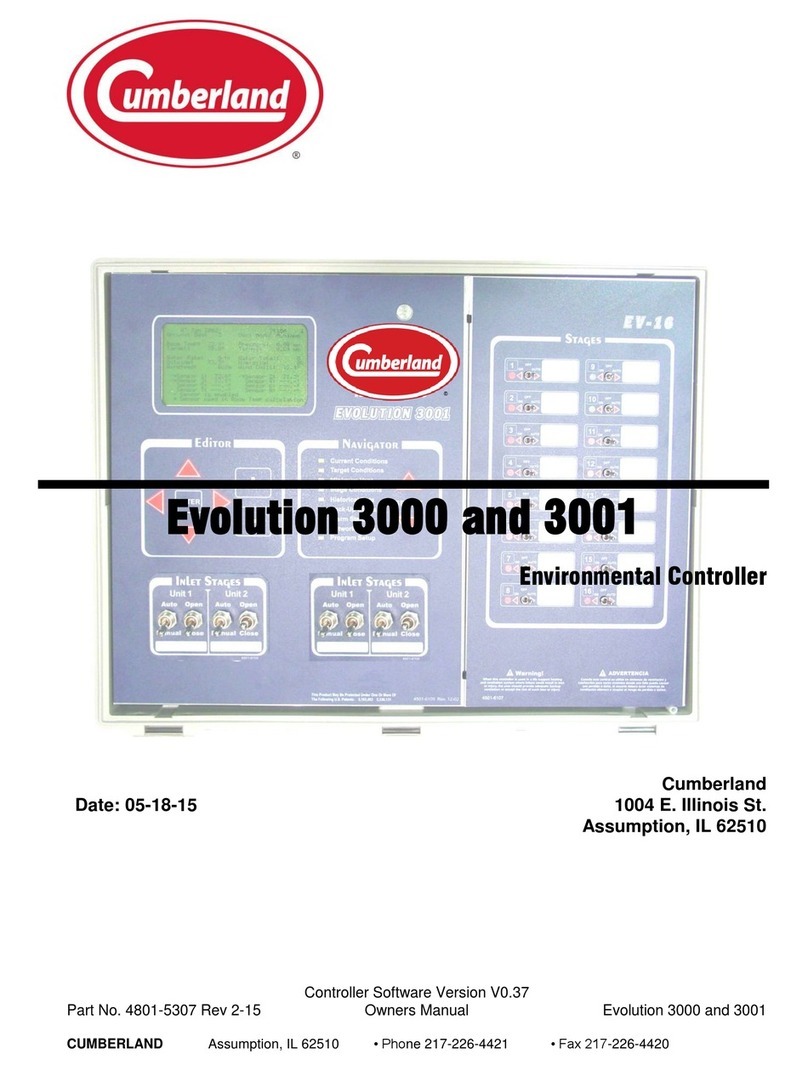

3. Introduction to the Evolution Back-Up System

The Evolution system has the

option of containing an integrated

Back-Up System. This Back-Up

System contains 4 stages: 1 Heat

and 3 Cool. This system’s

purpose is to back up the master

controller in the case of failure.

The Back-Up System is a stand-

alone control system. It contains

its own temperature sensors that

react to a High and Low Limit.

This Back-Up System is unlike

any emergency control system on

the market. This system offers a

much higher level of protection.

In addition to being able to

monitor for high and low

temperatures, it also stays in constant communication with the master controller. This communication

allows the Back-Up System to run a minimum ventilation timer on Cool 1 or override the Evolution panel

if certain conditions warrant. The conditions are explained in Section 4. All Back-Up Systems can protect

against a high or low temperature, but only this system can protect against today’s biggest grower concern:

MINIMUM VENTILATION FAILURE!

4. Evolution Back-Up Operating Conditions

As explained above, this is more than your customary Back-Up System. This system contains three

separate modes of operation that are entered depending on the circumstances. These modes are Normal

Operation, Emergency Operation, and Override Operation. These modes will be explained in more detail

below. These modes are entered based on information that it has received, or not received, from the master

controller. No matter what mode of operation the Back-Up System is in, it will always attempt to maintain

the temperature inside the High and Low Limits.

4.1 Normal Evolution Operation

During Normal Operation, the Back-Up System always maintains the temperature between its high and low

limits. It accomplishes this by using its

temperature sensors and its four stage

outputs. If the temperature drops below

the Low Limit, the Heat stage will come

on. That stage will not turn off until it

warms the building at least 2. The

same is true if the temperature goes

above the High Limit however, there

are three levels of cooling stages on the

Back-Up System. The following

example explains the operation of the

stages in relationship to the temperature

and the limits. In this example the Low

Limit is set as 66º F, and the High Limit

is set as 86º F. If the

temperature drops to 66º F, then the HEAT stage turns on. The HEAT stage turns off when the

temperature rises to 68º F (1º above the Low Limit). If the temperature rises to 86º F, then COOL 1 turns

on. If the temperature continues to rise to 87º F (1º above the High Limit), then COOL 2 turns on. If the

temperature rises to 89º F, then COOL 3 turns on. Stages turn off at temperatures as indicated by the

arrows in Graph 1. It is important to note, if COOL 3 turns ‘ON’, COOL 1 will be disabled to insure that

sidewall fans or vent inlets are not operating while the Back-Up system is in ‘Tunnel Vent’ mode.