tina84e1-a (2019-07) 19

3.2 Power Connection

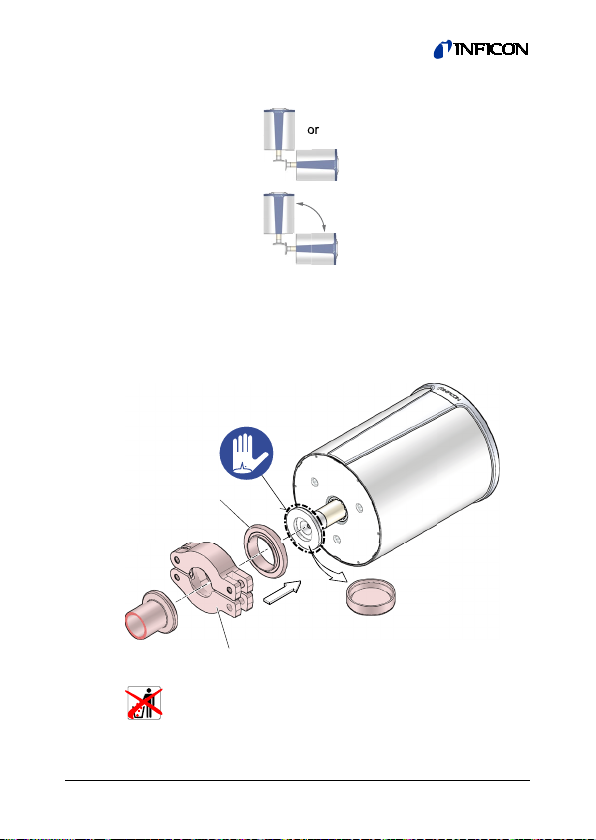

Make sure the vacuum connection is properly made

(→16).

The gauge may only be connected to power sup-

plies, instruments or control devices that conform

to the requirements of a grounded protective extra-

low voltage (PELV) The connection to the gauge

8)

Ground loops, differences of potential, or EMC problems

may affect the measurement signal. For optimum signal

quality, please do observe the following notes:

•Use an overall metal braided shielded cable. The

connector must have a metal case.

•Connect the cable shield to ground at one side via the

connector case. Make sure the connector case has

direct contact to the cable's shield on its whole cir-

cumference. Do not connect the other side of the

shield.

•Connect the supply common with protective ground

directly at the power.

•Use differential measurement input (signal common

and supply common conducted separately).

•Potential difference between supply common and

housing ≤18 V (overvoltage protection).

8) INFICON controllers fulfill this requirement.