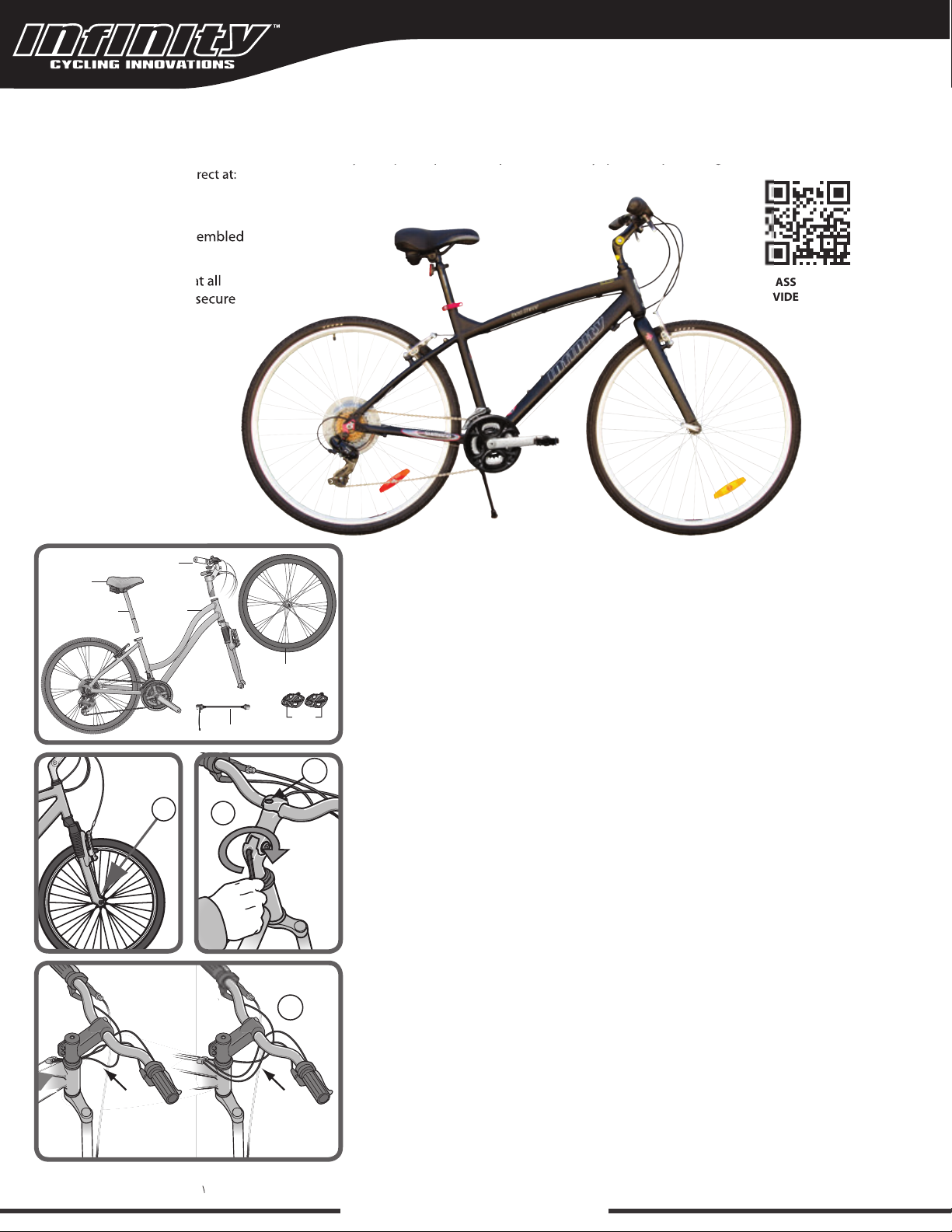

PEDALS AND CRANKS

achment of an incorrect pedal into a crank arm can strip pedal threads and

cause irr

pedals are a

Look for the le

Start each pedal spindle by hand to avoid stripping the threads. (Note that the

ri

(clockwise) thread. The le

hand (counter-clockwise thread). Tighten with a 15mm narrow open ended wrench.

It

before riding your bicycle.

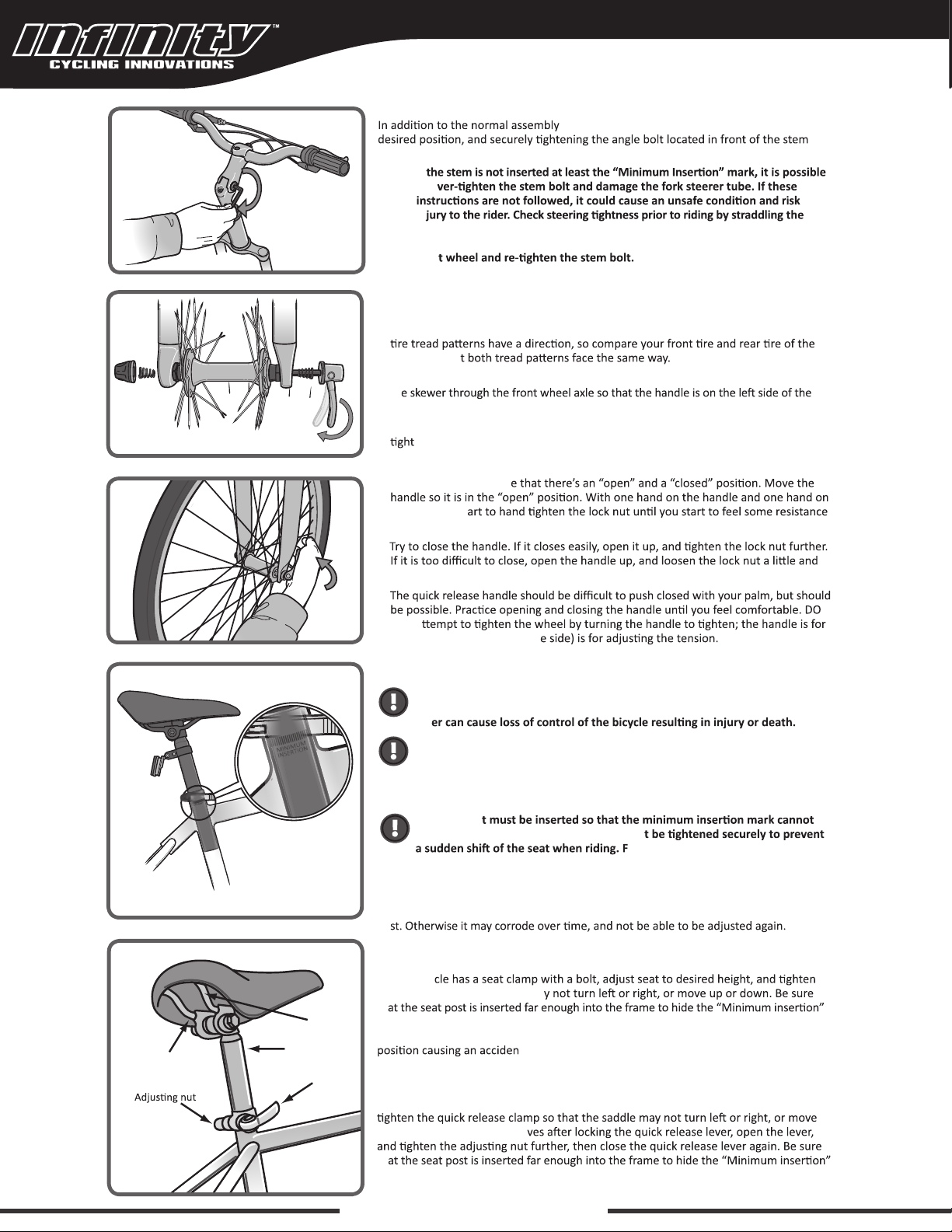

Linear Pull Brakes

If

halves t

brake cable so that the stepped end of the “noodle” can be inserted into the brake

carrier.

Brake adjustment

Check to be sure the cableis seated in the brake lever. Loosen the cableanchor bolt just

enough to allo

brak

t the cable end is seated in the brake lever, and the barrel adjuster

of the brak

squeezing the br

Check the brake pads to be sure they are aligned with the rim, and that they do

not con

sq

the cable ma

steps.

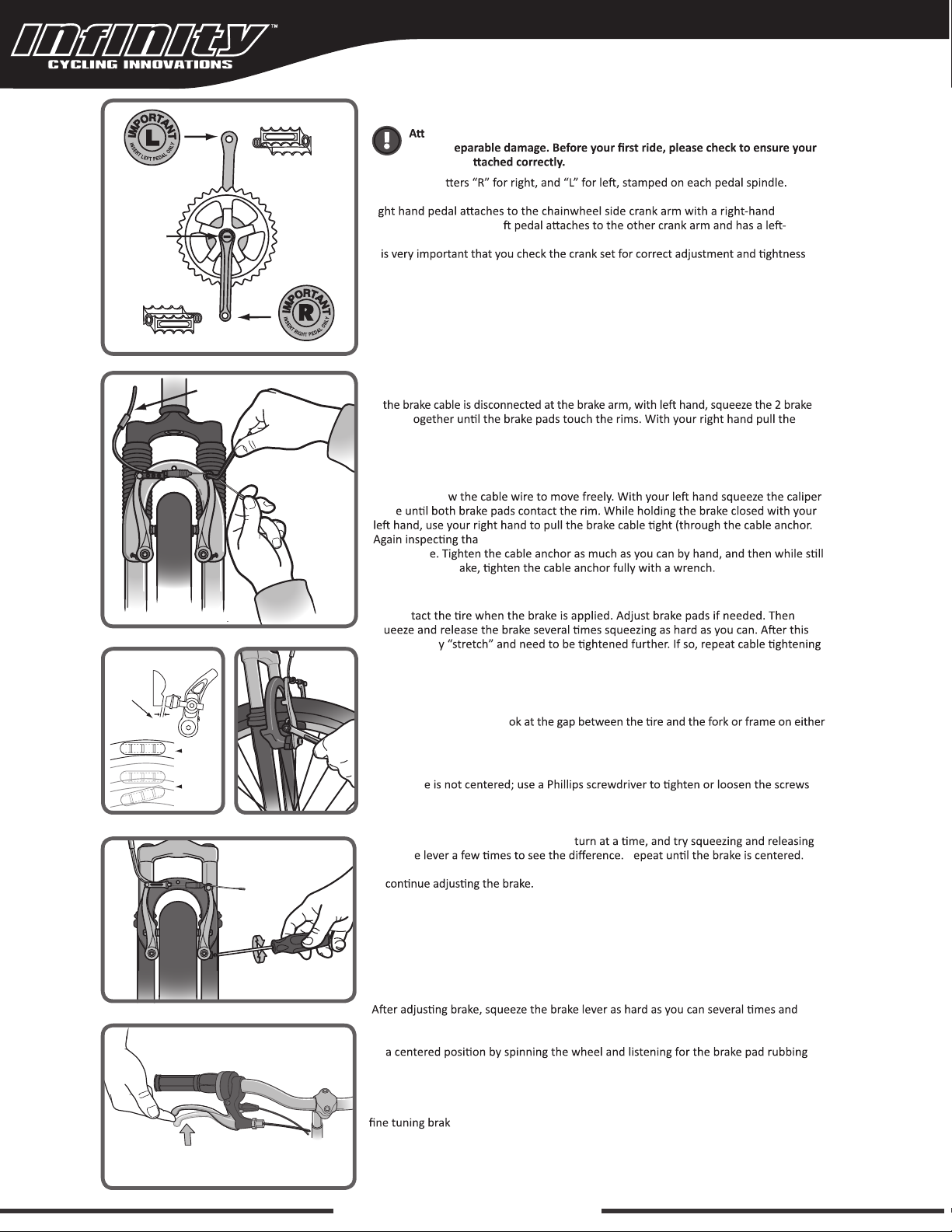

Centering brake

If you squeeze the brake and one side moves more than the other, or one side does not

move at all, then the brake is not centered, or the wheel is not centered.

if the wheel is centered. Lo

side. If it is not even, loosen wheel axle nuts and center the wheel, then proceed to

centering the brake.

Brake pad aligned

with the rim surface

Pad and

rim should

be parallel

1-2 mm

Incorrect

Correct

First determ eni

www.infinitycycleworks.com

copyright 2017 - Infinity Cycle Works Ltd.

If the brak

on either side of the linear pull brake where they mount to the frame or fork. If you

turn the screw clockwise it will increase spring tension on that side, counter clockwise

to decrease spring tension. Start by increasing tension on the side that is not moving or

not moving enough. Turn only about ½

the brak R If

you run out of adjustment, you can go to the other side and loosen the screw slightly

to When the brake is correctlyadjusted, both sides shou dl

move evenly when the brake lever is squeezed, and when released, the wheel should

rotate with no brake shoe contact.

Brake is correctly adjusted when:

• Both brake pads move away from the rim equally when the brake is released.

• The brake pads do not drag on the rim when the brake is open.

• When the brake is applied, the brake pads contact the rim before the brake

lever reaches about 1/3 of the way to the handlebar

re-inspect the brake pads, centering, and brake lever travel. If the brake pads are no

longer square to the rim, repeat brake pad adjustments. Be sure that brake pads return

to

the rim on either side. Readjust as needed. Check that the brake cable tension allows

the brake lever about 1/3 of the travel before the brake pads contact the rim. If the

cablehas stretched or slipped, readjust brake cable tension by loosening cable anchor

bolt and pulling more cable through the anchor or use brake adjustment barrels for

e cable tension.