16 17

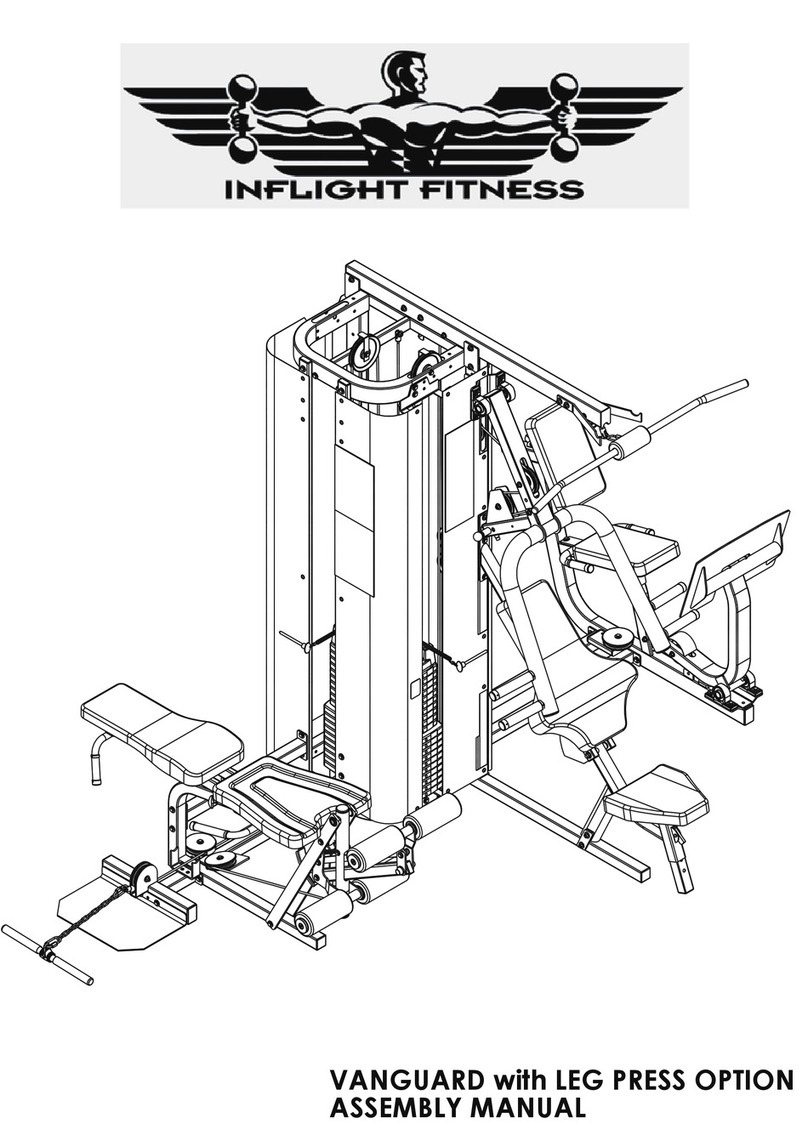

VANGUARD ASSEMBLY INSTRUCTIONS

MEC/LOW ROW STATION CABLE ASSEMBLY

G1. Thread the P13-0454 cable into the threaded boss in the Top Weight. Remember

to slide the loop of the weight pin lanyard onto the cable/topweight if you have not

done so already.

Note: There is a maximum 1” allowable from under the head of the threaded cable

end to the top of the threaded boss where the jam nut rests.

G2. Route the other end of the cable between the guide rodsand around a 6” pulley.

Attach the pulley and cable with an Angle Cable Retainer to the Top Frame using 1

–3/8” x 2 ¾” bolt, 2 –3/8” washers, and 1 –3/8” nut.

G3. Attach the end of the cable to the top frame using 1 –3/8” x 2 ¼” bolt, 2 –3/8”

washers and 1 –3/8” nut. Pull the excess cable down.

G4. Place a 4 ½” Pulley over the loop of upper cable and install it within one side of the

Double Pulley Bracket using 1 –3/8” x 2” bolt, 2 –3/8” washers and 1 –3/8” nut.

G5.Assemble the MEC Exercise Arm to the Bearing Flats using 1 –3/4” x 3” shaft, 2 -

3/8” button head cap screws and the two small diameter 3/8” washers.

G6.Attach the end of the P13-0455 Lower MEC Cable that does not have a ball to the

MEC Exercise Arm using the pre-installed pin and E-clip.

G7.Route the cable back between the Bearing Flats and around a 4 ½” pulley Attach

the pulley with a Round Cable Retainer to the closest hole of the two hole Bent

Pulley Bracket using 1 –3/8” x 2” bolt, 2 –3/8” washers, and 1 –3/8” nut.

G8.Assemble one 4 ½” pulley over the cable near the ball end. Install the pulley in the

Low Row Tube bracket using 1 –3/8” x 2” bolt, 2 –3/8” washers and 1 –3/8” nut.

G9.Route the cable back to the one hole Bent Pulley Bracket and place the cable within

the groove of a 4 ½” pulley. Install the pulley with a Round Cable Retainer to the

bracket using 1 –3/8” x 2” bolt, 2 –washers and 1 –3/8” nut.

G10.Push excess cable under the weight stack between the two rubber cushions. Wrap

the cable around two 4 ½” Pulleys and attach them to the Mid-Frame using 1 –3/8”

x 3 ½” bolt, two 3/8” washers and 1 –3/8” nut. Take care to keep the cables straight

and within the pulley grooves.

G11.Lift the loop of lower cable and wrap it around a 4 ½” pulley. Install the pulley

within the lower side of the Double Pulley Bracket using 1 –3/8” x 2” bolt, 2 –3/8”

washers and 1 –3/8” nut.

16

1 - 4 1/2" Pulley

1 - Round Cable

Retainer

1 - 3/8" x 2" Bolt

2 - Washers

1 - Nut

1 - P13-0455 Cable

1 - Pin

1 - E-Clip

1 - 4 1/2" Pulley

1 - Round Cable Retainer

1 - 3/8" x 2" Bolt

2 - Washers

1 - Nut

1 - 6" Pulley

1 - Angle Cable Retainer

1 - 3/8" x 2 3/4" Bolt

2 - Washers

1 - Nut

1 - 3/8" x 2 1/4" Bolt

2 - Washers

1 - Nut

1 - 4 1/2" Pulley

1 - 3/8" x 2" Bolt

2 - Washers

1 - Nut

1 - Double Pulley Bracket

1 - 4 1/2" Pulleys

1 - 3/8" x 2" Bolts

2 - Washers

1 - Nut

1 - MEC Exercise Arm

1 - 3/4" x 3" Shaft

2 - 3/8" x 1" Screws

2 - Small Washers

G5

G6

G7

G3

G4

1 - P13-0454 Cable

1- Weight Pin with

Lanyard

1 - 4 1/2" Pulleys

1 - 3/8" x 2" Bolts

2 - Washers

1 - Nut

G11

2 - 4 1/2" Pulleys

1 - 3/8" x 3 1/2" Bolt

2 - Washers

1 - Nut

G8

G9

G1

G2

G10