8 9

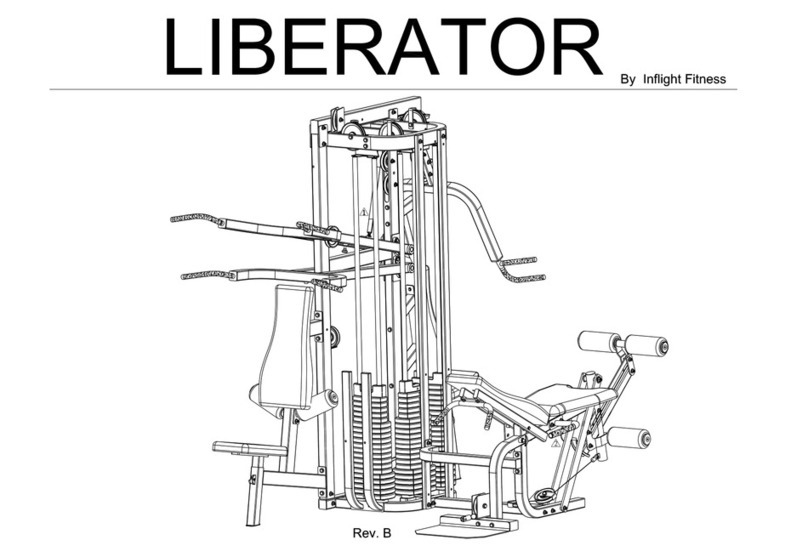

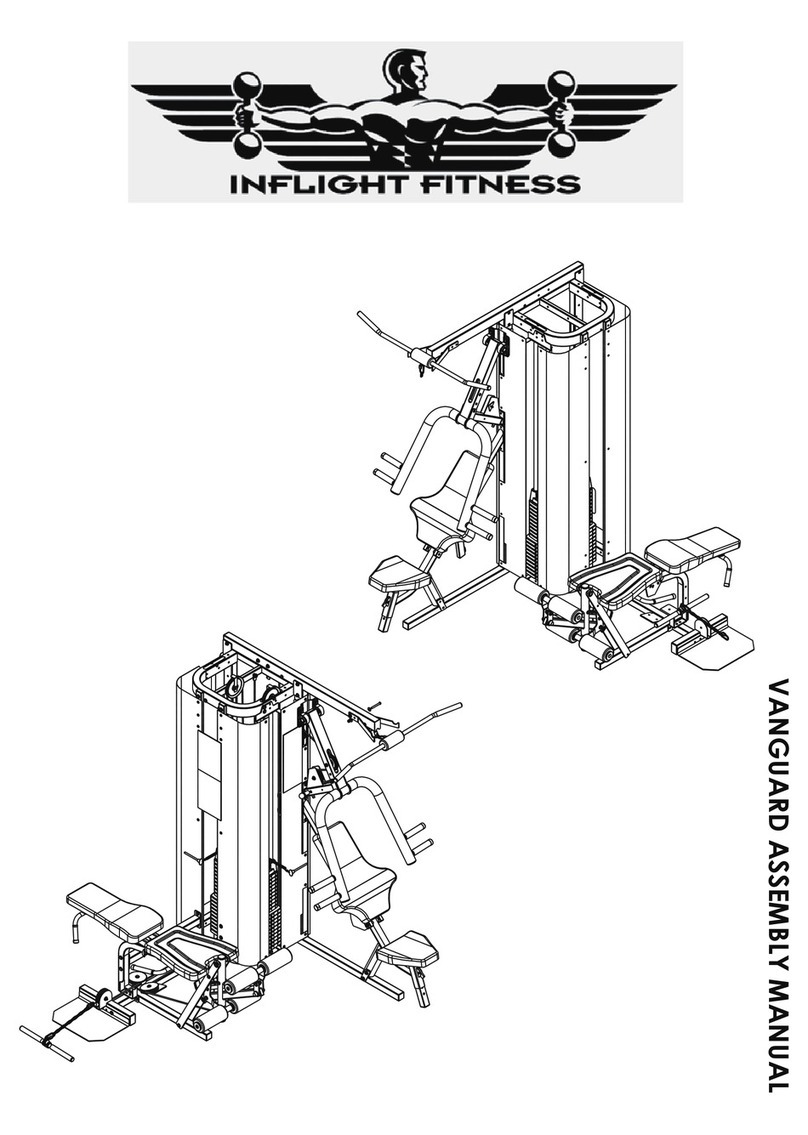

VANGUARD/LPO ASSEMBLY INSTRUCTIONS

WEIGHT STACK INSTALLATION

C1. Insert 2 - Guide Rods into the two large holes in the Mid Frame near the center of

the machine. Allow Guide Rods to lean together out the side of the machine. Place

one weight stack cushion on each Guide Rod and slide down to the base. Apply

lubricant to the Guide Rods from the weight stack cushions to the tops of the Guide

Rods.

Making sure that the recess for the weight labels is facing out from the frame and

that the three pads are facing down slide onto the Guide Rods: 10 –10lb. weights

and then 10 –5lb. weights. Place a Top Weight on the Guide Rods with the drilled

hole facing out from the machine and slide down to the stack. Slide the loop of the

weight pin lanyard over the threaded boss in the center of the top weight.

Insert the pins of the Notched Guide Rod Bracket into the rubber cushions on top of

guide rods. Give the guide rods a little shake to help align the weight plates. Bolt

the Notched Guide Rod Bracket to the Top Frame using 2 –3/8” x 2 ¾” bolts, 4 –

3/8” washers and 2 –3/8” nuts.

C2. Insert 2 -Guide Rods into the two large holes in the Base Frame near the side of

the machine where you will assemble the multi-press. Allow Guide Rods to lean

together away from the machine. Place one weight stack cushion on each Guide

Rod and slide down to the base. Apply lubricant to the Guide Rods from the weight

stack cushions to the tops of the Guide Rods.

Install the weight plates as in Step C1.

Install the Angled Guide Rod Bracket onto top of guide rods to the Top Frame (with

the Upper Shroud Bracket from the shroud box if shrouds will be installed later)

using 2 –3/8” x 2 ¾” bolts, 4 –3/8” washers and 2 –3/8” nuts.

C3. If shrouds will be installed, bolt the Lower Shroud Bracket from the shroud box to

the Base Frame using 2 – 3/8” x 2 ¾” bolts, 4 –3/8” washers, and 2 –3/8” nuts

2 - Guide Rods

2 - Weight Cushions

10 - 10lb. Weight Plates

10 - 5lb. Weight Plates

1 - Top Weight

1 - Notched G.R. Bracket

2 - 3/8" x 2 3/4" Bolts

4 - Washers

2 - Nuts

2 - Guide Rods

2 - Weight Cushions

10 - 10lb. Weight Plates

10 - 5lb. Weight Plates

1 - Top Weight

1 - Angled G. R. Bracket

1 - Upper Shroud Bracket*

2 - 3/8" x 2 3/4" Bolts

4 - Washers

2 - Nuts

Lower Shroud Bracket*

2 - 3/8" x 2 3/4" Bolts*

4 - Washers*

2 - Nuts*

C1

C2

C3*

Top Frame hidden for clarity

NOTE:

Steps and parts marked with* are

only if shrouds are to be installed -

parts are in shroud box.