Inflight Fitness FT1000 User manual

Table of contents

Other Inflight Fitness Fitness Equipment manuals

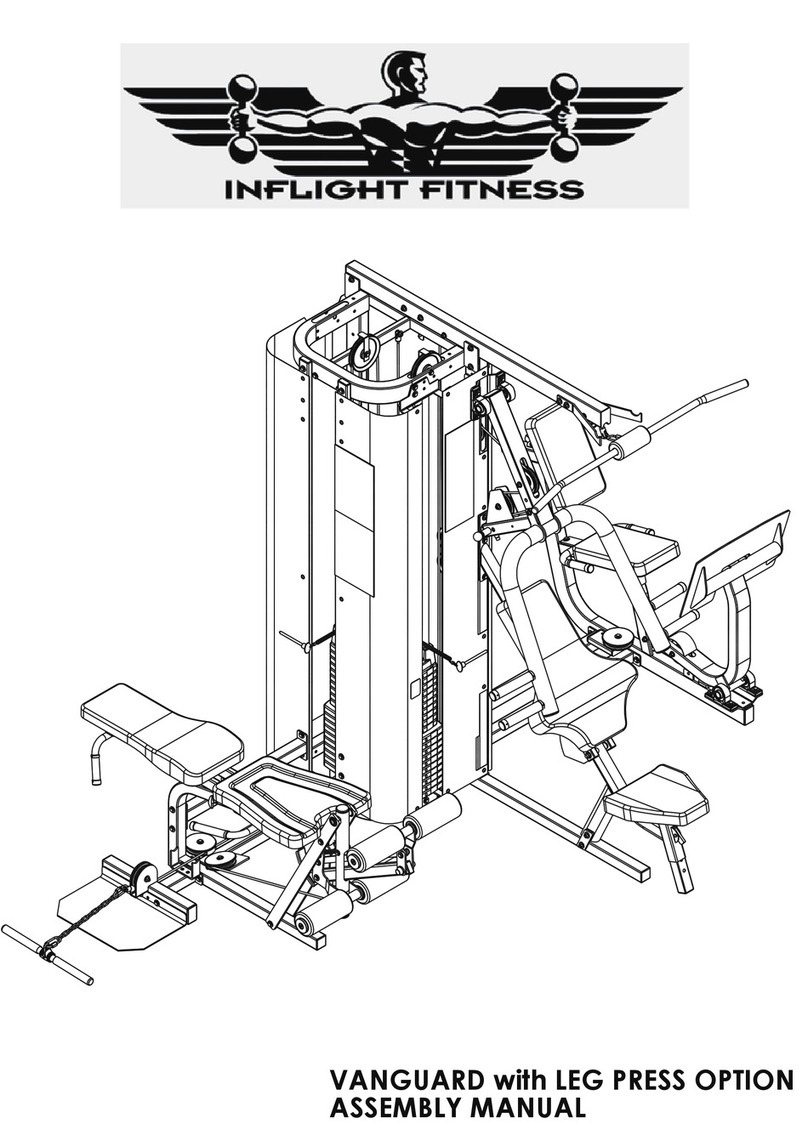

Inflight Fitness

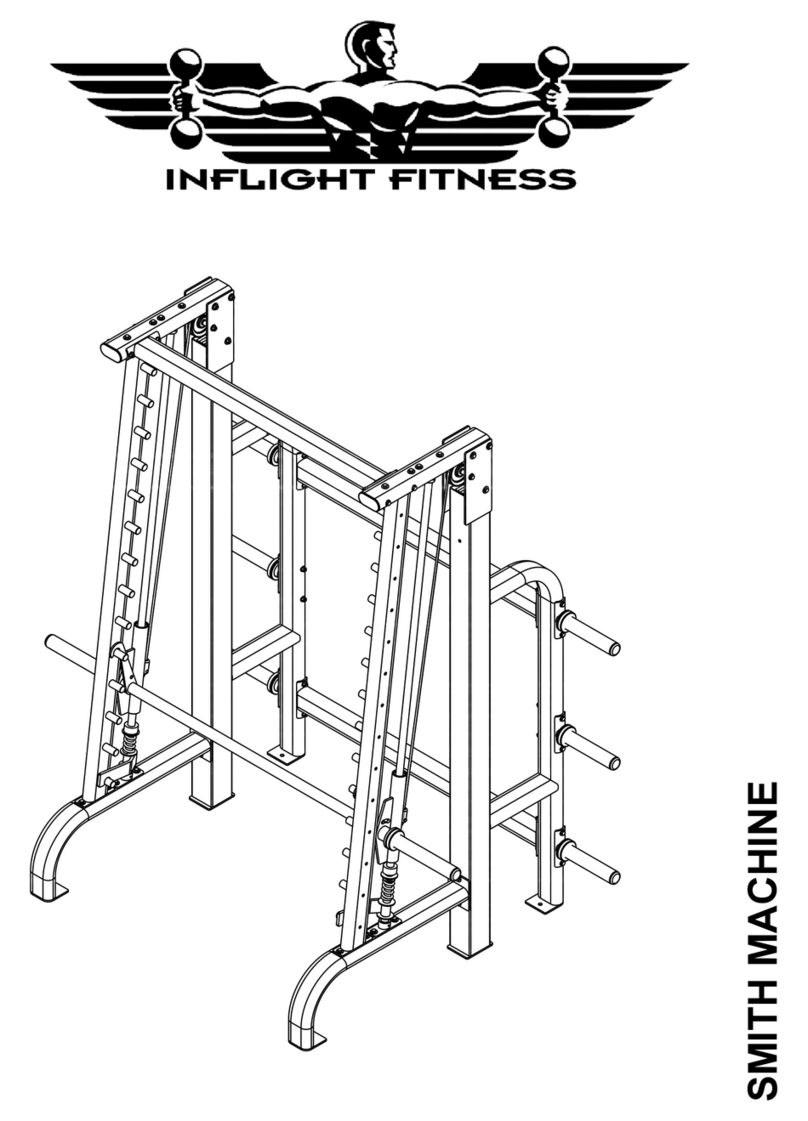

Inflight Fitness SMITH MACHINE User manual

Inflight Fitness

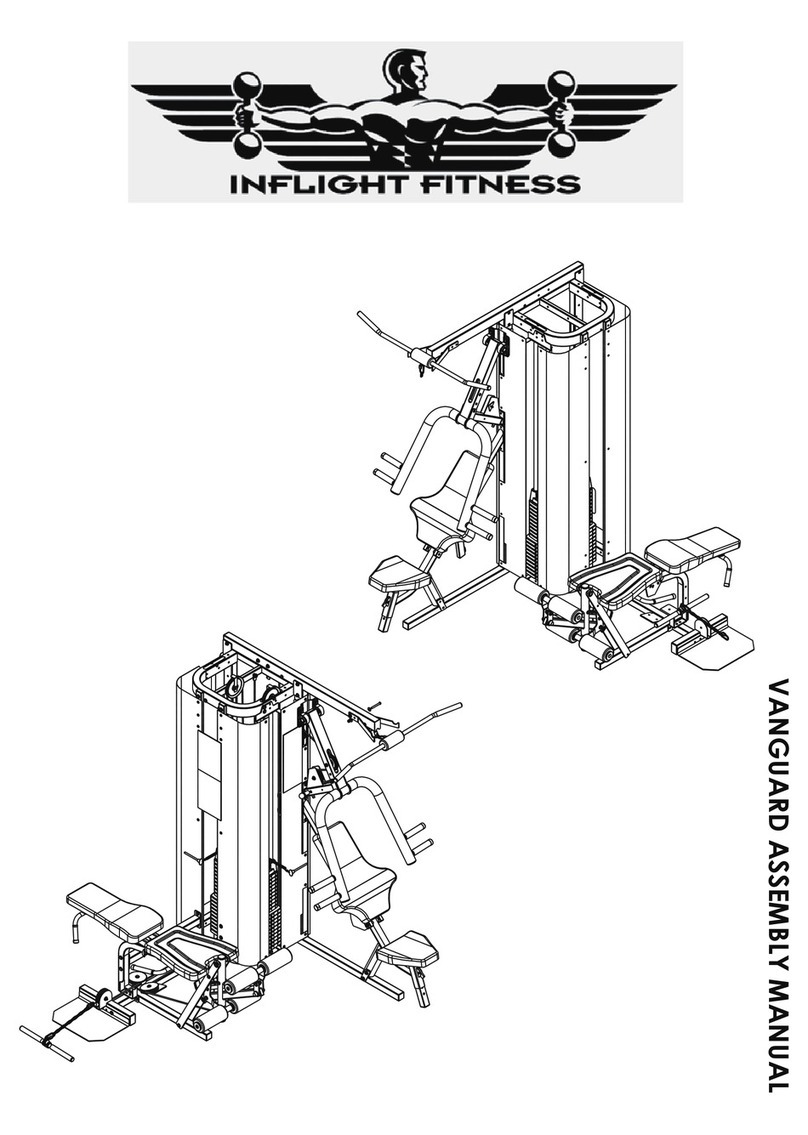

Inflight Fitness VANGUARD User manual

Inflight Fitness

Inflight Fitness CT-MHP User manual

Inflight Fitness

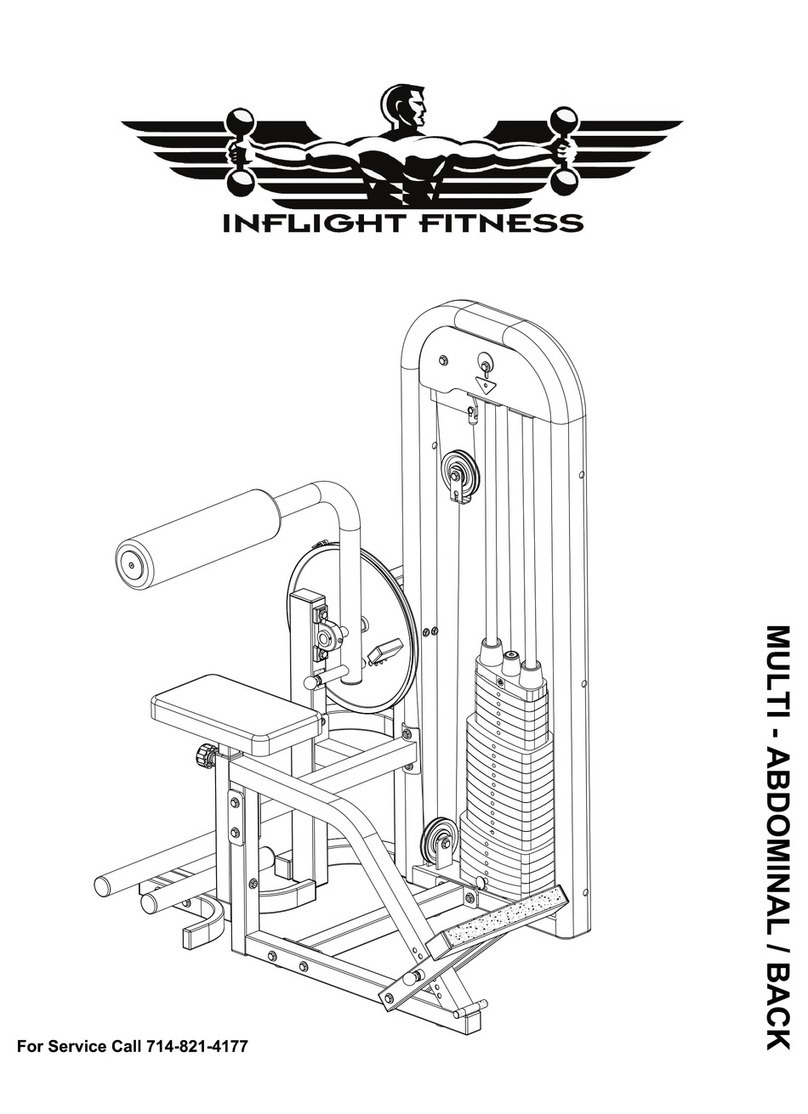

Inflight Fitness Mab User manual

Inflight Fitness

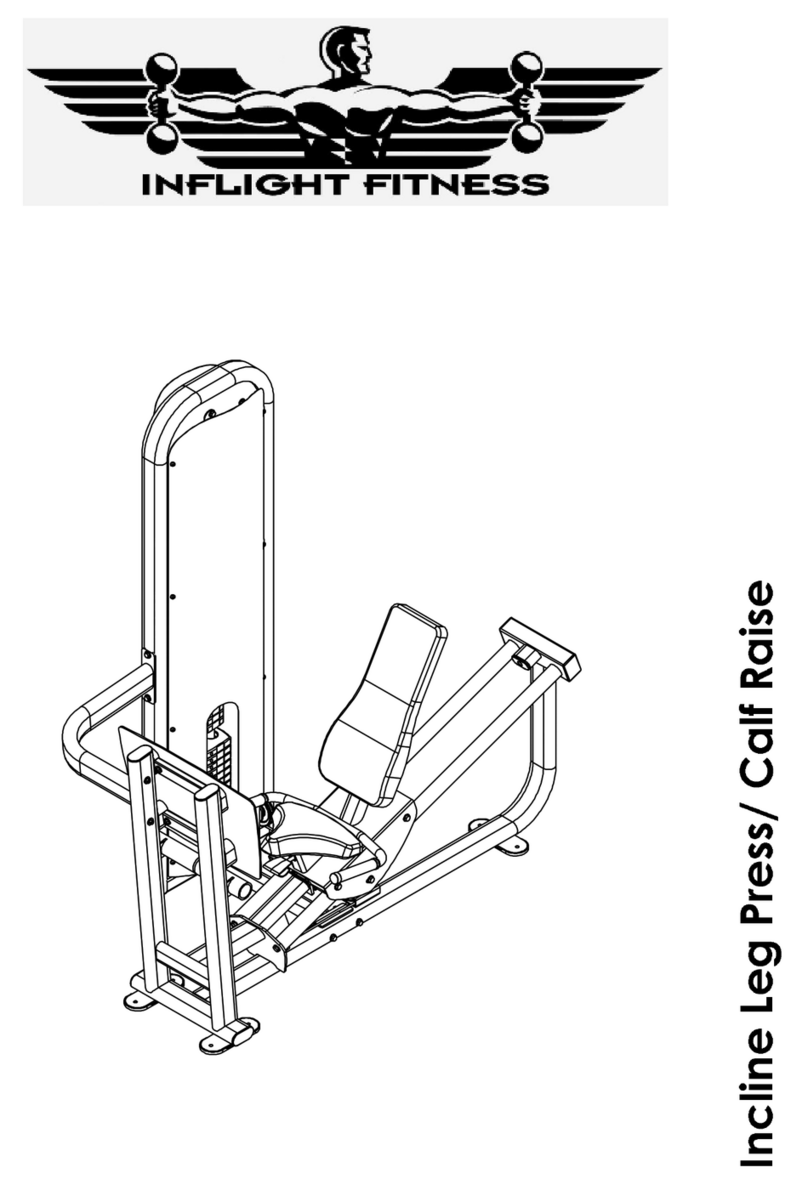

Inflight Fitness CT-ILPC User manual

Inflight Fitness

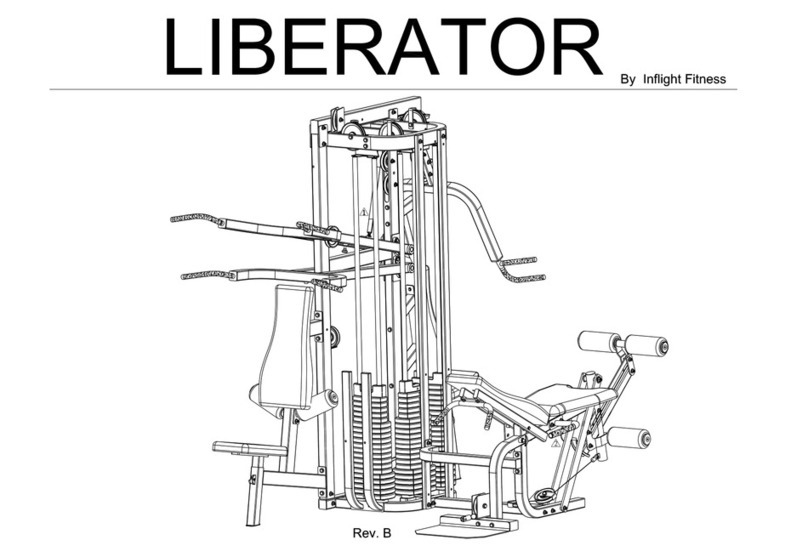

Inflight Fitness Liberator User manual

Inflight Fitness

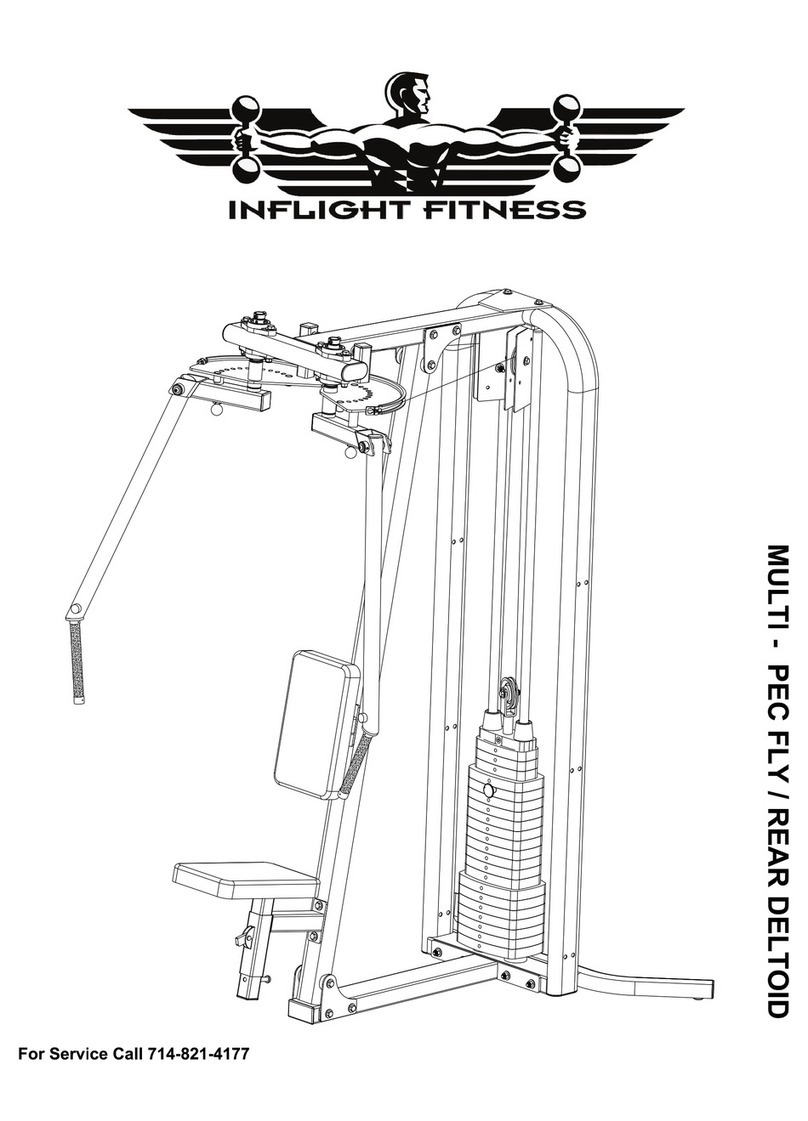

Inflight Fitness MULTI-FLY/DELT User manual

Inflight Fitness

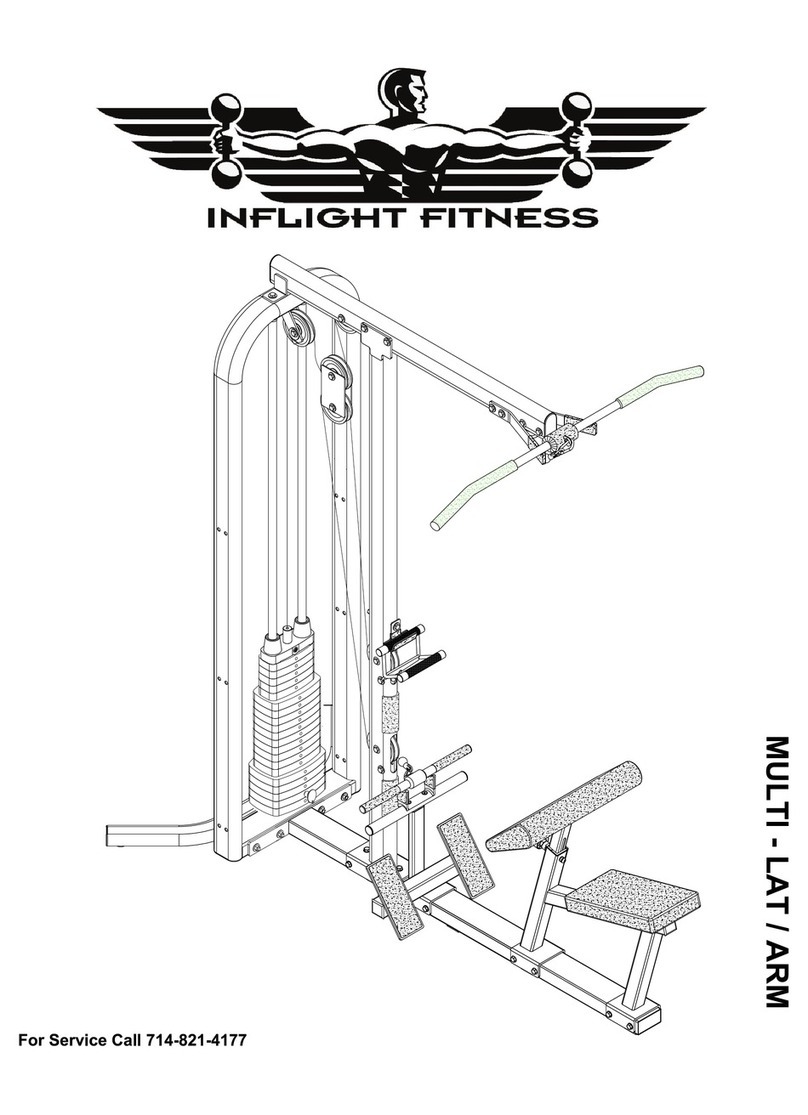

Inflight Fitness Multi-Lat/Arm User manual

Inflight Fitness

Inflight Fitness CT-MSEC User manual

Inflight Fitness

Inflight Fitness MEC User manual

Popular Fitness Equipment manuals by other brands

G-FITNESS

G-FITNESS AIR ROWER user manual

CAPITAL SPORTS

CAPITAL SPORTS Dominate Edition 10028796 manual

Martin System

Martin System TT4FK user guide

CIRCLE FITNESS

CIRCLE FITNESS E7 owner's manual

G-FITNESS

G-FITNESS TZ-6017 user manual

Accelerated Care Plus

Accelerated Care Plus OMNISTIM FX2 CYCLE/WALK user manual