inform InfoSTS User manual

CONTENTS

OVERVIEW ________________________________________________________________________1

InfoSTS………………………………………………………………………………………………………… 1

DESCRIPTION OF THE FUNCTIONS OF THE InfoSTS…………………………………………………1

BLOCK DIAGRAM OF THE STS…………………………………………………………………………… 4

MANUAL TRANSFER SWITCH……………………………………………………………………………..5

SAFETY WARNINGS………………………………………………………………………………………... 6

FRONT VIEWS OF THE STS……………………………………………………………………………….. 7

VIEW OF THE CONTROL PANEL…………………………………………………………………………. 8

INSTALLATION ____________________________________________________________________9

PREPARATION FOR INSTALLATION…………………………………………………………………………9

PRELIMINARY INFORMATION…………………………………………………………………………….. 9

ELECTROMAGNETIC COMPATIBILITY………………………………………………………………….. 9

INSTALLATION ENVIRONMENT………………………………………………………………………….. 9

REMOVING THE STS FROM PALLET……………………………………………………………………. 9

PRELIMINARY CHECK OF CONTENTS………………………………………………………………….. 10

INSTALLING THE STS………………………………………………………………………………………. 10

ELECTRICAL CONNECTIONS ________________________________________________________11

DIAGRAMS OF CONNECTION TO THE ELECTRICAL SYSTEM…………………………………….. 11

PROTECTIONS INSIDE THE STS…………………………………………………………………………. 11

CABLE SIZES………………………………………………………………………………………………….12

CONNECTIONS………………………………………………………………………………………………. 12

WIRING PROCEDURE………………………………………………………………………………………. 16

PROTECTIVE EARTH……………………………………………………………………………………….. 16

R.E.P.O (REMOTE EMERGENCY POWER OFF)……………………………………………………………. 16

USE ______________________________________________________________________________17

DESCRIPTION………………………………………………………………………………………………… 17

PRELIMINARY OPERATIONS……………………………………………………………………………… 17

POWERING ON FOR THE FIRST TIME…………………………………………………………………… 17

Switching On (Normal Operation) The STS From Off Position……………………………………… 18

Switching To Maintenance Bypass Position From Normal (automatic) Operation……………… 19

Switching From Maintenance Bypass To Normal Operation…………………………………………20

Switching Off The STS During Normal Operation……………………………………………………... 21

DISPLAY 22

ALPHANUMERIC LCD DISPLAY, MIMIC DIAGRAM, KEY SYMBOLS………………………………. 22

DISPLAY MENUS…………………………………………………………………………………………….. 23

MAIN MENU…………………………………………………………………………………………………… 23

MEASURES MENU ………………………………………………………………………………………….. 24

COMMAND MENU……………………………………………………………………………………………. 25

ALARMS MENU……………………………………………………………………………………………… 26

OPTIONS MENU……………………………………………………………………………………………… 27

TIME MENU…………………………………………………………………………………………………… 29

INFORMATION MENU………………………………………………………………………………………. 29

ADJUST MENU………………………………………………………………………………………………. 29

SERVICE PASSWORD……………………………………………………………………………………… 29

USER PASSWORD………………………………………………………………………………………….. 30

ALARM MESSAGES………………………………………………………………………………………… 30

INPUT SOURCE ALARM DESCRIPTIONS…………………………………………………………………… 31

TRANSFER FLOWCHART……………………………………………………………………………………… 31

OPTIONAL EXTERNAL POWER INPUT……………………………………………………………………… 32

COMMUNICATION INTERFACE AND REMOTE MANAGEMENT…………………………………………32

OPTIONAL TCP/IP ADAPTOR…………………………………………………………………………………. 34

TECHNICAL SPECIFICATIONS _______________________________________________________35

MECHANICAL CHARACTERISTICS___________________________________________________ 38

MAINTENANCE AND TROUBLESHOOTING _____________________________________________39

TCP/IP ADAPTOR SETUP____________________________________________________________40

- 1 -

OVERVIEW

InfoSTS

Thank you for choosing InfoSTS as your equipment protector.

It includes many features to protect your critical equipments.

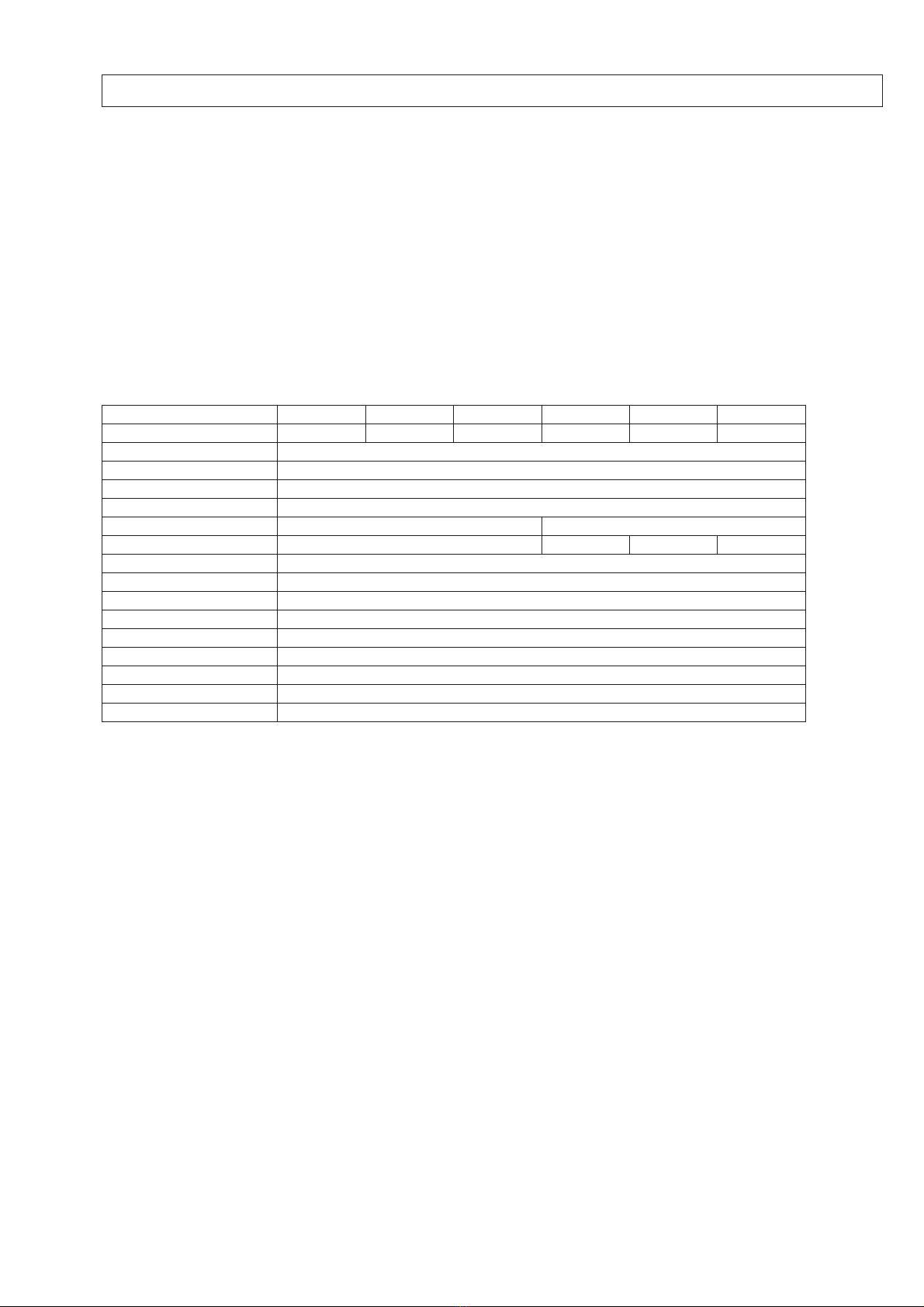

Power ranges according to models

4 pole model 3 pole model Output current per phase

STS450 STS350 50 amperes

STS4100 STS3100 100 amperes

STS4150 STS3150 150 amperes

STS4200 STS3200 200 amperes

STS4300 STS3300 300 amperes

STS4400 STS3400 400 amperes

This unit supplies continuous power to critical loads from 2 separate AC supplies. It monitors 2 input sources, if

one of the input sources fails, it transfers the load to the other input source automatically. The user can also

perform transfer from one source to another using the manual transfer switch.

The main functions of the STS unit are as follows :

•Increased power quality

•Increased noise reduction

•Power blackout protection

•Power redundancy

•Automatic static switching

•Remote monitoring of input power sources

•Easy static and mechanical transfer between separate input sources

•Remote management of power events

•Power event logging

•Redundancy

Therefore inclusion of INFORM Static Transfer Switches (STS) in an energy distribution system provides secure

protection against any possible faults in the AC power system. STS permits switching between two independent

AC power supplies (SOURCE 1 and SOURCE 2) without shutting down the critical load connected to its output.

DESCRIPTION OF THE FUNCTIONS OF THE InfoSTS

InfoSTS is a microprocessor controlled transfer switch, designed for automatic and manual switching between

two AC power sources, with interruption to the load of less than 2 msecs with synchronized sources and of less

than 12 msecs for unsynchronized sources.

STS utilizes SCRs connected in opposite parallel pairs (six pairs for 6 pole models ,eight pairs for 4 pole

models) . Three or four pairs of SCRs are used to connect the AC load to the power supply input referred to as

“PREFERRED”, under normal conditions. The other three (of four) pairs of SCRs are on standby to transfer the

load to the other power supply input referred to as “ALTERNATE” in case of a failure of the “PREFERRED”

input supply.

Source 1 and Source 2 supply inputs should come from two different AC sources with nominally identical

voltages, phases and frequencies. The aim of the STS is uninterrupted transfer from one AC power supply to

the other, in case of a fault in the “PREFERRED” supply.

Before and during transfer from one source to the other, the operating conditions of the SCRs are carefully

monitored to prevent crosscurrents between two sources. The break-before-make technique makes healthy and

uninterrupted transfers possible.

- 2 -

During normal operation, “PREFERRED” network supplies the load when both inputs are available. Selection of

the “PREFERRED” network, automatic re-transfer, retransfer delay, overload behavior of STS, alarm hold time,

nonsynchronized transfer behavior, overload and transfer inhibit reset modes may be set by the user on the

control panel of the unit.

Permitted voltage, phase difference and frequency tolerance are also adjustable by the service personnel on the

control panel.

Basic Features:

•Easy monitoring all parameters on LCD display

•Fast microcontroller (32 mips)

•Advanced RS232 communication features ,optional TCP/IP connection

•DRY contact alarm interface

•Password protected login system from remote site (timed Access)

•2 redundant power supplies for electronic boards (hot swappable)

•Easy front access to all components inside of the STS

•Second protection cover on live circuits which prevents electrical shock

•Input sources protected by fuses

•3 positioned Maintenance bypass switch which prevents cross currents between input sources

•User adjustable parameters by entering a password.

•Built in real time clock.

•Alarm history (with their date and time)

•Automatic transfer test from a remote site or using front panel

•Front panel Lamp test

•External emergency shutdown (EPO) input

•All boards are supplied by two separate power supplies.

•Hot plug construction during maintenance bypass

•High current output tolerant up to 1000%

•Adjustable long dead time during non synchron transfer up to 3 seconds

•SCR fault sense circuit

•Cabinet inside temperature sensor

•Fast voltage black-out circuit

•Input phase balance and phase sequence fault detect circuit

•Output alternance balance sense circuit

•Adjustable Input source frequency lower/upper limits

•Additional analog synchronous sense circuit

Control Circuit locations

The control circuits are located in a closed cabinet which is not directly accessible by the user.

Redundant power supply circuit

2 power supplies are installed inside the STS. They are connected to all boards separately. So the construction

is hot swappable. During operation, service personnel can replace one of the power supplies without effecting

the operation of the STS.

Power connections and terminals

All input and output power connections are located at the bottom of STS. At the bottom of the STS separate

panels let to the cables for easy installation.

Easy front Access to all components

All components are installed onto the front side of STS. During servicing, there is no need to remove any side or

rear panel of the STS.

Quick Access to static bypass switch

User can perform static transfer from remote panel but this will take a long time to surf on menu functions. A

separate static bypass switch is installed inside the STS and the priority of this switch is higher than the front

panel controls. This means that, it the user uses the manual bypass switch, all panel bypass commands will be

disabled.

- 3 -

Protections

- Two input sources are connected to STS by MCCB’s (S1 and S2)

- Suitable rating varistors protect the control circuits from high voltage transients.

- All power supply inputs are fuse protected

On SCR’s heat-sink, there is a thermal contact to warn the user in case of excessive heat-sink temperature.

Protection shield prevents direct touch to live parts, inside the unit.

Cooling

The cooling fans ( 2 cooling fans) are installed on to the top side of STS .

Figure – 1 Cooling outlets of the STS

- 4 -

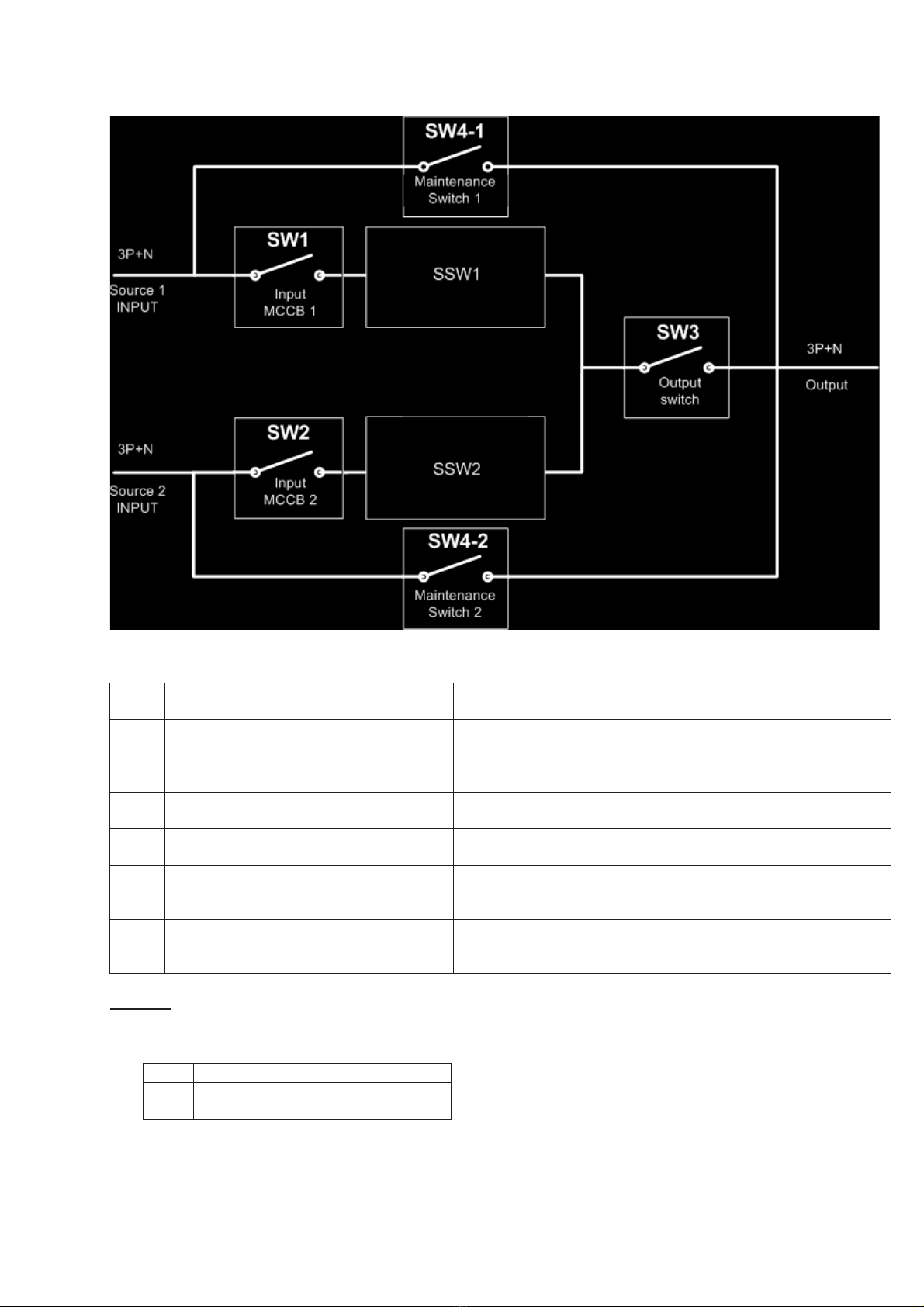

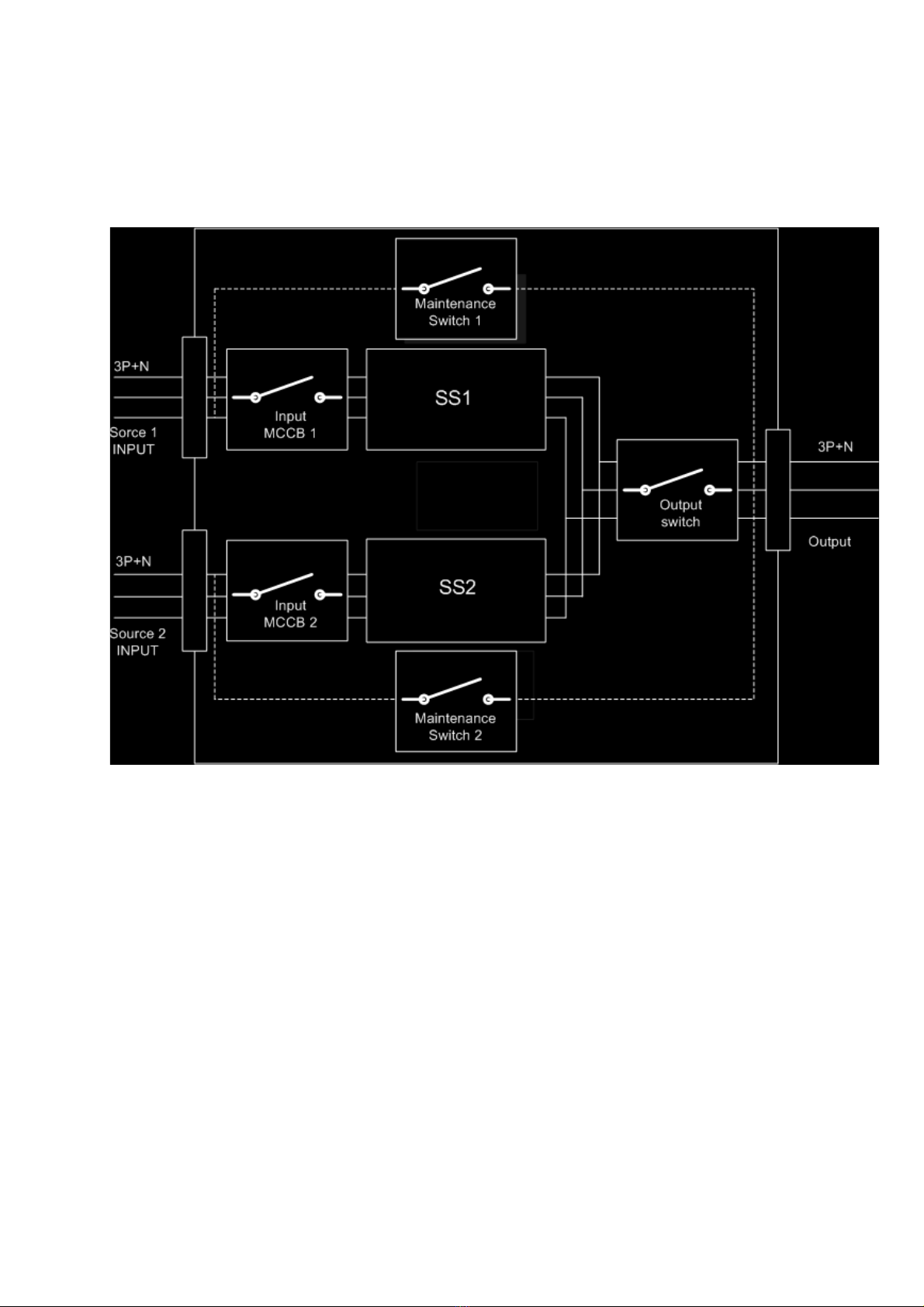

BLOCK DIAGRAM OF THE STS

Figure – 2 STS Block diagram

S1 Source 1 input circuit breaker (MCCB) This switch is thermal and magnetic protected type and

shutdowns source 1 input

S2 Source 2 input circuit breaker (MCCB) This switch is thermal and magnetic protected type and

shutdowns source 1 input

S4-1 Mechanical bypass switch to source 1 During maintenance these contacts connect Source 1 input

to STS output directly

S4-2 Mechanical bypass switch to source 2 During maintenance these contacts connect Source 2 input

to STS output directly

S3 Output switch This switch shutdowns the output voltage of STS . During

maintenance the position of this switch must be OFF.

SS1 Static transfer SCR circuit to source 1

This static switch contains SCRS and snubber components

and driven by a driver circuit which is controlled by the

microprocessor.

SS2 Static transfer SCR circuit to source 2

This static switch contains SCRS and snubber components

and driven by a driver circuit which is controlled by the

microprocessor.

NOTE : Figure 2 shows only 1 phase of 3 phase construction. The other phases are not shown.

The maintenance bypass switch is a 3 pole change-over switch

1 Maintenance bypass to source1

0 Automatic operation

2 Maintenance bypass to source2

Source 1 and Source 2 input circuit breakers are MCCB’s with thermal overload and magnetic short circuit

releases.

A Manual Static Bypass Switch is also available for easy load transfer.

- 5 -

MANUAL TRANSFER SWITCH

Manual transfer switch is located on back front panel and user transfers the load to input source1 or source2

rapidly. During normal operation this switch must be at AUTO position.

Figure – 3 Manuel transfer switch location

- 6 -

SAFETY WARNINGS

IMPORTANT NOTICES

1. This Manual must be carefully read before applying any power to the STS unit.

2. All warnings in the manual should be adhered to.

3. All operating instructions should be followed.

4. The unit should be supplied by a grounded outlet. Do not operate the unit without ground source.

5. Power input cords of the STS should be routed carefully so that they are not to be walked on.

6. Please save this manual.

7. Please save or recycle the packaging materials.

WARNING !!!

•Do not apply electrical power to the STS equipment before arrival of authorized service personnel.

•Installation and commissioning of STS must be performed by a qualified technician.

•Adequate protection against input over currents must be provided, considering the nominal current rating of

the STS.

•Do not insert any object into ventilation holes or other openings.

•To reduce the risk of fire or electric shock, install the unit in temperature and humidity controlled indoor area

free of flammable and corrosive substances.

•The unit have two power inputs ,if one of the supplies is connected risk of electric shock is valid.

•The unit is powered by more than one power mains. When one of the incoming power sources is active, the

unit contains a dangerous level of voltage, even when it is in “MAINTENANCE BYPASS” position

WARNING !!!

•Since it is a high voltage equipment, INFOSTS contains dangerously high voltages. The risk of

contact with these voltages is minimized using a lockable hinged door and internal safety shields in

accordance with IP20 standards.

•All maintenance and installation procedures requiring access to the inside of the device must be

exclusively performed by a trained personnel.

•InfoSTS DOES NOT HAVE AUTOMATIC PROTECTION AGAINST VOLTAGE RETURNING TO THE

INPUT. POWER SWITCHES OR FUSES OUTSIDE THE STS MAY HAVE VOLTAGES ON THEIR

CONNECTION TERMINALS EVEN WHEN THEY ARE TURNED OFF.

•SERVICE PERSONNAL MUST INSULATE THE STS (BY TURNING OF ITS INPUT SWITCHES S1 AND

S2) BEFORE WORKING ON THESE EQUIPMENT.

CAUTION !!!

•Installation and commissioning of this device must be performed by qualified service personnel

trained and authorized by the manufacturer (or distributor)

•Risk of electric shock, do not remove cover. No user serviceable parts inside, refer servicing to

qualified service personnel.

•Risk of electric shock, hazardous live parts inside .

- 7 -

FRONT VIEWS OF THE STS

Interior front view

S6

Manual

transfer

Switch

Dry contact outputs

EPO Input

S3

Output

Switch

S2

Source 2

I/P SW

S1

Source 1

I/P SW

RS232

Port

S4

Maintenance

Bypass

SW

figure - 4

- 8 -

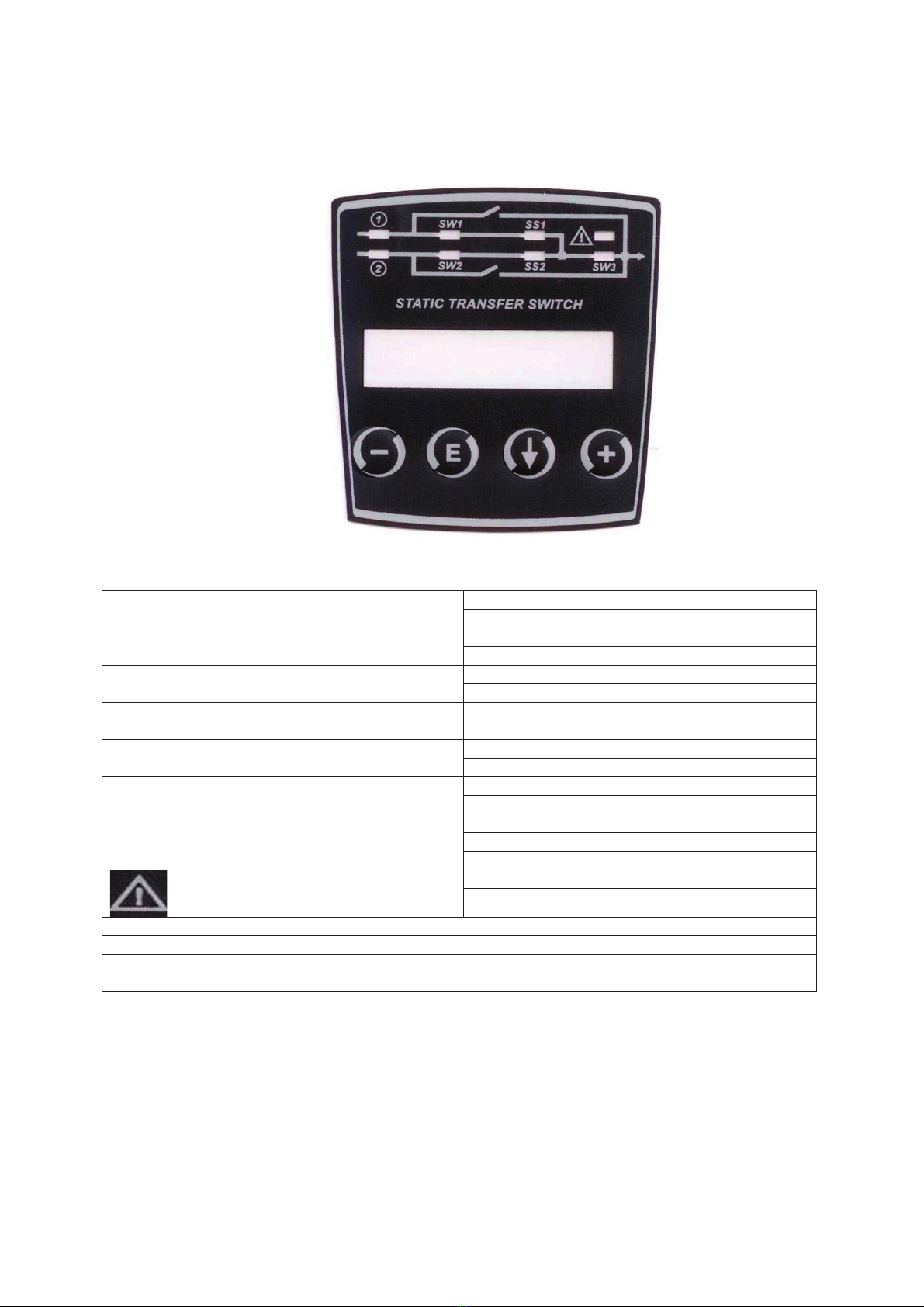

VIEW OF THE CONTROL PANEL

On the front panel of STS there are LEDs, control buttons and a two line alphanumeric LCD display. These

components interact with each other during STS operation. Buttons change menus and submenus on LCD

display. LEDs show the switching position of the STS on a mimic diagram.

figure – 5 STS front panel

On : source 1 is preferred source

1 Source 1 priority lamp Off : source 1 is alternate source

On : source 2 is preferred source

2 Source 2 priority lamp Off : source 2 is alternate source

On: source 1 input is OK

SW1 Source 1 input monitor lamp Off : source 1 input failed

On: source 2 input is OK

SW2 Source 2 input monitor lamp Off : source 2 input failed

On: SS1 SCR group fired

SS1 Source 1 static switch on lamp

S1 static switch on Off : SS1 SCR group open

On: SS2 SCR group fired

SS2 Source 2 static switch on lamp

S6 static switch on Off : SS2 SCR group open

On : output normal

Off : output switch off

SW3 Output monitor lamp

Flash : output voltage inhibit

Flash : previously an alarm occurred

Alarm monitoring lamp Off : there is no alarm on STS

Down button Moves menu item to 1 level down

Enter button Validates the adjusted data or OK confirmation

(+) button Increases the current data

(-) button Decreases the current data

- 9 -

INSTALLATION

ALL THE OPERATIONS DESCRIBED IN THIS SECTION MUST BE CARRIED OUT EXCLUSIVELY BY

QUALIFIED STAFF.

The company may no be held liable for any damage caused by incorrect connections or by operations

that are not described in this manual.

STORAGE OF THE STS

The storage area must have the following characteristics

Temperature : -10 to +50 C

Relative humidity : 95% max.

PREPARATION FOR INSTALLATION

PRELIMINARY INFORMATION

Model STS450 STS4100 STS4150 STS4200 STS4300 STS4400

Nominal current 50 100 150 200 300 400

Operating temperature 0 – 40 C

Non operating temper. -10 to + 50 C

Max. relative humidity 90% (non-condensing) during operation

Max. installation height 1000 m at nominal current rating

Dimensions WxDxH 685x530x1500 mm 685x580x1770 mm

Weight 175 Kg 205 Kg 220 Kg 240 Kg

Protection level IP20

Cable input From base / on front

Communication RS232 standard - TCP/IP option

Flying transfer Available - Standard

LCD panel and mimic Available - Standard

Backfeed protection Available - Standard

Software management Available - Standard

DRY contact outputs Available - Standard

EPO input Available – Standard ( NO)

<X> letter on table shows 3 pole or 4 pole model options ( 3 = 3 pole , 4 = 4 pole )

ELECTROMAGNETIC COMPATIBILITY

This static transfer switch (STS) conforms to the class C2 specifications (in accordance with the provisions laid

down by the EN62040-2 standard: STS – EMC requirement). In the home environment ,it may cause radio

interference. The user may have to take supplementary measures.

This product is designed for professional use in industrial and commercial environments . Connections to the

RS232 connectors should be made with the cables provided or ,in any case, with shielded cables less than 3

meters long.

INSTALLATION ENVIRONMENT

When choosing the site in which to install the STS , the following points should be taken into consideration :

•Avoid dusty environments

•Check that the floor is level and capable of withstanding the weight of the STS

•Avoid cramped environments that could impede the normal maintenance activities

•The relative humidity should not exceed 90%, non-condensing.

•Check that the ambient temperature, with the STS running, remains between 0 and 40 C

•Avoid installing the equipment in places exposed to the direct sunlight and hot air.

REMOVING THE STS FROM PALLET

The STS is packed and enclosed in a structural cardboard carton to protect it from damage.

1. Inspect for damage that may have occurred during the shipment If any damage is noted, call the shipper

immediately and retain the shipping carton and the STS.

2. Carefully open the carton and take the STS out.

Retain the carton and packing material for possible future use

- 10 -

PRELIMINARY CHECK OF CONTENTS

Having opened the package ,start by checking the contents

-User manual

-serial RS232 connection cable

-STS control software and user manual CD

-Guarantee document

INSTALLING THE STS

When installing the equipment the following points should be considered:

•The air outlets of the STS is on the top ,cause of this do not prevent air ventilation from the top side.

•No objects should be left on its top surface

•Sufficient space should be left in front of the equipment for it to be turned on/off and maintenance

operations to be performed on it (>1.5 m)

•Keep out of your equipment from the explosive and flammable items

- 11 -

ELECTRICAL CONNECTIONS

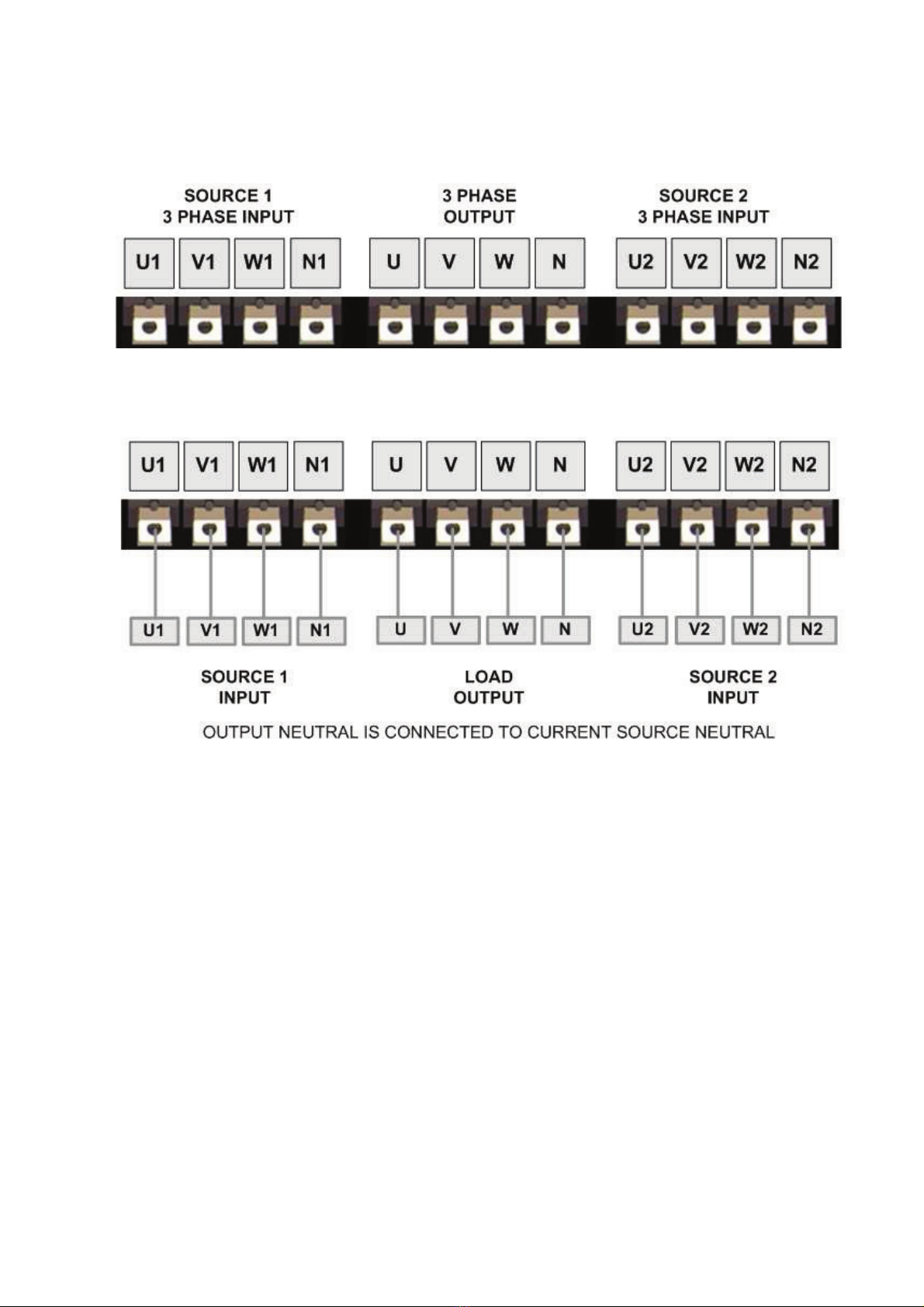

DIAGRAMS OF CONNECTION TO THE ELECTRICAL SYSTEM

WARNING: a 4-wire three-phase distribution system is required for three-phase input and output connections.

The standard version of the STS (3 pole) switches only 3 phases neutral is connected to the output directly. 3-

phase power line + neutral + protective earth (PE), in compliance with the IEC 60364-3 specifications.

Figure – 6 3 pole standard STS input and output block diagram

PROTECTIONS INSIDE THE STS

SHORT CIRCUIT

In the event of a fault on the load , in order to protect itself and the alternate source the STS inhibits the output

voltage. During short circuit event on the load, the connected source to load will be overloaded and the voltage

of this input source will be go down, at this point STS monitors the output current and if current is 200% of

nominal output current , if the input source phase voltages is lower than allowed limit at the same time it decides

that short circuit event occurred at the output of the STS.

At the other hand during over current status , if the input MCCB trips STS decides that short circuit event

occurred at the output of the STS.

OVERLOAD

Electronic overload protection system is used inside of the STS ,this protection system can be enabled or

disable by the user as an option.

BACKFEED

The STS have electronic protection system against backfeed from any input source ,if any backfeed current is

sensed the related input source input MCCB trips.

FUSES

There is no any replacable fuses inside of the STS ,only input MCCB’s protect against overcurrents.

- 12 -

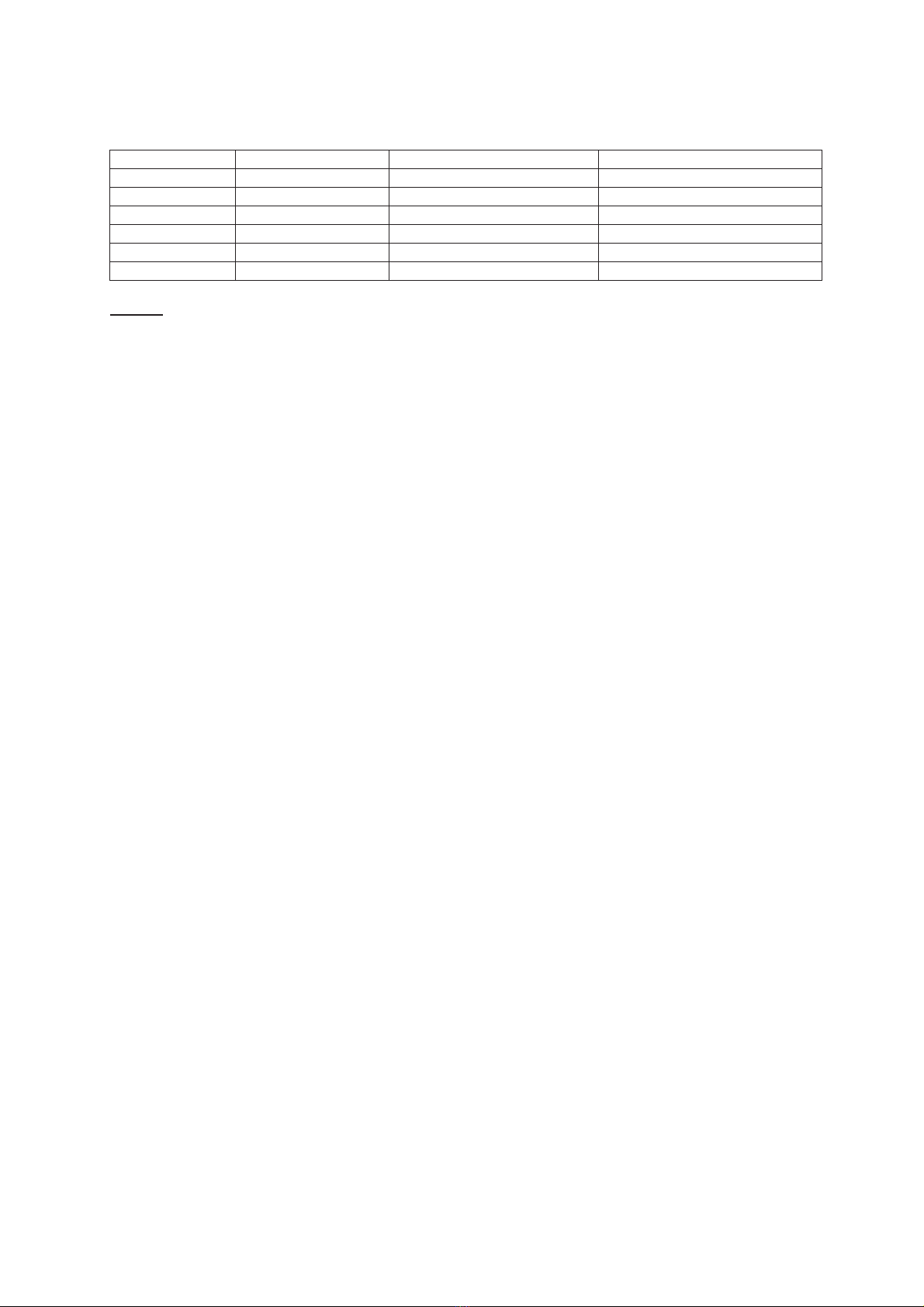

CABLE SIZES

The input/output cables can be sized to suit the STS rating according to the table below

4 pole model 3 pole model Input and output cables Cable type

STS450 STS350 25 mm

2

3 phase+1 neutral +earth

STS4100 STS3100 35 mm

2

3 phase+1 neutral +earth

STS4150 STS3150 50 mm

2

3 phase+1 neutral +earth

STS4200 STS3200 70 mm

2

3 phase+1 neutral +earth

STS4300 STS3300 95 mm

2

3 phase+1 neutral +earth

STS4400 STS3400 120 mm

2

3 phase+1 neutral +earth

NOTE: The neutral conductor should be sized for 1,5 times the output phase current. The Earth conductor

should be sized as 2 times the output conductor (this is dependent on the fault rating, cable lengths,

type of protection etc.) These recommendations are for guideline purposes only and are superceded

by local regulations and codes in practice.

CONNECTIONS

InfoSTS Series Static Transfer Switches run only on 3-Phase AC power supplies with a NEUTRAL line.

The STS unit must be grounded in accordance with electrical regulations

Before making power connections to the unit, ensure that all the incoming power sources are de-energized and

insulated

Cables can enter the InfoSTS from below, through the base panel of the cabinet. Top entry is also possible by

removing the cover panel on the top of the STS revealing the cables entry hole.

The connections of the STS should be supplied by grounded outlets. Cables enter the STS modules via entry

panels in the base of cabinet. All control cables should be screened and run in a separate trunking to the power

cables.

- 13 -

3 POLE STS POWER CONNECTIONS

Input and output terminals of the 3 pole STS are shown in the following figure

figure - 7 Connection terminals of 3 pole STS

figure – 8 3 Pole STS cable connections

- 14 -

4 POLE STS POWER CONNECTIONS

4 pole type STS units connects load output neutral to the current used source’s neutral ,the neutral of the other

source is isolated from output neutral.

Figure - 9 Connection terminals of 4 pole STS

Figure – 10 Input and output cable connections of 4 pole STS

- 15 -

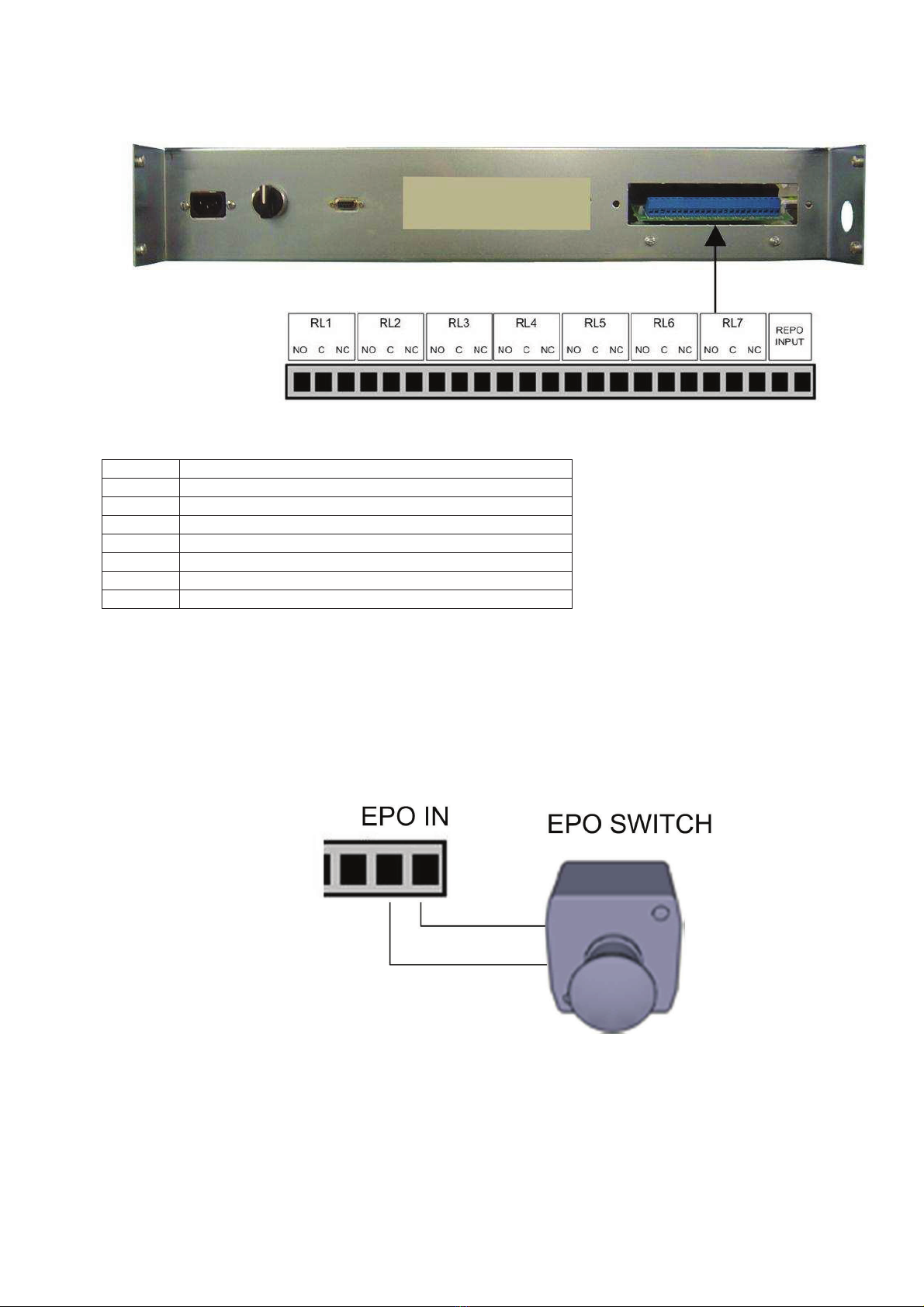

ALARM RELAY CONNECTIONS

Figure - 11 Alarm Relay Contacts and EPO Input Terminals

Relay Function

RL1 Load is connected to alternate input source

RL2 Preferred source indicator relay

RL3 Output Inhibit relay

RL4 Summary alarm relay

RL5 Manual or static transfer relay

RL6 S1 backfeed trip ( 1 second active)

RL7 S2 backfeed trip ( 1 second active)

EPO input is NO type interface (normally open) ,if EPO input terminals shorted to each other STS applies EPO

shutdown procedure.

EXTERNAL EPO BUTTON

figure – 12 Epo input connection

Epo input trips short circuit there is no need to lock EPO signal externally.

- 16 -

WIRING PROCEDURE

1.

Open the STS cabinet front door and remove the metal guard on the lower side to permit access to the

connection terminals and busbars (neutral and earth). Before connecting any power cables, please ensure

that all the circuit breakers on the STS are in “OFF” position. (S1, S2, S3 and S4)

SOURCE 1 Input Power Connections

2.

Connect the SOURCE 1 AC power cables to the terminals U1-V1-W1 of the STS (Figure 7,8,9,10) and

tighten the connections properly.

The neutral cable must be connected to the copper bus-bar identified as “NEUTRAL”.

CHECK FOR CORRECT PHASE ROTATION

SOURCE 2 Input Power Connections

3.

Connect the SOURCE 2 AC power cables to the terminals U2-V2-W2 of the STS (Figure 7,8,9,10) and

tighten the connections properly.

The neutral cable must be connected to the copper bus-bar identified as “NEUTRAL”.

CHECK FOR CORRECT PHASE ROTATION

Output Connections

4.

Connect the output cables to the terminals (U-V-W) of the STS (Figure 7,8,9,10) and tighten the connections

properly.

The output neutral cable must also be connected to the copper bus-bar identified as “NEUTRAL”.

CHECK THAT PHASES ARE CONNECTED IN THE RIGHT ORDER.

CHECK AGAIN ! that U1-U2, V1-V2 and W1-W2 are the corresponding phases of the two separate AC input

sources respectively.

5.

Also proper control and signal wire connections (Alarm relays, EPO etc.) should be made through the screw

terminal block shown in figure 11.

Note : These auxiliary cables must be shielded and double insulated.

(Recommended cross-section 1mm

2

)

6.

Reassemble the metal guard removed previously.

PROTECTIVE EARTH

The protective earth cable must be connected to the earth BUS BAR and bonded to each cabinets in the system

and also the earthing and neutral bonding arrangements must be in accordance with the local laws. Proper

grounding considerably reduces problems in systems caused by electromagnetic interference.

ATTENTION!!! Failure to follow adequate earthing procedures can result in electric shock

hazard to personnel, or the risk of fire

EMERGENCY POWER OFF

This isolated input is used to turn off the STS remotely in case of emergency.

The STS is supplied from the factory with the “Emergency Power Off ” (E.P.O.) terminals open-circuited ( see

“View of the STS connections”) if two (NO) terminals are shorted to each other STS shutdown the output

voltage.

In case of emergency ,by activating the stop device STS enters to stand-by mode and powers off the load

completely.

The E.P.O. circuit is self-powered ,no external power supply voltage is therefore required. If E.P.0. switch

pressed (at least 1 second) STS trips the signal.

- 17 -

USE

DESCRIPTION

The purpose of the STS is to select one of two input power lines which is in tolerant with predefined limits.

Users must decide that one of the input sources must have priority (preferred source) the other source is

alternate source. So the STS tries to stay at priority (preferred) source if this source in tolerant with predefined

values, if this source out of tolerant and the alternate source is in tolerant STS transfers the load to alternate

source. Always STS checks priority (preferred) source if it is in tolerant retransfers the load to priority (preferred)

source.

So before use the STS we must decide that which source is main (preferred) and which source is spare

(alternate).

IMPORTANT : Our STS are designed and produced for long life even under severest conditions. Remember

however that they are electrical power equipment items and as such are in need of periodic checks. Besides,

some components have a life cycle of their own and must therefore be checked at regular intervals and may

need to be replaced, where due to the conditions: in particular fans and some electrolytic capacitors.

It is recommended to implement a preventive maintenance program, using manufacturer authorized and trained

service personnel.

Our Technical Servicing department is at your disposal to discuss the different personalized preventive

maintenance options with you.

PRELIMINARY OPERATIONS

•Visual check of the connections

Check that all the connections have been made strictly following the indications given in the

“Connections” paragraph.

•Check that the following switch positions

S1 – input 1 MCCB 0 position (off)

S2 – input 2 MCCB 0 position (off)

S3 – output switch 0 position (off)

S4 – maintenance bypass switch 0 position (center)

Manual transfer switch auto position (center)

At this point there is no output voltage at the STS output terminals

POWERING ON FOR THE FIRST TIME

•Turn on input 1 power at external input power distribution box (apply power to input 1 terminals) . Measure

the voltages on terminals. (according to your local electricity nominals)

Phase to phase 400 volts AC ,Phase to neutral 230 volts AC.

•Turn on input 2 power at external input power distribution box (apply power to input 2 terminals) . Measure

the voltages on terminals. (according to your local electricity nominals)

Phase to phase 400 volts AC ,Phase to neutral 230 volts AC.

•Optional : If sources are synchronous to each other, Check that the phase sequency is matched between

two input sources (method: measure L1 phase to phase voltage between two sources, repeat this

measurement for L2 and L3 phases if the measured AC voltages is minimum the phases of two input

sources are matched.)

•Turn on S1 (1 position) wait and see the STS control panel activated and shows some messages (source 2

BAD ,output switch off messages are normal)

•Turn on S2 (1 position) wait and see only output switch off message is showed on the control panel.

•At this point according to your application you must select some user options from OPTIONS MENU of the

control panel. You need password to change options. The factory default password is “0000” 4 zeros ,you

can change the factory password after you logged in.(STS front panel functions)

•After you setup some options you can turn on S3 output switch (1 position)

•See that there is no alarm message or alarm sound on the STS

- 18 -

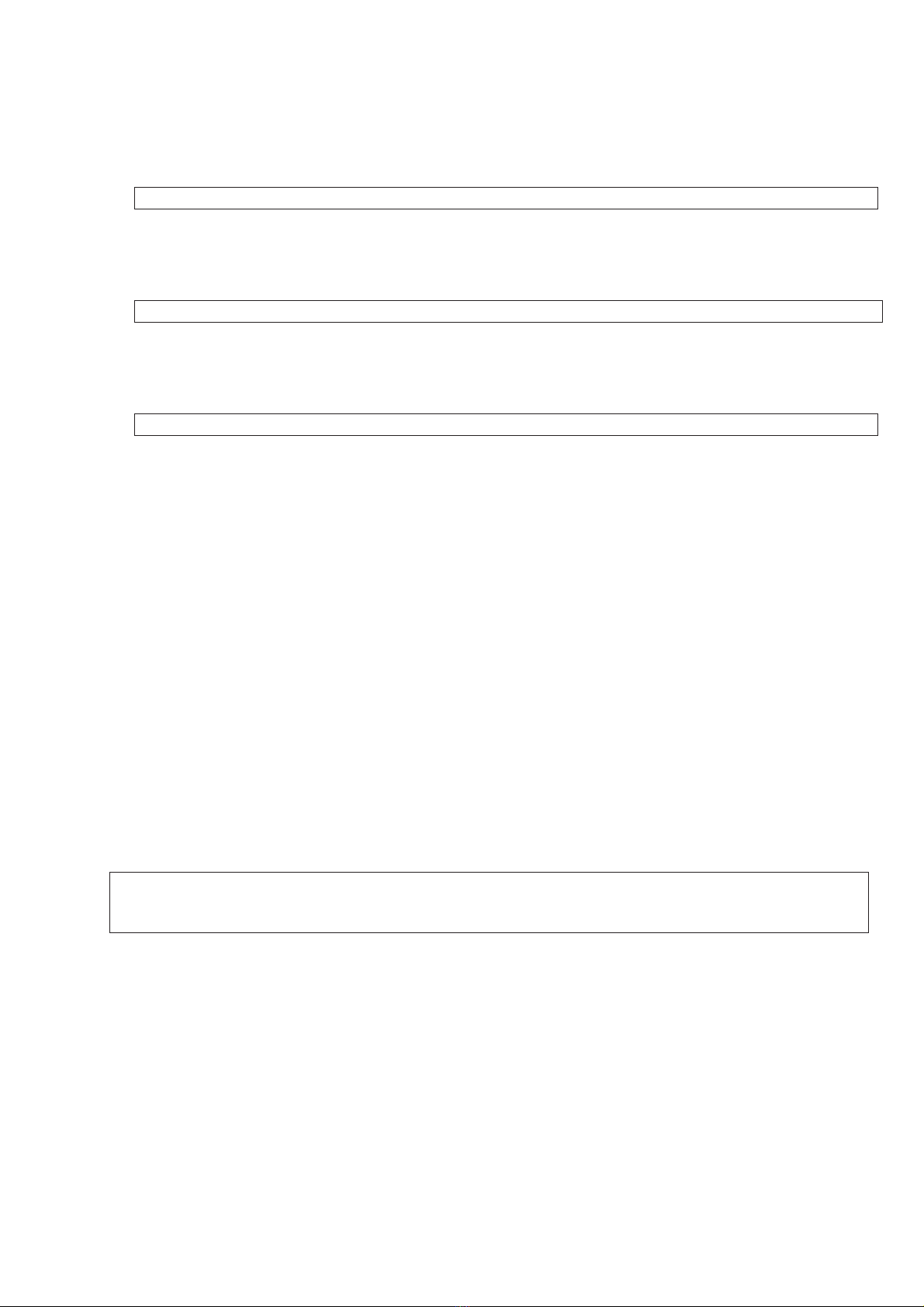

Switching On (Normal Operation) The STS From Off Position

1.

Ensure again that the Maintenance Bypass Switch (S4) is in “0” position and it is locked for safety.

1) Ensure that maintenance bypass switch (S4)

is in 0 position (center)

2) Turn on input switches (1 position) S1 and S2.

The STS control circuits will be energized and

will start functioning.

3) Select your “PREFERRED” source. (Default

factory setting is Source 1). You can change

your selection using the SETTINGS MENU

4) Check from the mimic diagram on the control

panel, that the static switch of the preferred

source is turned on (either SS1 or SS2).

5) Then turn on the output switch S3, to apply

power to the load connected to the output of

the STS

6) See there is no alarm on LCD display

7) STS unit is now ready to use

- 19 -

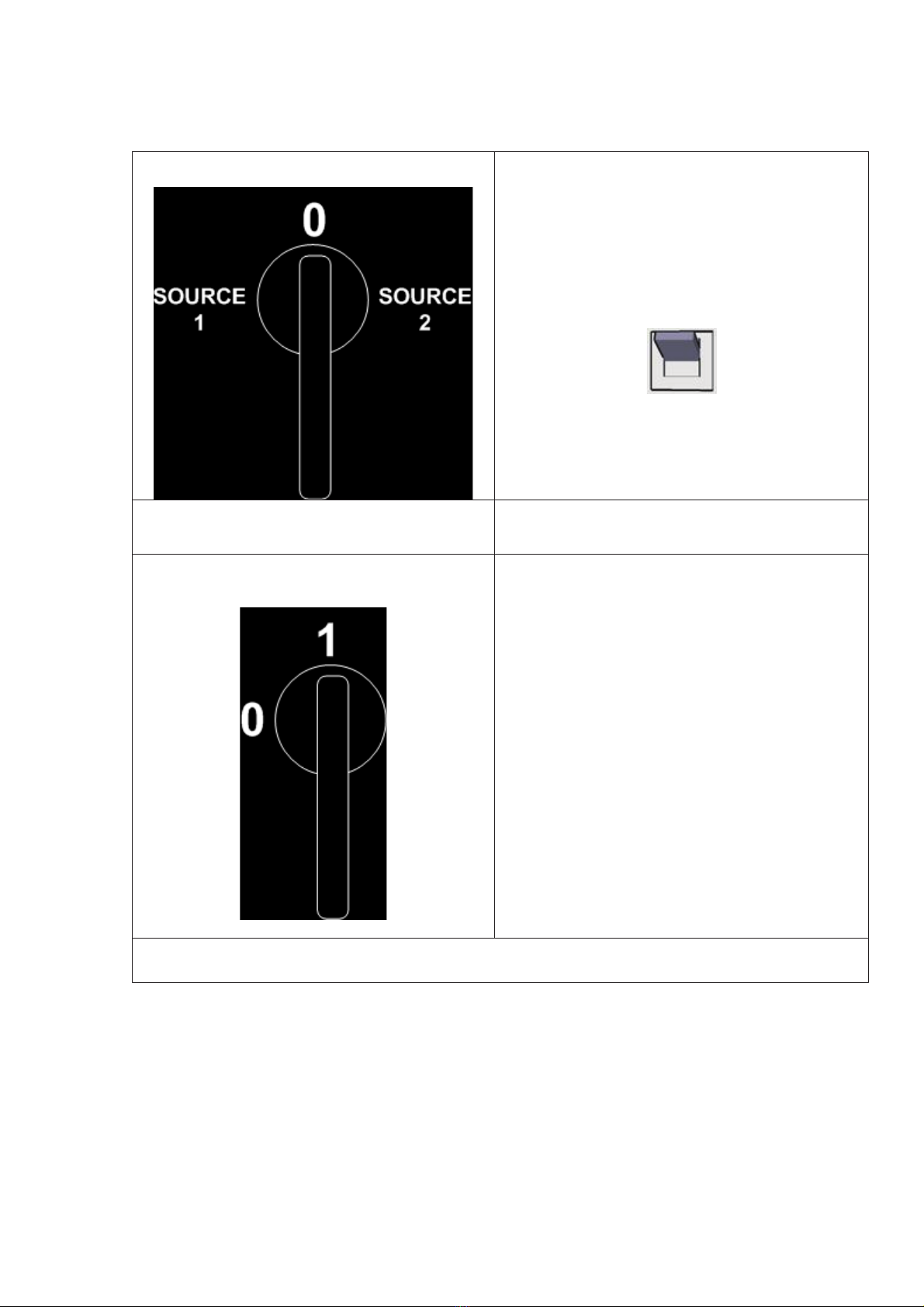

Switching To Maintenance Bypass Position From Normal (automatic) Operation

1) Select the input source which is going to supply the

load during maintenance, and turn the manual

XFER switch S6 to this selected source (either

Source 1 or Source 2)

2) Follow on the mimic diagram that the load is

switched to the source selected by the manual

XFER switch S6

3) Then turn the Maintenance Bypass Switch (S4) to

the selected source for maintenance. See the

maintenance bypass message on the LCD panel

4) Turn off the output switch S3. This switch

disconnects the static transfer switches SS1 and

SS2 from the STS output, but the load continues to

work on maintenance bypass line

5) Turn off the input switches S1 and S2

6) Now, the unit is ready for maintenance

This manual suits for next models

12

Table of contents

Other inform UPS manuals

inform

inform Informer 1000VA User manual

inform

inform Informer Compact Series User manual

inform

inform GUARDIAN User manual

inform

inform SAVER PLUS DSP SERIES User manual

inform

inform PDSP31010 User manual

inform

inform Pyramid Plus Specification sheet

inform

inform 500 User manual

inform

inform Pyramid DSP T Specification sheet

inform

inform PYRAMID DSP PREMIUM Series User manual

inform

inform Guard 500VA User manual