Infranor XtrapulsCD1-EM-400/70 User manual

XtrapulsCD1-EM-400/70-90

Drives for

AC servo motors

in embedded

applications

2

CD1-EM-400/70-90 servo drive

WARNING

This is a general manual describing a series of servo drives having output capability suitable for driving AC

brushless sinusoidal servo motors.

Instructions for storage, use after storage, commissioning as well as all technical details require the

MANDATORY reading of the manual before getting the drives operational.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60204-1 standard) and using proper test

equipment.

The conformity with the standards and the "CE" approval is only valid if the items are installed according to the

recommendations of the drive manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

© INFRANOR, February 2013. All rights reserved.

Issue: 2.4

!

Any contact with electrical parts, even after power down, may involve physical damage.

Wait for at least 5 minutes after power down before handling the drives (a residual voltage of several

hundreds of volts may remain during a few minutes).

ESD INFORMATION (ElectroStatic Discharge)

INFRANOR drives are conceived to be best protected against electrostatic discharges. However,

some components are particularly sensitive and may be damaged if the drives are not properly stored

and handled.

STORAGE

- The drives must be stored in their original package.

- When taken out of their package, they must be stored positioned on one of their flat metal

surfaces and on a dissipating or electrostatically neutral support.

- Avoid any contact between the drive connectors and material with electrostatic potential

(plastic film, polyester, carpet…).

HANDLING

- If no protection equipment is available (dissipating shoes or bracelets), the drives must be

handled via their metal housing.

-

Never get in contact with the connectors.

ELIMINATION

In order to comply with the 2002/96/EC directive of the European Parliament and of the Council of

27 January 2003 on waste electrical and electronic equipment (WEEE), all INFRANOR devices

have got a sticker symbolizing a crossed-out wheel dustbin as shown in Appendix IV of

the 2002/96/EC Directive.

This symbol indicates that INFRANOR devices must be eliminated by selective disposal and not

with standard waste.

3

CD1-EM-400/70-90 servo drive

Content

Content

Page

CONTENT ............................................................................................................................................... 3

CHAPTER 1 – GENERAL DESCRIPTION............................................................................................. 4

1.1 -INTRODUCTION.......................................................................................................................... 4

1.2 -OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING ............................................. 4

1.3 -ORDERING CODES .................................................................................................................... 5

CHAPTER 2 – SPECIFICATIONS.......................................................................................................... 6

CHAPTER 3 – MECHANICAL DATA..................................................................................................... 8

3.1 -DRIVE DIMENSIONS................................................................................................................... 8

3.2 -CABINET LAYOUT....................................................................................................................... 9

CHAPTER 4 - CONNECTIONS ............................................................................................................ 10

4.1 -DRIVE CONNECTION ............................................................................................................... 10

4.2 -MOTOR CONNECTION............................................................................................................. 10

CHAPTER 5 – SETUP & OPERATION................................................................................................ 11

CHAPTER 6 - FAN SPECIFICITIES..................................................................................................... 12

6.1 -FAN SPEED CONTROL............................................................................................................. 12

6.2 -FAN REPLACEMENT PROCEDURE ........................................................................................ 13

4

Chapter 1 - General description

CD1-EM-400/70-90 servo drive

Chapter 1 – General description

1.1 - INTRODUCTION

XtrapulsCD1-EM-400/70-90 all-digital drives with sinusoidal PWM control are servo drives that provide the control

of servo motors equipped with a position sensor. They can be configured for various position sensor types

(resolver, incremental encoder, absolute encoder). The appropriate position sensor configuration is selectable by

software and saved in the drive.

XtrapulsCD1-EM-400/70-90 drives power supply is 400 to 480 VAC three-phase mains. A soft start system of the

power supply allows to limit the inrush current at power on. The maximum output current is available during 1

second. The drive rated output current is the current value available for permanent operation.

The EM version of the CD1-400/70-90 drive is dedicated to embedded applications. This version differs from the

standard CD1-400/70-90 regarding the rugged mechanical housing and the modified mechanical mounting.

- The push through mounting allows to push the heatsink and the air forced cooling outside the electric cabinet.

- The flat fastening of the drive according to the larger surface area allows to improve its rigidity to shocks and

vibrations.

The CD1a-EM-400/70-90 version is dedicated to applications with ± 10 V analog input command. The CD1k-EM-

400/70-90 version is to be used in applications with input command via CAN fieldbus and is based on CANopen

DSP402 protocol. The CD1pm-EM-400/70-90 version is to be used in stand-alone positioning applications or with

input command via PROFIBUS fieldbus.

1.2 - OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING

Only the information specific to the EM-400/70-90 version of the XtrapulsCD1 drives can be found in this

document. Please refer to the standard XtrapulsCD1 range manuals for the complete information:

CD1-a servo drive manual,

CD1-k Installation Guide,

CD1-k User Guide,

CANopen Communication Protocol for CD1-k drives,

CD1-pm Installation Guide,

CD1-pm User Guide,

PROFIBUS Communication Protocol for CD1pm drives.

5

Chapter 1 - General description

CD1-EM-400/70-90 servo drive

1.3 - ORDERING CODES

1.3.1 – DRIVE ORDERING CODE

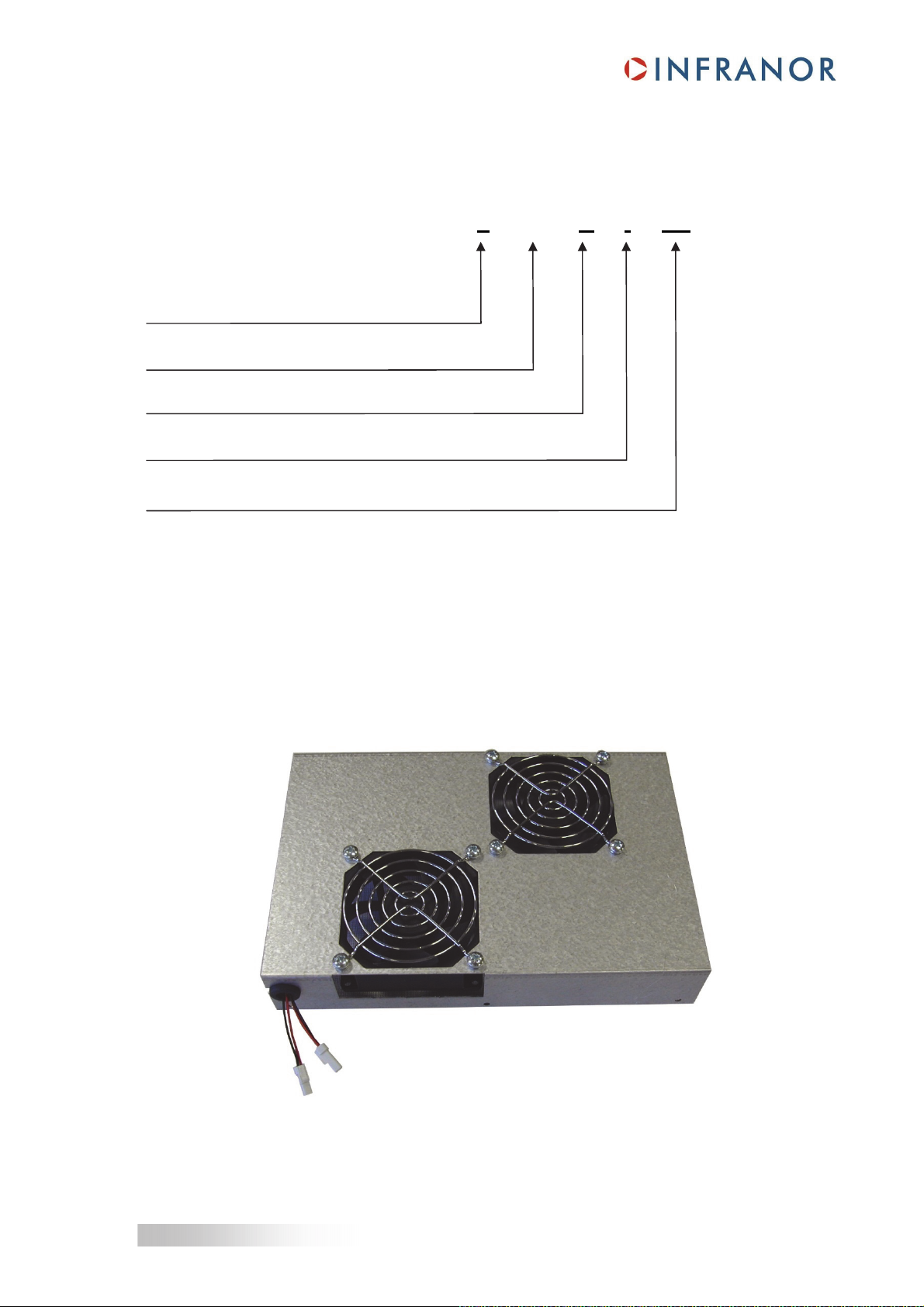

1.3.2 - FAN REPLACEMENT KIT

FAN CD1 - EM - 90

The fan replacement kit consists in the complete fan carter, equipped with fans, grids and connectors:

XTRAPULS CD1 - x - EM - U / I - CT

a: +/- 10 V analog interface

k: CANopen interface

pm: Profibus interface

EM: Embedded applications

U: 400: 400/480 Vac voltage rating

I: 70 / 90 Arms current ratings

CT: "Cogging torque compensation" option

6

Chapter 2 - Specifications

CD1-EM-400/70-90 servo drive

Chapter 2 – Specifications

Operating power supply voltage - 400 to 480 VAC + 10 %/- 15 % 3~ mains, TN or

TT system with earthed neutral point, 50 - 60 Hz

(Phase/Ground voltage must be balanced)

- 140 to 700 Vdc DC link power supply

Auxiliary logic and motor brake supply voltage 24 Vdc +/-15 % - 320 mA without brake

Motor RMS output voltage 95 % Udc/√2

Integrated braking system External resistor: 16.5 Ω/560 W (EF 400)

Output current ratings

Model

Max. output

current (Arms)

for 1 sec.

+/- 5 %

Rated

output

current

(Arms)

Power

losses

(W)

Rated input

current (Arms)

(400 VAC,

60 Hz)

Max. protection

fuses for line circuit

A60Q40 listed

Short-

circuit

power of

the mains

UL listed

CD1-EM-400/70 70 35 650 35 40 A 5 kA

No

CD1-EM-400/90 90 35 650 35 40 A 5 kA

No

Mains filter on power supply - Integrated EMC capacitors

- External common mode choke

- Recommended filter: F-400-70-90

Standard undervoltage threshold 140 Vdc

Standard braking threshold 790 Vdc

Standard overvoltage threshold 910 Vdc

Common mode filter on auxiliary supply Integrated in the drive

Common mode filter on motor brake supply Integrated in the drive

Motor brake control Open collector output protected against load short-circuit.

2 A maximum with 24 Vdc.

Compliance with the standards: CE certification.

360° shield connection, equipotentiality according

to the wiring rules and mains filter F-400-70/90.

EMC standards:

- immunity: EN 61000.4-2-3-4-5

- conducted and radiated disturbances: EN 55011, Group 1,

C3 category

Electrical standards for industrial machines:

- EN 60204-1: insulator 1500 Vac / 1 mn

leakage current > 30 mA (EMI filters).

Temperature

Storage: -20° C to +70° C

Operation: +5° C to +60° C

Altitude 1000 m

Moisture < 50% at 40° C and < 90% at 20° C: EN 60204-1 standard

Condensation prohibited (storage and operation)

Cooling Forced air (fan integrated in the drive).

Environment - Electronic part is IP20: it must be mounted in a housing

protecting the drive from conducting dust and condensation

(pollution degree 2 environment).

- Heatsink part is IP64: it is protected against dust and

splashed water. Periodic replacement is necessary,

according to the environment

7Chapter 2 -Specifications

CD1-EM-400/70-90 servo drive

Mounting location Closed cabinet without any conducting and/or corroding

agents and according to the environment conditions

requirements

Condensation prohibited inside the cabinet

Weight Approximately 8 kg

8Chapter 3 – Mechanical data

CD1-EM-400/70-90 servo drive

Chapter 3 – Mechanical data

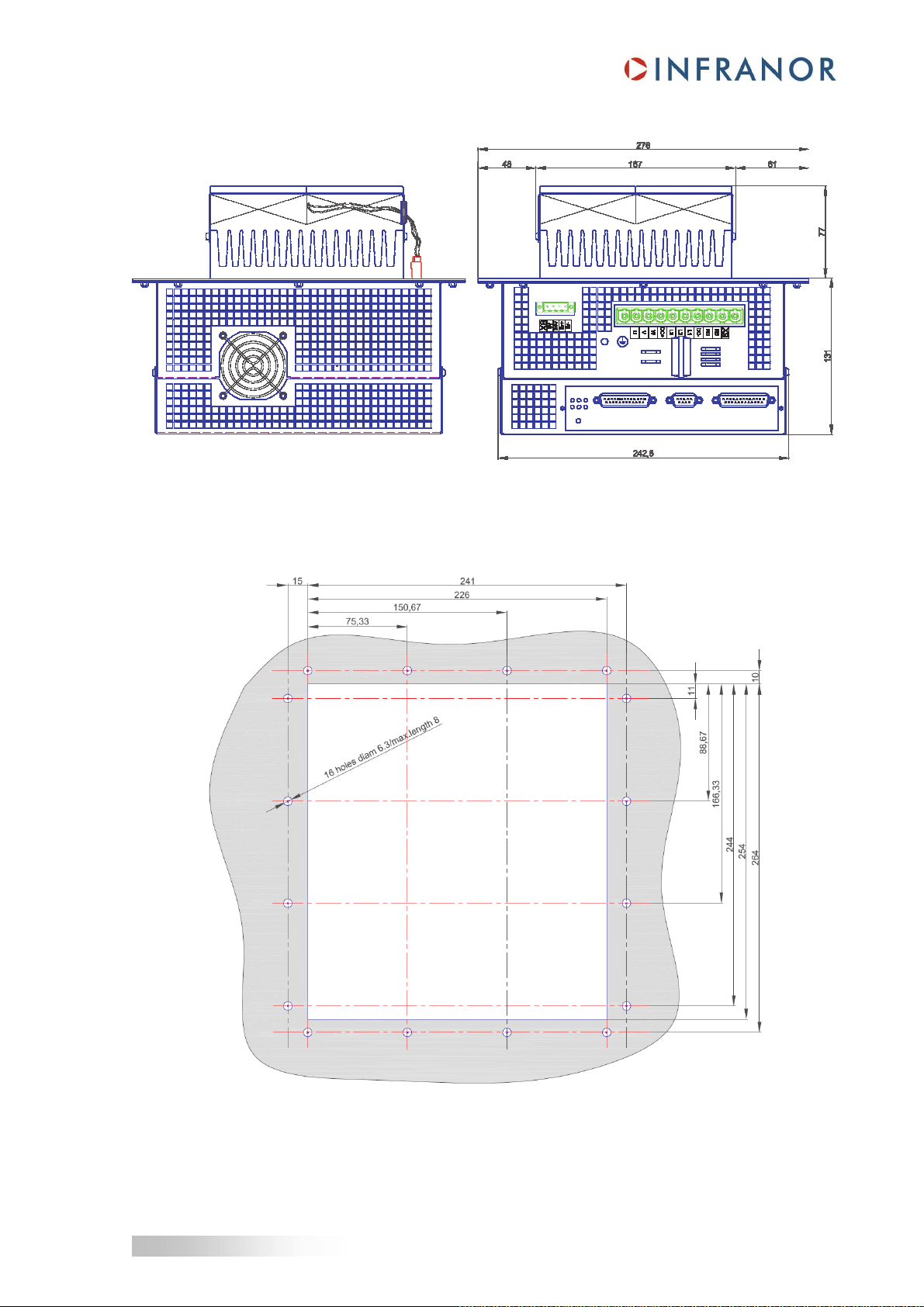

3.1 - DRIVE DIMENSIONS

FRONT VIEW

'A' VIEW 'B' VIEW

9

Chapter 3 – Mechanical data

CD1-EM-400/70-90 servo drive

'C' VIEW 'D' VIEW

3.2 - CABINET LAYOUT

It is highly recommended to place a silicone seal around the cut-out in order to avoid any entry of dust or humidity

inside the cabinet.

Recommended silicone reference: CAF530

Manufacturer: BLUESTAR SILICONES

10

CD1-EM-400/70-90 servo drive

Chapter 4 – Connections

Chapter 4 - Connections

4.1 - DRIVE CONNECTION

For complete information about the XtrapulsCD1-a, CD1-k or CD1-pm servo drive connections, please see the

pertaining installation manuals.

4.2 - MOTOR CONNECTION

Take great care about the motor connections:

- Connect the shield on the drive just before the ferrite core, preferably with a metallic collar,

- The motor phases run through the ferrite core to be connected on U, V and W outputs.

- The ground wire runs outside the ferrite core to be connected on the ground screw.

- The brake wires run outside the ferrite core to be connected on the Br+ and Br- outputs.

11

Chapter 5 – Setup & Operation

CD1-EM-400/70-90 servo drive

Chapter 5 – Setup & Operation

The Visual Drive Setup software is PC compliant under Windows® 1and allows an easy parameter setting of the

XtrapulsCD1 drive range. Please see our website www.infranor.com for downloading this software.

For information about the XtrapulsCD1-a, CD1-k or CD1-pm servo drive setup, commissioning and operation,

please see the appropriate manuals.

1Windows®is a registered trade mark of MICROSOFT®CORPORATION

12

CD1-EM-400/70-90 servo drive

Chapter 6 – Fan specificities

Chapter 6 - Fan specificities

6.1- FAN SPEED CONTROL

In order to increase the lifetime of fans, their rotation speed is controlled according to the motor

current.

A detailed description is available in the following diagram:

IMOTOR

(A)

t (s)

Fans

speed

5%.IMA

X

15%.IMA

X

100%

60%

100

t (s)

100 100

13

CD1-EM-400/70-90 servo drive

Chapter 6 - Fan specificities

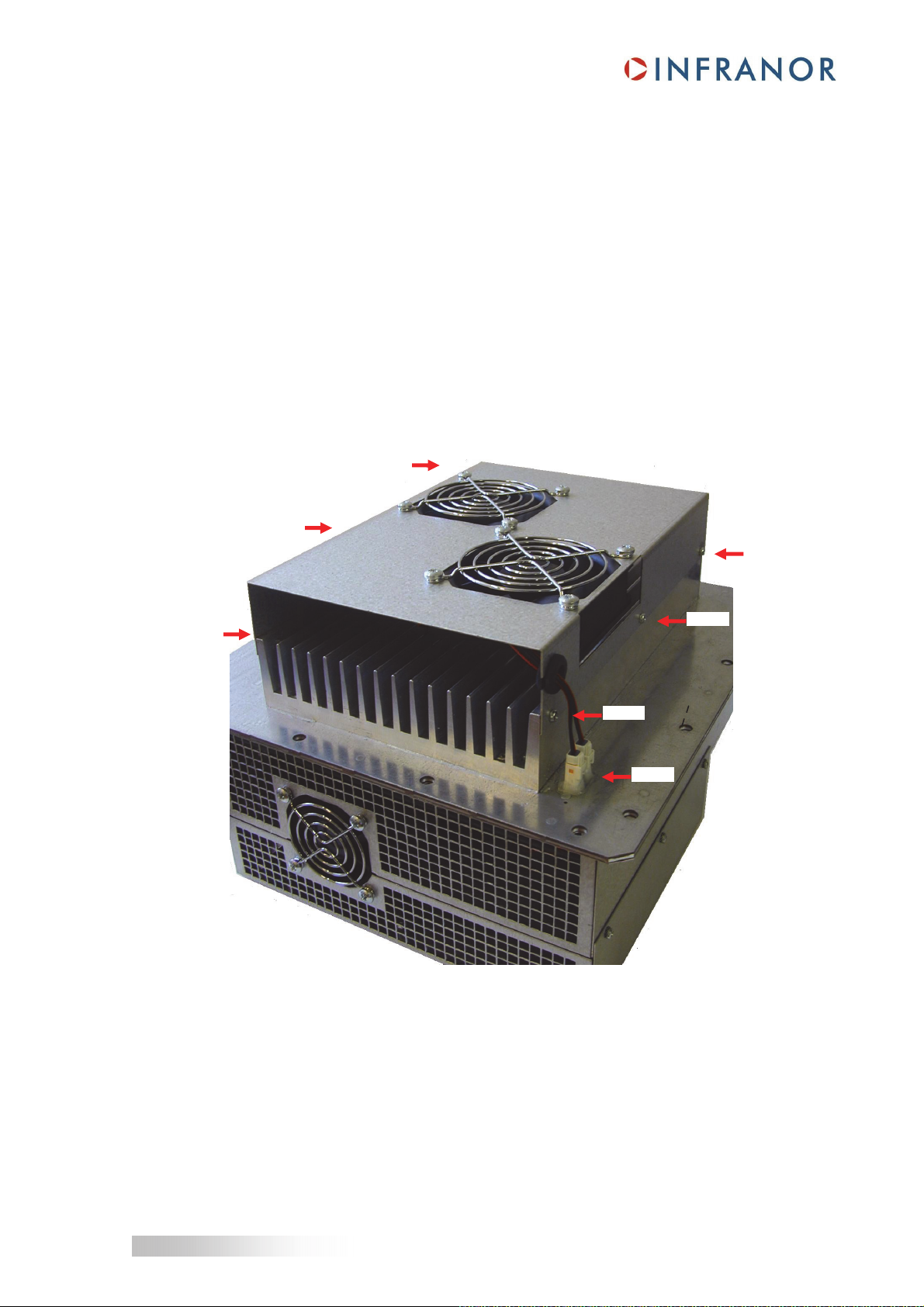

6.2 - FAN REPLACEMENT PROCEDURE

The drive is provided with two fans external to the cabinet.

These fans are developed to work in hard conditions and have a life expectancy of:

50'000 hours at 25°C, 65 % humidity, 90 % CL.

Although the lifetime greatly depends on the real environment where the drive is working, it is advised to replace

fans at least every 3 years.

To replace fans, proceed as follows:

1. Disable the drive

2. Switch off the power supply (power & auxiliary supplies) of the drive

3. Disconnect both fans

4. Remove the 6 screws fixing the fan carter

5. Mount the new fan carter with the 6 screws

6. Connect the two fans

7. Restart the drive.

4 & 5

4 & 5

4 & 5

4 & 5

4 & 5

4 & 5

3 & 6

This manual suits for next models

1

Table of contents

Other Infranor DC Drive manuals

Popular DC Drive manuals by other brands

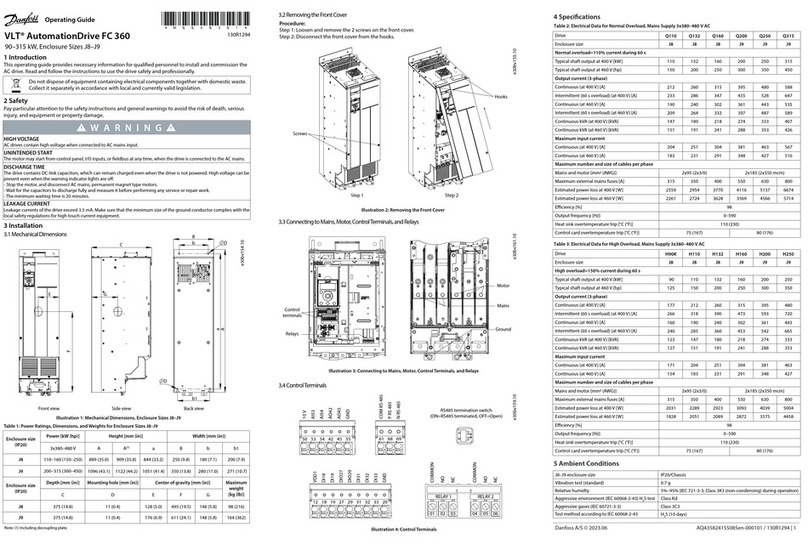

Danfoss

Danfoss VLT FC 103 Design guide

Danfoss

Danfoss VLT AutomationDrive FC 360 operating guide

Addonics Technologies

Addonics Technologies AD25MSD user guide

Fuji Electric

Fuji Electric Frenic lift Reference manual

Allen-Bradley

Allen-Bradley PowerFlex 70 installation instructions

ABB

ABB ACS880-07 user manual