Infranor XtrapulsCD1-k User manual

CD1-k 1

CANopen

Communication Profile

XtrapulsCD1-k

CANopen Drive

2

CD1-k CANopen Communication Profile

WARNING

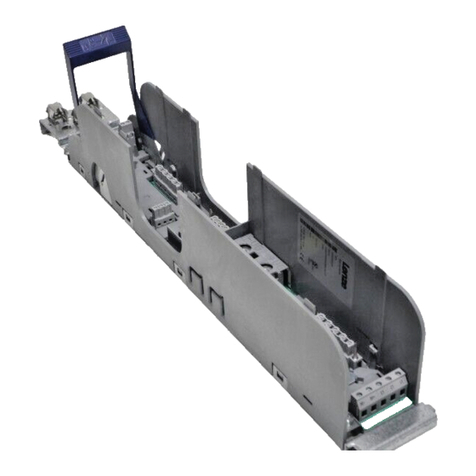

This is a general manual describing the CANopen Communication Profile of the INFRANOR CD1-k drive

(hardware release version 2.0 and firmware release from version 11.E3). For the installation and commissioning of

the drive, please refer to the appropriate manuals (CD1-k Installation Guide and CD1k User Guide).

Instructions for storage, use after storage, commissioning as well as all technical details require the

MANDATORY reading of the manual before getting the amplifiers operational.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60204-1 standard) and using proper test

equipment.

The compliance with the standards and the "CE" approval is only valid if the items are installed according to the

recommendations of the amplifier manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

INFRANOR does not assume any responsibility for physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

©INFRANOR,October 2014. All rights reserved.

Issue: 2.10.1

!

ELIMINATION

In order to comply with the 2002/96/EC directive of the European Parliament and of the Council of

27 January 2003 on waste electrical and electronic equipment (WEEE), all INFRANOR devices

have got a sticker symbolizing a crossed-out wheel dustbin as shown in Appendix IV of

the 2002/96/EC Directive.

This symbol indicates that INFRANOR devices must be eliminated by selective disposal and not

with standard waste.

Any contact with electrical parts, even after power down, may involve severe physical damage.

Wait for at least 5 minutes after power down before handling the amplifiers (a residual voltage of several

hundreds of volts may remain during a few minutes).

ESD INFORMATION (ElectroStatic Discharge)

INFRANOR amplifiers are conceived to be best protected against electrostatic discharges. However,

some components are particularly sensitive and may be damaged if the amplifiers are not properly

stored and handled.

STORAGE

- The amplifiers must be stored in their original package.

- When taken out of their package, they must be stored positioned on one of their flat metal

surfaces and on a dissipating or electrostatically neutral support.

- Avoid any contact between the amplifier connectors and material with electrostatic potential

(plastic film, polyester, carpet…).

HANDLING

- If no protection equipment is available (dissipating shoes or bracelets), the amplifiers must

be handled via their metal housing.

- Never get in contact with the connectors.

3

Conten

t

CD1

-

k

–

CANopen Communication Profile

Content

CHAPTER 1 – OVERVIEW..................................................................................................................... 8

3.13 -REFERENCE ............................................................................................................................ 8

1.2 -DEFINITIONS................................................................................................................................... 8

1.3 -ARCHITECTURE............................................................................................................................... 9

CHAPTER 2 – COMMUNICATION PROFILE...................................................................................... 10

2.1 -COMMUNICATION OBJECTS ........................................................................................................... 10

2.1.1 - CAN Telegram..................................................................................................................... 10

2.1.2 - Default COB-ID.................................................................................................................... 10

2.1.3 - Network Management Objects (NMT)................................................................................. 11

2.1.4 - Synchronisation Object (SYNC).......................................................................................... 11

2.1.5 - Process Data Object (PDO) ................................................................................................ 12

2.1.5.1 - Communication parameters.......................................................................................................... 12

2.1.5.2 - PDO Mapping ............................................................................................................................... 13

2.1.5.3 - Multiplexed data............................................................................................................................ 13

2.1.6 - Service Data Object (SDO) ................................................................................................. 13

2.1.7 - Emergency Object (EMCY)................................................................................................. 14

2.1.7.1 - CD1-k Specific Error Field ............................................................................................................ 14

2.2 -NETWORK INITIALISATION AND SYSTEM BOOT-UP ........................................................................... 15

2.2.1 - NMT State machine............................................................................................................. 15

2.2.2 - Initialisation procedure......................................................................................................... 15

2.3 -OBJECT DICTIONARY..................................................................................................................... 16

2.3.1 - General information............................................................................................................. 16

2.3.1.1 - Object 1000h: Device Type........................................................................................................... 16

2.3.1.2 - Object 1001h: Error Register ........................................................................................................ 16

2.3.1.3 - Object 1008h: Manufacturer Device Name ................................................................................... 16

2.3.1.4 - Object 1009h: Manufacturer hardware version ............................................................................. 16

2.3.1.5 - Object 100Ah: Manufacturer software version .............................................................................. 17

2.3.1.6 - Object 100Ch: Guard Time........................................................................................................... 17

2.3.1.7 - Object 100Dh: Life Time factor ..................................................................................................... 17

2.3.1.8 - Object 1010h: Store Parameters .................................................................................................. 17

2.3.1.9 - Object 1018h: Identity Object........................................................................................................ 18

2.3.2 - Sync Object ......................................................................................................................... 18

2.3.2.1 - Object 1005h: COB-ID Sync message.......................................................................................... 18

2.3.2.2 - Object 1006h: Communication Cycle Period ................................................................................ 18

2.3.2.3 - Object 3006h: Communication Cycle Period adjustment .............................................................. 19

2.3.2.4 - Object 1007h: Synchronous Window Length ................................................................................ 20

2.3.3 - SDO Objects........................................................................................................................ 20

2.3.3.1 - Object 1200h: Server SDO Parameter ......................................................................................... 20

2.3.4 - Emergency Object............................................................................................................... 20

2.3.4.1 - Object 1014h: COB-ID Emergency message ............................................................................... 20

2.3.5 - PDO Objects........................................................................................................................ 21

2.3.5.1 - Object 1400h: 1st Receive PDO Communication Parameter......................................................... 21

2.3.5.2 - Object 1401h: 2nd Receive PDO Communication Parameter........................................................ 21

2.3.5.3 - Object 1402h: 3rd Receive PDO Parameter .................................................................................. 22

2.3.5.4 - Object 1600h: 1st Receive PDO Mapping ..................................................................................... 22

2.3.5.5 - Object 1601h: 2nd Receive PDO Mapping .................................................................................... 23

2.3.5.6 - Object 1602h: 3rd Receive PDO Mapping ..................................................................................... 23

2.3.5.7 - Object 1800h: 1st Transmit PDO Parameter ................................................................................. 24

2.3.5.8 - Object 1801h: 2nd Transmit PDO Parameter ................................................................................ 24

2.3.5.9 - Object 1802h: 3rd Transmit PDO Parameter ................................................................................. 25

2.3.5.10 - Object 1A00h: 1st Transmit PDO Mapping.................................................................................. 25

2.3.5.11 - Object 1A01h: 2nd Transmit PDO Mapping ................................................................................. 26

2.3.5.12 - Object 1A02h: 3rd Transmit PDO Mapping.................................................................................. 26

4Conten

t

CD1

-

k

–

CANopen Communication Profile

CHAPTER 3 – DEVICE PROFILE........................................................................................................ 27

3.1 -PDO MAPPING ............................................................................................................................. 27

3.1.1 - Receive PDO....................................................................................................................... 27

3.1.2 - Transmit PDO...................................................................................................................... 27

3.2 -COMMON ENTRIES IN THE OBJECT DICTIONARY.............................................................................. 27

3.2.1 - Object Dictionary Entries..................................................................................................... 27

3.2.2 - Object Description ............................................................................................................... 27

3.2.2.1 - Object 6402h: Motor Type ............................................................................................................ 27

3.2.2.2 - Object 6410h: Motor Data............................................................................................................. 28

3.2.2.3 - Object 6502h: Supported Drive Modes ......................................................................................... 29

3.2.2.4 - Object 6504h: Drive Manufacturer ................................................................................................ 30

3.2.2.5 - Object 6510h: Drive Data.............................................................................................................. 30

3.2.2.6 - Object 60FDh: Digital Inputs ......................................................................................................... 31

3.2.2.7 - Object 60Feh: Digital Outputs....................................................................................................... 31

3.2.2.8 - Object 30FFh: Specific Outputs Configuration.............................................................................. 32

3.3 -DEVICE CONTROL ......................................................................................................................... 33

3.3.1 - Drive State Machine ............................................................................................................ 33

3.3.2 - Object Dictionary Entries..................................................................................................... 33

3.3.3 - Object Description ............................................................................................................... 34

3.3.3.1 - Object 6040h: Control Word ......................................................................................................... 34

3.3.3.2 - Object 6041h: Status Word........................................................................................................... 35

3.3.3.3 - Object 605Ah: Quick Stop Option Code........................................................................................ 36

3.3.3.4. Object 6060h: Mode of Operation .................................................................................................. 36

3.3.3.5. Object 6061h: Mode of Operation Display ..................................................................................... 36

3.4 –POSITION SENSOR GROUP............................................................................................................ 37

3.4.1 - Units..................................................................................................................................... 37

3.4.2 - Presentation......................................................................................................................... 37

3.4.3 - Object Dictionary Entries..................................................................................................... 37

3.4.4 - Object Description ............................................................................................................... 37

3.4.4.1 - Object 607Eh: Polarity .................................................................................................................. 37

3.4.4.2 - Object 608Fh: Position Resolution................................................................................................ 38

3.4.4.3 - Object 3080h: Encoder Input Selection......................................................................................... 39

3.4.4.4 - Object 308Fh: Encoder Input Resolution ...................................................................................... 39

3.4.4.5 - Object 3090h: Encoder Pulse Interpolation................................................................................... 39

3.4.4.6 - Object 3091h: Encoder Zero Mark Pitch....................................................................................... 40

3.4.4.7 - Object 3070h: Motor Feedback Selection ..................................................................................... 40

3.4.4.8 - Object 3098h: Motor Feedback Programming .............................................................................. 41

3.4.4.9 - Object 306Ah: Second Sensor Feedback ..................................................................................... 41

3.4.4.10 - Object 306Ch: Second Sensor Scaling factor............................................................................. 41

3.5 -PROFILE POSITION MODE.............................................................................................................. 42

3.5.1 - Object Dictionary Entries..................................................................................................... 42

3.5.2 - Object Description ............................................................................................................... 42

3.5.2.1 - Object 607Ah: Target Position ...................................................................................................... 42

3.5.2.2 - Object 6080h: Max Motor Speed .................................................................................................. 42

3.5.2.3 - Object 6081h: Profile Velocity....................................................................................................... 43

3.5.2.4 - Object 6082h: End Velocity........................................................................................................... 43

3.5.2.5 - Object 6083h: Profile Acceleration................................................................................................ 43

3.5.2.6 - Object 6084h : Profile Deceleration .............................................................................................. 43

3.5.2.7 - Object 6086h: Motion Profile Type................................................................................................ 44

3.5.2.8 - Object 607Dh: Software Position Limit.......................................................................................... 44

3.5.2.9 - Object 6067h: Position Window .................................................................................................... 45

3.5.2.10 - Object 307Fh: Position Modulo................................................................................................... 45

3.5.3 - Functional Description......................................................................................................... 45

3.6 -HOMING MODE ............................................................................................................................. 47

3.6.1 - Object Dictionary Entries..................................................................................................... 47

3.6.2 - Object Description ............................................................................................................... 47

3.6.2.1 - Object 607Ch: Homing Offset ....................................................................................................... 47

3.6.2.2 - Object 6098h: Homing Method ..................................................................................................... 47

3.6.2.3 - Object 6099h: Homing Speeds ..................................................................................................... 49

3.6.2.4 - Object 609Ah: Homing Acceleration ............................................................................................. 49

3.6.2.5 - Object 309Bh: Zero Shift .............................................................................................................. 49

3.6.2.6 - Object 309Ch: Homing Current Limit ............................................................................................ 50

3.6.3 - FUNCTIONAL DESCRIPTION............................................................................................ 50

5

Conten

t

CD1

-

k

–

CANopen Communication Profile

3.7 -POSITION CONTROL FUNCTION...................................................................................................... 51

3.7.1 - Object Dictionary Entries..................................................................................................... 51

3.7.2 - Object Description ............................................................................................................... 51

3.7.2.1 - Object 6063h: Position Actual Value* ........................................................................................... 51

3.7.2.2 - Object 6064h: Position Actual Value............................................................................................. 51

3.7.2.3 - Object 3067h: Position Loop Deadband ....................................................................................... 51

3.7.2.4 - Object 6065h: Following Error Window......................................................................................... 52

3.7.2.5 - Object 3031h: Position Following Error Dynamic Gain ................................................................. 52

3.7.2.6 - Object 3033h: Position Following Error Detection Mode............................................................... 52

3.7.2.7 - Object 3214h: Position Error......................................................................................................... 53

3.7.2.8 - Object 60FBh: Position Control Parameter Set............................................................................. 54

3.8 -INTERPOLATED POSITION MODE .................................................................................................... 55

3.8.1 - Object Dictionary Entries..................................................................................................... 55

3.8.2 - Object Description ............................................................................................................... 56

3.8.2.1 - Object 60C0h: Interpolation Submode Select ............................................................................... 56

3.8.2.2 - Object 60C1h: Interpolation Data Record ..................................................................................... 56

3.8.2.3 - Object 60C4h: Interpolation Data Configuration ........................................................................... 57

3.9 -PROFILE VELOCITY MODE ............................................................................................................. 58

3.9.1 - Object Dictionary Entries..................................................................................................... 58

3.9.2 - Object Description ............................................................................................................... 58

3.9.2.1 - Object 6069h: Velocity Sensor Actual Value................................................................................. 58

3.9.2.2 - Object 606Ah: Sensor Selection Code.......................................................................................... 59

3.9.2.3 - Object 606Bh: Velocity Demand Value ........................................................................................ 59

3.9.2.4 - Object 606Ch: Velocity Actual Value ............................................................................................ 59

3.9.2.5 – Object 606Dh: Velocity window.................................................................................................... 59

3.9.2.6 – Object 606Eh: Velocity window time ............................................................................................ 59

3.9.2.7 – Object 606Fh: Velocity threshold ................................................................................................. 60

3.9.2.8 – Object 6070h: Velocity threshold time.......................................................................................... 60

3.9.2.9 - Object 60FFh: Target Velocity ...................................................................................................... 60

3.9.2.10 - Object 604Fh: Ramp Function .................................................................................................... 60

3.9.2.11 - Object 60F9h: Velocity Control Parameter Set ........................................................................... 61

3.9.2.12 – Object 30F9h: Integrator low frequency limit .............................................................................. 62

3.9.2.13 - Object 30FBh: Regulator Gains Scaling ..................................................................................... 63

3.9.2.14 - Object 3422h: Time Interval for speed measurement ................................................................. 63

3.9.2.15 - Object 30F5h: Speed Following Error Limit ................................................................................ 63

3.10 -PROFILE TORQUE MODE ............................................................................................................. 63

3.10.1 - Object Dictionary Entries................................................................................................... 63

3.10.2 - Object Description ............................................................................................................. 64

3.10.2.1 - Object 6071h: Target Torque...................................................................................................... 64

3.10.2.2. Object 6087h: Torque Slope ........................................................................................................ 64

3.10.2.3 - Object 6088h: Torque profile type............................................................................................... 64

3.10.2.4 - Object 60F6h: Torque Control Parameter Set ............................................................................ 64

3.10.2.5 - Object 6078h: Filtered current monitor........................................................................................ 65

3.10.2.6 - Object 3078h: Current monitor filter............................................................................................ 65

3.11 –STEPPER EMULATION MODE....................................................................................................... 66

3.11.1 - Functional Description....................................................................................................... 66

3.11.2 – Parameter Setting............................................................................................................. 66

3.12 –ELECTRONIC GEARING MODE ..................................................................................................... 66

3.12.1 - Functional Description....................................................................................................... 67

3.12.2 – Parameter Setting............................................................................................................. 67

3.13 -MANUFACTURER DEVICE SPECIFIC .............................................................................................. 68

3.13.1 - Object Dictionary Entries................................................................................................... 68

3.13.2 - Error and Stop Function .................................................................................................... 69

3.13.2.1 - Object 3020h: Drive Error Code.................................................................................................. 69

3.13.2.2 - Object 3021h: Warning Code...................................................................................................... 69

3.13.2.3 - Object 3330h: Fault Reaction Mask 1......................................................................................... 69

3.13.2.4 - Object 3331h: Fault Reaction Mask 3......................................................................................... 70

3.13.2.5 - Object 3300h: Stop 1 Parameter ................................................................................................ 70

3.13.2.6 - Object 3301h: Stop 3 Parameter ................................................................................................ 71

3.13.2.7 - Object 305Ah: Inhibit Stop Option Code ..................................................................................... 71

3.13.2.8 - Object 3302h: Inhibit Current limit............................................................................................... 72

3.13.2.9 - Object 3310h: Low Speed Threshold.......................................................................................... 72

3.13.2.10 - Object 3320h: Motor Temperature Sensor................................................................................ 72

3.13.2.11 - Object 3321h: Motor Temperature Sensor Monitor................................................................... 73

6Conten

t

CD1

-

k

–

CANopen Communication Profile

3.13.3 - Current Functions.............................................................................................................. 73

3.13.3.1 - Object 30D0h: Current Offset ..................................................................................................... 73

3.13.3.2 - Object 30D1h: Current Limitation................................................................................................ 74

3.13.3.3 - Object 30D4h: Current Monitor ................................................................................................... 74

3.13.3.4 - Object 30D5h: I²t Monitor............................................................................................................ 74

3.13.3.5 - Object 30E0h: Voltage Monitor ................................................................................................... 74

3.13.4 - Inputs/Outputs ................................................................................................................... 75

3.13.4.1 - Object 30FDh: Digital Inputs Bitmask ......................................................................................... 75

3.13.4.2 - Object 30C1h: Analog input 1 voltage......................................................................................... 75

3.13.4.3 - Object 30C2h: Analog input 1 low pass filter............................................................................... 75

3.13.4.4 - Object 30C4h: Analog input 1 offset compensation .................................................................... 76

3.13.4.5 - Object 30C0h: Analog input 1 set point selection........................................................................ 76

3.13.4.6 - Object 30C3h: Analog input 2 voltage......................................................................................... 76

3.13.5 - Position Control Function .................................................................................................. 77

3.13.5.1 - Object 3210h: Internal Raw Position........................................................................................... 78

3.13.5.2 - Object 3211h: Internal Position Offset ........................................................................................ 78

3.13.5.3 - Object 3212h: Motor Position...................................................................................................... 78

3.13.5.4 - Object 3213h: Second Sensor Position ...................................................................................... 78

3.13.5.5 - Object 3360h: Axis Type............................................................................................................. 79

3.13.5.6 - Object 3361h: Software position limit operation .......................................................................... 79

3.13.5.7 - Object 3350h: Absolute 16-bit Mode........................................................................................... 79

3.13.5.8 - Object 3217h: Position reference error flag ................................................................................ 80

3.13.6 - Servo On/Off Timing Function........................................................................................... 80

3.13.6.1 - Object 3304h: Amplifier Reaction Delay ..................................................................................... 80

3.13.6.2 - Object 3305h: Motor Brake Reaction Delay................................................................................ 80

3.13.7 - Position Capture Function................................................................................................. 82

3.13.7.1 - Object 3389h: Capture Input Selection ....................................................................................... 82

3.13.7.2 - Object 3380h: Capture Configuration.......................................................................................... 82

3.13.7.3 - Object 3381h: Capture Status..................................................................................................... 83

3.13.7.4 - Object 338Ah: Capture Time Filter ............................................................................................. 83

3.13.7.5 - Object 3382h: Capture Position Filter ......................................................................................... 84

3.13.7.6 - Object 3383h: Capture 1 Position ............................................................................................... 85

3.13.7.7 - Object 3384h: Capture 2 Position ............................................................................................... 85

3.13.7.8 - Object 3385h: Single Shot Capture Command (trigger).............................................................. 85

3.13.7.9 - Object 3386h: Single Shot Capture Status ................................................................................. 86

3.13.7.10 - Object 3387h: Single Shot Capture 1 Position.......................................................................... 86

3.13.7.11 - Object 3388h: Single Shot Capture 2 Position.......................................................................... 86

3.13.8 - TPDO3 Control.................................................................................................................. 87

3.13.8.1 - Object 33A0h: TPDO3 Count...................................................................................................... 87

3.13.8.2 - Object 33A1h: TPDO3 Control.................................................................................................... 87

3.13.9 - phasing Function ............................................................................................................... 87

3.13.9.1 - Object 3410h: Auto-phasing procedure ...................................................................................... 87

3.13.9.2 - Object 3414h: Motor phasing procedure..................................................................................... 88

3.13.10 - Auto-tuning Function ....................................................................................................... 88

3.13.10.1 - Object 3421h: Auto-tuning Time Interval Selection Mode ......................................................... 88

3.13.10.2 - Object 3430h: Auto-tuning Application Requirements............................................................... 88

3.13.10.3 - Object 3420h: Auto-tuning procedure ....................................................................................... 89

3.13.11 – Encoder Output............................................................................................................... 90

3.13.11.1 - Object 3487h: Encoder Emulation Output................................................................................. 90

3.13.12 – COGGING TORQUE COMPENSATION (OPTION) ...................................................... 92

3.13.12.1 - Object 3491h: Enable / Disable Cogging Torque Compensation .............................................. 92

3.13.12.2 - Object 3492h: Cogging torque acquisition procedure ............................................................... 92

3.13.13 - Digital Cam...................................................................................................................... 93

3.13.13.1 - Object 2500h: Cam Configuration Register .............................................................................. 93

3. 13.13.2 - Object 2501h: Cam Positions .................................................................................................. 94

3. 13.13.3 - Object 2502h: Cam Status....................................................................................................... 95

3.13.14 – Absolute encoder feedback............................................................................................ 95

3.13.14.1 - Object 3216h: Absolute encoder Position ................................................................................. 95

3.13.14.2 - Object 3215h: Absolute encoder position Reset procedure ...................................................... 96

3.13.14.3 - Object 3219h: Absolute encoder Position offset ....................................................................... 96

3.13.14.4 - Object 3218h: Absolute Position Range ................................................................................... 97

3.13.15 – SinCos inputs calibration................................................................................................ 97

Object 3496h: SinCos inputs error compensation....................................................................................... 97

7

Conten

t

CD1

-

k

–

CANopen Communication Profile

APPENDIX 1 - OBJECT DICTIONARY................................................................................................ 98

COMMUNICATION .................................................................................................................................. 98

COMMON ENTRIES IN THE OBJECT DICTIONARY ..................................................................................... 99

DEVICE CONTROL............................................................................................................................... 100

POSITION SENSOR GROUP .................................................................................................................. 100

PROFILE POSITION MODE.................................................................................................................... 100

HOMING MODE ................................................................................................................................... 100

POSITION CONTROL FUNCTION............................................................................................................ 101

INTERPOLATED POSITION MODE .......................................................................................................... 101

PROFILE VELOCITY MODE ................................................................................................................... 101

PROFILE TORQUE MODE ..................................................................................................................... 102

MANUFACTURER SPECIFIC .................................................................................................................. 102

APPENDIX 2 - QUICK START........................................................................................................... 105

A2.1 -OVERVIEW ............................................................................................................................... 105

A2.2 -INSTALLATION........................................................................................................................... 105

A2.2.1 - Wiring .............................................................................................................................. 105

A2.2.2 - Powering ......................................................................................................................... 105

A2.2.3 - Commissioning................................................................................................................ 105

A2.3 -OPERATION.............................................................................................................................. 106

A2.3.1 - Start communication (NMT) ............................................................................................106

A2.3.2 - Setting communication parameters (SDO) ..................................................................... 106

A2.3.3 - Start Synchronisation (SYNC)......................................................................................... 106

A2.3.4 - Exchange data (PDOs)................................................................................................... 107

A2.3.5. Servo on / Servo off.......................................................................................................... 107

A2.3.6 - Move on........................................................................................................................... 107

A2.3.7 - Other considerations....................................................................................................... 107

8Cha

p

ter 1

-

Overview

CD1

-

k

–

CANopen Communication Profile

Chapter 1 – Overview

3.13- REFERENCE

CiA DS-201..207 CAN Application Layer for Industrial Applications Version 1.1

CiA DS-301 Application Layer and Communication Profile Version 4.01

CiA DSP-402 Device Profile: Drive and Motion Control Version 1.1

1.2 - DEFINITIONS

CAN Controller Area Network

CiA CAN in Automation e. V. CAN-Bus international manufacturer and user organisation.

CAL CAN Application Layer. The Application layer for CAN as specified by CiA.

COB Communication Object is a CAN message. Data must be sent accross a CAN network

inside a COB.

COB-ID COB-Identifier. Each CAN message has a single identifier. There are 2032 different

identifiers in a CAN network.

NMT Network Management. One of the services of the application layer. It performs

initialisation, configuration and error handling in a CAN network.

PDO Process Data Object.

SDO Service Data Object.

Pp Profile Position Mode

pv Profile Velocity Mode

hm Homing Mode

ip Interpolated Position Mode

tq Profile Torque Mode

pc Position Control Function

CD1-k Infranor C range servo drive with resolver and encoder feedback input

9

CD1

-

k

–

CANopen Communication Profile

Cha

p

ter 1

-

Overview

1.3 - ARCHITECTURE

Device Control: The drive starting and stopping are executed by the state machine.

The state machine - handled with a control word and a status word via CAN bus - gives the possibility to control

the state of the drive: servo on/off, start/stop movement, fault reset...

Operation modes: The operation mode defines the behaviour of the drive :

Homing Mode: In this mode, various methods can be used to find a home position.

Profile Position Mode: In this mode, a trapezoidal trajectory generator gives the drive the possibility to

execute a positioning with pre-set parameters such as target position, profile speed and acceleration.

Interpolated Position Mode: In this mode, the drive interpolates the continuous position reference from a

coordinator controller. This mode provides the possibility for multiaxis synchronisation.

Profile Velocity Mode: This is the simple speed mode with speed reference from a host controller.

Profile Torque Mode: Only current loops are closed in this mode.

By default, CD1-k drives are working in Interpolated Position Mode.

CD1-k

CAN Node

Communication Profile DS-301

Drive Profile DSP-402

Device Control

State machine

Mode of Operation

Homing Mode Position

Profile Mode

Interpolated

Position

Mode

Profile

Velocity

Mode

Profile

Torque Mode

CAN network

10 Chapter 2 – Communication Profile

CD1

-

k

–

CANopen Communication Profile

Chapter 2 – Communication Profile

2.1 - COMMUNICATION OBJECTS

2.1.1 - CAN TELEGRAM

SOM COB-ID RT

R

CTRL Data segment CRC ACK EOM

SOM : Start Of Message

COB-ID : COB-Identifier of 11 bits

RTR : Remote Transmission Request

CTRL: Control field

Data : up to 8 bytes

CRC : Cyclic Redundancy Check

ACK : Acknowledge

EOM : End Of Message

2.1.2 - DEFAULT COB-ID

The COB-ID is of 11 bits. Node-ID (bits 0 - 6) is the drive address from 1 to 127.

10 9 8 7 6 5 4 3 2 1 0

Function Code NODE-ID

Default COB-ID for the CD1-k drive:

Broadcast objects of the pre-defined connection set:

Object Function Code Resulting COB-ID Communication Parameter at Index

NMT 0000 0 -

SYNC 0001 128 (80h) 1005h, 1006h, 1007h

Peer-to-peer objects of the pre-defined connection set:

Object Function Code Resulting COB-ID Communication Parameter at Index

EMERGENCY 0001 129 (81h) - 255 (FFh) 1014h

PDO1 (TX) 0011 385 (181h) - 511 (1FFh) 1800h

PDO1 (RX) 0100 513 (201h) - 639 (27Fh) 1400h

PDO2 (TX) 0101 641 (281h) - 767 (2FFh) 1801h

PDO2 (RX) 0110 769 (301h) - 895 (37Fh) 1401h

PDO3 (TX) 0111 897 (381h) - 1023 (3FFh) 1802h

PDO3 (RX) 1000 1025 (401h) - 1151 (47Fh) 1402h

SDO (TX) 1011 1409 (581h) - 1535 (5FFh) 1200h

SDO (RX) 1100 1537 (601h) - 1663 (67Fh) 1200h

TX = Transmit from drive to master

RX = Receive by drive from master

11

Chapter 2 – Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.1.3 - NETWORK MANAGEMENT OBJECTS (NMT)

NMT Protocols

NMT Protocol Command Specifier CS Remarks

Start Remote Node 1 Change to NMT Operational state

Stop Remote Node 2 Change to NMT Stop state

Enter Pre-Operational 128

Reset Node 129

Reset Communication 130

Node-ID: The Node-ID indicates the address of the CD1-k (defined by switches). If Node_ID = 0, the protocol

addresses all NMT slaves.

2.1.4 - SYNCHRONISATION OBJECT (SYNC)

The SYNC object is a broadcast message sent by the master. This message provides a network clock. The period

is specified by the communication cycle period (object 1006h). The Infranor servo-drives use this SYNC message

to synchronize their clock.

At least 180 ms are necessary for the servo-drive to start the synchronisation.

CS Node-ID

0 1 2

NMT Master NMT Slave(s)

Indication

Request

COB-ID = 0

Execution

of RPDO3

Communication cycle

SYNC

message

TPDO3

actual feedback

RPDO3

demand value

Asynchronous PDO

SYNC

message

Synchronous Window Length

Actuate on object

mapped in TPDO3

12 Cha

p

ter 2

-

Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.1.5 - PROCESS DATA OBJECT (PDO)

PDOs are unconfirmed messages used for real-time data exchange.

PDOs sent by the master are RPDOs and PDOs sent by the drive are TPDOs.

Data in each PDO are defined by a list of objects (PDO mapping).

Infranor servo drives have TPDO1, RPDO1, TPDO2, RPDO2, TPDO3 and RPDO3.

Each PDO is defined by:

- PDO communication parameters at object 1400h + RPDO_number-1 (for RPDO) or 1800h + TPDO_number-1

(for TPDO)

- PDO mapping at object 1600h + RPDO_number-1 (for RPDO) or 1A00h + TPDO_number-1 (for TPDO)

2.1.5.1 - Communication parameters

Communication parameters are:

- PDO COB-ID

- Transmission type

The distribution of COB-ID is defined by default (see section 2.1.2). The modification of COB-ID of PDO can be

made in NMT Pre-Operational State; the new COB-ID will take effect when the NMT state machine changes to

Operation State. The modification must not be taken in NMT Operational State, otherwise a

Reset_Communication will be necessary before the new COB-ID takes effect.

Transmission type supported by Infranor Servo Drives:

Transmission type PDO transmission

cyclic acyclic synchronous asynchronous RTR only

1 TPDO1

TPDO2

TPDO3

2-240 TPDO3

253 TPDO1

TPDO2

TPDO3

TPDO1

TPDO2

TPDO3

254 TPDO3

255 TPDO1

-Transmission types 1 - 240 are synchronous transmissions with regard to the SYNC messages. A value

between 1 and 240 means that the PDO is synchronously and cyclically transferred. The transmission type

indicates the number of SYNC which is necessary to trigger PDO transmissions.

- Transmission type 253 means that the PDO is only transmitted on remote transmission request.

- Transmission type 255 is event triggered. The CD1-k supports 2 events: change of status word and change of

Capture status.

- Transmission type 254 is specific to CD1-k (described in Chapter 3.13.8: PDO3 control).

PDO transmission modes of:

- Synchronous: the message is transmitted in synchronisation with the SYNC message. A synchronous message

must be transmitted within a pre-defined time-window immediately after the SYNC message.

- Asynchronous: the message is sent independently of the SYNC message.

Triggering modes:

- Event _Driven:

Message transmission by reception of SYNC. In the Infranor Servo Drives, TPDO3 is used for this purpose.

Message transmission by specific event. In the Infranor Servo Drives, TPDO1 is used for this purpose.

- Remotely requested: the transmission of an asynchronous PDO is initiated on reception of a remote request by

any other device.

13

Chapter 2 – Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.1.5.2 - PDO Mapping

The sub-index 0 of the mapping parameter contains the number of valid entries within the mapping record. This

number of entries is also the number of application variables which shall be transmitted/received with the

corresponding PDO. The sub-index 1 to number of entries contains the information about the mapped application

variables. These entries describe the PDO contents by their index, sub-index and length (in bits).

Structure of PDO Mapping Entry:

Byte : MSB LSB

index (16 bit) sub-index (8 bit) object length (8 bit)

Principle of PDO mapping:

2.1.5.3 - Multiplexed data

The multiplexed data is used to multiplex more than one axis demand value into one message RPDO3.

It is possible to send 4 axis demand values (16 bit absolute) with one RPDO3. Therefore, the controller must

modify the COB-ID of RPDO3 of each axis to the same cob-ID. For example, for axis 1, object 60C1-1 is mapped

into the first mapped object (object 1602-1), for axis 2, object 60C1-1 is mapped into the 2nd mapped object

(object 1602-2) and so on... For each axis, the balance of the mapped objects must be mapped with a dummy

object.

A dummy object mapped is realized with objects 0002h (integer8), 0003h (integer16), 0004h (integer32), 0005h

(unsigned8), 0006h (unsigned16) or 0007h (unsigned32). These objects can be used to map a PDO as a dummy

object but cannot be accessed via SDO (see DS-301, 9.5.3 Data type entry specification).

2.1.6 - SERVICE DATA OBJECT (SDO)

The SDO is a communication channel with 2 basic characteristics:

- Client/Server relationship,

- Object Dictionary.

Client/Server:

This is a relationship between a single client and a single server (Infranor Servo Drive). A client issues a request

(upload/download) thus triggering the server to perform a certain task. After finishing the task, the server answers

the request.

Object Dictionary:

All the objects (variables, constants, records...) of the server are defined as a list of objects where each element is

appointed by an index and a sub-index. This list of objects is called object dictionary. This object dictionary allows

the client the access to all objects of the server. The Infranor Servo Drive object dictionary consists of 2 parts: the

communication profile (DS-301) for the objects related to the CAN communication and the device profile (DSP-

402) for objects related to the drive functionality.

For more information about the SDO protocol, please report to the CiA DS-301 version 4.01 specification.

PDO mapping

0 3 (nb of entries)

1 yyyyh (index) yyh (sub-index) 08h (size)

2 zzzzh zzh 10h

3 xxxxh xxh 08h

Object Dictionary

xxxxh xxh Application object 1

yyyyh yyh Application object 2

zzzzh zzh Application object 3

PDO Appl. Obj. 2 Appl. Obj. 3 Appl. Obj. 1

14 Cha

p

ter 2

-

Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.1.7 - EMERGENCY OBJECT (EMCY)

The Emergency telegram consists of 8 bytes:

Byte 0 1 2 3 4 5 6 7

Content Emergency Error

Code

Error

register

(object

1001h)

Manufacturer Specific Error Field

(object 3020h)

LSB MSB

2.1.7.1 - CD1-k Specific Error Field

Bit Fault treatment / Cycle Stop Remarks

0 Position Limits Software / 500 µs 0, 1, 3

1 I2t Software / 2 ms 0, 1, 3, warning

2 RDC / Counting Software / 500 µs 0

3 Following error Software / 500 µs 0, 3

4 EEPROM Software

5 Synchro_CAN Software / cycle 0, 1, 3

6 LowSpeed Software / 500 µs 3, 0, 1

7 Procedure Software 0

8 Current_Offset Software Not erasable

13 Motor Temperature Software / 500 µs 0, 1, 3, warning

14 Init_400V Software Not erasable

15 Overcurrent Software / 62.5 µs 0, 1, 3

16 power Hardware 0 see below

17 power Hardware 0 see below

18 power Hardware 0 see below

19 IGBT Hardware 0 s.c. ASIPM / PWM Error /

Alim ASIPM / T° ASIPM /

Over I

20 Power Supply

Undervoltage

Hardware 0 not stored

21 Resolver / Encoder

Cable Interruption

Hardware 0

24 Second sensor

Cable Interruption

Hardware 0

25 Hall Effect Sensors /

Com. Channel (for

absolute encoders)

Hardware 0

The power faults are coded with bits 16, 17 and 18. The meaning is:

Bit Meaning

18 17 16

0 1 0 Overvoltage error

0 1 1 24 V error (18 V to 29 V)

1 0 0 Short-circuit motor phases/ground

1 0 1 System braking resistor error (short-circuit or overload)

1 1 0 Fan system error

1 1 1 Motor brake error

15

Chapter 2 – Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.2 - NETWORK INITIALISATION AND SYSTEM BOOT-UP

2.2.1 - NMT STATE MACHINE

The NMT state machine defines the communication status.

(1) At Power on, the initialisation state is automatically entered

(2) Once the Initialisation over, Pre-Operational is automatically entered

(3), (6) Start_Remote_Node indication

(4), (7) Enter_Pre-Operational_State indication

(5), (8) Stop_Remote_Node indication

(9), (10), (11) Reset_Node indication

(12), (13), (14) Reset_Communication indication

Minimum Boot-Up consists of one CAN telegram : a broadcast Start_Remote_Note message.

2.2.2 - INITIALISATION PROCEDURE

Initialisation

Pre-operational

NMT, SDO, Sync, Emcy

Operational

NMT, SDO, Sync, Emcy, PDO

Stop

NMT

(1)

(2)

(3) (4)

(5)

(7)

(11)

(10)

(9)

(6)

(8)

(14)

(13)

(12)

Power On

Configuration of all devices parameters,

including communication parameters (via

default SDO)

Start transmission of SYNC, wait for

synchronisation of all devices

Setting of all nodes at the operational state

16 Cha

p

ter 2

-

Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.3 - OBJECT DICTIONARY

2.3.1 - GENERAL INFORMATION

2.3.1.1 - Object 1000h: Device Type

This object describes the type of a device.

Index 1000h

Name Device Type

Object Code VAR

Data Type Unsigned32

Access ro

PDO Mapping No

Default Value 00020192h

Device Profile Number : 402

Additional Information : 02 Servo Drive

2.3.1.2 - Object 1001h: Error Register

Index 1001h

Name Error Register

Object Code VAR

Data Type Unsigned8

Access ro

PDO Mapping No

Default Value 0

Bit Number Description

0 Generic Error

2.3.1.3 - Object 1008h: Manufacturer Device Name

Index 1008h

Name Manufacturer Device Name

Object Code VAR

Data Type Visible String

Access ro

PDO Mapping No

Default Value 'CD1-k' for CD1-k drive.

2.3.1.4 - Object 1009h: Manufacturer hardware version

Index 1009h

Name Manufacturer Hardware Version

Object Code VAR

Data Type Visible String

Access ro

PDO Mapping No

17

Chapter 2 – Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.3.1.5 - Object 100Ah: Manufacturer software version

Index 100Ah

Name Manufacturer Software Version

Object Code VAR

Data Type Visible String

Access ro

PDO Mapping No

2.3.1.6 - Object 100Ch: Guard Time

The guard time (in ms) multiplied by the life time factor gives the life time for Life Guarding Protocol. It is 0 if not

used.

Index 100Ch

Name Guard time

Object Code VAR

Data Type Unsigned16

Access rw

PDO Mapping No

Default Value 0

2.3.1.7 - Object 100Dh: Life Time factor

Index 100Dh

Name Life Time Factor

Object Code VAR

Data Type Unsigned8

Access rw

PDO Mapping No

Default Value 0

2.3.1.8 - Object 1010h: Store Parameters

This object supports the saving of parameters in a non volatile memory. By read access, the device provides

information about its saving capacities.

Sub-index 0: largest sub-index that is supported.

Sub-index 1: refers to all parameters that can be stored in the device.

In order to avoid storage of parameters by mistake, storage is only executed when a specific signature is written to

the appropriate sub-index. The signature is 'save'.

Signature MSB LSB

ASCII e v a s

hex 65h 76h 61h 73h

On read access to the appropriate sub-index, the device provides information about its storage capabilities:

bit value meaning

31-2 0 reserved (=0)

1 0

1

Device does not save parameters autonomously

Device saves parameters autonomously

0 0

1

Device does not save parameters on demand

Device saves parameters on demand

For the Infranor CD1-k servo drive, parameters are saved on demand, when the drive is disabled.

18 Cha

p

ter 2

-

Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.3.1.9 - Object 1018h: Identity Object

Index 1018h

Name Identity Object

Object Code RECORD

Number of Elements 1

Value Description

Sub Index 1

Description Vendor ID

Data Type Unsigned32

Access ro

PDO Mapping No

Default Value 00000082h

The Vendor ID for Infranor is 082h.

2.3.2 - SYNC OBJECT

2.3.2.1 - Object 1005h: COB-ID Sync message

Index 1005h

Name COB-ID Sync message

Object Code VAR

Data Type Unsigned32

Access rw

PDO Mapping No

Default Value 00000080h

This object defines the COB-ID of the synchronisation object (SYNC).

The new COB-ID takes immediately effect if it is not changed in NMT Operation State. Otherwise, a

reset_communication message is necessary.

2.3.2.2 - Object 1006h: Communication Cycle Period

Index 1006h

Name Communication Cycle Period

Object Code VAR

Data Type Unsigned32

Access rw

PDO Mapping No

Unit µs

Value Range 1000..20000 (only the values multiples of 500 are correct for the CD1-k)

Default Value eeprom

This object defines the communication cycle. This period is also used for the synchronisation in interpolated

position mode. When the value of this object is reset at 0, the synchronisation is no more operative.

19

Chapter 2 – Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.3.2.3 - Object 3006h: Communication Cycle Period adjustment

Index 3006h

Name Communication cycle period adjustment

Object Code RECORD

Number of Elements 2

Value Description

Sub Index 1

Description Cycle period adjustment limit

Data Type Unsigned16

Access rw

PDO Mapping No

Unit us

Value Range 1.5us (0xF) to 20us (0xC8)

Default Value 1.5 us (0xF)

Conversion 0.1us

Write Condition Drive disabled.

Sub Index 2

Description Cycle period adjustment parameter 2

Data Type Unsigned16

Default Value 0x3C

Remark Reserved for future use. Not to be modified.

Communication cycle period adjustment :

- The SYNC cycle time T is set with object 1006 sub index 0.

- The maximum permissible jitter is T/2.

- The accuracy of the SYNC period must be better than 0.3%.

If the last condition cannot be fulfilled because the average value of the real communication cycle period given by

the host controller differs too much from the theoretical value defined in the object 1006 sub index 0, the object

3006 sub index 1 allows to modify the "Cycle period adjustment limit ".

SYNC period error limit (%) = ABS(Treal - Ttheoretical) / Ttheoretical

Cycle period adjustment limit (us) = SYNC period error limit (%) x 500 (500us is the Tick of the CD1-k)

Object 3006 sub index 1 value = Cycle period adjustment limit (us) x 10 (conversion factor 0.1 us)

If, for example, the SYNC period error limit is 2 %, Cycle period adjustment limit (μs) = 2% x 500 μs = 10 μs and

object 3006 sub index 1 value = 10 x 10 = 100 = 0x64

This object is not saved in the CD1-k EEPROM, so its value must be sent at each amplifier power up.

20 Cha

p

ter 2

-

Communication Profile

CD1

-

k

–

CANopen Communication Profile

2.3.2.4 - Object 1007h: Synchronous Window Length

Index 1007h

Name Synchronous Window Length

Object Code VAR

Data Type Unsigned32

Access rw

PDO Mapping No

Unit µs

Value Range 1500..20000

Default Value

This object defines the synchronous window in which the drive can latch the value from synchronous PDO

(RPDO3). Generally, it can be set at a value equal to (object 1006h) - 10000

2.3.3 - SDO OBJECTS

2.3.3.1 - Object 1200h: Server SDO Parameter

Index 1200h

Name Server SDO parameter

Object Code RECORD

Number of Elements 2

Value Description

Sub Index 1

Description COB-ID Client -> Server (rx)

Data Type Unsigned32

Access ro

PDO Mapping No

Default Value 600h + Node-ID

Sub Index 2

Description COB-ID Client -> Server (rx)

Data Type Unsigned32

Access ro

PDO Mapping No

Default Value 580h + Node-ID

For the CD1-k it is not possible to modify the COB-ID of the SDO objects.

2.3.4 - EMERGENCY OBJECT

2.3.4.1 - Object 1014h: COB-ID Emergency message

Index 1014h

Name COB-ID Emergency message

Object Code VAR

Data Type Unsigned32

Access rw

PDO Mapping No

Default Value 80h + Node-ID

Table of contents

Other Infranor DC Drive manuals

Popular DC Drive manuals by other brands

RTA

RTA HI-MOD ET A Hardware instruction manual

ABB

ABB ACS880-307LC Hardware manual

D+H

D+H ZA 105-K Original instructions

Leadshine Technology Co.

Leadshine Technology Co. DM422 user manual

HAUTAU

HAUTAU SM 101 Installation and operating instructions

Allen-Bradley

Allen-Bradley PowerFlex 755 Product information