Contents

I

TableofContents

1. Introduction, FeaturesandApplications....................................................................1

Introduction...........................................................................................................1

Features.................................................................................................................1

Applications..........................................................................................................1

2. Specifications............................................................................................................2

ElectricalSpecifications........................................................................................2

MechanicalSpecifications.....................................................................................2

EliminationofHeat...............................................................................................2

OperatingEnvironmentandotherSpecifications..................................................3

3. PinAssignmentandDescription...............................................................................3

ConnectorP1 Configurations................................................................................3

SelectingActivePulseEdgeandControlSignalMode........................................4

ConnectorP2 Configurations................................................................................4

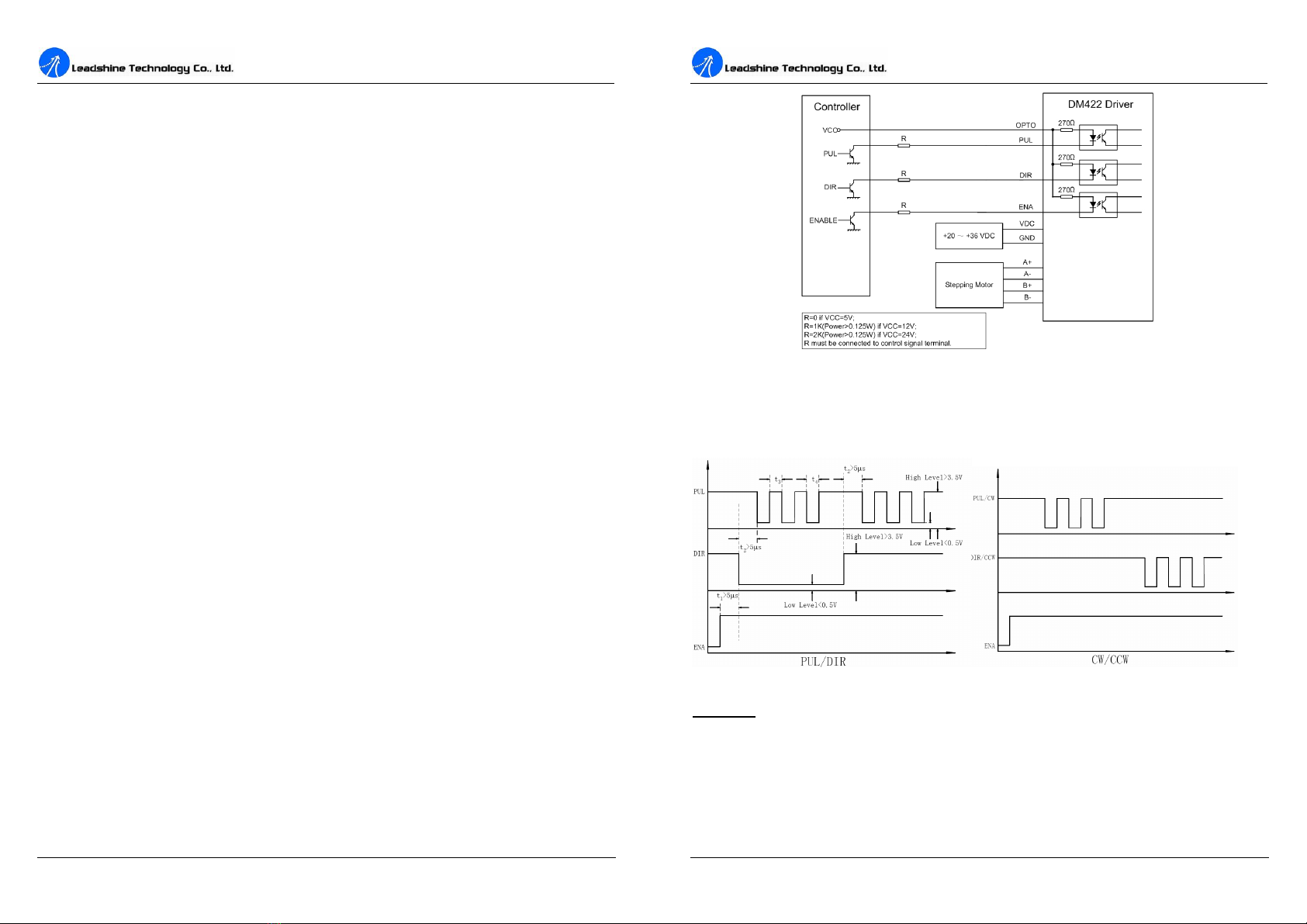

4. ControlSignalConnector(P1)Interface...................................................................4

5. Connecting theMotor................................................................................................5

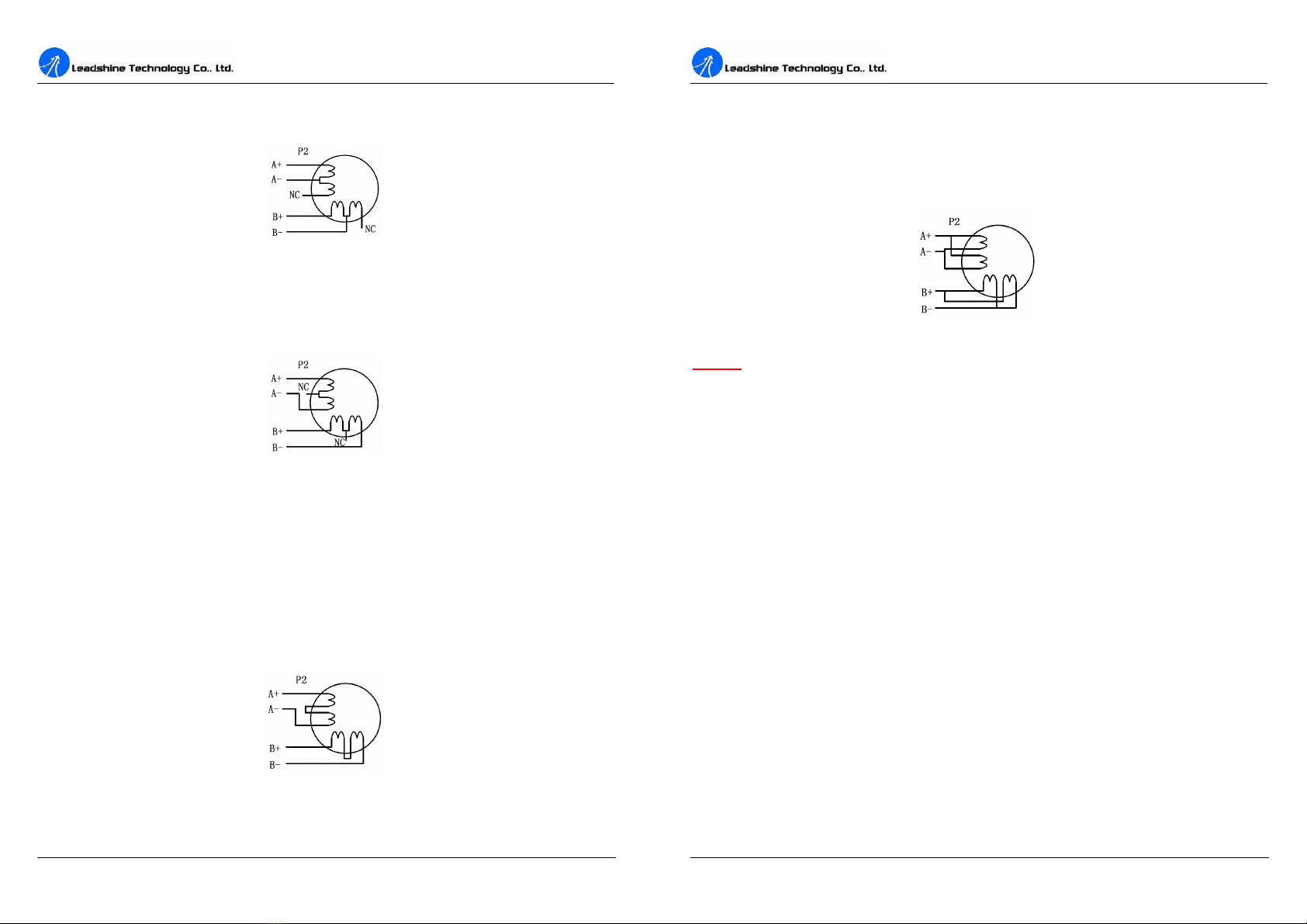

Connectionsto4-leadMotors...............................................................................5

Connectionsto6-leadMotors...............................................................................5

HalfCoil Configurations...............................................................................5

FullCoil Configurations................................................................................6

Connectionsto8-leadMotors...............................................................................6

SeriesConnections........................................................................................6

ParallelConnections......................................................................................7

6. PowerSupplySelection............................................................................................7

RegulatedorUnregulatedPowerSupply..............................................................7

MultipleDrivers....................................................................................................8

SelectingSupplyVoltage.......................................................................................8

7. SelectingMicrostepResolutionand DriverOutputCurrent.....................................8

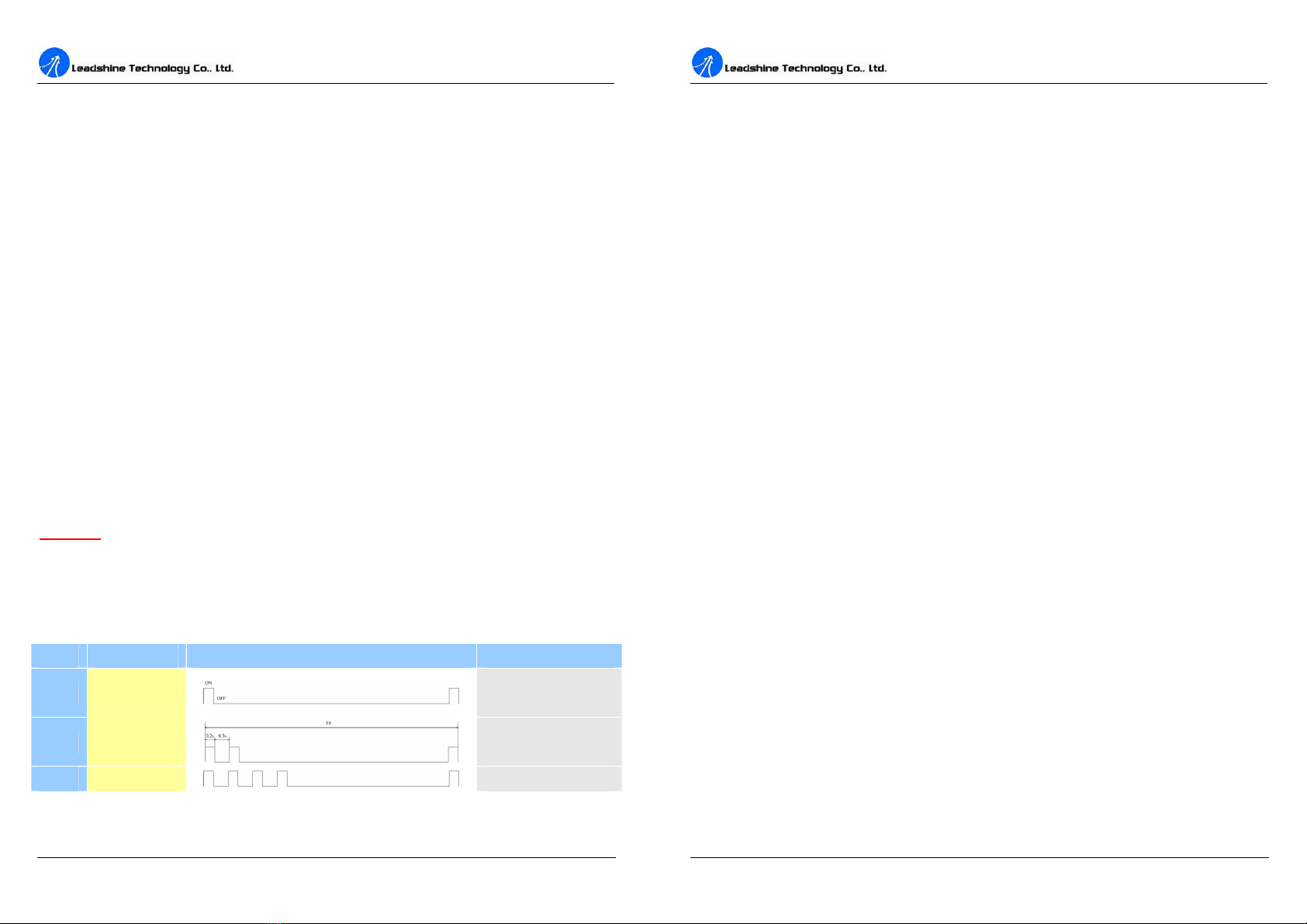

MicrostepResolutionSelection............................................................................8

CurrentSettings.....................................................................................................9

Contents

II

Dynamiccurrentsetting................................................................................9

Standstill currentsetting..............................................................................10

8. Wiring Notes...........................................................................................................10

9. TypicalConnection..................................................................................................10

10. Sequence ChartofControlSignals.......................................................................11

11. ProtectionFunctions..............................................................................................12

Over-currentProtection...............................................................................12

Over-voltageProtection..............................................................................12

PhaseErrorProtection.................................................................................12

ProtectionIndications..................................................................................12

12. FrequentlyAskedQuestions..................................................................................13

ProblemSymptomsand PossibleCauses............................................................14

13. ProfessionalTuningSoftwareProTuner................................................................15

Introduction.........................................................................................................15

SoftwareInstallation...........................................................................................15

ConnectionsandTesting.....................................................................................19

RS232 Interface Connection...............................................................................19

TestingtheSteppingSystem...............................................................................19

SoftwareIntroduction..........................................................................................20

ProTunerMain Window..............................................................................20

ProTunerToolbar.........................................................................................20

Option..........................................................................................................21

ComConfig Window..................................................................................21

ParametersConfiguration Window.............................................................21

Tuning.........................................................................................................22

Anti-ResonanceIntroduction......................................................................25

InternalPluser.............................................................................................26

ProcedureforAchieving OptimumPerformance........................................27

Err_check....................................................................................................28

About...........................................................................................................29

APPENDIX.................................................................................................................29