Ingecon SUN 125 U 208 Outdoor User manual

INGECON SUN Power U

Outdoor

Installation manual

ABB2000IKI01_B

05/2013

Ingeteam Inc

3550 W. Canal St.

Milwaukee, WI 53208 - USA

Tel.: +1 (414) 934 4100

Fax.: +1 (414) 342 0736

e-mail: solar.us@ingeteam.com

Service Call Center: +1 (414) 934 4158

The copy, distribution or use of this document or of its content requires written authorisation. Any breach thereof will

be reported for damages. All rights reserved including those of patent rights or design registration.

The conformity of the document content with the hardware described has been checked. However, discrepancies may

exist. Liability will not be assumed for total concordance. The information contained in this document is regularly

reviewed and it is possible that there may be changes in subsequent editions. Other functions may be available which

are not covered by this document.

This document may be changed.

ABB2000IKI01 iii

Installation manual Ingeteam

Important safety precautions

This manual contains important instructions for the installation, handling and use of the following models:

Units with a transformer

INGECON SUN 125 U 208 Outdoor

INGECON SUN 125 U 480 Outdoor

Units without a transformer

INGECON SUN 125 TL U 208 Outdoor

INGECON SUN 165 TL U 275 Outdoor

INGECON SUN 200 TL U 330 Outdoor

INGECON SUN 220 TL U 360 Outdoor

Read these instructions and keep them in a safe place.

General warnings

The operations described in the manual may be performed only by qualified personnel.

The status of qualified personnel referred to in this manual will be, as a minimum, that which meets

all the standards, regulations and laws regarding safety applicable to the tasks of installing and oper-

ating this unit.

The responsibility for designating qualified personnel will always fall to the company to which the

personnel belong. It is necessary to decide which workers are suitable or not for carrying out specific

work to preserve their safety at the same time as complying with occupational safety legislation.

These companies are responsible for providing appropriate training in electrical equipment to their

personnel and for familiarizing them with the contents of this manual.

All applicable safety-related legislation for electrical work must be complied with. Danger of electric

shock.

Compliance with the safety instructions set out in this manual or in the suggested legislation does

not imply exemption from other specific standards for the installation, place, country or other circum-

stances that affect the inverter.

Opening the door of the housing does not imply there is no voltage inside.

The risk of electric shock exists even after disconnecting from the grid, the PV array and the auxiliary

supply.

Only qualified personnel may open it, following the instructions in this manual.

The entire manual must be read and understood in full prior to manipulating, installing or operating

the unit.

Category III - 1000-Volt measuring instruments must be used for checking for the absence of voltage.

Ingeteam accepts no liability for any damages caused by improper use of the equipment.

ABB2000IKI01

iv

Installation manual

Ingeteam

Carry out all control and handling without voltage.

As a minimum security measure in this operation, the so-called five golden rules should always be

followed:

1. Disconnect

2. Prevent any possible resupply

3. Check there is no voltage

4. Ground and short circuit the equipment

5. Protect from live elements, if any, and put up safety signs around the work zone.

Until these five steps are completed, the work area cannot be considered voltage-free and any work

performed will be considered to be work on live equipment.

Potential hazards for people

Bear in mind the following warnings concerning personal safety.

DANGER: Electric shock.

The equipment may remain charged after disconnecting the PV array, mains power and auxiliary

power.

Carefully follow the mandatory steps in the manual for removing the voltage.

DANGER: Explosion.

There is a very low risk of explosion in very specific cases of malfunction.

The casing will protect people and property from the explosion only if it is correctly closed.

DANGER: Crushing and joint injuries.

Always follow the indications in the manual on moving and placing the unit.

The weight of this unit can cause lesions, serious injury and even death if not handled correctly.

DANGER: High temperature.

The flow of outlet air can reach high temperatures which can cause injury to anybody exposed to it.

ABB2000IKI01 v

Installation manual Ingeteam

Potential hazards for the equipment

Bear in mind the following warnings concerning protection of the equipment.

CAUTION: Ventilation.

The unit requires quality air flow while it is operating.

Keeping the unit in the upright position and the inlets free of obstacles is essential for this air flow

to reach the inside.

CAUTION: Connections.

After all duly authorized handling, check that the equipment is ready to start operation. Only after this

can it be connected following the instructions in the manual.

Do not touch boards or electronic components. The most sensitive components can be damaged or

destroyed by static electricity.

Do not disconnect or connect any terminal while the unit is operating. Disconnect and check for

absence of voltage first.

Personal protection equipment (PPE)

Use all items comprising the protection equipment.

Chapter “4. Safety instructions” contains references to the use of this equipment depending on the situation.

The standard personal protective equipment is:

• Safety goggles for mechanical hazards

• Safety goggles for electrical hazards

• Safety footwear

• Helmet

ABB2000IKI01

vi

Installation manual

Ingeteam

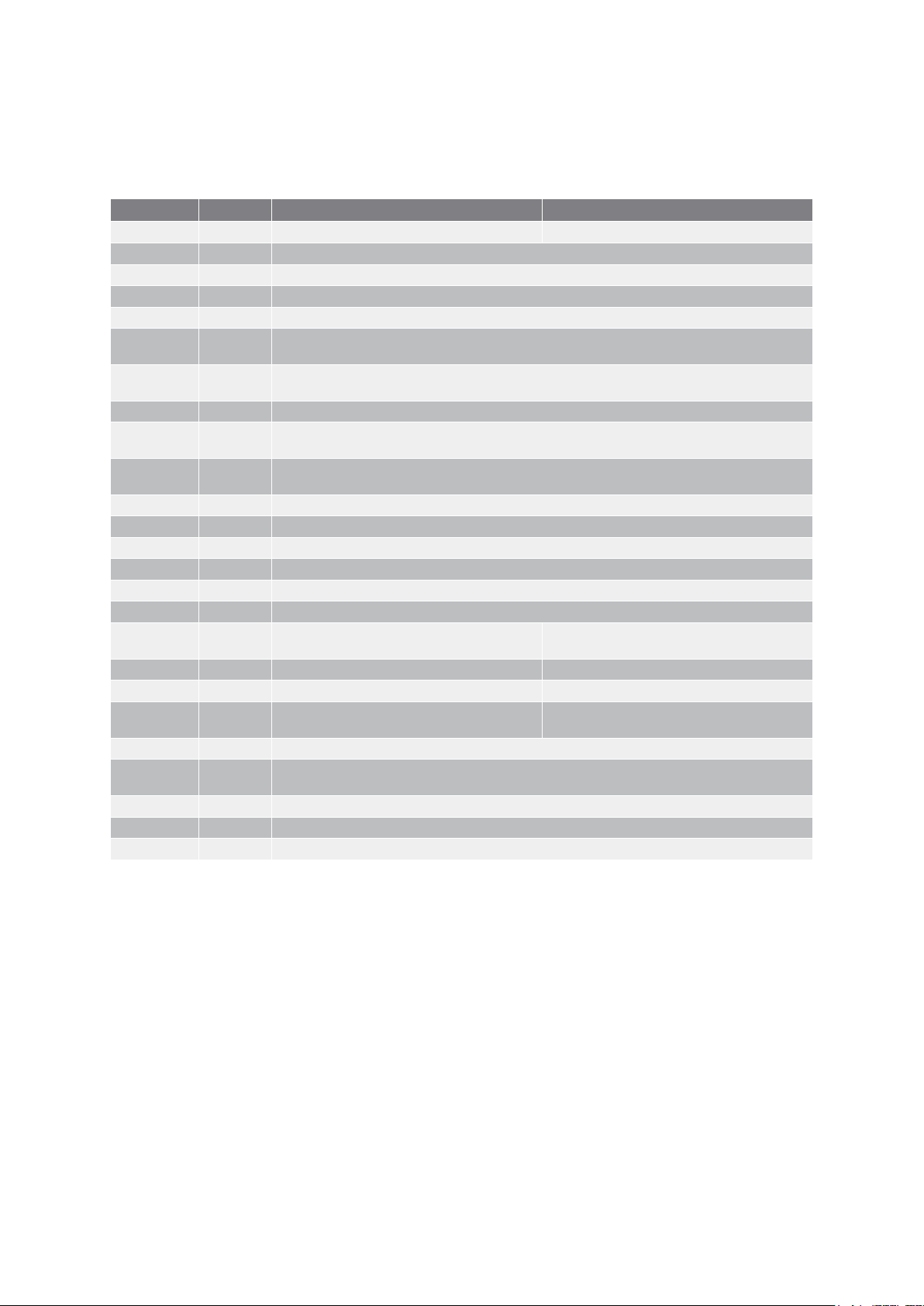

Cabling and torque requirements

Connection to the PV array must be with the following minimum types of cable; the maximum for input terminals is

DC 250 kcmil (0.2 in2, 127 mm2) and for output terminals AC 300 kcmil (0.24 in2, 152 mm2):

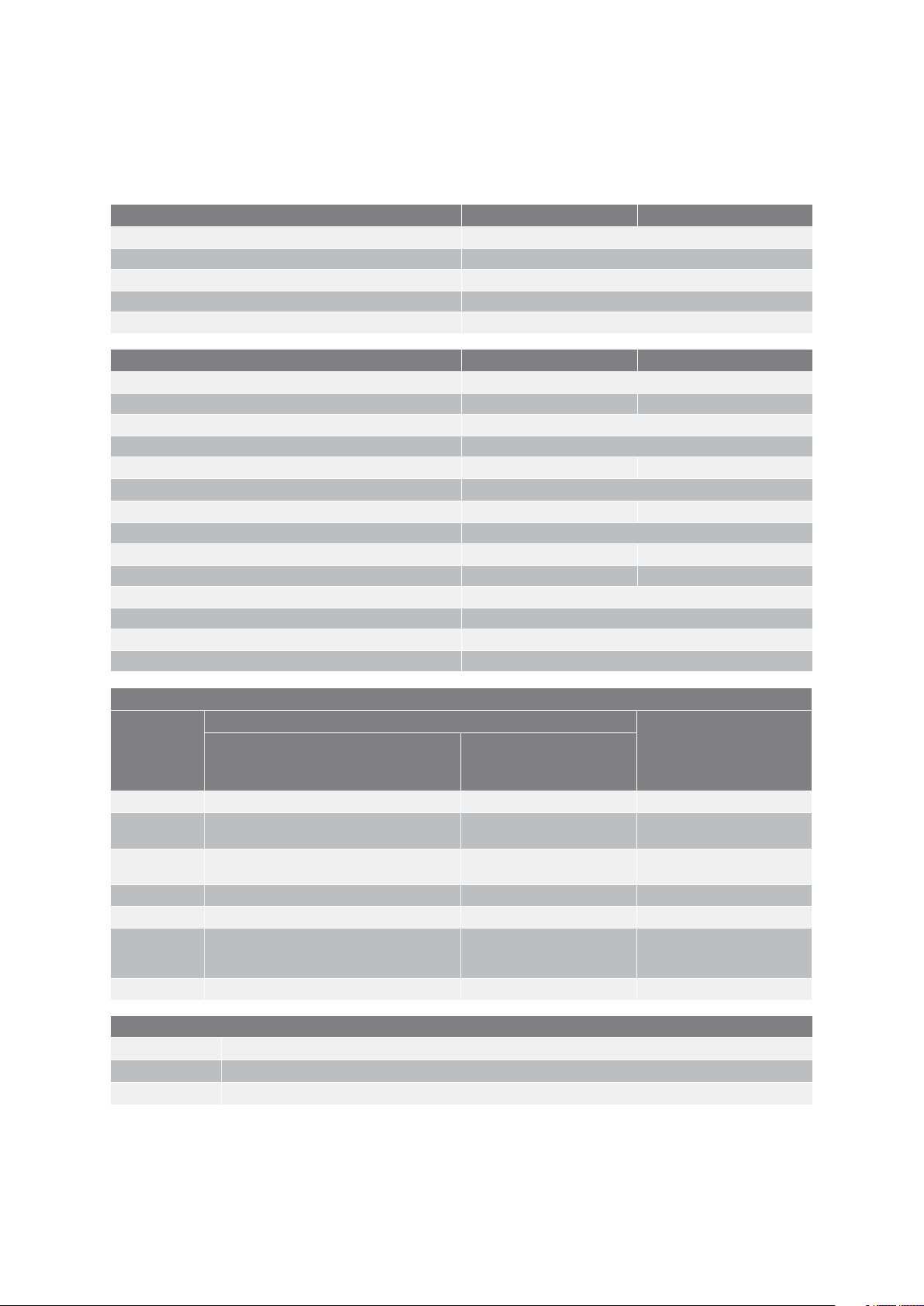

Models Wiring Material Section

Tightening torque

St.st. bolts

(unlubricated)

13/12”

(M10)

31/64”

(M12)

Input terminals (DC)

All models

8 cables per polarity 4 AWG 194 °F (90 °C) Copper

41.7 kcmil

(0.03 in2,

21.2 mm2)

385 lb.in

(43.5 Nm)

650 lb.in

(73.4 Nm)

2 AWG 194 °F (90 °C) Aluminium

66.4 kcmil

(0.05 in2,

33.6 mm2)

385 lb.in

(43.5 Nm)

650 lb.in

(73.4 Nm)

All models

4 cables per polarity 2/0 AWG 194 °F (90 °C) Copper

133 kcmil

(0.1 in2,

67.4 mm2)

385 lb.in

(43.5 Nm)

650 lb.in

(73.4 Nm)

4/0 AWG 194 °F (90 °C) Aluminium

212 kcmil

(0.17 in2,

107 mm2)

-650 lb.in

(73.4 Nm)

Output values (AC)

125 U 208, 125 TL U 208,

165 TL U 275, 200 TL U 330

220 TL U 360

2 cables per phase

250 kcmil 194 °F (90 °C) Copper

250 kcmil

(0.2 in2,

127 mm2)

-650 lb.in

(73.4 Nm)

300 kcmil 194 °F (90 °C) Aluminium

300 kcmil

(0.24 in2,

152 mm2)

-650 lb.in

(73.4 Nm)

125 U 480

2 cables per phase 2 AWG 194 °F (90 °C) Copper

66.4 kcmil

(0.05 in2,

33.6 mm2)

385 lb.in

(43.5 Nm)

650 lb.in

(73.4 Nm)

1/0 AWG 194 °F (90 °C) Aluminium

106 kcmil

(0.08 in2,

53.5 mm2)

385 lb.in

(43.5 Nm)

650 lb.in

(73.4 Nm)

In order to keep the nuts and bolts of the equipment in a proper condition, it is important while tight-

ening them to make sure there is no dirt or shavings on the threads and to apply a suitable lubricant.

Cabling must comply with the following codes:

• National Electrical Code ANSI/NFPA.

• Canadian Electrical Code CEC.

• Other local or state codes if applicable.

Ingeteam recommends the use of 31/64” (M12) terminals.

Inverter installation

The inverter must always be installed in accordance with the relevant requirements of the NEC (National Electrical

Code ANSI/NFPA), CEC (Canadian Electrical Code), and other applicable codes, including those relating to circuits

and equipment operating at over 600 V.

ABB2000IKI01 vii

Installation manual Ingeteam

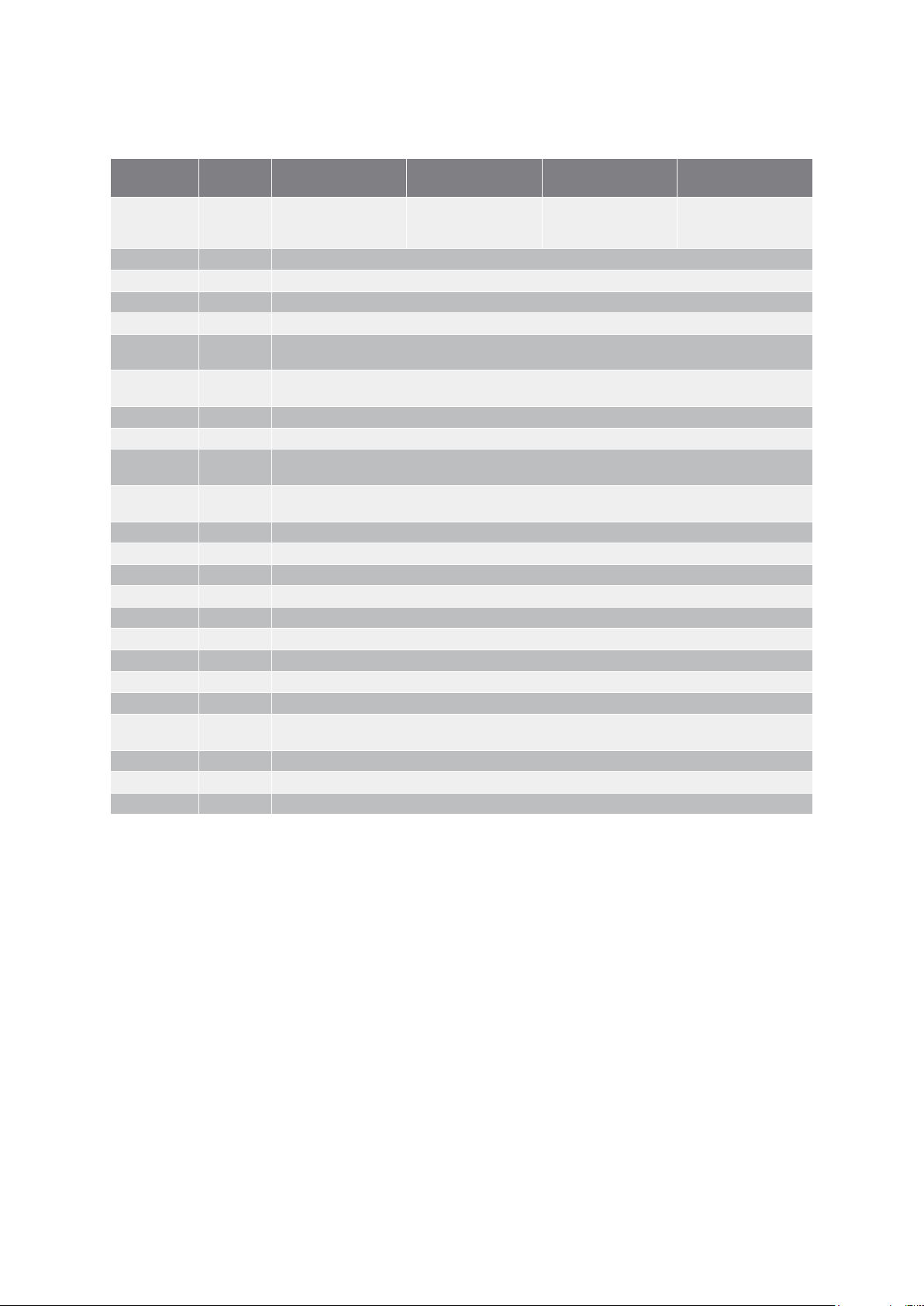

Spares

Units with a transformer

Reference Quantity INGECON SUN 125 U 208 Outdoor INGECON SUN 125 U 480 Outdoor

U1 1 INGECON SUN 208 V 3 ph electronics block INGECON SUN 480 V 3 ph electronics block

R1, R2, R3 3 Tubular silicon power resistor 200 W

C1, C2, C3 3 Single phase condenser 1 x 150 uF - 440 Vac

Q2 1 Thermomagnetic protection K 45 A 400 V 3P 30 kA

IQ2 1 Lateral auxiliary contact K 45 A 400 V 3P 30 kA

F1, F2, F3,

F4 4 Fuses gPV 1000 V 250 A 50 kA

PF1, PF2,

PF3, PF4 4 Base fusible 1200 V 400 A

F5, F6, F7 3 1000 Vdc 4 A 33 kA fuse, cylindrical 10 x 38

PF5, PF6,

PF7 3 Fuse holder 1000 V 1P cylindrical 1 0 x 38

+ 15 Vdc

Supply 1 AC/DC and DC/DC supply 230 Vac-12 Vdc 48 W

RVDC 1 DC arrester 1000 VDC 2 Class II 40 kA

QDC 1 Isolating switch 1000 V 630 A 4P

QAUX 1 Thermomagnetic circuit breaker K 10 A 400 V 2P 6 kA

IQAUX 1 Lateral auxiliary contact K 10 A 400 V 2P 6 kA

Q4 1 Thermomagnetic protection K 0.5 A 400 V 4P 7.5 kA

Lmc 1 Toroidal magnetic core 3 or 4 cores 1 step

K1, IK1 1Contactor with closing coil 1000 V 305 A

100-250 V AC/DC 3P

Contactor with closing coil 1000 V 145 A

100-250 V AC/DC 3P

CC1 1 EMI 480 Vac 400 A CN filter EMI 480 Vac 180 A CN filter

RVAC 1 AC ARRESTER 120 VAC 4+0 Class II 40 kA AC ARRESTER 277 VAC 4+0 Class II 150 kA

Q1 1Thermomagnetic circuit breaker 600 A 600 V

3P 65 kA

Thermomagnetic circuit breaker 225 A 600 V

3P 25 kA

EMI DC 1Filter MC DC 470 nF

VENT1,

VENT2 2 Radial fan 230 VAC 170 W 2510 rpm

LS 1Limit switch

AAS0091 1 HW matrix display, keyboard, LEDs.

AQE0131 1 Three-phase cover

Contact the Ingeteam telephone customer assistance with any questions.

ABB2000IKI01

viii

Installation manual

Ingeteam

Units without a transformer

Reference Quantity INGECON SUN 125

TL U 208 Outdoor

INGECON SUN 165

TL U 275 Outdoor

INGECON SUN 200

TL U 330 Outdoor

INGECON SUN 220

TL U 360 Outdoor

U1 1

INGECON SUN

Trifásico 208 V TL

electronics block

INGECON SUN

Trifásico 275 V TL

electronics block

INGECON SUN

Trifásico 330 V TL

electronics block

INGECON SUN

Trifásico 360 V TL

electronics block

R1, R2, R3 3 Tubular silicon power resistor 200 W

C1, C2, C3 3 Single phase condenser 1 x 150 uF - 440 Vac

Q2 1 Thermomagnetic protection K 45 A 400 V 3P 30 kA

IQ2 1 Lateral auxiliary contact K 45 A 400 V 3P 30 kA

F1, F2, F3,

F4 4 Fuses gPV 1000 V 250 A 50 kA

PF1, PF2,

PF3, PF4 4 Base fusible 1200 V 400 A

F5 1 1000 Vdc 4 A 33 kA fuse, cylindrical 10 x 38

F6, F7 2 1000 Vdc 15 A 33 kA fuse, cylindrical 10 x 38

PF5, PF6,

PF7 3 Fuse holder 1000 V 1P cylindrical 1 0 x 38

+ 15 Vdc

Supply 1 AC/DC and DC/DC supply 230 Vac - 12 Vdc 48 W

RVDC 1 DC arrester 1000 VDC 2 Class II 40 kA

QDC 1 Isolating switch 1000 V 630 A 4P

QAUX 1 Thermomagnetic circuit breaker K 10 A 400 V 2P 6 kA

IQAUX 1 Lateral auxiliary contact K 10 A 400 V 2P 6 kA

Q4 1 Thermomagnetic protection K 0.5 A 400 V 4P 7.5 kA

K1, IK1 1 Contactor with closing coil 1000 V 305 A 100-250 V AC/DC 3P

RVAC 1 AC ARRESTER 750 VAC 4+0 Class II 40 kA

Q1 1 Thermomagnetic circuit breaker 600 A 600 V 3P 65 kA

EMI DC 1MC DC 3 μF filter

VENT1,

VENT2 2 Radial fan 230 VAC 170 W 2510 rpm

LS 1Limit switch

AAS0091 1 HW matrix display, keyboard, LEDs.

AQE0131 1 Three-phase cover

Contact the Ingeteam telephone customer assistance with any questions.

ABB2000IKI01 ix

Installation manual Ingeteam

Symbols on the inverters

Warning symbols on the inverter are as follows:

Ø 1 Connection from cable and phase 1 terminal.

Ø 2 Connection from cable and phase 2 terminal.

Ø 3 Connection from cable and phase 3 terminal.

DC outlet.

AC outlet

Ground terminal

Grounded points

On

Off

WARNING

For Continued Protection

Against Risk Of Fire

Replace Only With Same

Fuse Type And Rating.

WARNING

RISK OF ELECTRIC SHOCK.

Normally grounded conductors

may be ungrounded and energized

when a ground-fault is indicated.

ABB2000IKI01

x

Installation manual

Ingeteam

WARNING

RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVER.

No user serviceable parts inside.

Refer servicing to qualied

service personnel.

WARNING

RISK OF ELECTRIC SHOCK

FROM ENERGY IN CAPACITOR.

Do not remove cover until 5

minutes after disconnecting

all sources of supply.

WARNING

HOT SURFACES.

To reduce the risk of burns

do not touch.

ABB2000IKI01 xi

Installation manual Ingeteam

Table of Contents

1. Overview ...............................................................................................................................................14

1.1. Equipment description ....................................................................................................................14

1.1.1. Models ..................................................................................................................................14

1.1.2. Options .................................................................................................................................14

1.2. Configuration parameters ................................................................................................................15

1.2.1. Units with a transformer..........................................................................................................15

1.2.2. Units without a transformer (TL) ..............................................................................................16

1.3. Compliance with regulations ............................................................................................................17

2. System description .................................................................................................................................17

2.1. Location ........................................................................................................................................17

2.1.1. Environment...........................................................................................................................17

2.1.2. Protection class......................................................................................................................17

2.1.3. Ambient temperature ..............................................................................................................17

2.1.4. Atmospheric conditions...........................................................................................................18

2.1.5. Contamination class ...............................................................................................................18

2.1.6. Acoustic contamination...........................................................................................................18

2.1.7. Ventilation..............................................................................................................................18

2.1.8. Environmental characteristics ..................................................................................................19

2.2. Characteristics of the electrical installation .......................................................................................19

2.3. EMC requirements..........................................................................................................................19

2.4. Location of the components ............................................................................................................19

3. Operating, conservation and transport conditions.......................................................................................23

3.1. Symbols ........................................................................................................................................23

3.2. Equipment reception ......................................................................................................................23

3.3. Handling and unpacking ................................................................................................................24

3.4. Moving the equipment ....................................................................................................................25

3.5. Storage .........................................................................................................................................26

3.6. Conservation..................................................................................................................................27

3.7. Waste handling...............................................................................................................................27

4. Safety instructions .................................................................................................................................28

4.1. Symbols ........................................................................................................................................28

4.2. General safety precautions ..............................................................................................................28

4.3. General.........................................................................................................................................29

4.3.1. General risks existing and preventive measures..........................................................................30

4.3.2. Additional risks and measures in handling tasks .......................................................................30

4.4. Type of tasks to be carried out.........................................................................................................30

4.4.1. Inspection tasks .....................................................................................................................30

4.4.2. Handling tasks.......................................................................................................................30

4.4.3. Personal protection equipment (PPE) .......................................................................................31

4.5. Safety measures while working ........................................................................................................31

5. Installation ............................................................................................................................................33

5.1. General requirements for installation ................................................................................................33

5.2. Fixing the unit to the floor ...............................................................................................................33

5.3. Requirements for transformers and insulation monitor........................................................................36

5.3.1. Grid connection transformer (units without a transformer)...........................................................36

5.3.2. Auxiliary transformer ..............................................................................................................36

5.4. Insulation monitor (units without an ungrounded transformer) .............................................................37

5.5. Electrical connection ......................................................................................................................37

5.5.1. Description of cable inlets.......................................................................................................38

5.5.2. Description of cabling connections...........................................................................................39

5.5.3. Order of connecting the unit....................................................................................................39

5.5.4. Inverter wiring diagram ...........................................................................................................40

5.5.5. System wiring diagram............................................................................................................42

5.5.6. Insulation fault contact / grid connection indicator ....................................................................47

5.5.7. Access to auxiliary connections ............................................................................................... 48

5.5.8. Connection for communication via RS-485 serial port .............................................................. 48

5.5.9. Connection for communication via modem-GSM/GPRS + RS-485 .............................................. 48

ABB2000IKI01

xii

Installation manual

Ingeteam

5.5.10. Connection for Ethernet communication .................................................................................50

5.5.11. Ground connections .............................................................................................................50

5.5.12. Grid connection ...................................................................................................................51

5.5.13. Connecting to the PV array ....................................................................................................53

Units fitted with ground connection on the positive pole ..................................................................54

Units fitted with ground connection on the negative pole .................................................................54

Non-grounded units.....................................................................................................................55

5.6. Available kits .................................................................................................................................55

5.6.1. Nighttime power supply kit ......................................................................................................55

5.6.2. Remote triggering kit ..............................................................................................................56

5.6.3. Heating element kit................................................................................................................56

5.6.4. Auxiliary services kit...............................................................................................................57

5.6.5. Voltage fall-out kit..................................................................................................................57

5.6.6. Synchronization kit.................................................................................................................58

6. Commissioning ......................................................................................................................................60

6.1. Equipment inspection .....................................................................................................................60

6.1.1. Inspection..............................................................................................................................60

6.1.2. Shutting down........................................................................................................................60

6.2. Start-up ........................................................................................................................................61

6.2.1. Start-up ................................................................................................................................61

6.2.2. Checking and measurement ....................................................................................................61

7. Preventive maintenance...........................................................................................................................62

7.1. Maintenance tasks ..........................................................................................................................62

8. Display control.......................................................................................................................................65

8.1. Keypad and LEDs...........................................................................................................................65

8.2. Display..........................................................................................................................................66

8.3. Main menu....................................................................................................................................67

8.4. Monitoring.....................................................................................................................................67

8.5. Reasons for shutdown.....................................................................................................................68

8.6. Settings ........................................................................................................................................69

Date and Time ............................................................................................................................69

Inverter number change ...............................................................................................................69

Language ...................................................................................................................................69

Grid quality.................................................................................................................................70

Ground connection ......................................................................................................................70

Connection time..........................................................................................................................70

Total reset ..................................................................................................................................70

Other adjustments.......................................................................................................................70

Change NumCAN ........................................................................................................................70

8.7. Inverter data ..................................................................................................................................70

8.8. Change inverter number..................................................................................................................71

9. Troubleshooting......................................................................................................................................71

9.1. LED messages ...............................................................................................................................71

9.1.1. Green LED .............................................................................................................................71

Slow flashing ..............................................................................................................................71

Fast flashing ...............................................................................................................................71

Steady light ................................................................................................................................71

9.1.2. Orange LED ...........................................................................................................................72

Fast flashing ...............................................................................................................................72

9.1.3. Red LED................................................................................................................................72

Steady light ................................................................................................................................72

9.2. List of alarms and reasons for shutdown ...........................................................................................73

9.3. Inverter alarms due to protections ....................................................................................................74

9.4. Action protocol for responding to incidents........................................................................................74

9.4.1. Voltage and/or frequency out of range.......................................................................................75

9.4.2. Temperature ..........................................................................................................................77

9.4.3. AC circuit protection...............................................................................................................78

9.4.4. Reason for contactor shutdown................................................................................................79

9.4.5. DC circuit protections .............................................................................................................79

9.4.6. Insulation fault.......................................................................................................................79

ABB2000IKI01 xiii

Installation manual Ingeteam

External to the unit......................................................................................................................80

Internal to the unit ......................................................................................................................80

9.4.7. Manual shutdown ...................................................................................................................81

9.4.8. Protection of the switching filter ..............................................................................................81

9.5. Replacing the electronics block........................................................................................................81

9.6. Replacing varistors in the intake board ............................................................................................ 83

9.7. Description of terminal strip............................................................................................................ 84

ABB2000IKI01

14

Installation manual

Ingeteam

1. Overview

The purpose of this manual is to describe the INGECON SUN Power U and to give appropriate information for its

correct receipt, installation, start-up, maintenance and operation.

1.1. Equipment description

An inverter is a circuit used to convert direct current to alternating current. The function of these units is to convert

the direct current generated by photovoltaic solar panels to alternating current and so enable it to be fed to the elec-

tricity grid.

Depending on installation requirements, the unit may be ordered:

• With ground connection on the positive pole.

• With ground connection on the negative pole.

• No grounding.

1.1.1. Models

The INGECON SUN Power U product family comprises units without a transformer (TL) and units with a transformer:

Units with a transformer Units without a transformer (TL)

INGECON SUN 125 U 208 Outdoor INGECON SUN 125 TL U 208 Outdoor

INGECON SUN 125 U 480 Outdoor INGECON SUN 165 TL U 275 Outdoor

INGECON SUN 200 TL U 330 Outdoor

INGECON SUN 220 TL U 360 Outdoor

1.1.2. Options

These models may include the following options:

• Nighttime power supply.

• Remote triggering kit.

• Heating element kit.

• Auxiliary services kit.

• Voltage fall-out kit.

• Synchronization kit.

ABB2000IKI01 15

Installation manual Ingeteam

1.2. Configuration parameters

1.2.1. Units with a transformer

DC input 125 U 208 125 U 480

Range of input operating voltage 330 ~ 920 V

Maximum input voltage 1000 V (1)

Maximum input current 390 A

Maximum input short circuit current 250 A (4 fused inputs)

Maximum input source backfeed current to input source 0 A

AC output 125 U 208 125 U 480

Output power factor rating > 0.99

Operating voltage range (ac) (L-L) 183 ~ 229 V 422.5 ~ 528 V

Operating frequency range or single frequency 57 ~ 60.5 Hz

Number of phases 3

Nominal output voltage (AC) 208 V 480 V

Normal output frequency 60 Hz

Maximum continuous output current (AC) per line 347 A 151 A

Rated power (AC) 125 kW

Maximum output fault current (ac) and duration 860 A at 11 ms 372 A at 6.5 ms

Maximum output overcurrent protection 600 A (MCB setting Q1) 225 A (MCB setting Q1)

Reconnection time 5 minutes

Normal operation temperature range -4 º F (-20 º) ~ 149 °F (65 °C)

Maximum full power operating ambient 122 °F (50 °C)

Enclosure Rating Type NEMA 3R

Utility interconnection voltage and frequency trip limits and trip times

Condition

Simulated utility source Maximum time (sec) at

60 Hz before cessation of

current to the simulated

utility

Voltage (V) Frequency (Hz)

A< 0.50 Vnor Rated 0.16

B0.50 Vnor ≤ V < 0.88 Vnor (Adjustable Set

Points, default 0.88 Vnor) Rated 0.16 ~ 2 (Adjustable Set

Points, default 0.16)

C1.10 Vnor < V < 1.20 Vnor (Adjustable Set

Points, default 1.10 Vnor) Rated 0.16 ~ 1 (Adjustable Set

Points, default 0.16)

D1.20 Vnor ≤ V Rated 0.16

ERated f > 60.5 0.16

FRated

f < (59.8 ~ 57.0)

(Adjustable Set Points, default

59)

0.16 ~ 300

GRated f < 57 0.16

Precision of values and disconnection time of the voltage and frequency protections.

Voltage ± 1%

Frequency ± 0.1 Hz

Time 0.06 s

(1) above 920 V the unit remains in standby.

ABB2000IKI01

16

Installation manual

Ingeteam

1.2.2. Units without a transformer (TL)

DC input 125 TL U 208 165 TL U 275 200 TL U 330 220 TL U 360

Range of input operating voltage 330 ~ 920 V 440 ~ 920 V 525 ~ 920 V 570 ~ 920 V

Maximum input voltage 1000 V (1)

Maximum input current 390 A

Maximum input short circuit current 250 A (4 fused inputs)

Maximum input source backfeed current to input source 0 A

AC output 125 TL U 208 165 TL U 275 200 TL U 330 220 TL U 360

Output power factor rating > 0.99

Operating voltage range (ac) (L-L) 183 ~ 229 V 242 ~ 303 V 290 ~ 319 V 317 ~ 396 V

Operating frequency range or single frequency 57 ~ 60.5 Hz

Number of phases 3

Nominal output voltage (AC) 208 V 275 V 330 V 360 V

Normal output frequency 60 Hz

Maximum continuous output current (AC) per line 347 A

Rated power (AC) 125 kW 165 kW 200 kW 220 kW

Maximum output fault current (ac) and duration 860 A at 11 ms

Maximum output overcurrent protection 600 A (MCB setting Q1)

Reconnection time 5 minutes

Normal operation temperature range -4 º F (-20 º) ~ 149 °F (65 °C)

Maximum full power operating ambient 122 °F (50 °C)

Enclosure Rating Type NEMA 3R

Utility interconnection voltage and frequency trip limits and trip times

Condition

Simulated utility source Maximum time (sec) at

60 Hz before cessation of

current to the simulated

utility

Voltage (V) Frequency (Hz)

A< 0.50 Vnor Rated 0.16

B0.50 Vnor ≤ V < 0.88 Vnor (Adjustable Set

Points, default 0.88 Vnor) Rated 0.16 ~ 2 (Adjustable Set

Points, default 0.16)

C1.10 Vnor < V < 1.20 Vnor (Adjustable Set

Points, default 1.10 Vnor) Rated 0.16 ~ 1 (Adjustable Set

Points, default 0.16)

D1.20 Vnor ≤ V Rated 0.16

ERated f > 60.5 0.16

FRated

f < (59.8 ~ 57.0)

(Adjustable Set Points, default

59)

0.16 ~ 300

GRated f < 57 0.16

Precision of values and disconnection time of the voltage and frequency protections.

Voltage ± 1%

Frequency ± 0.1 Hz

Time 0.06 s

(1) above 920 V the unit remains in standby.

ABB2000IKI01 17

Installation manual Ingeteam

1.3. Compliance with regulations

UL 1741

UL Standard for Safety for Inverters, Converters, Controllers and Interconnection System Equipment for Use With

Distributed Energy Resources, Second Edition, Dated Janauary 28, 2010.

CSA

CAN/CSA-C22.2 No. 0-M91 - General Requirements - Canadian Electrical Code - Part II.

0.4-04 - Bonding of Electrical Equipment.

107.1-01 - General Use Power Supplies.

IEEE 1547.1TM

IEEE Standard Conformance Test Procedures for Equipment Interconnecting Distributed Resources with Electric

Power Systems.

FCC Part 15 B (class A) EMC tests

2. System description

2.1. Location

These units must be installed in environments with specific characteristics.

Guidelines are provided in this section for choosing a suitable environment and adapting the unit to it properly.

2.1.1. Environment

Place the units in a place which is accessible for installation and maintenance work and which

permits use of the keyboard, the display and the reading of the front indicator LEDs.

A minimum space of 40 in (1 m) must be maintained on both sides and in front and behind the unit

to allow the free circulation of air through the circulation vents.

The air vents and part of the cabinet close to them can reach 185 °F (85 °C). Do not place any

material nearby which is sensitive high air temperatures.

Avoid corrosive environments that may affect the proper operation of the inverter.

Never place any object on top of the unit.

2.1.2. Protection class

These units meet NEMA type 3R degree of protection against external agents.

They are therefore designed to be suitable for outdoor location.

2.1.3. Ambient temperature

These units are designed to operate in a temperature range from -4 °F (-20 °C) to 149 °F (65 °C). Nominal power

may be input at up to 122 °F (50° C). Above this temperature the unit limits input power in order to cool the internal

temperature of the electronics.

ABB2000IKI01

18

Installation manual

Ingeteam

2.1.4. Atmospheric conditions

The ambient air must be clean and relative humidity must not exceed 50% at over 104 °F (40 °C). Higher levels of

relative humidity, up to 95%, can be tolerated at below 86 °F (30 °C).

It should be borne in mind that moderate condensation may occasionally occur as a consequence of temperature

variations. For this reason, apart from the unit’s own protection, vigilance of these units is necessary once they have

been started up on sites where the conditions described above are not expected to be present.

In the event of condensation, never apply voltage to the unit.

2.1.5. Contamination class

The pollution class for which the units have been designed is grade 3.

Suitable measures should be taken to provide dust-free air of sufficient quality in the vicinity of the inverter.

2.1.6. Acoustic contamination

When on, the inverter generates a buzzing sound.

Do not place it in an occupied room, or on light supports which might amplify this buzz. The mounting surface must

be firm and appropriate for the weight of the unit.

2.1.7. Ventilation

These units intake air through the sides of the housing and expel it from the front and back.

A minimum obstacle-free space of 40 in (1 m) must be maintained on both sides as well as in front of and behind the

unit to allow the free circulation of air.

These units are fitted with two cooling fans on the top of the cabinet. These fans start up for a few

seconds each time the inverter is connected to the mains and is about to inject power. This procedure

makes it possible to easily check proper operation.

The fans require an adequate flow of clean, dust-free air for proper operation.

Do not place any object on top of the unit.

ABB2000IKI01 19

Installation manual Ingeteam

2.1.8. Environmental characteristics

The environmental conditions for operation are:

Ambient conditions

Minimum temperature (1) -4 °F (-20 °C)

Minimum surrounding air temperature (1) -4 °F (-20 °C)

Minimum surrounding air temperature 149 °F (65 °C)

Temperature at which power limiting commences 122 °F (50 °C)

Maximum relative humidity without condensation 95%

(1) Units including a heating element kit may be installed in locations with a minimum temperature of -13 °F (-25 °C).

For further information see Chapter “2.4. Location of the components”.

2.2. Characteristics of the electrical installation

These units are designed to be connected to the low voltage public grid.

2.3. EMC requirements

These units are equipped with the necessary filtering elements to comply with EMC requirements for industrial appli-

cations in order to prevent disturbances in other equipment outside the installation.

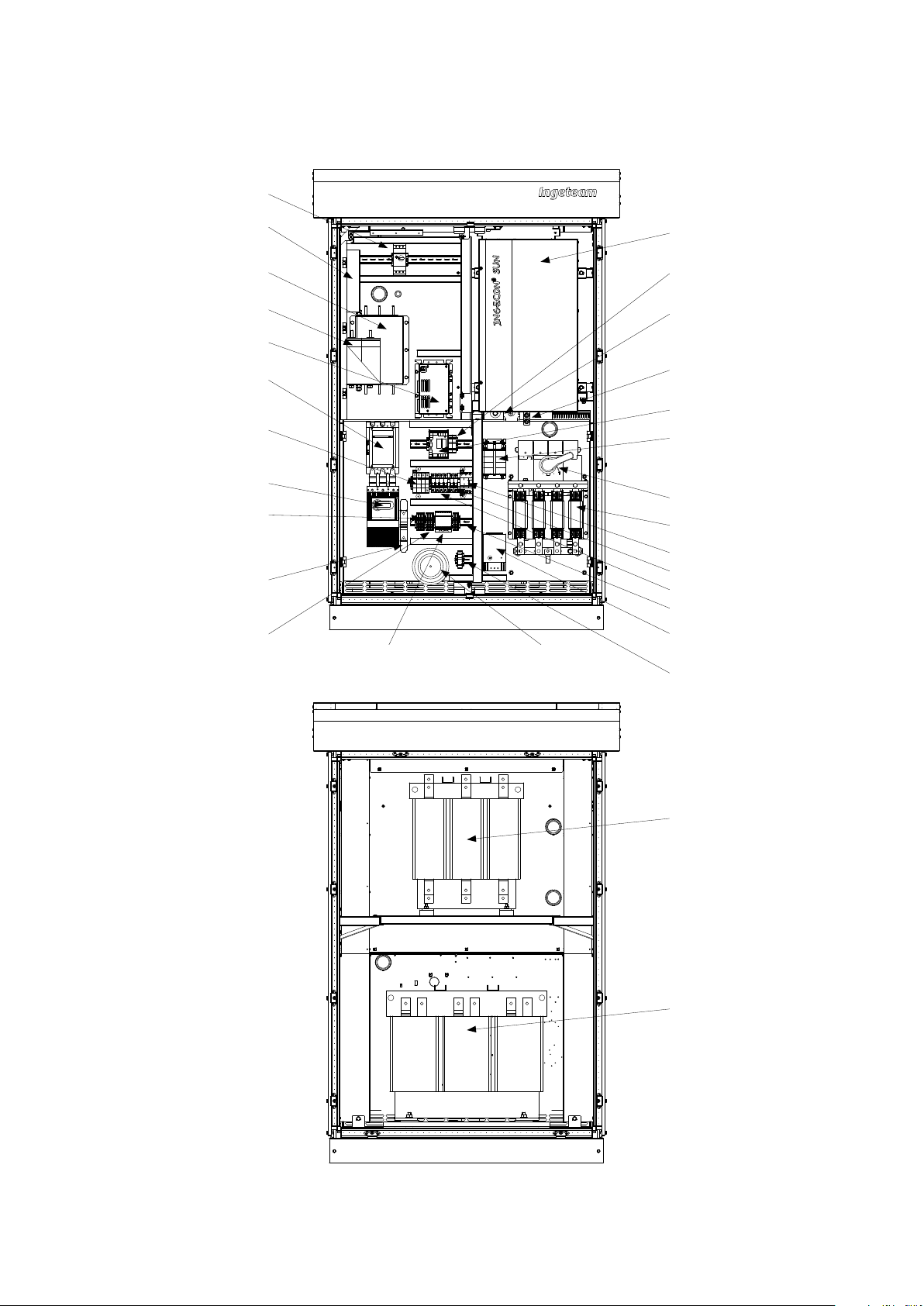

2.4. Location of the components

See next pages.

ABB2000IKI01

20

Installation manual

Ingeteam

INGECON SUN 125 U 208 Outdoor

Shock absorbing

resistors

Q2

Harmonic filter

AC contactor

AC thermomagnetic

circuit breaker

Ground connection

fuse

Inductance

Transformer

* Optional

Q4

XAUX

QAUX

DC arresters

Heating

element*

DC breaker

EMC filter

EMI DC filter

Electronics block

DC fuses

DC plates

Electronics block AC

plates

DC fuses

+15 Vdc supply Auxiliary service

transformer*

X7

X9

X8

AC arresters

SAC*

EMI AC filter

This manual suits for next models

5

Table of contents

Other Ingecon Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual