1. Table of Contents

1. Table of Contents 2

2. General Information 4

2.1. Manual revision history.......................................................................................................................................... 4

2.2. Disclaimers and limitations of liability ................................................................................................................. 4

2.3. Contact ................................................................................................................................................................... 4

3. Safety Information 5

3.1. For your safety........................................................................................................................................................ 5

3.2. Warnings................................................................................................................................................................. 5

3.3. Precautions ............................................................................................................................................................ 5

3.4. Pour votre sécurité................................................................................................................................................. 5

3.4.1. Avertissements....................................................................................................................................................... 6

3.4.2. Précautions ............................................................................................................................................................ 6

4. Product Description 7

4.1. Part numbering ...................................................................................................................................................... 7

4.2. Specifications......................................................................................................................................................... 8

4.2.1. Electrical and Power Specifications......................................................................................................................8

4.2.2. Motion Control Specifications............................................................................................................................... 9

4.2.3. Inputs/Outputs and Protections ......................................................................................................................... 10

4.2.4. Communication for Operation ............................................................................................................................11

4.2.5. Environmental Specifications ............................................................................................................................. 11

4.2.6. Reliability Specifications ..................................................................................................................................... 12

4.2.7. Mechanical Specifications ................................................................................................................................... 12

4.2.8. Compliance .......................................................................................................................................................... 13

4.3. Thermal and Power Specifications .....................................................................................................................14

4.3.1. Standby power consumption.............................................................................................................................. 14

4.3.2. Thermal model..................................................................................................................................................... 14

4.3.3. Current derating................................................................................................................................................... 15

4.3.4. Heat dissipation and heatsink calculation .........................................................................................................15

4.3.5. Energy efficiency .................................................................................................................................................. 17

5. Pinout 18

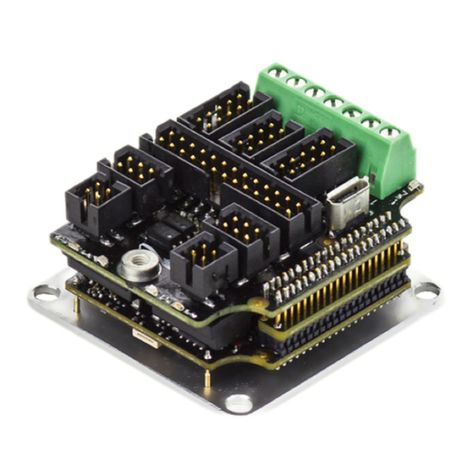

5.1. Connectors Overview........................................................................................................................................... 18

5.2. P1 and P2 Power pins .......................................................................................................................................... 18

5.3. P3 Feedback connector .......................................................................................................................................20

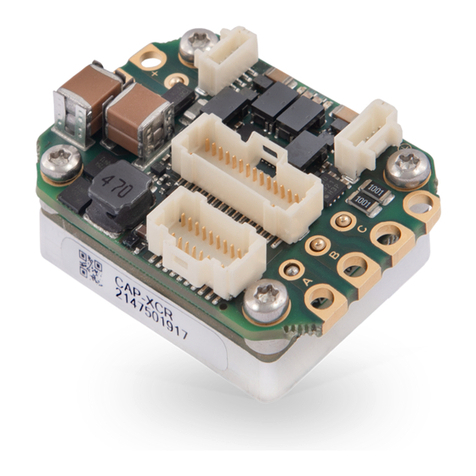

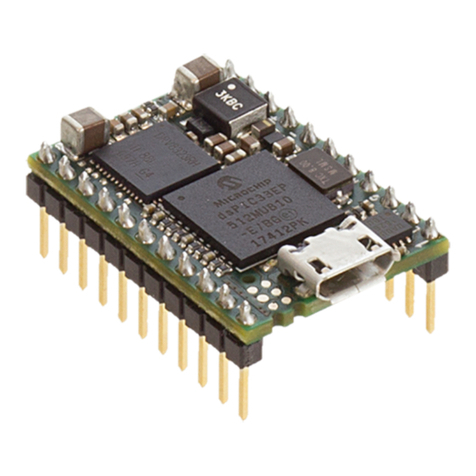

5.4. P4 Everest CORE Interface connector ................................................................................................................. 24

6. Safe Torque Off (STO) 29

6.1. Safety Function Specifications............................................................................................................................ 29

6.2. Integration Requirements ................................................................................................................................... 30

6.3. STO External Diagnostic Test .............................................................................................................................. 33