10 MHD56162 - Edition 2

OPERATION

Description Of Operation

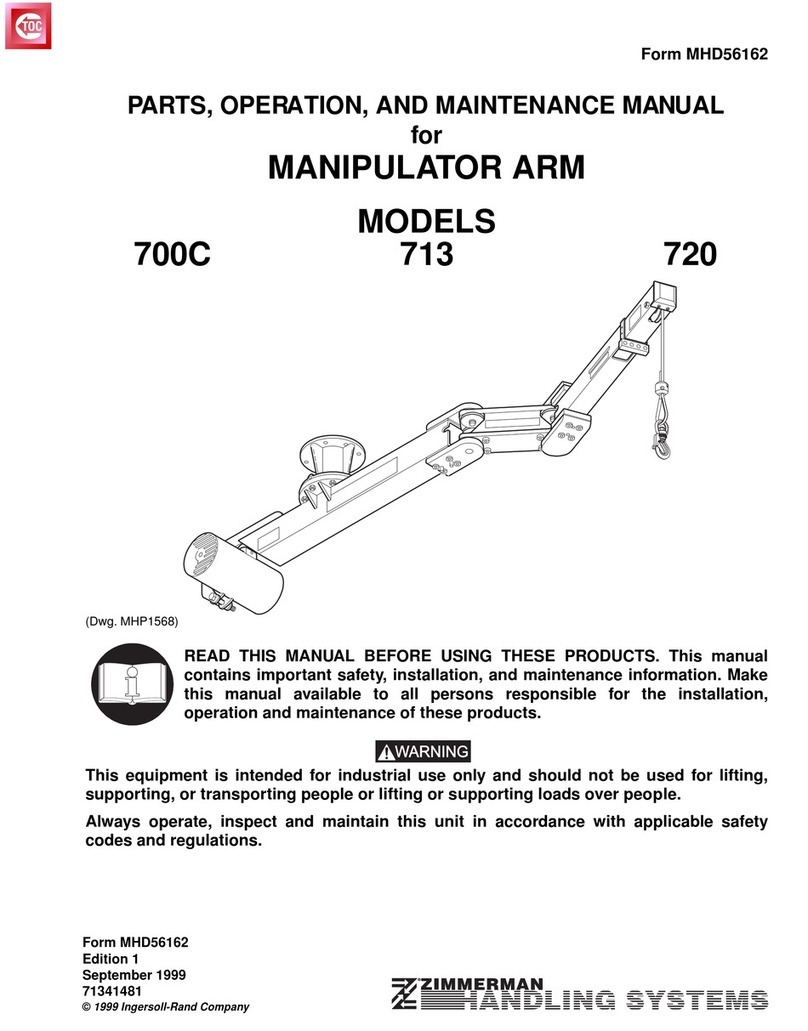

The Manipulator Arm is an integrated group of components

designed to maximize the interaction of man and machine. The

Manipulator Arm mounts to an overhead beam or rail system and

incorporates a Zimmerman balancer. The balancer has a wire

rope with load hook which is fed through the Manipulator Arm to

the work area. The operator controls the system by use of the

Zimmerman ZA (Zim-Air) up and down control or the

Zimmerman 2PS (2 Position Sensor) zero gravity control.

The system renders the load virtually weightless through the

balancer’s compressed air operation. When the Manipulator Arm

is mounted to a rail system it provides for ease of horizontal

movement. This combination requires little physical strength to

operate and reduces operator fatigue.

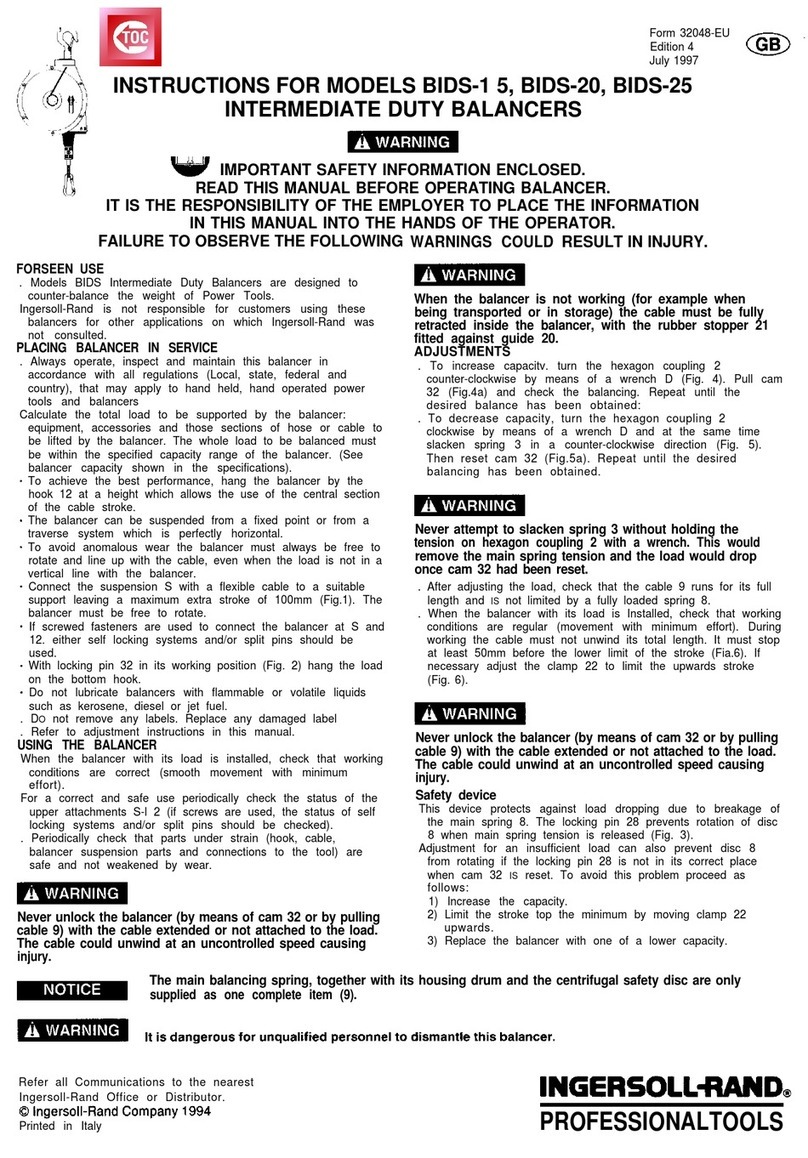

Balancer Operation

Energy used to power the balancer is compressed air, a minimum

of 70 psig (4.8 bar/480 kPa) is required. Air is controlled by an

external control package. Compressed air pushes against the

piston, causing it to move laterally.

The piston pushes the reel assembly causing the reel to move

laterally as well as rotate which winds the wire rope into the

balancer, raising the hook or handling device. Compressed air is

released through the controls to atmosphere and the reel rotates in

the opposite direction lowering the hook or handling device.

The balancer reaches maximum capacity when 100 psig (6.9 bar/

690 kPa) is applied. As air pressure decreases the unit capacity

decreased proportionally. If 80 psig (5.5 bar/552 kPa) is applied to

the balancer, maximum balancer operational capacity is 80% of

rated capacity.

Control Operation

The Manipulator Arm uses the Zimmerman ZA (Zim-Air) or

2PS (2 Position Sensor) control package.

ZA Control

The Zim-Air control package utilizes an up/down control

pendant, connected to the manifold mounted to the balancer. The

top of the manifold has two flow control valves, labeled “UP” and

“DN”. They control the speed with which a load will raise and

lower. The center screw control is for “hook balance adjustment”

to maintain the hook in a floating condition when it does not have

a load on it.

Air is supplied through the manifold to the control pendant. When

the “UP” lever is depressed, air passes through a passage in the

pendant and into the balancer piston chamber resulting in the

balancer raising the load. Lowering the load is accomplished by

depressing the “DN” lever, which releases air in the balancer to

atmosphere through the block, and lowers the load.

2PS (2 Position Sensor)

This style control utilizes the EA Regulator and Two Position

Sensor Valve.

The EA Regulator provides a control circuit and a work circuit

through the regulator for balancer operation. The trim valve is an

adjustable flow control providing a (control circuit) regulated low

volume of air to the main regulator. The main regulator provides a

higher volume of air to the piston chamber of the balancer. The

auxiliary flow control allows air to be bled to atmosphere to

support a lighter load.

The Two Position Sensor Valve is a pilot operated, four way, spring

return valve. Pilot signal is sent to the valve by a switch mounted

on the handling device, or by a pilot line from the clamp circuit.

The EA Regulator controls operation of the balancer when the

handling device has a load attached to it.

The Two Position Sensor Valve controls balancer operation when

the handling device is empty by bleeding air pressure from the

EA Regulator to atmosphere.

The pilot signal shifts the 2PS valve to a blocked port giving the

EA Regulator full balancing control of the handling device and

load. Once the load is placed and released, the spring return will

over come the pilot signal shifting the valve back to a bleed

condition balancing the empty handling device.

Manipulator Arm Operation

WARNING

• If system air pressure is lost, lower the load immediately. The

operator must stay out of the path of the load. Clamp may lose

force required to hold load resulting in injury.

The “UP” and “DN” levers allow adjustable speed control. As

lever is depressed further, operational speed increases. Use lever

to ‘throttle’ speed to ensure controlled movement of the hook or

handling device.

CAUTION

• Do not wrap control hoses around the wire rope. Damage to

hoses and failure of unit may result.

Raising and lowering of the load is dependent on the type of

control circuit on the handling device. The Zim-Air (ZA) type

control requires manual lever operation to raise and lower the

device. If the handling device has a 2PS (2 Position Sensor)

control, the device is in zero gravity with or without a load and

requires the operator to push up or down to raise and lower the

device.

1. Move Manipulator Arm to the pick up point, and position it

over the load for pick up.

2. Slowly lower balancer and engage load until completely

seated.

3. Raise load and maneuver to the set down point.

4. At the set down point lower the load.

5. Maneuver the Manipulator Arm back to the pick up point

and repeat steps.

Positioning of the load is best accomplished by the operator, when

moving away from the manipulator arm pivot point. Manipulator

arm will freely follow.