Form 32048-EU

Edition 3

December 1994

INSTRUCTIONS FOR MODELS BMDL-4, BMDL-6, BMDL-8,

BMDL-10, BMDL-12 MEDIUM DUTY BALANCERS

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING BALANCER.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

FORSEEN USE

. Models BMDL-4, BMDL-8, BMDL-8, BMDL-10, BMDL-12

Medium Duty Balancers are designed to counter-balance

the weight of Power Tools.

. Ingersoll-Rand is not responsible for customers using

these balancers for other applications on which

Ingersoll-Rand was not consulted.

PLACING BALANCER IN SERVICE

Always operate, inspect and maintain this balancer in

accordance with all regulations (Local, state, federal and

country), that may apply to hand held, hand operated

powertools and balancers.

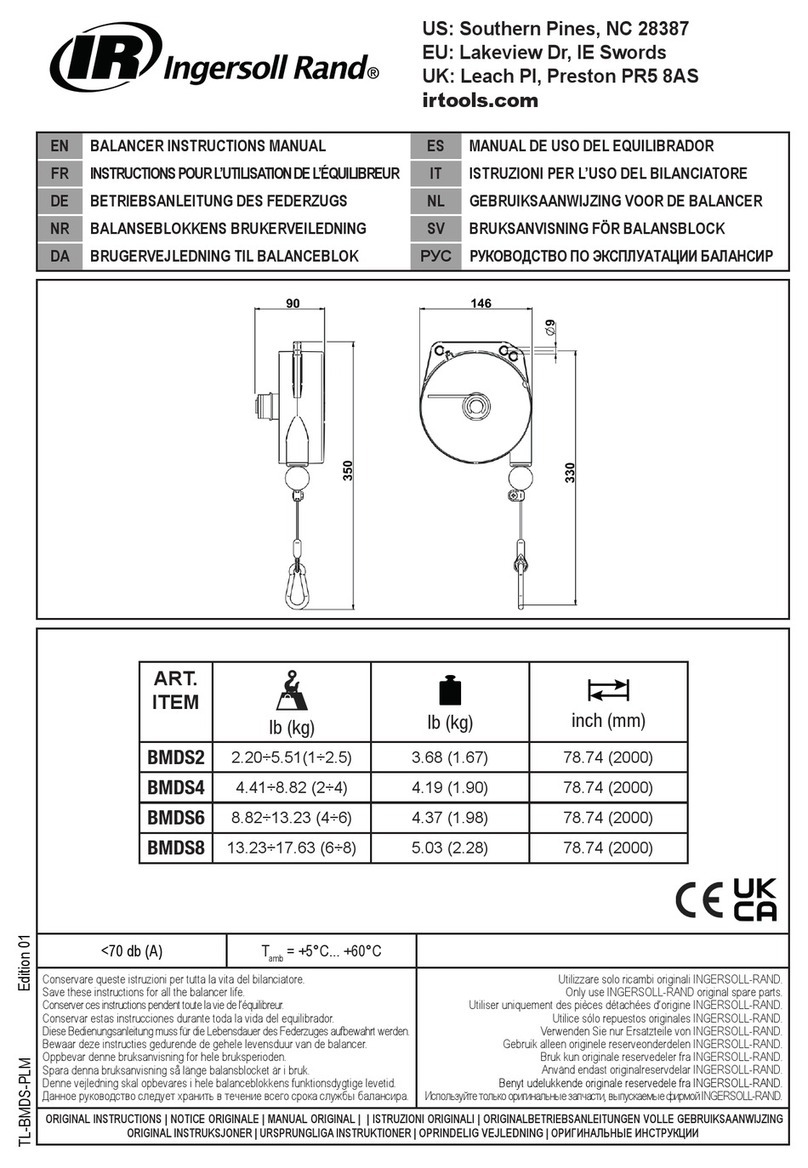

. Calculate the total load to be supported by the balancer.

equipment, accessories and those sections of hose or

cable to be lifted by the balancer. The whole load to be

balanced must be within the specified capacity range of

the balancer. (See balancer capacity shown in the

specifications).

. To achieve the best performance, hang the balancer in A

for capacities up to 4 kg (Fig.1a) and in A for higher

capacities (Fig. 1 b), at a height which allows the use of the

central section of the cable stroke 11.

Connect the suspension in the free hole with a flexible

cable to a suitable support leaving a maximum extra

stroke to 100mm (Fig.1a - 1b). The balancer must be free

to line up with the load.

If screwed fasteners are used to connect the balancer at

point A or S, either self locking systems and/or split pins

should be used.

Hang the load on the hook 15.

Do not lubricate balancers with flammable or volatile

liquids such as kerosene, diesel or jet fuel.

. Do not remove any labels. Replace any damaged label.

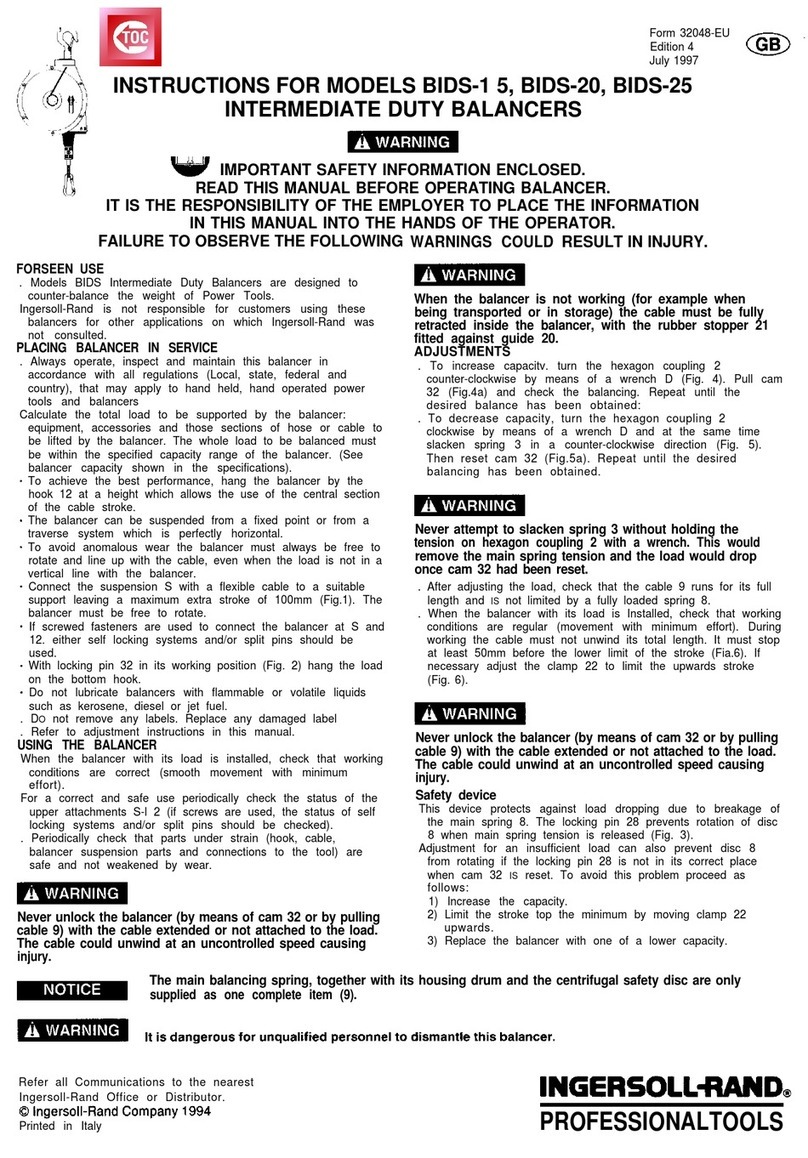

ADJUSTMENTS

. To increase capacity rotate the axis F counter-clockwise

using a wrench D (Fig. 2).

To decrease capacity, press spring 8 in a clockwise

direction whilst rotating axis F counter-clockwise using a

wrench D (Fig. 3).

During working the cable must not unwind its total length.

It must stop at least 50mm before the lower limit of the

stroke. If necessary adjust the clamp 13 to limit the

upwards stroke (Fig. 4).

. Since a correct spring tension keeps the drum rotating

freely, the balancer must not be used for lesser loads than

its minimum capacity.

. If the drum blocks during initial adjustment, it could be due

to an insufficient load. Increase capacity by using the

wrench D as in (Fig. 2). Check that with the cable 11

completely wound, the working is regular.

If the drum blocks with the load at the top of the stroke,

proceed as in the previous section, either by increasing

the capacity, or by limiting the upwards stroke by adjusting

clamp 13. If this does not solve the problem, replace the

balancer with one of a lower capacity.

USING THE BALANCER

When the balancer with its load is installed, check that

working conditions are correct (smooth movement with

minimum effort)

For a correct and safe use periodically check the status of

the upper attachments A and S (if screws are used, the

status of self locking systems and/or split pins should be

checked).

Periodically check that parts under strain (hook, cable,

balancer suspension parts and connections to the tool) are

safe and not weakened by wear.

The main balancing spring, together with its housing drum and the centrifugal safety disc are only supplied as one complete item (5).

It IS dangerous for unqualified personnel to dismantle this balancer.

The use of other than Ingersoll-Rand replacement parts may result in safety hazards, decreased performance and increased

maintenance, and may invalidate all warranties. Repairs should be made only by authorised trained personnel. Consult your

nearest Ingersoll-Rand Authorised Service Centre.

SAVE THESE INSTRUCTIONS, DO NOT DESTROY.

When the life of the balancer has expired, it should be returned to the nearest Authorised Ingersoll-Rand Service Center for

dismantling and recycling.

Refer all Communications to the nearest

Ingersoll-Rand Office or Distributor.

PROFESSIONALTOOLS