,

Form 32048-EU

Edition 4

July 1997

INSTRUCTIONS FOR MODELS BIDS-1 5, BIDS-20, BIDS-25

INTERMEDIATE DUTY BALANCERS

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING BALANCER.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING

WARNINGS COULD

RESULT IN INJURY.

FORSEEN USE

. Models BIDS Intermediate Duty Balancers are designed to

counter-balance the weight of Power Tools.

Ingersoll-Rand is not responsible for customers using these

balancers for other applications on which Ingersoll-Rand was

not consulted.

PLACING BALANCER IN SERVICE

. Always operate, inspect and maintain this balancer in

accordance with all regulations (Local, state, federal and

country), that may apply to hand held, hand operated power

tools and balancers

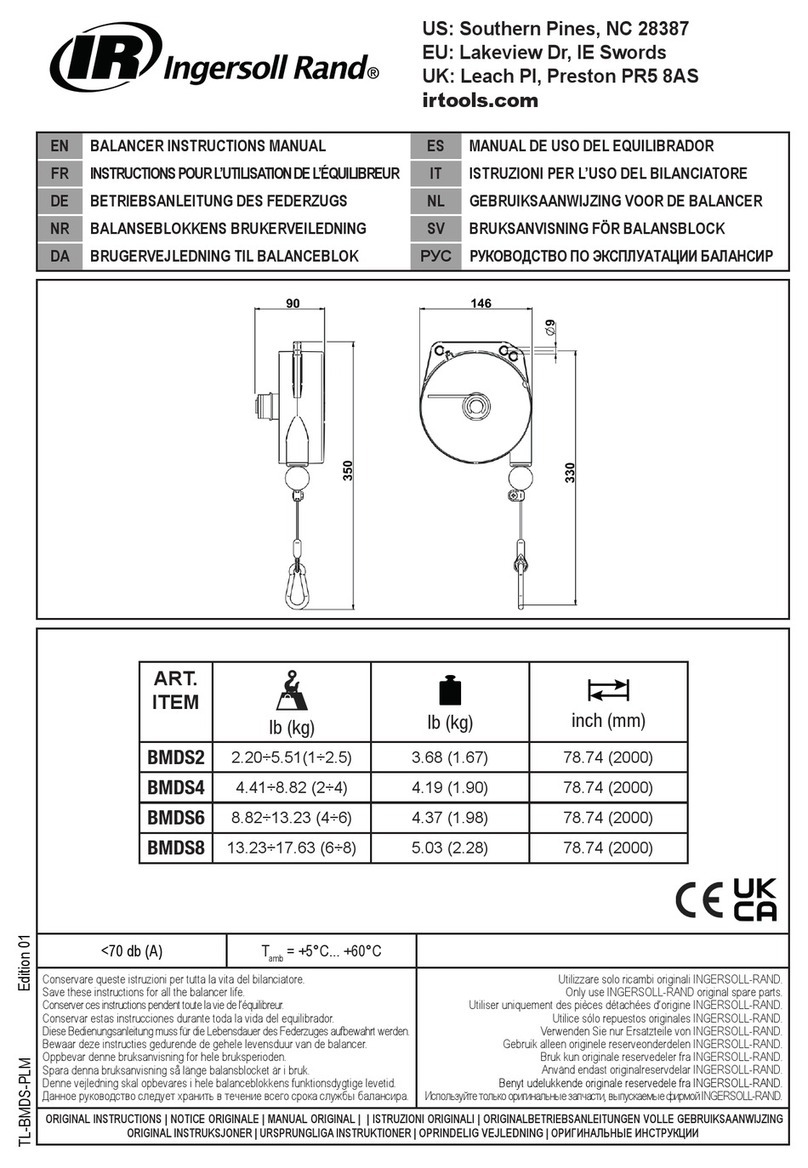

Calculate the total load to be supported by the balancer:

equipment, accessories and those sections of hose or cable to

be lifted by the balancer. The whole load to be balanced must

be within the specified capacity range of the balancer. (See

balancer capacity shown in the specifications).

To achieve the best performance, hang the balancer by the

hook 12 at a height which allows the use of the central section

of the cable stroke.

The balancer can be suspended from a fixed point or from a

traverse system which is perfectly horizontal.

To avoid anomalous wear the balancer must always be free to

rotate and line up with the cable, even when the load is not in a

vertical line with the balancer.

Connect the suspension S with a flexible cable to a suitable

support leaving a maximum extra stroke of 100mm (Fig.1). The

balancer must be free to rotate.

If screwed fasteners are used to connect the balancer at S and

12. either self locking systems and/or split pins should be

used.

With locking pin 32 in its working position (Fig. 2) hang the load

on the bottom hook.

Do not lubricate balancers with flammable or volatile liquids

such as kerosene, diesel or jet fuel.

. DOnot remove any labels. Replace any damaged label

. Refer to adjustment instructions in this manual.

USING THE BALANCER

When the balancer with its load is installed, check that working

conditions are correct (smooth movement with minimum

effort).

For a correct and safe use periodically check the status of the

upper attachments S-l 2 (if screws are used, the status of self

locking systems and/or split pins should be checked).

. Periodically check that parts under strain (hook, cable,

balancer suspension parts and connections to the tool) are

safe and not weakened by wear.

Never unlock the balancer (by means of cam 32 or by pulling

cable 9) with the cable extended or not attached to the load.

The cable could unwind at an uncontrolled speed causing

injury.

When the balancer is not working (for example when

being transported or in storage) the cable must be fully

retracted inside the balancer, with the rubber stopper 21

fitted against guide 20.

ADJUSTMENTS

. To increase capacitv. turn the hexagon coupling 2

counter-clockwise by means of a wrench D (Fig. 4). Pull cam

32 (Fig.4a) and check the balancing. Repeat until the

desired balance has been obtained:

. To decrease capacity, turn the hexagon coupling 2

clockwise by means of a wrench D and at the same time

slacken spring 3 in a counter-clockwise direction (Fig. 5).

Then reset cam 32 (Fig.5a). Repeat until the desired

balancing has been obtained.

Never attempt to slacken spring 3 without holding the

tension on hexagon coupling 2 with a wrench. This would

remove the main spring tension and the load would drop

once cam 32 had been reset.

. After adjusting the load, check that the cable 9 runs for its full

length and IS not limited by a fully loaded spring 8.

. When the balancer with its load is Installed, check that working

conditions are regular (movement with minimum effort). During

working the cable must not unwind its total length. It must stop

at least 50mm before the lower limit of the stroke (Fia.6). If

necessary adjust the clamp 22 to limit the upwards stroke

(Fig. 6).

Never unlock the balancer (by means of cam 32 or by pulling

cable 9) with the cable extended or not attached to the load.

The cable could unwind at an uncontrolled speed causing

injury.

Safety device

This device protects against load dropping due to breakage of

the main spring 8. The locking pin 28 prevents rotation of disc

8 when main spring tension is released (Fig. 3).

Adjustment for an insufficient load can also prevent disc 8

from rotating if the locking pin 28 is not in its correct place

when cam 32 IS reset. To avoid this problem proceed as

follows:

1) Increase the capacity.

2) Limit the stroke top the minimum by moving clamp 22

upwards.

3) Replace the balancer with one of a lower capacity.

The main balancing spring, together with its housing drum and the centrifugal safety disc are only

supplied as one complete item (9).

Refer all Communications to the nearest

Ingersoll-Rand Office or Distributor.

Printed in Italy

PROFESSIONALTOOLS