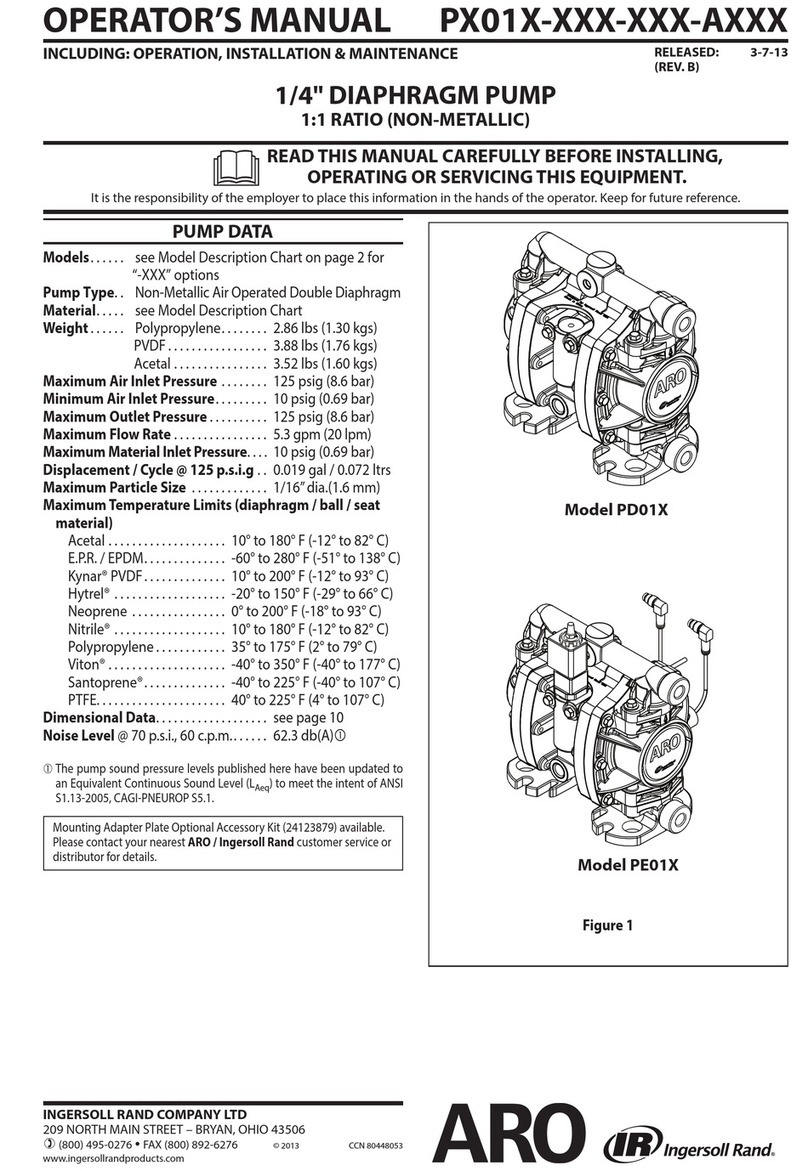

Ingersoll-Rand ARO 612729 User manual

Other Ingersoll-Rand Water Pump manuals

Ingersoll-Rand

Ingersoll-Rand PM10X-X-X-A02 User manual

Ingersoll-Rand

Ingersoll-Rand ARO SP0665S2 Series User manual

Ingersoll-Rand

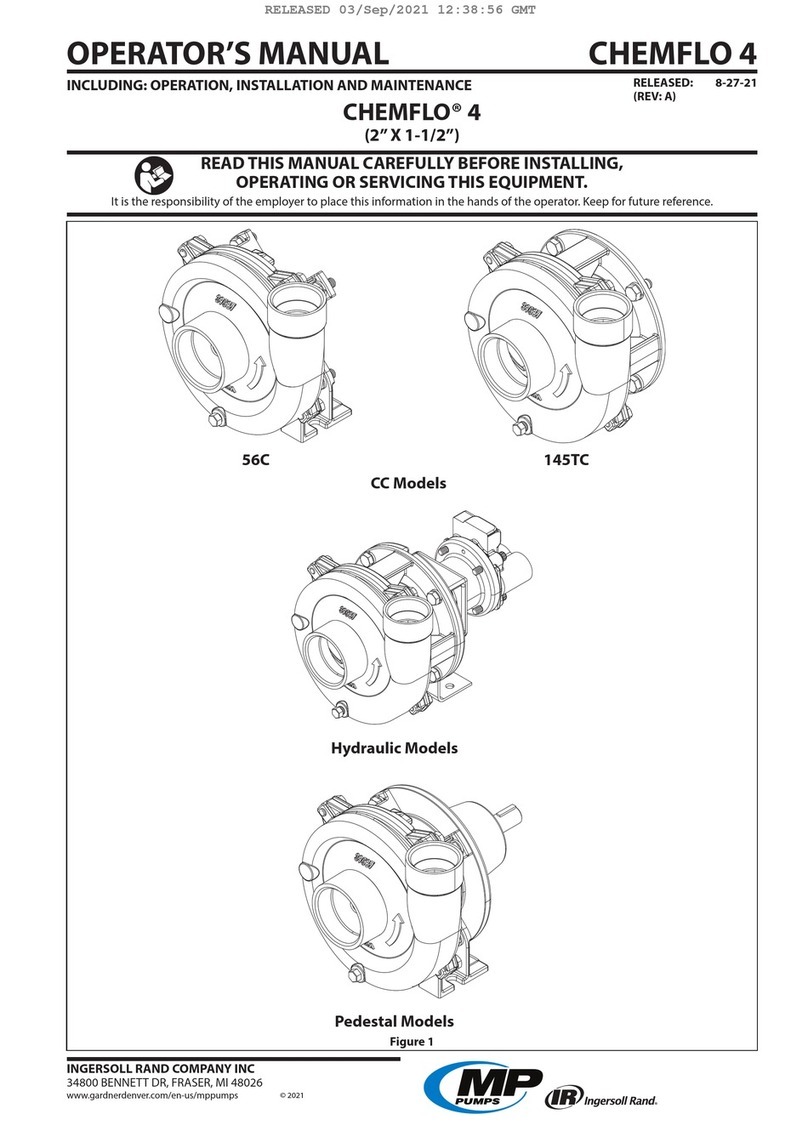

Ingersoll-Rand MP PUMPS CHEMFLO 4 56C User manual

Ingersoll-Rand

Ingersoll-Rand ARO 670098 User manual

Ingersoll-Rand

Ingersoll-Rand MP PUMPS CHEMFLO 1 User manual

Ingersoll-Rand

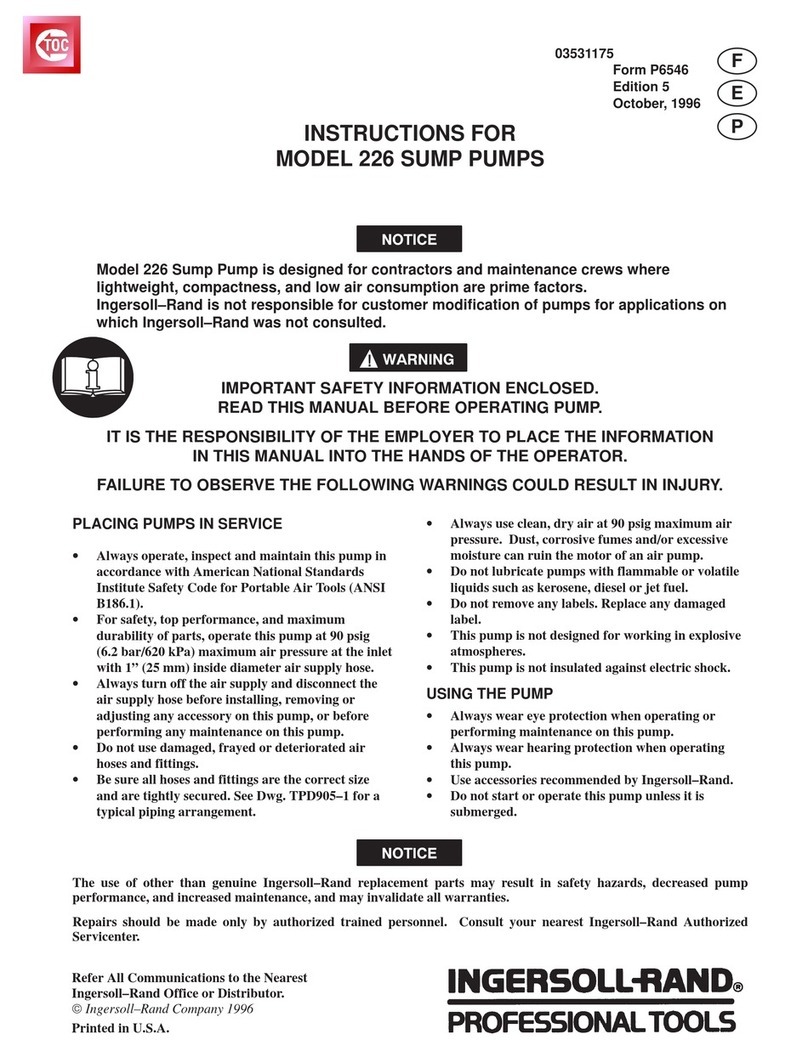

Ingersoll-Rand 226 User manual

Ingersoll-Rand

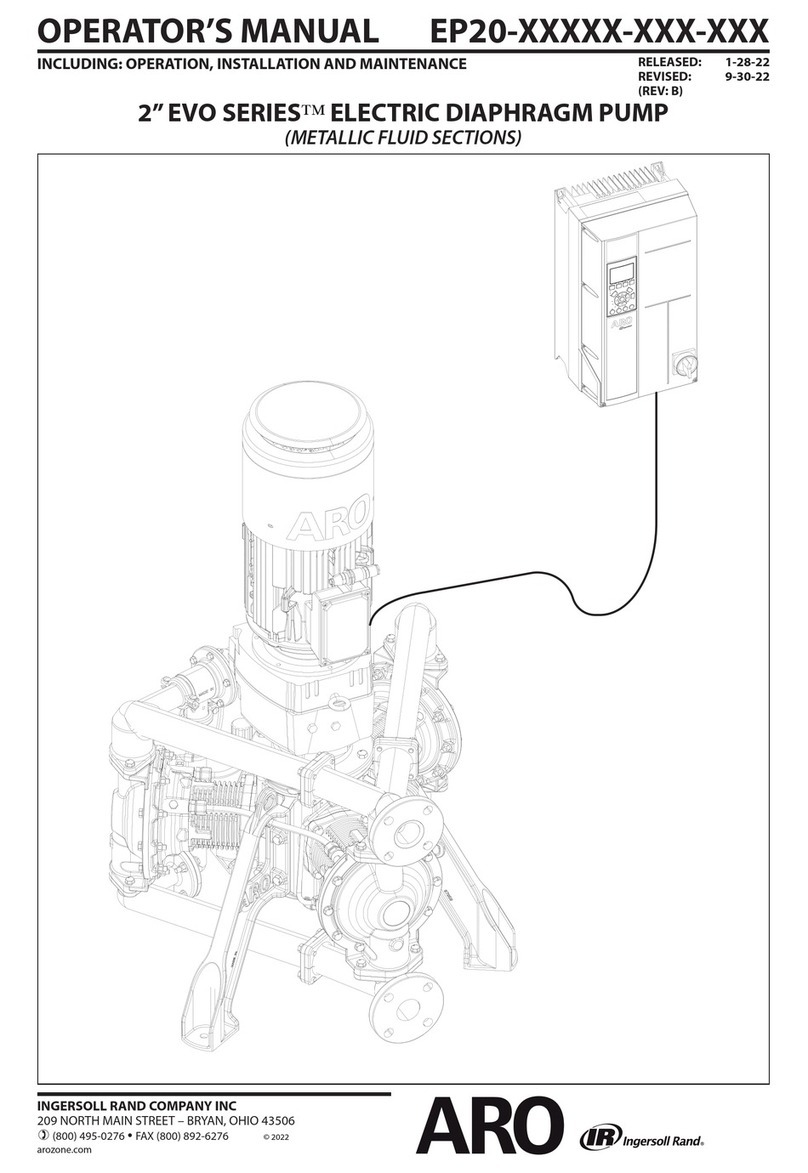

Ingersoll-Rand ARO EVO Series User manual

Ingersoll-Rand

Ingersoll-Rand ARO SD20 B Series User manual

Ingersoll-Rand

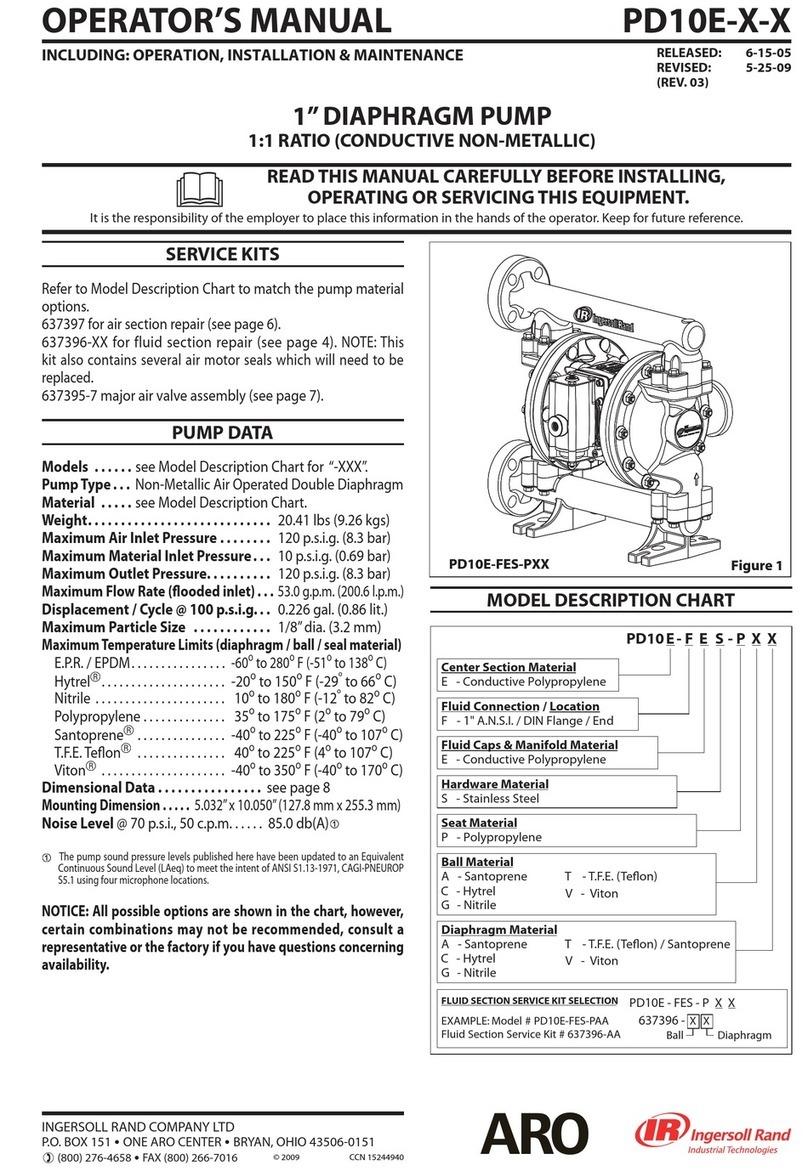

Ingersoll-Rand PD10E-X-X User manual

Ingersoll-Rand

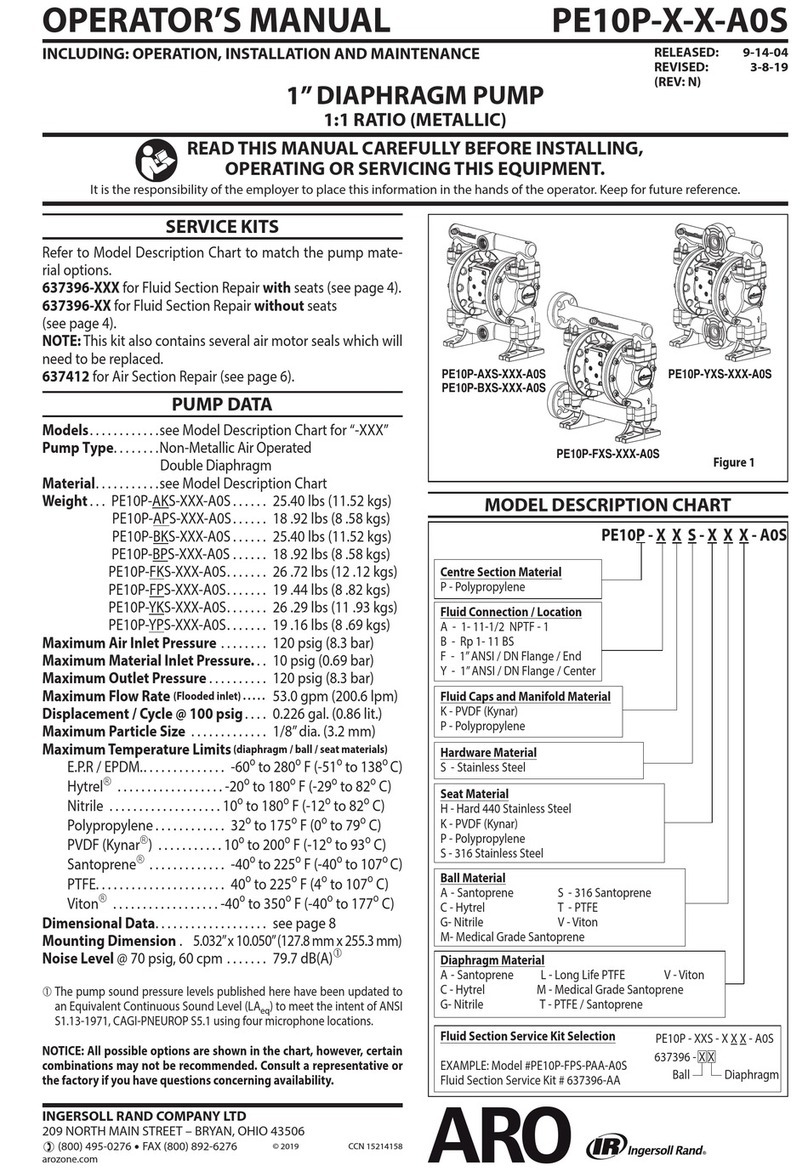

Ingersoll-Rand PE10P-A0S Series User manual

Ingersoll-Rand

Ingersoll-Rand PD07P-X-X User manual

Ingersoll-Rand

Ingersoll-Rand 6662AX-X-C User manual

Ingersoll-Rand

Ingersoll-Rand 66M150-XXX-C User manual

Ingersoll-Rand

Ingersoll-Rand 66243-X User manual

Ingersoll-Rand

Ingersoll-Rand ARO PD10 Series User manual

Ingersoll-Rand

Ingersoll-Rand ARO 666300 C Series User manual

Ingersoll-Rand

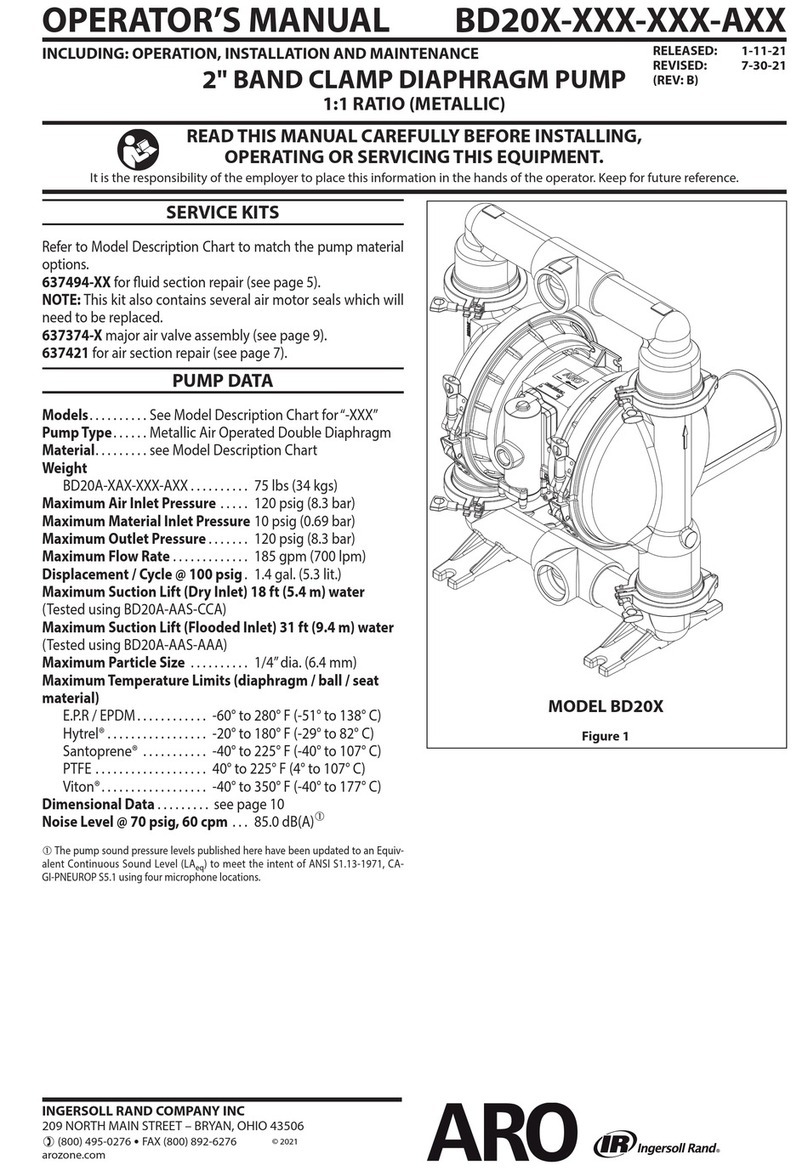

Ingersoll-Rand ARO BD20-A Series User manual

Ingersoll-Rand

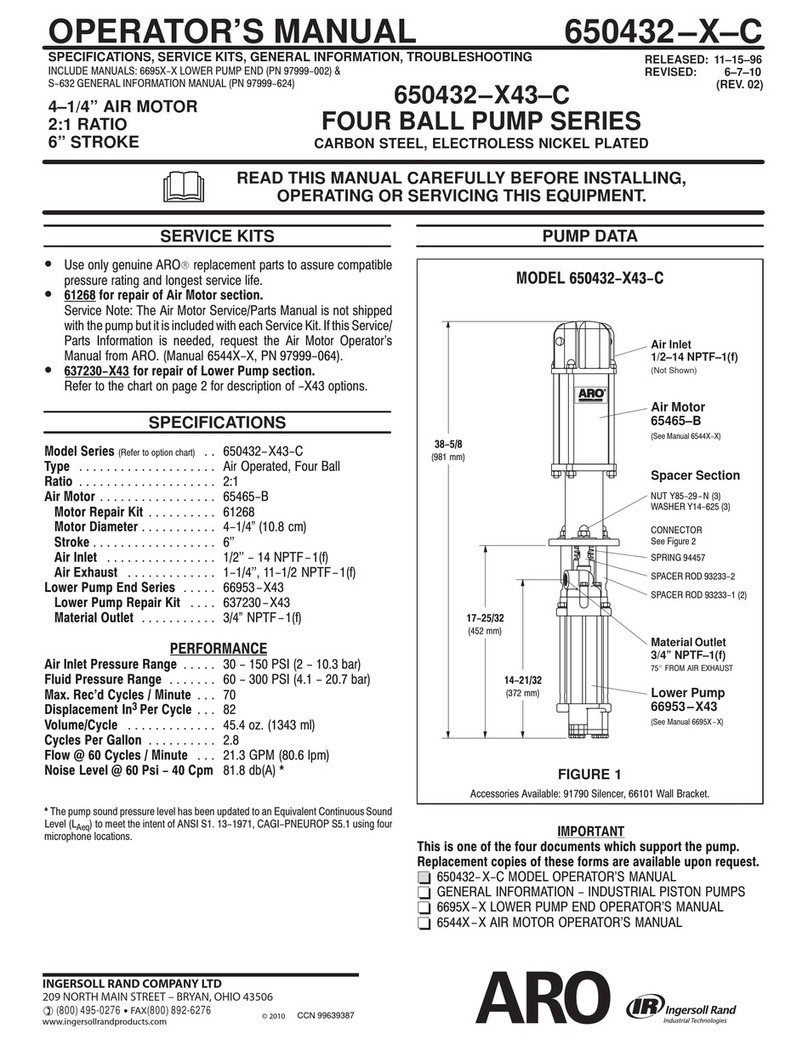

Ingersoll-Rand ARO 650432-X43-C Series User manual

Ingersoll-Rand

Ingersoll-Rand ARO 66625 Series User manual

Ingersoll-Rand

Ingersoll-Rand ARO PX03P Series User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual