INNALABS AI-Q-2010 User manual

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 1of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

Quartz Accelerometer

AI-Q-2010

AI-Q-2020

AI-Q-2030

USER MANUAL

Revision 1.0

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 2of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

PROPRIETARY NOTE

The information contained within this user manual (the

“Documentation”) is proprietary to InnaLabs, and is intended solely

for the use of InnaLabs customers, in the design or development of

systems whose purpose is to operate using InnaLabs inertial sensors.

You may not reproduce, distribute, republish, download, display,

post, or transmit this Documentation in any form or by any means

including, but not limited to, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written consent of

InnaLabs.

InnaLabs disclaims any liability arising out of use of this

Documentation.

This Documentation is disclosed as seen with no warranties other

than that defined in Appendix A.

© 2015 InnaLabs Ltd. All rights reserved.

INNALABS is a trademark of InnaLabs Ltd.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 3of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

This user manual supports the following INNALABS accelerometer part numbers:

AI-Q-2010

AI-Q-2020

AI-Q-2030

Quartz Pendulous Accelerometers

Technical and performance specifications, interface data and mounting guidelines are

included.

Throughout this document, AI-Q-20X0 refers collectively to the 3 different part numbers AI-

Q-2010, AI-Q-2020, and AI-Q-2030.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 4of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................................ 6

1.1 Reference documents...........................................................................................................................6

1.2 Abbreviations .......................................................................................................................................6

1.3 Product description ..............................................................................................................................6

1.4 Product Performance ...........................................................................................................................7

1.5 Technology description ........................................................................................................................8

2. INTERFACES .............................................................................................................................10

2.1 Interface Control Drawing ..................................................................................................................10

2.2 Electrical Interface and Wiring ...........................................................................................................10

2.3 Mass...................................................................................................................................................14

2.4 Mounting ...........................................................................................................................................15

2.5 Preliminary Testing ............................................................................................................................15

2.6 Electrical characteristics .....................................................................................................................17

3. FUNCTIONAL CHARACTERISTICS ..................................................................................... 18

3.1 General comment...............................................................................................................................18

3.2 Handling Requirements ......................................................................................................................18

3.3 Error model ........................................................................................................................................19

3.4 Start-up time ......................................................................................................................................19

3.5 Warm-up time....................................................................................................................................20

3.6 Input Acceleration and input Acceleration Limits ...............................................................................20

3.7 Scale factor.........................................................................................................................................20

3.8 Bias ....................................................................................................................................................21

3.9 Frequency response and bandwidth...................................................................................................22

3.10 Vibration Sensitivity ...........................................................................................................................23

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 5of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

3.11 Misalignment .....................................................................................................................................23

4. ENVIRONMENTAL CONDITIONS ........................................................................................ 24

4.1 Operating temperature ......................................................................................................................24

4.2 Non-Operating temperature ..............................................................................................................24

4.3 Humidity ............................................................................................................................................24

4.4 Mechanical environment....................................................................................................................24

4.5 EMI - EMC...........................................................................................................................................26

5. PRODUCT MARKING..............................................................................................................26

6. PACKAGING AND TRANSPORT...........................................................................................27

7. ACCEPTANCE TEST ................................................................................................................27

8. ACCEPTANCE TEST CERTIFICATE.....................................................................................29

9. TECHNICAL SUPPORT ...........................................................................................................29

APPENDIX A –LIMITED WARRANTY ON HARDWARE ......................................................30

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 6of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

1. INTRODUCTION

1.1 RE F E RE N C E D O C U ME N T S

[RD1] IEEE Std 1293-1998 R2008, IEEE Standard Specification Format Guide and Test

Procedure for Linear, Single-Axis, Nongyroscopic Accelerometers

[RD2] IN-IR-DWG-0447-02, AI-Q-20X0 Accelerometer Interface Control Document,

revision 2, 27/04/2015

1.2 AB B RE V I A T I ON S

°C

Degrees Celsius

ATC

Acceptance Test Certificate

dB

Decibels

EMC/EMI

Electromagnetic Compatibility, Electromagnetic Interference

g

Acceleration due to gravity

GND

Ground

Hz

Hertz

ICD

Interface Control Document

K

Kelvin

mA

Milliamps

mrad

Milliradians

MTBF

Mean Time Between Failures

mV

Millivolts

mW

Milliwatts

N/A

Not Applicable

Ppm

Parts Per Million

PSD

Power Spectral Density

rad

Radians

RMS

Root Mean Square

s

Second

T

Temperature

V

Volts

VDC

Volts Direct Current

W

Watts

1.3 PR O D U CT D E S C R I PT I O N

The AI-Q-20X0 is a family of single axis, closed loop quartz pendulous accelerometers. These

accelerometers offer navigation grade performance with exceptional repeatability and

reliability, making it the ideal choice for demanding navigation systems. Each accelerometer

is provided with thermal compensation models for bias, scale factor and misalignment (up

to 4th order), and is focussed on fulfilling the operational requirements of inertial systems

which require navigation grade performance, low output noise, large bandwidth, small size,

low weight and high reliability.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 7of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

The accelerometer is ready for use within 100 milliseconds of power-on (typically 20 ms)

and provides an analogue current output proportional to applied acceleration along the

reference axes (up to ±60 g).

1.4 PR OD U C T PE R F O R M A N C E

Parameters

Units

AI-Q-2010

AI-Q-2020

AI-Q-2030

Input Range

g

±60

±60

±60

Bias

mg

<4

<4

<4

One-year Composite Repeatability (3)

μg

<550

<220

<160

Temperature Sensitivity

µg/°C

<30

<30

<30

Scale Factor

mA/g

1.2 to 1.46

1.2 to 1.46

1.2 to 1.46

One-year Composite Repeatability (3)

ppm

<600

<500

<310

Temperature Sensitivity

ppm/°C

<180

<180

<180

Axis Misalignment

µrad

<2000

<2000

<2000

One-year Composite Repeatability (3)

µrad

<100

<100

<100

Vibration Rectification

μg/g2RMS

<40 (50-500 Hz)

<150 (500-2000 Hz)

<40 (50-500 Hz)

<60 (500-2000 Hz)

<20 (50-500 Hz)

<60 (500-2000 Hz)

Intrinsic Noise

μgRMS

<7 (0-10 Hz)

<70 (10-500 Hz)

<1500 (500-10 kHz)

<7 (0-10 Hz)

<70 (10-500 Hz)

<1500 (500-10000 Hz)

<7 (0-10 Hz)

<70 (10-500 Hz)

<1500 (500-10000 Hz)

Operating Temperature

°C

-55 to +95

-55 to +95

-55 to +95

Shock

g

250

250

250

Vibration Peak Sine

g, Hz

15g @ 20 to 2000 Hz

15g @ 20 to 2000 Hz

15g @ 20 to 2000 Hz

Resolution/Threshold

μg

<1

<1

<1

Bandwidth

Hz

>300

>300

>300

Temperature Model

Yes

Yes

Yes

Quiescent Current per Supply

mA

<16

<16

<16

Quiescent Power @ ±15VDC

mW

<480

<480

<480

Electrical interface

Temp Sensor

Temp Sensor

Temp Sensor

Voltage Self-Test

Voltage Self Test

Voltage Self Test

Current Self-Test

Current Self Test

Current Self Test

Power/Signal Ground

Power/Signal Ground

Power/Signal Ground

-10 VDC Output

-10 VDC Output

-10 VDC Output

+10 VDC Output

+10 VDC Output

+10 VDC Output

Input Voltage

VDC

±13 to ±28

±13 to ±28

±13 to ±28

Weight

g

71 ±4

71 ±4

71 ±4

Diameter below mounting surface

mm

25.45 Max

Ø 25.45 Max

Ø 25.45 Max

Height –bottom to mounting surface

mm

14.85 Max

14.85 Max

14.85 Max

Case Material

300 Series Stainless

Steel

300 Series Stainless

Steel

300 Series Stainless

Steel

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 8of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

1.5 TE C H N OL O G Y D E S C R I PT I O N

The core of the proof (or seismic) mass of InnaLabs® pendulous accelerometers is a high

purity fused quartz disc structure connected to a rigid outer frame by two thin hinges

(Figure 1). The overall structure is monolithic and a deposited gold film is used to form an

electrode pattern onto the surface of the pendulum as required for capacitive detection and

for connection to the torque conducting leads

Figure 1 –Pendulum

Figure 2 –Accelerometer

Each accelerometer (Figure 2) includes a central ‘cell’, which contains the pendulum and

electrostatic and electromagnetic circuit components used as parts of the closed loop

control system.

When acceleration is applied perpendicularly to the proof mass, the servo loop circuit

derives an error signal from the capacitive detection and delivers a current into two coils

attached symmetrically to each side of the proof mass. Laplace forces are then applied to

the winding and therefore the proof mass will be maintained in a capture or null mode with

its centre in a null position, over a broad frequency band of input accelerations (i.e. >2 kHz

typical). As the current through the coils is proportional to the applied acceleration, the

same current flowing through an external load resistor will then generate an output voltage

proportional to acceleration.

Figure 3 shows a simplified diagram of the closed loop system.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 9of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

N

S

Pendulum

N

S

Capacitive Plate

(Lower Case)

Current

Amplifier

&

PID Control

Servo

Amplifier

-

+

Feedback

Compensation

Signal Out

Pin 1

Current Torque

Pin 2

Self Test

Pin 7

Torque

Motor

Coils

Capacitive Plate

(Upper Case)

Magnet

(Upper Case)

Magnet

(Lower Case)

Torque Motor Coil

(Upper Case)

Torque Motor Coil

(Lower Case)

Detector

Lower

Case

Temperature Output

Pin 6

Power Supply

Negative Power Supply

Pin 3

Positive Power Supply

Pin 4

Ground

Pin 8

-9V

Pin 9

+9V

Pin 10

GND

VIN-

VIN+

–VREF

+ VREF

Upper

Case

Note: The mechanical

(chassis) ground is isolated

from the electrical ground

(pin 8)

Figure 3 –System Block Diagram

The current required in the torque motor coils to re-centre the pendulum is directly

proportional to the applied acceleration. This current is output on the Signal Out pin as the

acceleration signal. Typically, a precision resistor is used externally to the accelerometer to

convert the current output to a voltage.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 10 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

The definition of the accelerometer axes, as described in annex 3 of [RD1], are shown in

Figure 4.

Input Axis

(IA)

Hinge Axis

(OA)

Pendulum Axis

(PA)

Figure 4 –AI-Q-20X0 Axes

The axes are:

Input Axis (IA)

–

The sensitive axis of the accelerometer

Pendulous Axis (PA)

–

The axis normal to the plane of the pendulum

Output (Hinge) Axis (OA)

–

The axis parallel to the line through the hinge of the pendulum

The positive direction of OA is defined by the vector operation:

Note: For more information about the technology or physical principles see [RD1] , Annex C,

pp. 110-117:

2. INTERFACES

2.1 IN TE R F AC E CO N T R O L DR A W I N G

The reference document [RD2] provides all necessary information about the AI-Q-20X0

mechanical interfaces.

2.2 EL EC T R I C AL IN T E R F A CE A ND WI R I N G

The AI-Q-20X0 has ten connection pins, as shown in Figure 5, below.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 11 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

Figure 5 –AI-Q-20X0 Pins

The assignment of pins on the AI-Q-20X0 is shown in the following table:

Pin

Function

Type

Characteristics

1

Signal Out

Analogue

Acceleration output, current signal, section 2.2.1

2

Current Torque

Analogue

Current input test pin, section 2.2.5

3

Negative Power Supply

Power

-13 V to -28 V, section 2.2.4

4

Positive Power Supply

Power

+13 V to +28 V, section 2.2.4

5

Not Connected

N/A

Do not connect to this pin.

6

Temperature Sensor Output

Analogue

Temperature output, current signal, section 2.2.3

7

Voltage Self-Test

Analogue

Voltage input test pin, section 2.2.5

8

Signal & Power Return

Ground

Ground reference for power supplies and signals

9

-10 V DC

Analogue

Voltage output, section 2.2.5

10

+10 V DC

Analogue

Voltage output, section 2.2.5

2.2.1 Electrical Connection

The diagram in Figure 6 shows the connections to the accelerometer for normal operation.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 12 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

Power Supply

+VIN -VIN GND

RMEAS

RTEMP

UTEMP

UMEAS

1

2

3

4

5

6

78

Figure 6 –AI-Q-20X0 Measurement Connections

2.2.2 Acceleration Measurement

The AI-Q-20X0 accelerometer produces an output current proportional to the acceleration

applied along the sensitive axis of the accelerometer.

The output of the accelerometer is typically connected to a load resistor, RMEAS, which

provides a voltage output, UMEAS. The nominal output is:

2.2.3 Temperature Measurement

The AI-Q-20X0 internal temperature sensor produces an output current proportional to

absolute temperature. The device acts as a high impedance, constant current regulator

passing 1 µA/°C. The temperature sensor is calibrated to output 303.2 µA at 30 °C (303.2 K).

Parameters of the internal temperature sensor are shown in the table below.

Parameters

Units

Values

Typical

Maximum

Nominal Current Output at 30 °C

µA

303.2

Nominal Temperature Coefficient

µA/°C

1

Calibration Error @ 30 °

°C

±5.0

Nonlinearity#1

°C

±1.5

Repeatability

°C

±0.1

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 13 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

Parameters

Units

Values

Long-Term Drift

°C

±0.1

Current Noise

pA/√Hz

40

Effective Shunt Capacitance

pF

100

Electrical Turn-On Time

µs

20

Note #1: Nonlinearity is defined as the deviation of current over temperature from a best-fit straight line.

The output of the temperature sensor is typically connected to a load resistor RTEMP, which

provides a voltage output, UTEMP. The nominal output at a given temperature is:

2.2.4 Power Supplies

The AI-Q-20X0 requires a bipolar power supply in the range ±13 V to ±28 V. It is not

necessary for the two supplies to be of equal magnitude. The quiescent current

consumption will increase at higher input voltages.

The AI-Q-20X0 has a ripple rejection characteristic as shown in Figure 7 (for an RMEAS value of

1 kΩ). The ripple rejection is presented in dB(mA/V), as the acceleration sensitivity depends

on the scale factor.

Figure 7 –AI-Q-20X0 Ripple Rejection Characteristics

2.2.5 Test Functionality

The AI-Q-20X0 has three options for test functionality: the current torque connection (pin

2), the voltage self-test connection (pin 7) and the voltage output pins (pins 9 and 10).

0

10

20

30

40

50

60

70

80

90

100

110 100 1000 10000 100000

PSRR [dB(ma/V)]

Frequency [Hz]

Positive Rail Negative Rail

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 14 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

2.2.5.1 Current Torque

The current torque pin (2) is a current input pin. Current on this pin is injected into the

output of the servo amplifier, as shown in Figure 3. The servo loop acts to null the injected

current, increasing current draw on the appropriate power pin (a positive input current

increases current draw on the negative supply and vice versa):

PositiveCurrentonPin2=NegativeCurrentonPin3

NegativeCurrentonPin2=PositiveCurrentonPin4

This functionality can be used to verify that the electronics in the accelerometer can deliver

the current required under high g conditions (static and/or dynamic). Based on the scale

factor of the accelerometer:

In normal operation, this pin should be left unconnected.

2.2.5.2 Voltage Self-Test

The voltage self-test pin (7) is a voltage input pin. A voltage applied to this pin injects a

signal into the integrator of the control loop electronics, as shown in Figure 3. As the

integrator input is offset (assuming a DC input), the servo loop compensates the input,

offsetting the position of the pendulum, and is visible as a transient on the accelerometer

output. A step input to this test pin can be used to measure the accelerometer bandwidth

from the transient response.

In normal operation, this pin should be left unconnected.

2.2.5.3 Voltage Output Pins

Pins 9 and 10 of the accelerometer are used to check the correct operation of the AI-Q-20X0

internal electronics. In normal operation, the output of these pins can be measured:

Pin9Output=10VDC

Pin10Output=+10VDC

In normal operation, these pins should be left unconnected, as loading these pins can affect

the operation of the accelerometer.

2.3 MA S S

The mass of the AI-Q-20X0 accelerometers is 71 g ±4 g.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 15 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

2.4 MO U N TI N G

The external mounting holes for the AI-Q-20X0 are shown in Figure 8 (see [RD2] for full

details). The mounting holes are designed for metric M3 screws with a tightening torque of

20 –40 cNm.

Figure 8 –AI-Q-20X0 Mounting Holes

N.B.: For optimum thermal misalignment performance, it is recommended the accelerometer be

mounted to a 300 series stainless steel base

The recommended material for screws is stainless steel, in order to match the thermal

expansion rate of the accelerometer housing.

During mounting, if a torque wrench is used, it is recommended to maintain it not triggered,

in order to avoid propagating shocks into the accelerometer.

2.5 PR E L IM I N A R Y TE S T I N G

Before connecting and mounting the AI-Q-20X0, a simple familiarisation test is suggested if

this is the User’s first introduction to the product. This test will also verify proper unit

operation and assist in troubleshooting.

2.5.1 Equipment needed to Test

±(13 –28) VDC power supply limited to 20 mA

Load resistor (RMEAS), up to 10 kΩ

A voltmeter / oscilloscope

2.5.2 Test Procedure

Place the AI-Q-20X0 on a flat surface with the connector pins facing up.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 16 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

Connect the power supply according to §2.2 (positive supply to pin 4 and negative

supply to pin 3, ground to pin 8).

Connect the load resistor between the Signal Out (pin 1) and Signal Return (pin 8).

Connect the voltmeter / oscilloscope across pins 1 (Signal Out) and 8 (Signal/Power

Return) of the AI-Q-20X0 interface connector to test

Wires can be connected to the accelerometer using a test connector (InnaLabs can provide

these connectors on request), or by soldering wires directly to the pins. If soldered

connections are used, this should be done as per the state of the art, in such a way as to

avoid short circuits between pins.

Figure 9 –Electrical Connection to AI-Q-20X0

2.5.2.1 ±1 g Tumble Test

Switch on the power supply

Observe the output of the accelerometer on the voltmeter / oscilloscope.

oThe output should show the equivalent of +1 g, according to the following

equation (from Figure 6):

Acceleration = (UMEAS / RMEAS) / Scale Factor

Rotate the accelerometer through 180°, so that the connector pins are now facing

down.

oThe output should now show the equivalent of -1 g.

Switch off the power supply.

Figure 10 and Figure 11 show the orientations for ±1 g measurements.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 17 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

Figure 10 –+1 g Orientation

Figure 11 –-1 g Orientation

2.6 EL EC T R I C AL C H A RA C TE R I S T I C S

2.6.1 Load Resistor Selection

The external resistor used affects the maximum g-range measurable by the test system, due

to voltage drop across both it and the internal coil resistance.

Where:

VIN: Absolute Power Supply Voltage

K1: Scale Factor (from ATC)

RL: Coil Resistance (from ATC)

RMEAS: Measurement Resistance

For example:

VIN = ±13 V

K1= 1.20 mA/g

RL= 170 Ω

RMEAS = 10 Ω

The acceleration range (at which point the accelerometer output saturates) using the

parameters above is ±60.2 g. As the input voltage is increased, a larger voltage drop is

available, enabling the same acceleration level to be measured with a larger measurement

resistor (thus improving signal-to-noise ratio). Using the same formula with a 215 Ω

measurement resistor, at ±28 V, the saturation range is ±60.6 g.

With a scale factor of 1.46 mA/V, a 147 Ω (or less) resistor is required at ±28 V in order to

meet the full measurement range.

The absolute acceleration limit over temperature is dependent on the range of the

parameters in the equation above.

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 18 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

This can be re-written as:

When selecting a load resistor, the resistance of any associated interconnecting cables must

be taken into account as these add to the overall resistance. As such, the maximum cable

length depends on the voltage drop that can be tolerated.

It is recommended the resistance (and by association the length) of the cable is kept to a

minimum in order to minimise variations in the measured output due to resistance changes

over temperature.

3. FUN CT ION AL C HA RA CT ER I ST I CS

3.1 GE N E RA L C O M M EN T

When not specified, the performance detailed below is available over the full operating

conditions as described in section 4.

3.2 HA N D L IN G RE Q U I R E ME N T S

Preventing ESD Damage

An unpackaged AI-Q-20X0 is to only be handled, stored or transported in an ESD

protected area [EPA]

When handling the accelerometer, the person is to be grounded via a wrist strap system

or a flooring/footwear system

Outside the EPA, the AI-Q-20X0 is to be enclosed in ESD protective packaging. An

unpackaged AI-Q-20X0 inside the EPA is to be stored or transported on grounded work

surfaces or shelving

When soldering to the pins the soldering iron tip should be grounded. Alternatively,

prior to connecting the accelerometer pins to the user system (including cable wires,

power supply, electronics, etc.), as a precaution, it is recommended that all pins be

shorted to the mechanical ground (accelerometer housing). Once the accelerometer is

connected to the user system, before power on, the short to ground should be released

Preventing Physical Damage

Handle the AI-Q-20X0 with care at all times

The unpowered shock limit of the AI-Q-20X0 is 250 g in any axis

Preventing Electrical Damage

Do not touch or make connections to the unit with the power on. Doing so may damage

the unit and/or cause injury to personnel

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 19 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

Double-check all test equipment connections before applying power

Use battery-operated test equipment whenever possible

Make sure that all test equipment is isolated from ground

3.3 ER R O R M O D E L

3.3.1 General

When the pendulum is servo controlled in position, the current in the torque motor acts as

a biased estimator of the specific force applied along the pendulum input axis.

The accelerometer model equation is defined as a series that mathematically relates the

accelerometer output amto the components of applied acceleration along the reference

axes. Each accelerometer input axis has two misalignments relative to the nominal IA, in the

IA-PA and IA-OA planes.

The expression of the accelerometer model at the centre of mass of the pendulum is:

Where:

Indicated accelerometer output (g)

Components of the acceleration along the nominal I, P and O axes (g)

Accelerometer output current (mA)

Bias (g)

Scale factor of the torque motor (mA/g)

Quadratic nonlinearity (g/g²)

Direction cosine misalignment angle of the IA axis relative to the nominal in the IA-PA and IA-OA

planes (rad)

Un-modelled error (g)

9.81792 m/s-2 at InnaLabs Dublin (IRELAND)

3.3.2 Thermal Modelling

The accelerometer performance over temperature is modelled for bias, scale factor and

misalignment using polynomial functions (first to fourth order), generated using the least-

squares method.

3.4 ST A R T-U P T I M E

The accelerometer output is within of the input acceleration, at an input acceleration of

±1 g, within 100 ms of power on (20 ms typical).

AI-Q-20X0 Accelerometers User Manual

IN-IR-MPD-72-256

Rev 1.0

22/09/2015

Page 20 of 31 INNALABS PROPRIETARY INFORMATION

www.innalabs.com

3.5 WAR M -U P T I M E

At ambient temperature (25 °C ± 5 °C), over the first 30 minutes of operation, the un-

modelled parameters and the modelled parameters of the accelerometer drift as shown in

the table below. After 30 minutes, the performance parameters are described by the

following sections:

Warm-Up Drift

No Temp. Comp.

With Temp. Comp.

Bias, K0

20µg

5µg

Scale Factor, K1

20ppm

5ppm

3.6 IN PU T AC C E L E RA T I O N A N D I N P U T AC C E L E RA T I O N LI M I T S

Once the applied in-axis acceleration comes back within the operational limits, the recovery

time to get a functional output with full performance is less than 10 ms.

Measurable input acceleration limits along the sensitive axis (IA) of the AI-Q-20X0:

The measurable acceleration limit is also affected by the selection of the load resistor, see

section 2.6.1.

3.7 SC A L E F A C T O R

3.7.1 Nominal value

The scale factor nominal value is in the range:

K1

1.20mA/g1.46mA/g

3.7.2 Scale factor thermal sensitivity

At the beginning of life, the average change in the scale factor resulting from a change in

steady state operating temperature is as follows:

dK1/dT

3.7.3 Scale factor One Year Composite Repeatability

The scale factor one year composite repeatability parameter is the overall variation arising

from a number of different errors, including hysteresis and ageing, and under some specific

external conditions. The mission profile considered is based on two full-range temperature

cycles per month.

This manual suits for next models

2

Table of contents

Popular Measuring Instrument manuals by other brands

Sony

Sony MAVE-F555 Operation manual

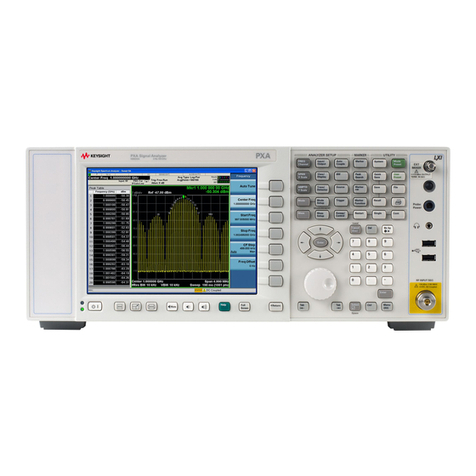

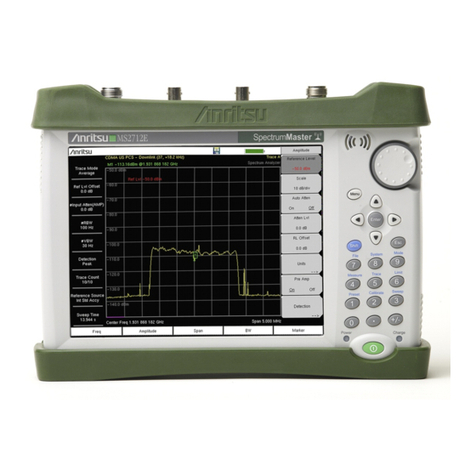

Anritsu

Anritsu Spectrum Master MS2712E user guide

General

General EP8710 user manual

ScottishPower

ScottishPower Aclara SMETS2 Guide

Büttner Elektronik

Büttner Elektronik Dometic MT iQ Basic Pro Installation and operating manual

Ambient Weather

Ambient Weather BA30806 user manual