Shimadzu PDA-7000 User manual

211-78001E

Jun. 2018

SHIMADZU OPTICAL EMISSION SPECTROMETER

PDA-7000

INSTRUCTION MANUAL

Read the instruction manual thoroughly before you use the product.

Keep this instruction manual for future reference.

* Refer to the following document for detailed operation of software.

Data Processing Software PDAfor Windows Operatioin Manual

P/N 211-54796

Data Processing Software PDA for Windows Installation Manual

P/N 211-78114

ANALYTICAL & MEASURING INSTRUMENTS DIVISION

(This page is intentionally left blank.)

i

Introduction

Read this Instruction Manual thoroughly before using the product.

Thank you for purchasing Shimadzu optical emission spectrometer PDA-7000.

PDA-7000 is a PDA photoelectric-photometric optical emission spectrometer which

simultaneously and quickly carries out analyses of multi-elements in metal with a high

precision. The photoelectric-photometric emission spectrometer, which is adopted in a

wide range of fields, is an essential instrument for quality control.

This manual describes the installation, operation, usage cautions, accessories and

options for this product. Read this manual thoroughly before using the product and

operate the product in accordance with the instructions in this manual.

Also, keep this manual for future reference.

ii

IMPORTANT

•If the user or usage location changes, ensure that this Instruction Manual is always

kept together with the product.

•If this manual or a product warning label is lost or damaged, immediately contact

your Shimadzu representative to request a replacement.

•To ensure safe operation, read all Safety Instructions before using the product.

•To ensure safe operation, contact your Shimadzu representative if product

installation, adjustment, or re-installation (after the product is moved) is required.

Notice

•Information in this manual is subject to change without notice and does

not represent a commitment on the part of the vendor.

•Any errors or omissions which may have occurred in this manual despite

the utmost care taken in its production will be corrected as soon as

possible, although not necessarily immediately after detection.

•All rights are reserved, including those to reproduce this manual or parts

thereof in any form without permission in writing from Shimadzu

Corporation.

•Microsoft and Windows are registered trademarks of Microsoft

Corporation in the United States and/or other countries. Other company

names and product names mentioned in this manual are trademarks or

registered trademarks of their respective companies.

The TM and ® symbols are omitted in this manual.

© 2004-2018 Shimadzu Corporation. All rights reserved.

iii

Indications Used in This Manual

Dangers, Warnings, Cautions, and Notes are indicated using the following conventions:

Note

Dangers, Warnings, Cautions, and Notes are indicated using the

following conventions:

Warning

Indicates a potentially hazardous situation which, if not

avoided, could result in serious injury or possibly

death.

Caution

Indicates a potentially hazardous situation which, if not

avoided, may result in minor to moderate injury, or

equipment damage.

Note

Emphasizes additional information that is provided to

ensure the proper use of this product.

iv

Warning Labels

Warning

Electric Shock

Before removing the excitation unit front panel, be sure to turn OFF

the power of the excitation source unit. Never remove other panels.

Front Panel of Excitation Unit

v

Safety Instructions

To ensure safe product operation, read these important safety instructions carefully before

use and follow all DANGER, WARNING and CAUTION instructions given in this section.

Installation Site

Warning

Do not operate PDA-7000 under explosive and/or corrosive

atmosphere.

Note

When installing PDA-7000 near apparatus generating a ferromagnetic

field such as an electric arc furnace, contact your Shimadzu

representative.

Installation

To ensure safe operation, contact your Shimadzu representative if product installation,

adjustment, or re-installation (after the product is moved) is required.

vi

Operation

PDA-7000 generates high voltage based on the measurement principles. If it is correctly

used, no problem will occur. If not, it may cause an accident and damage. For safety

operation and dangerous accident prevention, strictly observe the following precautions.

1. Precautions for operator safety and for handling the instrument

Warning

PDA-7000 may cause radio disturbance during discharge. Personnel

with pacemakers should be especially careful during discharge.

Caution

Electric Shock

Never start the discharge without correctly setting and holding the

sample on the spark stand.

Caution

●Thoroughly read the instruction manual to strictly observe it. If you

have any question, contact your Shimadzu representative.

●Keep this instruction manual near the instrument for quick

reference of the operation procedures and safety precautions

anytime necessary.

Note

The contents of the hard disk of the personal computer may be lost as

the result of an unforeseen accident. Always create a backup to

protect critical data from such accidents.

vii

2. Restriction of operators

Warning

The inside of the instrument should only be repaired by personnel

specially trained by Shimadzu Corporation since it is dangerous. Do

not disassemble or modify the instrument without permission as it

may compromise the safety of the instrument.

Caution

Use of the instrument is allowed only to personnel who have

understood the safety precautions well and have been well-trained for

the operating procedure.

It is a must to establish a system by which no one other than the

operator above is allowed to use it.

viii

In an emergency

Warning

●In case of leakage of argon gas

If it is left, lack of oxygen may occur. Immediately ventilate the

working area and check for gas piping.

●In case of abnormal temperature raise of the spectrometer unit

The room temperature should be kept within the range of 10 - 28°C.

If it exceeds 30°C, the temperature of the spectrometer unit may

raise abnormally.

If the temperature of the spectrometer unit exceeds 42°C, the buzzer

at the temperature alarm will give a warning sound. In that case,

turn OFF the AIRCON switch on the switch panel and make sure the

room temperature is within the range of 10 - 28°C. Then, wait until

the temperature inside the spectrometer goes down to the room

temperature, and turn ON the AIRCON switch again.

If the buzzer gives a warning sound even after that, turn OFF the

AIRCON switch and contact your Shimadzu representative.

●Safety measure for other emergency occurrences

If an unpredictable happening like an earthquake, fire, etc. occurs,

first press the emergency stop switch, and then turn OFF all the

power of the distribution panel. After this, each staff must carefully

take an appropriate action to maintain his/her safety.

During a power outage

In case of a power failure, follow the procedure described below.

1. Turn off the MAIN breaker on the switch panel.

2. Turn off theAIRCON, CONSOLE, and SOURCE switches on the switch panel.

3. Turn off the power switch of the vacuum pump.

4. When the power is back, turn on the MAIN breaker on the switch panel.

5. Turn on the AIRCON, CONSOLE, and SOURCE switches on the switch panel.

6. Turn on the power of the vacuum pump.

ix

Handling High-pressure Gas

PDA-7000 requires the use of high-pressure argon gas.

Note that the following points regarding the handling of high-pressure gases in Japan:

1) By law, permission is required to use cylinders containing more than 300m3.

2) When using gas of a pressure that exceeds 980.665kPa (10kgf / cm2) inside the

equipment at room temperature, the equipment is regarded as high-pressure gas

equipment and, by law, notification of use must be submitted.

Refer to your government laws and regulations related to high pressure gas control,

liquefied petroleum gas control, general high pressure gas control, and fire defense.

Also, follow the precautions and instructions below for the safe use of high-pressure gas.

Warning

●Install the gas cylinder in a well-ventilated outdoor location that is

not exposed to direct sunlight and convey the gas indoors via a pipe.

Regarding liquefied gases in particular, this setup is required by law

in Japan.

●Ensure that the temperature of the gas cylinder never exceeds 40°C.

Also, ensure that there are no open flames within 2m of the gas

cylinder.

●Ensure that the location where high-pressure gas is used is well

ventilated and, as part of initial inspection, check for gas leaks with

soapy water.

●Prevent the cylinder from falling or toppling over by securing it with

rope or chain. Be sure not to let liquefied-gas cylinders topple over

into a horizontal position.

●After using the gas, close the cylinder's main valve immediately.

●Inspect the functional capability of the pressure gauge at least once

every three months.

xi

Warranty

Shimadzu provides the following warranty for this product.

1. Period:

Please contact your Shimadzu representative for information about the period of this

warranty.

2. Description:

If a product/part failure occurs for reasons attributable to Shimadzu during the warranty

period, Shimadzu will repair or replace the product/part free of charge. However, in the

case of products which are usually available on the market only for a short time, such as

personal computers and their peripherals/parts, Shimadzu may not be able to provide

identical replacement products.

3. Limitation of Liability:

(1) In no event will Shimadzu be liable for any lost revenue, profit or data, or for special,

indirect, consequential, incidental or punitive damages, however caused regardless of

the theory of liability, arising out of or related to the used of or inability to use the

product, even if Shimadzu has been advised of the possibility of such damage.

(2) In no event will Shimadzu’s liability to you, whether in contract, tort (including

negligence), or otherwise, exceed the amount you paid for the product.

4. Exceptions:

Failures caused by the following are excluded from the warranty, even if they occur

during the warranty period.

(1) Improper product handling

(2) Repairs or modifications performed by parties other than Shimadzu or Shimadzu

designated companies

(3) Product use in combination with hardware or software other than that designated

by Shimadzu

(4) Computer viruses leading to device failures and damage to data and software,

including the product's basic software

(5) Power failures, including power outages and sudden voltage drops, leading to

device failures and damage to data and software, including the product's basic

software

(6) Turning OFF the product without following the proper shutdown procedure leading

to device failures and damage to data and software, including the product's basic

software

(7) Reasons unrelated to the product itself

(8) Product use in harsh environments, such as those subject to high temperatures or

humidity levels, corrosive gases, or strong vibrations

(9) Fires, earthquakes, or any other act of nature, contamination by radioactive or

hazardous substances, or any other force majeure event, including wars, riots, and

crimes

(10) Product movement or transportation after installation

(11) Consumable items

Recording media such as floppy disks and CD-ROMs are considered consumable

items.

* If there is a document such as a warranty provided with the product, or there is a

separate contract agreed upon that includes warranty conditions, the provisions of those

documents shall apply.

xii

After-sales Service and Availability of Replacement Parts

After-Sales Service

If any problem occurs with this product, perform an inspection and

take appropriate corrective action as described in this manual's

troubleshooting section. If the problem persists, or the symptoms

are not covered in the troubleshooting section, contact your

Shimadzu representative.

Replacement Parts

Availability

Replacement parts for this product will be available for a period of

seven (7) years after the product is discontinued. Thereafter, such

parts may cease to be available.

Note, however, that the availability of parts not manufactured by

Shimadzu shall be determined by the relevant manufacturers.

If Shimadzu receives notice of the discontinuation of units or parts,

the necessary quantity for the above period is immediately

calculated and secured. However, such units or parts may cease to

be available within seven years after the discontinuation of the

product, depending on individual manufacturer conditions and on

changes in the quantity required.

Note

When contacting your Shimadzu representative, please provide the

following information.

(1) Product model

(2) Year/Month/Date of purchase

(3) Version No. (for software)

(4) Detailed explanation of the problem

xiii

Disposal Precautions

Dispose of this product using a qualified industrial waste management company, in

compliance with the applicable laws in the country where it is used.

xiv

Introduction..................................................................................................................i

Indications Used in This Manual...............................................................................iii

Warning Labels..........................................................................................................iv

Safety Instructions......................................................................................................v

Installation Site .......................................................................................................................... v

Installation.................................................................................................................................. v

Operation...................................................................................................................................vi

In an emergency......................................................................................................................viii

During a power outage ............................................................................................................viii

Handling High-pressure Gas.....................................................................................ix

Warranty.....................................................................................................................xi

After-sales Service and Availability of Replacement Parts....................................xii

Disposal Precautions ..............................................................................................xiii

Definition of Terminology......................................................................................xviii

Parts List ..................................................................................................................xix

Checking of parts.....................................................................................................................xix

Consumables and maintenance parts......................................................................................xx

Repair parts .............................................................................................................................xxi

How to distinguish similar parts..............................................................................................xxii

1Configuration and Function of the Instrument ..................................................1-2

1.1 Switch panel................................................................................................................1-3

1.2 Spark stand .................................................................................................................1-5

1.3 Spectrometer...............................................................................................................1-7

(1) Condenser lens .......................................................................................................1-7

(2) Temperature control circuit......................................................................................1-7

(3) Lamp........................................................................................................................1-8

(4) Evacuation system ..................................................................................................1-8

Contents

xv

1.4 Read-out unit...............................................................................................................1-9

(1) Photo detector (PMT)..............................................................................................1-9

(2) Photo detector sensitivity controller (Attenuator) ....................................................1-9

(3) Integrator.................................................................................................................1-9

1.5 Data processor system .............................................................................................1-10

2Specification.........................................................................................................2-2

2.1 Spectrometer...............................................................................................................2-2

2.2 Excitation unit..............................................................................................................2-2

(1) Spark stand..............................................................................................................2-2

(2) Excitatiion source unit .............................................................................................2-2

2.3 Read-out unit...............................................................................................................2-3

2.4 Data processor system ...............................................................................................2-3

(1) Hardware.................................................................................................................2-3

(2) Software ..................................................................................................................2-4

3Starting and Stopping the Instrument ................................................................3-2

3.1 Inspection before using the instrument.......................................................................3-2

3.2 Starting the instrument (Daily use)..............................................................................3-3

3.3 Starting the instrument after it has not been used for a long time ..............................3-4

3.4 Shutting down the instrument (Daily use) ...................................................................3-5

3.5 Shutting down the instrument for a long time..............................................................3-6

3.6 Emergency stop and recovering .................................................................................3-7

(1) Emergency stop ......................................................................................................3-7

(2) Recovering from emergency stop ...........................................................................3-8

4Operation..............................................................................................................4-2

4.1 Argon gas bubbler.......................................................................................................4-2

4.2 Checking gas flow rate................................................................................................4-4

(1) When the instrument is in operation........................................................................4-4

(2) When the instrument is not used or at nighttime.....................................................4-5

4.3 Turning ON / OFF photo detector ...............................................................................4-6

4.4 Sample pretreatment...................................................................................................4-7

4.5 Setting the sample ......................................................................................................4-9

4.6 Content analysis........................................................................................................4-10

4.7 Recalibration .............................................................................................................4-11

4.8 Master curve recalibration.........................................................................................4-13

4.9 Check analysis..........................................................................................................4-14

xvi

5Maintenance.........................................................................................................5-2

5.1 Maintenance and inspection items..............................................................................5-2

(1) Periodical Maintenance...........................................................................................5-2

(2) Other Maintenance..................................................................................................5-2

(3) Work required after maintenance service................................................................5-3

(4) Maintenance service by Shimadzu service engineer..............................................5-3

5.2 Maintenance Flow.......................................................................................................5-4

5.3 Maintaining the spark stand ........................................................................................5-5

(1) Maintenance cycle...................................................................................................5-6

(2) Maintenance procedure...........................................................................................5-8

5.4 Exchanging the electrode O-ring ..............................................................................5-18

5.5 Cleaning the condenser lens.....................................................................................5-19

5.6 Adjusting the control gap...........................................................................................5-23

5.7 Replacing pump oil....................................................................................................5-26

5.8 Manual scanning.......................................................................................................5-27

5.9 Lamp test...................................................................................................................5-29

5.10 Waste discharge........................................................................................................5-30

5.11 File utility ...................................................................................................................5-31

(1) Saving (Backup)....................................................................................................5-31

(2) Loading (Restoration)............................................................................................5-32

5.12 Replacing recalibration samples...............................................................................5-33

5.13 Replacing argon gas cylinder....................................................................................5-34

5.14 Periodic inspection....................................................................................................5-34

5.15 Cleaning the temperature control fan heater ............................................................5-34

6Installation............................................................................................................6-2

6.1 Temperature and humidity...........................................................................................6-2

6.2 Vibration ......................................................................................................................6-2

6.3 Dust.............................................................................................................................6-2

6.4 Grounding....................................................................................................................6-2

6.5 Power supply...............................................................................................................6-3

6.6 Argon gas....................................................................................................................6-3

6.7 Exhaust equipment .....................................................................................................6-3

6.8 Peripheral equipment..................................................................................................6-4

6.9 Other environmental requirement ...............................................................................6-4

6.10 Moving and Disposing of the product..........................................................................6-4

xvii

7Troubleshooting...................................................................................................7-2

7.1 Basic items to be checked ..........................................................................................7-2

7.2 Troubleshooting...........................................................................................................7-3

7.3 Installing the software..................................................................................................7-4

xviii

Definition of Terminology

Emission analysis

Quantitative analysis method using the emission

spectrometer by measuring the intensity of

emission of atomic spectral line obtained by

vaporized excitation by means of discharge of the

analytical object element contained in a sample.

Photoelectric photometric method

Spectrum intensity measurement method using

the photomultiplier

Electrode

Same as “Counter Electrode”. (tungsten electrode)

Strictly, the sample is also an electrode, because

the discharge is generated in the gap between the

counter electrode and the sample. But, in this

instruction manual, it means counter electrode

unless specially noted.

Pre-burn time

Time set as non-measurement time from

discharge start until emission intensity is stabilized

Integral time

Measurement time in case of measurement of

emission intensity by a specified-time integration

Argon gas

Gas to be carried around the electrode in order to

stabilize discharge and remove influence due to

sample history or absorption by oxygen in air

Analysis sample

Sample prepared for measurement

Standard sample

Sample for creating a working curve of which

quantitative element content was precisely

determined by the chemical analysis method

Set up sample

Sample to be used for calibration of the working

curve for a specified time or at every

measurement of a specified number of samples

Table of contents

Other Shimadzu Measuring Instrument manuals

Shimadzu

Shimadzu UV-2401 PC User manual

Shimadzu

Shimadzu UV-1800 User manual

Shimadzu

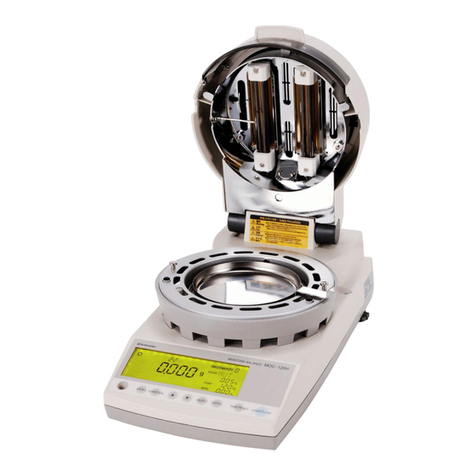

Shimadzu MOC-120H User manual

Shimadzu

Shimadzu MOC-120H User manual

Shimadzu

Shimadzu TOC-V CPH User manual

Shimadzu

Shimadzu MOC63u User manual

Shimadzu

Shimadzu GCMS-QP2010 Series User manual

Shimadzu

Shimadzu UV-1700 series User manual

Shimadzu

Shimadzu MOC63u User manual

Shimadzu

Shimadzu AGS-X Series User manual