InnoSenT SMR-313 User manual

Page 1 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

User Manual SMR-313/323/333

Version 2.0 - 08.05.2018

SMT mountable K-Band Movement Sensor

• Industrial Applications

• Security Applications

PRODUCT FAMILY

APPLICATIONS

FEATURES:

»Radar-based motion detector working in the 24GHz - ISM - Band

»Detection of direction and velocity of moving objects

»Mounting by standard SMT-Process

»Delivery on Tape & Reel

»Integrated Low Noise Amplifier

»Extended temperature range from -40°C up to +85°C

»Very small outline dimensions

»Available with different antenna patterns by same interface

DESCRIPTION

K-Band based motion detector. The ultra small device

will be delivered directly on tape for mounting within a

standard SMT. Due to the pulse capability the sensor

is also suitable for low-power applications.

ADDITIONAL INFORMATION

InnoSenT Standard Product. Changes will not be

notified as long as there is no influence on form, fit

and within this User Manual specified function of the

product.

CERTIFICATES

InnoSenT GmbH has established and applies a quality

system for: development, production and sales of

radar sensors for industrial and automotive sensors.

RoHS-INFO

This product is compliant to the restriction of

hazardous substances (RoHS - European Union

directive 2011/65/EU).

Movement

Velocity

Direction

Presence

Distance

Angle

designed

and manufactured

in Germany

ETSI / FCC

All SMR modules are compliant to ETSI 300 440. The

US Version is compliant to FCC 15.249.

Page 2 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

PARAMETER CONDITIONS SYMBOL MIN TYP MAX UNITS

Radar

transmit frequency frequency band for US and EU f 24.150 24.250 GHz

output power (EIRP) Pout 20 dBm

IF-Bandwidth (-3dB) B 0 1M Hz

noise level 100Hz...1kHz N1/2 20 µVrms

quadrat. phase imbalance εp-25 25 °

Power supply

supply voltage VCC 3.2 3.3 3.4 V

supply current ICC 47 57 mA

Environment

operating temperature TOP -40 +85 °C

storage temperature TSTG -40 +85 °C

Mechanical Outlines

outline dimensions compare to schematic on page 5

height

length

width

3.1

21.4

15.0

mm

PARAMETERS

Page 3 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

ANTENNA PATTERN

-

45°

90°

0°

-45°

-90°

-10

-20

-30

-40

-50

-

45°

90°

0°

-45°

-90°

-10

-20

-30

-40

-50

-

45°

90°

0°

-45°

-90°

-10

-20

-30

-40

-50

system pattern (-10dB) azimuth system_az 121 °

elevation system_el 111 °

system pattern (-10dB) azimuth system_az 100 °

elevation system_el 104 °

system pattern (-10dB) azimuth system_az 43 °

elevation system_el 116 °

-

45°

90°

0°

-45°

-90°

-10

-20

-30

-40

-50

-

45°

90°

0°

-45°

-90°

-10

-20

-30

-40

-50

-

45°

90°

0°

-45°

-90°

-10

-20

-30

-40

-50

System Pattern SMR-313:

System Pattern SMR-323:

System Pattern SMR-333:

Page 4 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

PULSE SCHEME

In order to use the pulse capability of the SMR the following scheme is recommended to avoid out of band

emissions:

3.3V

> 3µs

0V

VCC

3.3V

> 1µs

0V

1µs 1µs

enable

INTERFACE

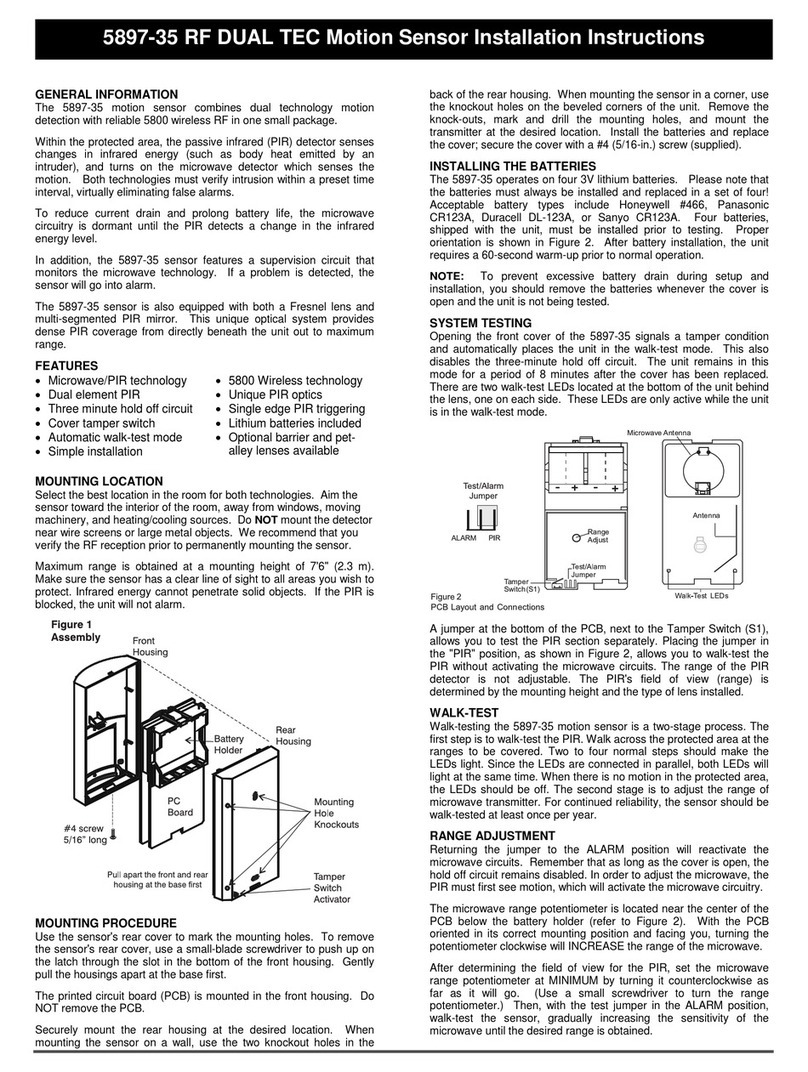

The sensor provides solder pads for SMT mounting.

PIN # DESCRIPTION IN/OUT COMMENT

1 d.n.c. do not connect

2 d.n.c. do not connect

3 IF1 output signal I(nphase)

4 IF2 output signal Q(adrature)

5 enable* input TX output power enable (active high)

6 GND input analog ground

7 Vcc input supply voltage

8 d.n.c. do not connect

9 d.n.c. do not connect

10 GND input analog ground

*the enable has no influence on current consumption rather reduces the TX output power by about 30dB. To save

power use a pulse scheme as described on page 3.

enable pin off: 0 - 0.8V

enable pin on: 2 - 3.3V

Page 5 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

OUTLINE DIMENSIONS

1.05

21.4 ±0.3

15 ±0.3

antenna centroid

rotational pivot

0.9 ±0.1

3.1 ±0.3

20.4 ±0.3

14 ±0.3

soldering pad (10x)

Pin 1

21.4

A

1.4

1.6

1.5

2.2

2.3

2.15

Copper

Solder

Paste

Footprint

Recommended stencil thickness 225µm

Pin 5

Pin 6

Pin 10

1

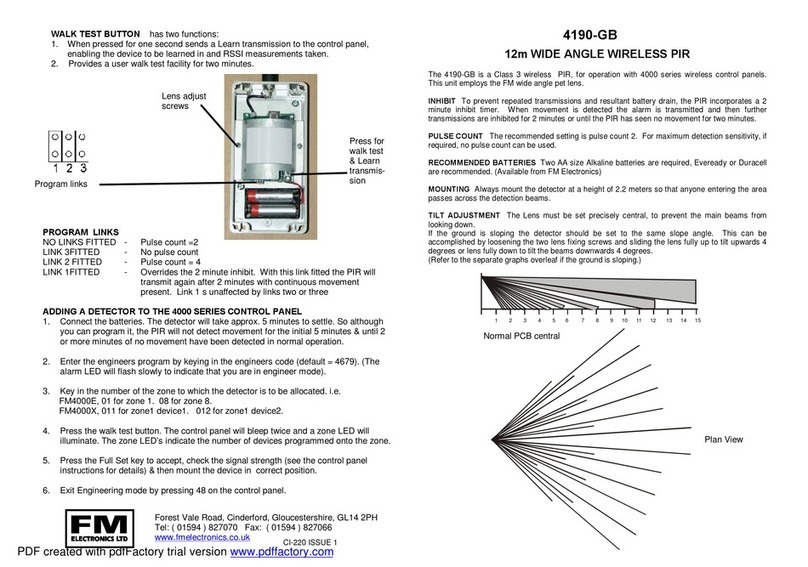

SMT GUIDELINES

The SMR device is 100% Pb-free. Therefore, Pb-free solder paste with a Pb-free re flow profile is recommended.

Do not use solder paste with active or acid-based flux. To avoid submerging the device in the solder paste, the

placement height (Z) of the device on the pick-and-place equipment should be controlled carefully. Optimally, the Z

height should be set at one-half the printed solder paste height. Maintaining board flatness (coplanarity) is important

in keeping the Z height under control.

If possible use a pick-and-place machine with a visions-alignment system for proper centering on the PCB.

For the soldering process we recommend the following:

• For optimum results the reflow oven should have nitrogen purge (we recommend 1000ppm)

• To avoid damage during assembly solder re flow attachment, follow the guidelines in IPC/JEDEC J-STD-

020D.1. The device is qualified at 260 °C re flow. The following figure shows a typical temperature profile for

Pb-free (Sn-Ag-Cu or Sn-Ag) solder and the corresponding critical re flow parameters.

• Assemble the SMR within 5 days after opening the packing

• Not assembled SMR must be dried for 500h at 40 degree Celsius; 1% r.H. before repacking in a dry pack.

220

180

Time

Temperature (°C)

Min. 60sec

Max. 120sec

Min. 30 sec

Max. 90sec

Max. 260°C, Min 230°C

150

Page 6 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

PACKAGE FOOTPRINT

Recommended Footprint and Stencil Layout

1.05

21.4 ±0.3

15 ±0.3

antenna centroid

rotational pivot

0.9 ±0.1

3.1 ±0.3

20.4 ±0.3

14 ±0.3

soldering pad (10x)

Pin 1

21.4

A

1.4

1.6

1.5

2.2

2.3

2.15

Copper

Solder

Paste

Footprint

Recommended stencil thickness 225µm

Pin 5

Pin 6

Pin 10

1

TAPE OF SMR-313/323/333

The SMR-313/323/333 will be delivered on tape with a width of 32mm.

Page 7 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

Annex A

The information that will be given below is only a rough overview; for details please contact the local approval

agencies. An overview over the frequency bands in Europe can also be found in the REC 70-03 (Annex 6) which is

available under www.ero.dk

24.000 24.250

For the US-market the SMR-3X3 can be used

US-frequency

FCC approval

This device complies with Part 15 of the FCC Rules [and with Industry Canada licence-exempt RSS standard(s)].

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

Warning: Changes or modifications made to this equipment not expressly approved by InnoSenT GmbH may void

the FCC authorization to operate this equipment.

Manufacturers of mobile or fixed devices incorporating SMR-3X3 modules are authorized to use the FCC Grants

of the SMR-3X3 modules for their own final products according to the conditions referenced in these documents.

In this case, the FCC label of the module shall be visible from the outside, or the host device shall bear a second

label stating „Contains FCC ID: UXS-SMR3X3 “

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes:

(1) l’appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est suscep-

tible d’en compromettre le fonctionnement.

NOTICE:

Changes or modifications made to this equipment not expressly approved by (manufacturer name) may void the

FCC authorization to operate this equipment.

Frequency Bands in US FCC 15.249

Page 8 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

Labeling

SMR-3X3

Generally the SMR-3X3 can be used also for all countries in Europe.

24.000 24.150 24.250

Europe-frequency

Frequency Bands in Europe

www.InnoSenT.de

SMR

HANDLING PRECAUTIONS

To avoid damage to the devices, care should be exercised during handling. Proper Electrostatic Discharge (ESD)

precautions should be observed at all stages of storage, handling, assembly, and testing.

ESD Robustness HBM = +/- 1kV according to ANSI/ESDA/JEDEC JS-001

(R = 1.5kOhm, C = 100pF) for Electrostatic Discharge Sensitivity Testing, Human Body Model

(HBM)-Component Level; CDM = +/- 500V according to JEDEC JESD22-C101 Field-Induced

Charged Device Model (CDM), Test Method for Electrostatic-Discharge-Withstand Thresholds

of Microelectronic Components.

ESD INTEGRITY

ORDER INFORMATION

antenna

3dB: 121° x 111°

(1 x 1 Patch)

3dB: 100° x 104°

(1 x 2 Patch)

3dB: 43° x 116°

(1 x 4 Patch)

SMR-313

SMR-323

SMR-333

Page 9 USER MANUAL SMR-313 / 332 / 333 Version 2.0

CONFIDENTIAL AND PROPRIETARY

The information contained in this document shall remain the sole and exclusive property of InnoSenT GmbH and shall not be

disclosed by the recipient to third parties without prior consent of InnoSenT in writing.

Experience and Reliability in Radar Technology

www.InnoSenT.de

SMR

APPROVAL

This User Manual contains the technical specifications of the described product. Changes of the specification

must be in written form. All previous versions of this User Manual are no longer valid.

VERSION DATE COMMENT

1. 0 08.04.2016 initial release

1.1 26.07.2016 Data matrix code in outline dimensions removed

1.2 06.03.2017 changing recommended footprint; addition information in interface

1. 3 16.06.2017 adding label

1. 4 21.09.2017 changing frequency band information

1. 5 06.10.2017 changing frequency band information

1. 6 14.11.2017 changing transmit frequency condition

1. 7 20.12.2017 changing recommended footprint

1. 8 12.02.2018 remove SMR-323; changing frequency band and handling information

1. 9 13.04.2018 adding SMR-323

2.0 08.05.2018 changing Frequency Bands information

InnoSenT GmbH

Am Rödertor 30

97499 Donnersdorf

GERMANY

Tel.:

E-Mail:

URL:

+49 (0)9528 - 9518 - 0

www.innosent.de

This manual suits for next models

2

Table of contents

Other InnoSenT Security Sensor manuals