INNOVATIVE CIRCUIT TECHNOLOGY Distribution 2 Series User manual

Innovative Circuit

Technology Ltd.

Distribution Series 2

Intelligent Distribution Panel

with Remote Power Control

INSTRUCTION MANUAL

855-313-500

Model:

ICT180SE-12IRC

2Innovative Circuit Technology Ltd.

WARNING

Risk of serious personal injury or damage to equipment and property! Always

observe the following:

•Use an appropriately rated over-current protection device in line with the

main battery connections to the panel

•Use an appropriately rated disconnect switch or circuit breaker in line with

the dc inputs to enable installation and service of the panel with the dc

source disconnected

•Shut off or disconnect all dc power sources before connecting or

disconnecting wiring

•Use wire and connectors rated for the maximum load current and size of

fuse or circuit breaker, and keep cable lengths as short as practical

•Carefully observe wiring polarity when making input and output connections

•Securely tighten all connections

•Do not attempt to service any internal parts. Refer all product service to an

authorized ICT Ltd. service facility

CAUTION

Risk of personal injury or damage to equipment! Always observe the following:

•Fuses may be HOT to touch. Disconnect power and allow to cool before

removing or replacing

•Wiring terminals may be HOT to touch. Disconnect power and allow to cool

before disconnecting load wires

•Install unit in a restricted access location (such as an equipment rack) to limit

unintentional contact with terminals and wiring. Keep sources of moisture

away from unit

•Do not block air inlet or outlet openings in the panel sides

NOTE:

Due to the fuse detection circuitry internal to the distribution panel, it may be

possible to measure a voltage on the output terminal(s) even if that output’s

fuse is open (with no load connected). This is normal operation. The detection

circuitry is a high-impedance circuit, and while a voltage may be present on the

output terminal, it is purely a signal voltage and does not support loading. Any

load device connected to the output will immediately pull this voltage to zero

volts.

Rev 0

2022

Copyright © 2022 Innovative Circuit Technology Ltd. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording or otherwise, without the prior

written consent of Innovative Circuit Technology Ltd.

Innovative Circuit Technology Ltd. 3

Contents

PRODUCT DESCRIPTION............................................................................. 4

INSTALLATION ............................................................................................ 5

LCD/SELECT BUTTON OPERATION ................Error! Bookmark not defined.

WEB-BASED CONFIGURATION UTILITY.........Error! Bookmark not defined.

Status & Control ................................................................................... 11

Alarm Status ......................................................................................... 12

Device Setup......................................................................................... 12

Output Setup ........................................................................................ 14

Network setup...................................................................................... 16

E-mail Setup.......................................................................................... 19

Alarm setup .......................................................................................... 20

User Setup ............................................................................................ 22

Maintenance......................................................................................... 22

MOBILE WEB APP ..................................................................................... 23

PASSWORD RESET .................................................................................... 24

ROUTER CONFIGURATION ....................................................................... 25

TEXT MESSAGE ALARM NOTIFICATIONS ................................................. 27

TROUBLESHOOTING ................................................................................. 27

PRODUCT SPECIFICATIONS....................................................................... 29

LIMITED WARRANTY ................................................................................ 31

4Innovative Circuit Technology Ltd.

PRODUCT DESCRIPTION

The ICT180SE-12IRC Intelligent Distribution Panel with Remote Power Control is

designed for either 12 or 24VDC applications. It provides 12 output positions that

are individually protected by blade type fuses. Nine of the outputs use ATO/ATC

blade fuses that are rated up to 25A each. Three of the outputs use JCASE fuses

and are rated up to 40A each. These fuses are located on the front of the panel

for easy monitoring and replacement. Each positive output terminal point is

connected through a fuse to a positive internal bus. All negative output terminal

points are connected to a negative internal bus.

There are five alarm inputs on the back of the panel for connecting external Dry

Contact sensors for site monitoring and reporting of alarms such as door, water,

and smoke detectors. System voltage, system current, output currents, fuse

status, and alarm input status can be monitored onsite through the LCD graphics

display. Fuse status is also displayed by an LED indicator located over each fuse.

Form “C” alarm contacts (C/NO/NC) are provided on the back of the panel which

can be connected to an external alarm circuit for monitoring alarms generated by

the panel.

Remote monitoring is available through the integrated security protected

Ethernet communications port on the back of the panel. The panel has a built-in

web server with an embedded web-based GUI that can be accessed using any

standard commercial web browser. The web server not only displays panel

information, it can also be set up to send an alarm to user-defined email

accounts in the event a fault occurs. The web server can also be used for data

logging of up to 30 days of time stamped event information. All these features

are packaged in a 1RU enclosure to save valuable rack space and fit standard 19”

equipment racks. The rack mounting position is adjustable.

DC outputs can be turned on and off remotely, allowing connected loads to be

power-cycled through the Ethernet connection.

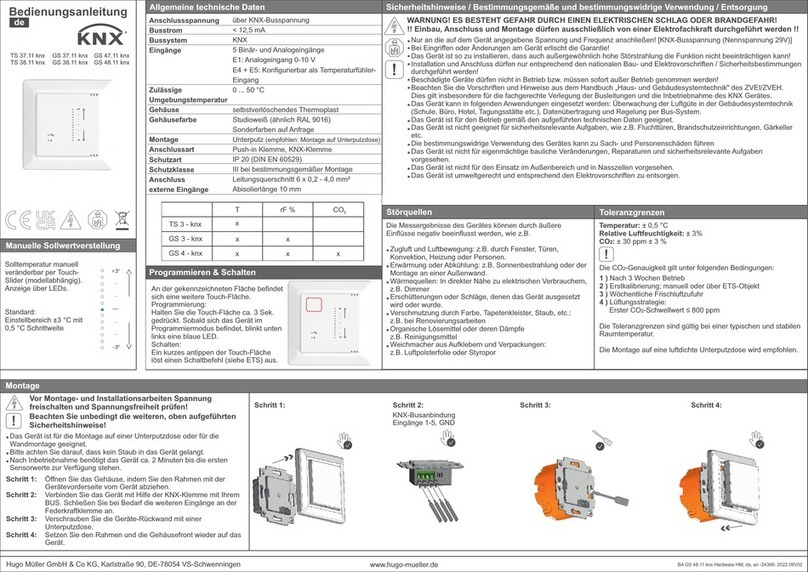

FRONT PANEL

Figure 1.

1. FUSE STATUS LEDs: Turns on when a fuse is blown or missing.

2. ATO/ATC FUSES: Location of the ATO/ATC fuses rated up to 25A.

Innovative Circuit Technology Ltd. 5

3. LCD: Displays system voltage, system current, output current and fuse status

for each of the 12 output positions.

4. OUTPUT SELECT BUTTON: For switching between LCD screens, and resetting

network, web server and password settings to original factory default values.

5. JCASE FUSES: Location of the JCASE fuses rated up to 40A.

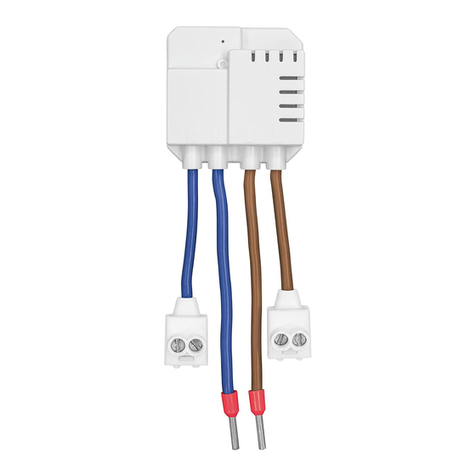

BACK PANEL

Figure 2.

1. NEGATIVE INPUT STUD: For DC power source connection up to 180A peak and

150A continuous.

2. OUTPUT TERMINAL BLOCK 10 –12: For DC load connections up to 40A each

pair.

3. ALARM FORM “C” CONTACTS: For external alarm circuit to monitor alarms

generated by the panel.

4. ALARM SENSOR INPUTS: Inputs for external Dry Contact sensors.

5. LAN PORT: For remote monitoring via TCP/IP network.

6. CHASSIS GROUND STUD: For Earth ground connection.

7. OUTPUT TERMINAL BLOCK 1 –9: For DC load connections up to 25A each pair.

8. POSITIVE INPUT STUD: For DC power source connection up to 180A peak and

150A continuous.

INSTALLATION

1. Inspect panel and accessories to make sure everything is complete and in good

condition.

2. For rack set up, install panel on the rack using appropriate size screws and star

washers on all four mounting holes. If equipment rack is not electrically

connected to Earth ground, connect a ground cable from the ground stud on the

back of the panel to a known Earth ground point. Otherwise, the four mounting

screws and washers may be sufficient for earth ground connection.

OR

For non-rack set up, connect a ground cable from the ground stud on the back of

the panel to a known Earth ground point.

6Innovative Circuit Technology Ltd.

3. Remove the plastic shield(s) covering the output terminal block(s) located on

the back of the panel. Connect the positive of the load to the positive terminal

point (labeled “+”) and the negative of the load to the negative terminal point

(labeled “-”).

4. Install fuse on the front of the panel for each output terminal block. The fuse

number on the front of the panel matches the output terminal block number on

the back of the panel. Consult your local electrical codes for wire ampacity and

fuse sizing. Typically, fuses and wiring are derated to 80% of their rating (e.g. 12

Amps maximum for a 15 Amp fuse). For terminal blocks with no load connected,

insert any size fuse to prevent the LED on the front of the panel from turning on

and the alarm from activating if the form “C” alarm is used.

5. Remove the plastic caps covering the input insulated studs. Connect the

positive of the power source to the red insulated stud (labeled “+”) and the

negative of the power source to the black insulated stud (labeled “-”).

6. Re-install plastic shield(s) to the output terminal block(s) and plastic caps to

the input studs.

7. For remote monitoring and power control, connect your network interface to

the Ethernet port on the back of the panel. The recommended cable for Ethernet

connection is Cat5e UTP network cable.

8. The Alarm Form “C” Contacts on the back of the panel can be connected to an

external alarm circuit to monitor alarms generated by the panel. Depending on

the alarm circuit (refer to table 2), connect it between normally open (NO) and

common (C), between normally close (NC) and common (C), or both. The built-in

web server controls this alarm. The alarm connector can be unplugged from the

panel for easy installation.

9. For monitoring external Dry Contact sensors, connect each sensor between an

Alarm Input (1 - 5) and common (C) on the alarm input connector. The alarm

input connector can be unplugged from the panel for easy installation. Refer to

table 3 for the alarm input connector pin-out.

Table 1: Fuse Status LED

LED

FUSE STATUS

ON

Blown or missing

OFF

Good

Innovative Circuit Technology Ltd. 7

NC/C PINS

NO/C PINS

CONDITION

Open

Closed

Fuse Alarm

• Activate Alarm Form C Contact is checked

• One or more blown or missing fuse

System Under - Voltage Alarm

• Activate Alarm Form C Contact is checked

• System Voltage is below the set value

System Over - Voltage Alarm

• Activate Alarm Form C Contact is checked

• System voltage is above the set value

System Over - Current Alarm

• Activate Alarm Form C Contact is checked

• System current is above the set value

Alarm Input #1 - #5

• Activate Alarm Form C Contact is checked

• Digital Alarm is triggered

Output Over - Current Alarm #1 - #12

• Activate Alarm Form C Contact is checked

• Output Current is above the set value

Output Under - Current Alarm #1 - #12

• Activate Alarm Form C Contact is checked

• Output Current is below the set value

No power to unit

Closed

Open

Activate Alarm Form C Contact is checked and

no fault occurred

All Activate Alarm Form C Contact is not checked

Table 2: Form “C” Alarm

PIN

DESCRIPTION

1

Common

2

Alarm Input # 1

3

Common

4

Alarm Input # 2

5

Common

6

Alarm Input # 3

7

Common

8

Alarm Input # 4

9

Common

10

Alarm Input # 5

Table 3: Alarm Input Connector Pin-out

8Innovative Circuit Technology Ltd.

LCD/SELECT BUTTON OPERATION

At power up, the LCD of the panel will display the main screen. To switch

between the various LCD screens, press the Output Select button on the front of

the panel (see Figure 3 for screen order).

Figure 3: LCD Display Screens

Holding the Output Select button for 2 seconds at any screens will return you to

the main screen.

Holding the Output Select button for 20 seconds at any screens will reset the

password to the factory default (see Password Reset section).

The backlight of the LCD turns off if the Output Select button is not pressed for

15 minutes.

Press the Output Select button to turn the backlight back on.

Innovative Circuit Technology Ltd. 9

MAIN SCREEN

Line 1: Displays the name of the panel, which is customizable through the web-

based configuration utility.

Line 2: blank

Line 3: Displays the system voltage. Voltage display will blink if the system

voltage exceeds the Under-Voltage or Over-Voltage Thresholds set on the

Alarm Setup page.

Line 4: Displays the system current. Current display will blink if the system

current exceeds the Over-Current Threshold set on the Alarm Setup

page.

NETWORK SCREEN

Line 1: Displays the network status.

Line 2: Displays the connection type.

Line 3: Displays the IP address assigned to the panel.

Line 4: Displays the MAC address of the panel.

OUTPUT SCREEN (1 –12)

Line 1: Displays the name of the load, which is customizable through the web-

based configuration utility.

Line 2: Displays the output status. ENABLED for output enabled, DISABLED for

output disabled, and FUSE OPEN for blown or missing fuse.

Line 3: Displays the output voltage. Voltage display will blink if the voltage

exceeds the Under-Voltage or Over-Voltage Thresholds set on the Alarm

Setup page.

Line 4: Displays the output current for that individual output. Current display will

blink if the output current exceeds the Output Over-Current or Under-

Current Thresholds set on the Output Setup page.

ALARM INPUT SCREEN (1 –5)

Line 1: Displays the alarm input number.

Line 2: Displays the name of the alarm input if it has been entered through the

web-based configuration utility. Otherwise, this line is blank.

Line 3: blank

Line 4: Display the alarm input status. ALARM if the alarm input is triggered,

READY if the alarm input is not triggered.

Note: The alarm input screens are only displayed if the alarm input has enabled

(see Alarm Setup section in the instruction manual).

10 Innovative Circuit Technology Ltd.

WEB-BASED CONFIGURATION UTILITY

These panels are equipped with a built-in web server to enable full remote

monitoring and control using any standard web browser, such as Microsoft Edge,

Google Chrome, or Mozilla Firefox. To connect with your networked panel, do

the following:

1. Start Your Browser.

2. Enter the IP address of the panel in the address field of your browser as

shown.

Figure 4.

If the panel is connected to a network with a DHCP server, the panel will

be assigned an IP address automatically. To find the current address of

your panel check the Network screen, line three, on the unit’s front

panel LCD display. (see Fig. 4) Otherwise the panel will use the factory

default IP address of 192.168.0.180, as shown above.

3. Enter your user name and password. The default Administrator user

name is admin, and there is no password by default.

Figure 5.

Once your browser is connected to the unit, the Status & Control page for the

panel will be displayed, as shown. See the following section for descriptions on

how to use the various monitoring, configuration, and control features available

through the panel’s graphical web interface.

To log out, click on the Logout link on the top right of your browser window. The

system will also automatically log off the user after 20 minutes of inactivity.

Innovative Circuit Technology Ltd. 11

Figure 6.

Click on any one of the blue buttons in the menu bar on the left side of the

screen to select the desired page.

Status & Control

This page provides information on system voltage, system current, alarm status,

output status, and current level by output contact (1 through 12). It also allows

you to manually enable or disable DC power to the each of the output terminals.

The status of any of the five Input Alarms for alarms that have been enabled (see

Alarm Setup page) will be shown on this page. A grey Alarm Input indicator box

shows that the sensor input is ready; a red box indicates that that external sensor

is in an alarm condition.

Enable All Outputs: Pressing this button will enable DC power to all outputs. If

power-on sequencing is enabled on the Device Setup page, the outputs will be

enabled in sequence, instead of enabling them simultaneously.

Disable All Outputs: Pressing this button will disable DC power to all outputs.

Output On/Off Buttons: Pressing these buttons will enable or disable DC power

to individual outputs.

12 Innovative Circuit Technology Ltd.

Alarm Status

This page displays the status of currently active alarms as well as the alarm

history.

Device Setup

Use this page to configure the panel settings. Click on the Save Settings button

when finished to save and implement all new changes.

Device Info

Site Name: Enter a custom descriptive name for the panel

Model: Displays the ICT model number for the panel

Hardware: Displays the hardware version of the panel

Date and Time Settings

Current System Time: Displays the date and time used in the panel’s internal

clock for time stamping data entries in the data logs. This clock may be set

manually, or synchronized with a remote NTP Time Server over the Internet

(recommended).

Synchronize with NTP Server: Check this box to select automatic

synchronization with the external server. (recommended)

NTP Server: Enter the name or IP address of the NTP Server used for date

and time synchronization, such as “pool.ntp.org”.

Time Zone: Select the appropriate time zone relative to GMT for your unit so

that the NTP server time can be converted to your local time zone.

Set Time Manually: Checking this box will allow the unit’s clock and calendar

to be set manually by entering date and time in MM/DD/YY and HH:MM:SS

format.

Power-On Sequencing/Cycling

Sequence/Cycle Delay: Entering a time delay in this field (0-60s) will cause

all outputs to be enabled in sequence when the Enable All Outputs button is

pressed on the Status & Control page, rather than enabling all outputs

simultaneously. This delay helps prevent power surges that can occur when

too many devices are turned on at the same time. Setting this time to 0 or

leaving the box blank will cause all outputs to always be enabled

simultaneously. (Factory default).

Note the Sequence Delay time will also be used as the Power Cycling time

delay for each output that has the Power Cycling feature enabled on the

Output Setup page.

Innovative Circuit Technology Ltd. 13

Reverse Sequence Order: Checking this box will cause the power on

sequence to run in reverse order with output channel 12 on first, ending

with output 1, when the Enable All Outputs button is pressed on the Status

& Control page.

Network Watchdog:

Select a Watchdog to edit: Select one of the six independent Watchdogs to

configure. Each Watchdog, if enabled, will cause the unit to periodically ping

up to two remote IP addresses to verify the network connection status. If

there is no response from either address the unit will cycle the power on all

outputs that are configured in the Cycle Outputs setting below. This feature

is useful for re-booting a modem or other network device that is powered by

one of the distribution panel outputs, to help recover the network IP

connection when one of these devices has crashed. A delay time must be

entered in the Sequence/Cycle Delay field for this function to work. Power

for a cycled channel will be held in the off state for the duration set by the

Sequence/Cycle delay time, then will be turned back on.

Watchdog Enabled: Check this box to enable the selected Watchdog.

Primary IP Address: Enter the remote IP address you would like the selected

Watchdog to monitor. If left blank the unit will monitor the Gateway IP

address listed in the Network Setup page.

Secondary IP Address: Enter an optional second IP address that the unit can

monitor to verify network status. The Network Watchdog will only trigger if

both the Primary and Secondary IP addresses fail to respond.

Cycle Outputs: This sets which output(s) to power cycle when the Network

Watchdog triggers.

Watchdog Timeout: Enter the time (1 to 80 minutes) that the remote IP

address must stop responding to ping requests from the panel, before the

Network Watchdog will trigger an output power cycle. Ensure this time is

greater than the normal start-up time for the network hardware to prevent

nuisance power cycle events at system start up.

Maximum Cycle Attempts: This setting will limit the maximum number of

times the panel can attempt to cycle power to the output(s) before giving

up, if the remote IP address continues to be unresponsive. Set Maximum

Cycle Attempts to zero for no limit.

Data Logging:

Data Logging rate: Enable this feature to keep a running record the system

voltage, system current, channel output currents, fuse status, and alarm

14 Innovative Circuit Technology Ltd.

inputs at a rate of up to 1 sample per minute. View this Comma Separated

Values (CSV) format log by clicking the Download Log button, and open in

any Spreadsheet software, such as Microsoft Excel. The log will store up to

30days of data, with the oldest entries at the top of the file, newest at the

bottom.

Log Start Date: Shows the date/time the most recent log began.

Output Setup

This page allows you to configure the output settings of the panel. In the Select

an Output to edit box, click on the output number of the output you wish to

configure. To save any changes to the output settings, click on Save Settings at

the bottom of this page.

To copy the configuration settings from one output to all of the other outputs,

click on Copy Settings to All, and then click on Save Settings to save the new

settings.

Output Settings:

Output Label: Enter a descriptive label for the selected output channel if

desired.

Output State After Panel Reset: Sets the state for the output after an input

power failure, or soft reset of the panel. Select one of the following:

•Restore last State: If this option is selected, the panel will

remember if this output was enabled or disabled prior to the

power failure or reset. The output will be restored to the same

state after the panel starts up. (default)

•Enable Output: If this option is selected, this output will always

be enabled after the panel starts up after a power failure or

reset.

•Disable Output: If this option is selected, this output will always

be disabled after the panel starts up after a power failure or

reset.

Ignore Fuse Status: Will mask the fuse open circuit detection, to prevent

false alarms on unused channels.

Enable Power Cycling: Check this box to enable output power cycling for the

selected output, so that the output will automatically be re-enabled after

the Sequence/Cycle Delay time whenever the output is disabled using the

Output Off button on the Status & Control page. This feature is useful for

remotely resetting power to hardware required for the network connectivity

of the panel.

Innovative Circuit Technology Ltd. 15

The Sequence/Cycle Delay time must be set on the Device Setup page with

duration long enough for the connected network hardware to fully reset for

this function to be effective. Multiple outputs that are disabled using Power

Cycling will be re-enabled in sequence.

Output Load Shedding:

Enable Load Shedding: Check this box to disable this output when the

system voltage drops below the load-shedding threshold for at least 30s.

This feature can be used to disconnect less critical loads to preserve back-up

battery power as the battery voltage drops.

Load-Shedding Threshold: Enter the voltage level at which the selected

output will be disconnected.

Load-Shedding Auto Recovery: Check this box to allow the output to be

automatically reconnected when the system voltage is above the Auto

Recovery Threshold for at least 60s. The output must be manually re-

enabled using the Output ON button on the Status & Control page if the

Auto Recovery function is not enabled.

Auto Recovery Threshold: Enter the voltage level at which the selected

output will automatically be reconnected. This value must be at least 0.5V

above the Load-Shedding Threshold voltage.

NOTE:

Outputs that have been disabled on the Status & Control Page will reconnect

automatically if Load-Shedding Auto Recovery is enabled for that output. To prevent this,

ensure that Load-Shedding Auto Recovery is not enabled.

Output Over-Current Alarm:

Over-Current Threshold: Enter the over-current level. Output current above

this level for at least 5s will trigger the Over-Current Alarm. Disable this

alarm by setting the threshold to 0A.

Activate Form-C Contact: Checking this box will cause the Alarm relay to

trigger for an over-current condition.

Send E-mail: Checking this box will cause the unit to send an output Over-

Current alarm e-mail to the assigned address entered on the E-mail Setup

page.

Output Under-Current Alarm:

Under-Current Threshold: Enter the under-current level. Output current

below this level for at least 5s will trigger the Under-Current Alarm. Disable

this alarm by setting the threshold to 0A.

16 Innovative Circuit Technology Ltd.

Activate Form-C Contact: Checking this box will cause the Alarm relay to

trigger for an under-current condition.

Send E-mail: Checking this box will cause the unit to send an output Under-

Current alarm e-mail to the assigned address entered on the E-mail Setup

page.

Network Setup

Use this page to configure the network settings for the panel. Click on the Save

Settings button at the bottom of the page to save any changes and re-boot the

panel.

Network:

MAC Address: Displays the MAC address assigned to the panel. It is also

shown on line four of the LCD Network Status screen.

Enable DHCP: Turn on this setting if your network uses a DHCP server to

automatically assign IP addresses. (Enabled as default setting). To manually

assign a static IP address to the unit uncheck this box, then set the following

parameters.

IP Address: Specify a unique IP address for the unit.

Subnet Mask: Specify the mask for the subnet the panel is located on

Gateway: Specify the IP address of the default router (Gateway) used for

connecting attached devices to different networks.

Primary DNS: Specify the IP address of the Primary DNS Server for your

network.

Secondary DNS: Specify the IP address of the Secondary DNS Server for your

network.

Web Server:

CAUTION:

Changing the web server port numbers may cause loss of communication with

the panel

The following ports may be changed within a range of 1 to 65565, if

required.

HTTP Port: This port is used for HTTP traffic between the panel and your

browser. The default HTTP port is 80, and if you change this the new HTTP

Innovative Circuit Technology Ltd. 17

Port number must be appended to the URL used to access the panel. (e.g.

use URL http://192.168.0.180:8000 for IP address 192.168.0.180, port 8000)

HTTPS Port: The HTTPS (HTTP Secure) protocol uses encrypted data transfer

between web browsers and servers for higher security. The default HTTPS

port is 443. Append any changed HTTPS port to the end of the URL for the

panel.

To access the panel through a secure HTTPS connection, use https:// at the

start of the units URL. (e.g. https://192.168.0.180:8888 for IP address

192.168.0.180, HTTPS port 8888)

SNMP:

Configure these settings if you would like to use SNMP based monitoring. SNMP

(Simple Network Management Protocol) is an industry standard protocol for

network management software. Enabling the SNMP function on the panel will

allow standard SNMP management software to connect to the SNMP agent

running on the panel and read real time system information such as system

voltage, and channel currents. The panel can send SNMP traps to the external

management software when an alarm or fault occurs.

The information available from the SNMP agent is described in a MIB

(Management Information Base) file, which can be downloaded from the panels

Help page. The unique panel MIB file must then be imported into your external

SNMP management software.

Enable SNMP: Check this box to enable the SNMP agent

SNMP Version: Sets the SNMP version (v1/v2c, v3, or All) supported by the panel

SNMP agent. If All is selected, all SNMP versions will be supported

simultaneously. The appropriate settings for the selected SNMP version will need

to be configured.

Enable SNMP Write Access: Turning on this setting will allow you enable or

disable DC power to individual outputs through SNMP. If this box is unchecked,

all information available from the SNMP agent will be read-only.

SNMP Control Access: Sets the level of device control that is allowed through

SNMP. This setting is only available if Enable SNMP Write Access is enabled.

•Output Control: Allows DC power to individual outputs to be

enabled or disabled through SNMP. No other settings can be

configured through SNMP.

•Full Device Control: Allow SNMP clients to set all device settings

through SNMP. MIB files for full SNMP device control can be

downloaded from the ICT Website:

18 Innovative Circuit Technology Ltd.

https://www.ict-power.com/tools-utilities/

SNMP Contact Information: Assign contact information, such as an operator

name and phone number for the panel, which can be read via SNMP queries.

(This information is optional)

SNMPv1/v2c Settings:

Read Community: Enter the community string/password here for read-

only SNMP access. The default read community string is “public”.

Write Community: Enter the community string/password here for

read/write SNMP access. The default write community string is “write”.

It is recommended to change the community strings before enabling

SNMP, as the defaults are well known.

SNMPv3 Settings:

User Name: Enter the user name for SNMPv3 access.

Authentication Protocol: Select the SNMPv3 authentication protocol

(None, MD5, or SHA).

Authentication Password: If an authentication protocol is selected,

enter the authentication password.

Privacy Protocol: Select the SNMPv3 privacy protocol (None, or AES).

Privacy Password: If a privacy protocol is selected, enter the privacy

password.

SNMP Trap Settings:

Trap Version: Sets the SNMP version (v1 or v3) for SNMP traps sent

from the panel. The appropriate settings for the selected SNMP version

will need to be configured.

Trap Community: Assign the community string/password that will be

sent with all SNMPv1 traps. Some trap receivers are able to filter based

on Trap Community.

Trap User Name: Assign the user name for SNMPv3 traps.

Innovative Circuit Technology Ltd. 19

Authentication Protocol: Select the authentication protocol for SNMPv3

traps (None, MD5, or SHA).

Authentication Password: If an authentication protocol is selected,

enter the authentication password for SNMPv3 traps.

Privacy Protocol: Select the privacy protocol for SNMPv3 traps (None, or

AES).

Privacy Password: If a privacy protocol is selected, enter the privacy

password for SNMPv3 traps.

Trap IP Addresses: Enter the IP addresses for up to two devices that will

receive SNMP traps from the panel.

E-mail Setup

Configure these settings to enable automatic e-mail notifications directly

from the panel. The information required for this is available from your

Network Administrator, or Internet Service Provider. (ISP)

E-mail:

SMTP Server: Enter the name or the IP address of your SMTP server used for

sending outgoing e-mail. (e.g. “smtp.gmail.com”)

SMTP Port: Enter the port used by your SMTP server. (Normally 25)

SMTP Server requires SSL: Check this box if your SMTP server requires an

encrypted SSL connection.

This box should normally be checked if the SMTP port used by the SMTP

server is 465.

If the SMTP server uses STARTTLS (normally port 587), this box should be

unchecked.

Sender E-mail Address: Enter an e-mail address that will appear as the

sender for all e-mail notifications sent from the panel.

Recipient E-mail Addresses: Enter one or more e-mail addresses that are to

receive all e-mail notifications from the panel. Use commas to separate

multiple addresses. This field can also be used to send a text message

notification to a phone; see the Text Message Alarm Notifications section

for further information.

20 Innovative Circuit Technology Ltd.

SMTP User Name: Enter a SMTP user name here, if required by your SMTP

server. Leave this field blank if the server does not require authentication.

SMTP Password: Enter a SMTP password here, if required by your SMTP

server. Leave this field blank if the server does not require authentication.

Minimum E-mail Interval: Specify a minimum interval required between e-

mail notifications. (Default 1 minute, range 0 to 60 minutes) This time

interval is used to prevent an un-intended flood of e-mail alarm notifications

that could occur when an alarm limit is incorrectly configured, for example.

General E-mail Notifications:

Select these options to receive an e-mail when one or more of these events

occurs.

The Distribution Panel restarts: Check this box to receive an e-mail

notification when the panel restarts after a power failure or a soft reset.

Load-Shedding is activated: Check this box to receive an e-mail notification

when any of the outputs are disabled or enabled due the voltage crossing

one of the load-shed settings configured on the Output Setup page.

The Network Watchdog triggers: Check this box to receive an e-mail

notification after the Network Watchdog triggers due to a loss of the

network connection and the network has comes back online.

Alarm setup

Use this page to configure the set points of alarms to be monitored, and set the

required actions when an alarm is triggered. Click on the Save Settings button at

the bottom of the page to save any changes.

Fuse Alarm:

Activate Alarm Form-C Contact: Checking this box will cause the Alarm relay

to trigger when an output fuse is blown.

Send E-mail: Check this box to cause an e-mail notification to be sent when

an output fuse is blown. Note that the e-mail settings must be fully

configured on the E-mail Setup page for this to occur.

System Under Voltage Alarm:

Under-Voltage Threshold: If the system voltage drops below the value in

this field, the system under-voltage alarm will trigger.

Under-Voltage Recovery: If the system voltage rises above the value in this

field, the system under-voltage alarm will clear. The value in this field must

be at least 0.50V higher than the Under-Voltage Threshold.

This manual suits for next models

1

Table of contents