Refer to the instructions manual before

installing and using this device.

WARNING: Incorrect installation, adjustment,

replacement, service or maintenance may

result in material damages, injury or death.

Read installation, operation, and

maintenance instructions before installing or

servicing this equipment.

WARNINGS

Installation, modifications and maintenance of

the appliance must be carried out by authorised

personnel in compliance with current safety

standarts.

The manufacturer declines all responsibility for

failure to comply with these obligations.

The instructions contained in this manual give

important regarding security for installing and

maintaining the appliance. The manufacturer

recommends that this manual be carefully stored

in the work zone where it can be consulted by

technicians and workers.

Gas connection of the appliance must be

according to the instructions given in table “T1”.

Disrespect of the instruction given by producer

with the appliance (Use, maintenance, gas

connectin, technical data table and data plate)

may compromise the appliance safety and will

result in immediate loss of the warranty. The

manufacturer declines all responsibility for injury

or damage to persons or things, due to disrespect

of the instructions.

INSTALLATION

Positioning

The appliance should be placed under an exhaust

hood to remove smoke and smell which may

occur during the cooking process.

Position the appliance at least 10 cm from

surrounding walls. This distance may be reduced

if the walls are flameproof or protected by

insulating material.

Assembly

The appliance should be placed on a flat surface

by balancing it due to its four adjustable feet.

Remove the protective nylon on the appliance. If

sticky particles left on the appliance, clean them

with a suitable solvent.

In the case of cantilever installations, refer to the

corresponding instructions.

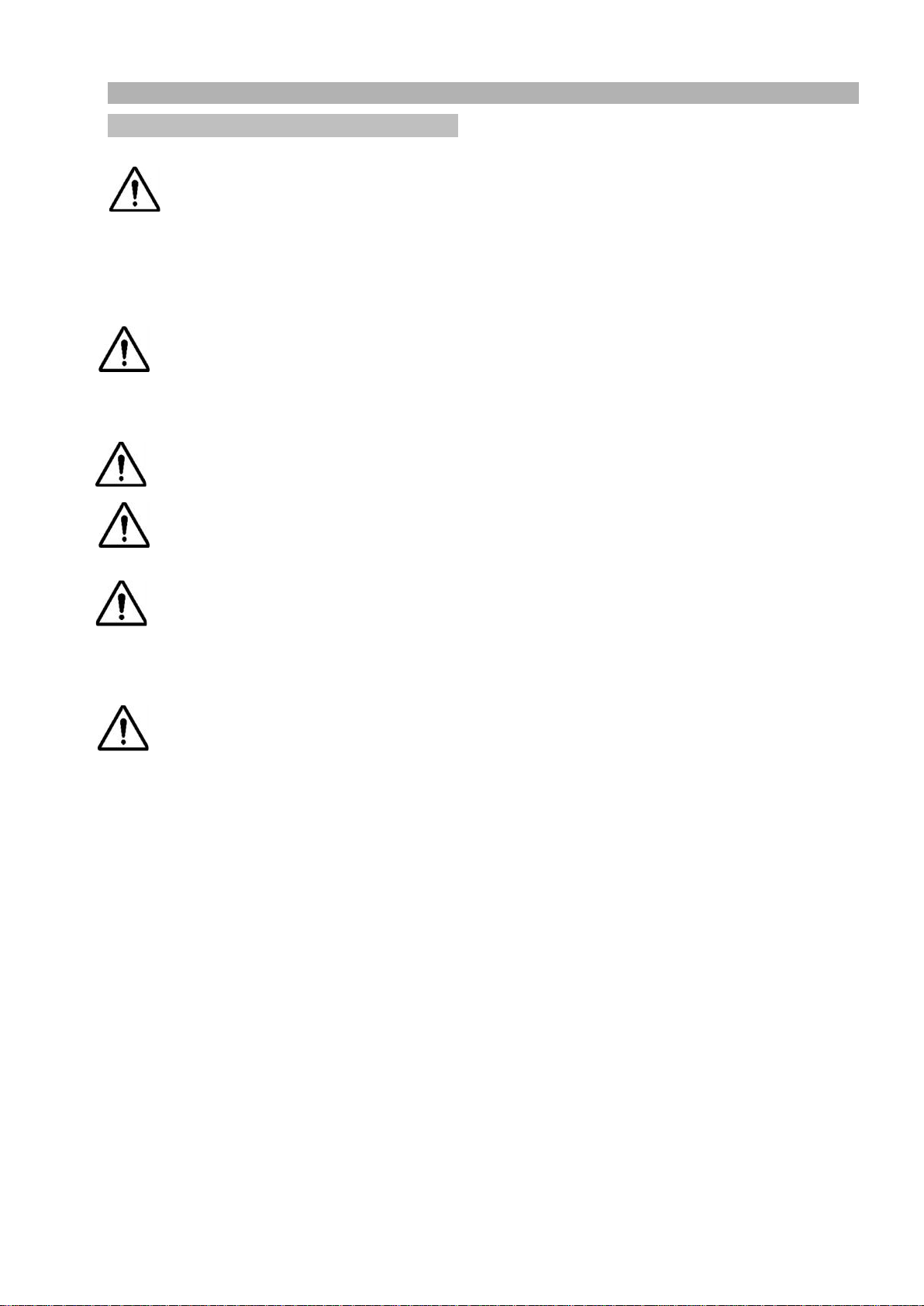

Joining appliances together in line (Fig. 1)

Place the appliances side by side and level to the

same height.

Join the appliances by use of the special fixing

holes on the side of the fryer.

GAS CONNECTION

The appliance should be connected to gas source

by means of metal pipes with suitable diameter.

A suitable valve should be placed before the

appliance to stop gas flow.

After all connections have been completed, any

probable gas leakage should be controlled.

Confirm that the appliance is suitable for the type

of gas with which it will be supplied. If not, read

the paragraph "Modification for other type of

gas".

All pieces needed for montage will be supplied by

manufacturing company.

Gas flex and gas hose connections must be carried

out in accordance with TS EN 14800 standard.

MODIFICATION FOR OTHER TYPE OF

GAS

The appliance has been adjusted to operate with

20mbar NG(G20). If the appliance will be

operated with any other gas type, the following

steps should be considered.

Replacement of burner injector (Figure-2)

Remove the front panel from the appliance.

Unscrew the injector “A” from injector

connection part “C”.

Choose a suitable injector indicated in table “T2”.

Screw the new injector to injector connection part

“B”.

Adjustment of air supply (Figure.2)

• Remove the front panel of the device.

• Turn on the main burner and turn the gas control

knob to the "max. Flame" position.

• Loosen screw "C" hareket and move the injector

fitting "B" ileri back and forth according to the

type of gas to ensure an ideal combustion of the

gas flame.

Replacement of pilot burner injector(Fig-3)

Remove the front panel.

Unscrew the connector "A" and substitute the

injector “B” with that indicated in table “T2”.

Screw in the connector "B".

Adjustment of Main Burner (Figure-4)

Ignite the burner and set the control button to

stage "5".

The burner should operate at the highest stage for

15 minutes then set the button to stage "1". The

flame should be observed while setting the button

from "5" to "1". If the burner extinguishes or the

flame is higher than the normal output, "C" button