InoTec SCAMAX 2600 User manual

SCAMAX®2600/4000 Tech. Manual 06/2002 T-1

Service Manual

Document Scanner

SCAMAX®2600/4000

As at 04.06.2002 (SB)

SCAMAX®2600/4000 Tech. Manual 06/2002 T-2

Table of Contents

Technical Manual Part T

1INTRODUCTION................................................................................................................................... 4

1.1 SCANNER MODELS, OPTIONS AND ACCESSORIES .............................................................................. 4

1.2 TECHNICAL DATA ............................................................................................................................. 5

1.3 COMPLIANCE WITH REGULATIONS AND STANDARDS: .......................................................................... 6

2SYSTEM COMPONENTS..................................................................................................................... 8

2.1 SCAMAX 2600 WITH VIDEO INTERFACE ........................................................................................... 8

2.2 SCAMAX 2600 WITH SCSI INTERFACE ............................................................................................ 8

2.3 SCAMAX 2600 WITH GREYSCALE INTERFACE .................................................................................. 9

3SCANNER COMPONENTS AND FUNCTIONS................................................................................. 11

3.1 CCD-LINEAR-CAMERA ................................................................................................................... 15

3.1.1 Camera types........................................................................................................................ 17

3.1.2 Camera Faults ...................................................................................................................... 18

3.1.2.1 Changing Camera Board Type 2+3 ................................................................................................. 18

3.1.2.2 Changing Camera Board Type 0 ..................................................................................................... 19

3.1.2.3 Changing the CCD Linear Sensor ................................................................................................... 19

3.1.2.4 Camera Adjustment for SCAMAX®2600 Type 3 ............................................................................. 21

3.1.2.5 Camera Adjustment for SCAMAX®2600 Type 0. ............................................................................ 24

3.1.2.6 Camera Adjustment for SCAMAX®4000 Type 2 ............................................................................. 25

3.2 CONTROLLER-BOARD REV. B ......................................................................................................... 26

3.3 EXCHANGING THE CONTROLLER BOARD .......................................................................................... 29

3.4 DTPLUS BOARD ............................................................................................................................. 30

3.5 I/O BOARD..................................................................................................................................... 33

3.6 ULTRASOUND DOUBLE-FEED DETECTOR ......................................................................................... 35

3.7 FOOTSWITCH ................................................................................................................................. 36

3.8 ENDORSER .................................................................................................................................... 36

3.8.1 Printhead............................................................................................................................... 36

3.8.2 Photocell ............................................................................................................................... 37

3.8.3 Processor Board ................................................................................................................... 37

3.8.4 Endorser Settings ................................................................................................................. 39

3.8.4.1 Print Density for Text/Barcodes (Druckdichte/BcDichte%) .............................................................. 40

3.8.4.2 Character Distance (CharAbstand) .................................................................................................. 41

3.8.4.3 Thickness for Text/Barcodes (Fettdruck/BcFettdruck) ..................................................................... 42

3.8.4.4 Barcode Lines Ratio (BcBalkenVerh.) .............................................................................................42

3.8.4.5 Endorser Counter (PagiNummerH/L)............................................................................................... 43

3.8.4.6 Time & Date (Zeit Datum) ................................................................................................................ 43

3.8.4.7 Print Position Time (KopfStbyZeit)................................................................................................... 43

3.8.4.8 Cleaning the Print Head (Kopfreinigung) .........................................................................................43

3.8.4.9 Print Head Voltage (InkHead Spng)................................................................................................. 44

3.8.5 Change Endorser Settings.................................................................................................... 44

3.9 POWER SUPPLY ............................................................................................................................. 47

3.9.1 Mains Power Switch Unit ...................................................................................................... 47

3.9.2 Mains Transformer................................................................................................................ 48

3.9.3 Switching Power Supply ....................................................................................................... 48

3.10 LAMP UNIT ................................................................................................................................. 50

3.10.1 Rectifier Board ...................................................................................................................... 50

3.10.2 Electronic Lamp Ballasts ...................................................................................................... 50

3.10.3 Fluorescent Lamps ...............................................................................................................50

3.11 OPERATOR PANEL ...................................................................................................................... 51

3.12 OPTICAL COMPONENTS UNIT....................................................................................................... 53

3.13 PAPER TRANSPORT .................................................................................................................... 54

3.13.1 Input Hopper with Drive Motor .............................................................................................. 54

3.13.2 Diagnosing Paper Input Hopper Faults ................................................................................ 57

3.13.2.1 General Faults ................................................................................................................................. 57

SCAMAX®2600/4000 Tech. Manual 06/2002 T-3

3.13.2.2 Condition dependent Faults with GAL 2.2 ....................................................................................... 58

3.13.2.3 Condition dependent Faults with GAL 2.3 ....................................................................................... 59

3.13.3 Paper Feed with Separation System .................................................................................... 60

3.13.4 Rubber Roller Pairs (two) ..................................................................................................... 63

3.13.5 Paper Output Path ................................................................................................................ 63

3.13.6 Output Hopper ...................................................................................................................... 64

3.13.7 Drive Mechanism with Stepper Motor................................................................................... 65

3.14 DESCRIPTION OF SCAN ROUTINE FLOW ....................................................................................... 68

Spare Parts List Part E

Service Program Part S

SCAMAX®2600/4000 Tech. Manual 06/2002 T-4

1 INTRODUCTION

The SCAMAX 2600 is a bitonal document scanner. It is designed to be used in document conversion

projects of medium volume requiring medium speed. The scanner is driven from a PC connected to it.

This PC also receives the scanned images and processes them further as required.

The SCAMAX 4000 is a colour document scanner. It is identical in construction to the SCAMAX 2600 ,

except that it is equipped with a colour camera.

1.1 Scanner Models, Options and Accessories

The scanners are currently available in the following Models:

Description Part Number

SCAMAX 2600 Simplex Video, B/W with one scan unit for single sided

scanning and video interface

s2600010

SCAMAX 2600 Duplex Video, B/W with two scan units for double sided

scanning and video interface

s2600020

SCAMAX 2600 Simplex SCSI, B/W with one scan unit for single sided

scanning and SCSI interface

s2600030

SCAMAX 2600 Duplex SCSI, B/W with two scan units for double sided

scanning and SCSI interface

s2600040

SCAMAX 4000 Simplex Video, Colour with one scan unit for single sided

scanning and video interface

s4000010

SCAMAX 2600 Duplex Video, Colour with two scan units for double sided

scanning and video interface

s4000020

Options:

Greyscale interface (SCAMAX 2600 only)

8 Bit; 256 Greyscales

s0000055

DTplus-Board (SCAMAX 2600 only)

To scan difficult, low contrast documents

s0000500/1

Endorser

Prints text, numbers or dates on backside of documents

s2600200

Acid resistant paper rollers

For self-carbonising (impregnated) paper

s2500130

Accessories:

Purpose built work desk s0000055

Optical Filter #60 green (SCAMAX 2600 only) s9000030

Optical Filter #40 red/orange (SCAMAX 2600 only) s9000021

Optical Filter #90 red (SCAMAX 2600 only) s9000020

Optical Filter #81 blue (SCAMAX 2600 only) s9000010

Feeder extension for A3 documents s2500122

Foot Switch (Paper separation On/Off) s9000100

Anti-Static Brush for output hopper s2500125

SCSI-Cable (50 Pin) high density s9020100

SCSI-Cable (68 Pin) high density s9020110

White Calibration Paper (10 sheets) s9100000

Cleaning Kit s9100010

Vacuum Cleaner s9100020

SCAMAX®2600/4000 Tech. Manual 06/2002 T-5

1.2 Technical Data

- Scanner type: CCD array camera

- Number of scan units:

- 1 scan unit for single sided scanning

- 2 scan units for simultaneous scanning of front and back page

- Resolutions: 200, 240 (SCAMAX2600 only), 300 and 400 dpi

- Document widths: 26 mm - 320 mm

- Document lengths: from 60 mm upward

- Document thickness: various, can be set for each stack or single sheet

- Document feed: automatic from stack or single sheet hand feed

- Stack height: max. 50 mm

- Double Feed Detection: document length check and ultrasound sensor

- Video Port out to PC: V24, video digital, bitonal

optional: video with 256 greyscales (8 bit greyscale)

with

- Control Port to PC: serial, 9 pin, RS232

or:

- SCSI 2 Port to PC: 50 pin, high density

with

- serial interface to service PC

- Binarisation method:

- Standard unit 1. with fixed threshold

and

2. with one-dimensional auto-threshold

- with Dtplus board: with two-dimensional auto-threshold

SCAMAX®2600/4000 Tech. Manual 06/2002 T-6

- Scan speed (at 200 dpi resolution):

- A4 portrait:

- 75 sheets per minute (simplex)

150 pages per minute (duplex)

- A4 landscape:

- 90 sheets per minute (simplex)

180 pages per minute (duplex)

- Electrical requirements:

230 V, 50 Hz, 1,0 A

115 V, 60 Hz, 2,0 A

- Dimensions (width, height, depth):

510 mm, 365 mm, 650 mm

- Weight: 39 kg

- Endorser: the optionally fitted endorser

facilitates printing of free-dorm text, date, time and sequence number

on the back of documents

- Environmental requirements:

- room temperature: 10° to 35°C.

- relative humidity: 30% to 80% without condensation

- Noise level: less than 70 dB

1.3 Compliance with Regulations and Standards:

The scanners Scanner SCAMAX 2600/4000 comply with the regulations and standards that form the

basis of the CE compliance declaration that follows:

SCAMAX®2600/4000 Tech. Manual 06/2002 T-7

SCAMAX®2600/4000 Tech. Manual 06/2002 T-8

2 SYSTEM COMPONENTS

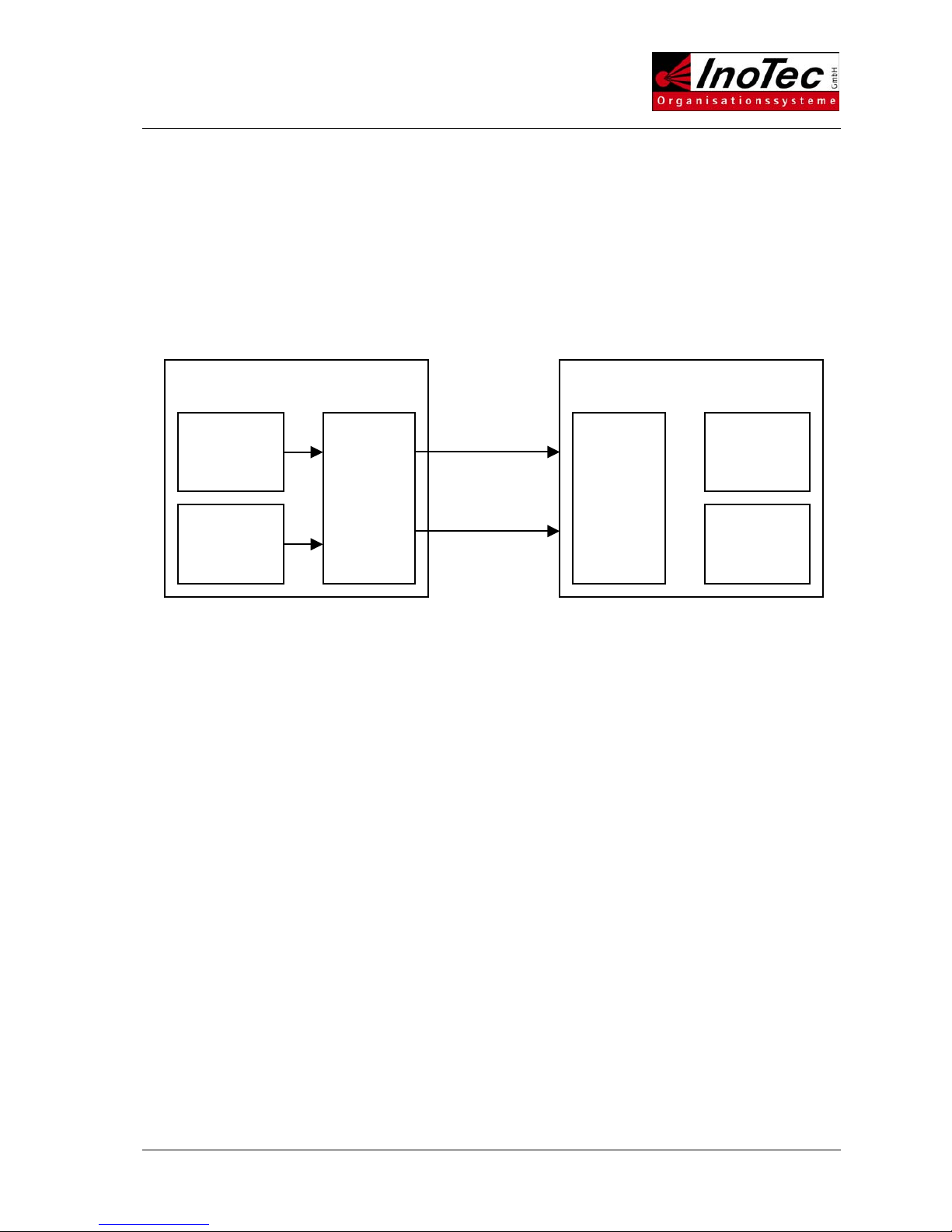

2.1 SCAMAX 2600 with video interface

Documents are illuminated and scanned inside the SCAMAX 2600. The picture information is digitised

and then sent to the external PC as an 8-bit parallel bitonal video signal for each side (front and back

respectively) via the video interface. Compression, image manipulation and storage 9in TIFF-G4 format

takes place in the PC.

Scan module 1 is used to scan the front of each document.

Scan module 2 (present in the duplex scanner model) is used to scan the back of each document.

For difficult documents, like handwriting or coloured paper with low contrast, a DTplus board can be

installed for each scan module. This enhances image quality greatly.

Image information is transmitted digital bitonal (black&white) from the scanner’s video interface to the

video board (f. ex. HISCAN or dunord board) in the scan PC. A separate control cable for communication

purposes is fitted.

The PC’s scan controls the video board via appropriate drivers, which in turn controls the scanner.

2.2 SCAMAX 2600 with SCSI interface

In a SCAMAX 2600 with SCSI interface the bitonal image data and all commands are transmitted via a

SCSI cable.

The scan PC must be fitted with a SCSI controller (f.ex. ADAPTEC 2940 AU). The scan application

(client) controls the scanner via the Twain or ISIS driver supplied.

Scanner S26/S40 Scan PC

Scanner

module 1

Controller

Board

&

Video-

interface

Scanner

module 2

Scanner

Interface

Driver

Application

Video

V 24

8 bit

p

arallel

SCAMAX®2600/4000 Tech. Manual 06/2002 T-9

It is possible to control the SCAMAX 2600 via SCSI commands without using the Twain or ISIS driver.

Since the command set of the SCSI interface is by and large compatible with other manufacturers it is

relatively easy to generate a generic driver without great programming effort.

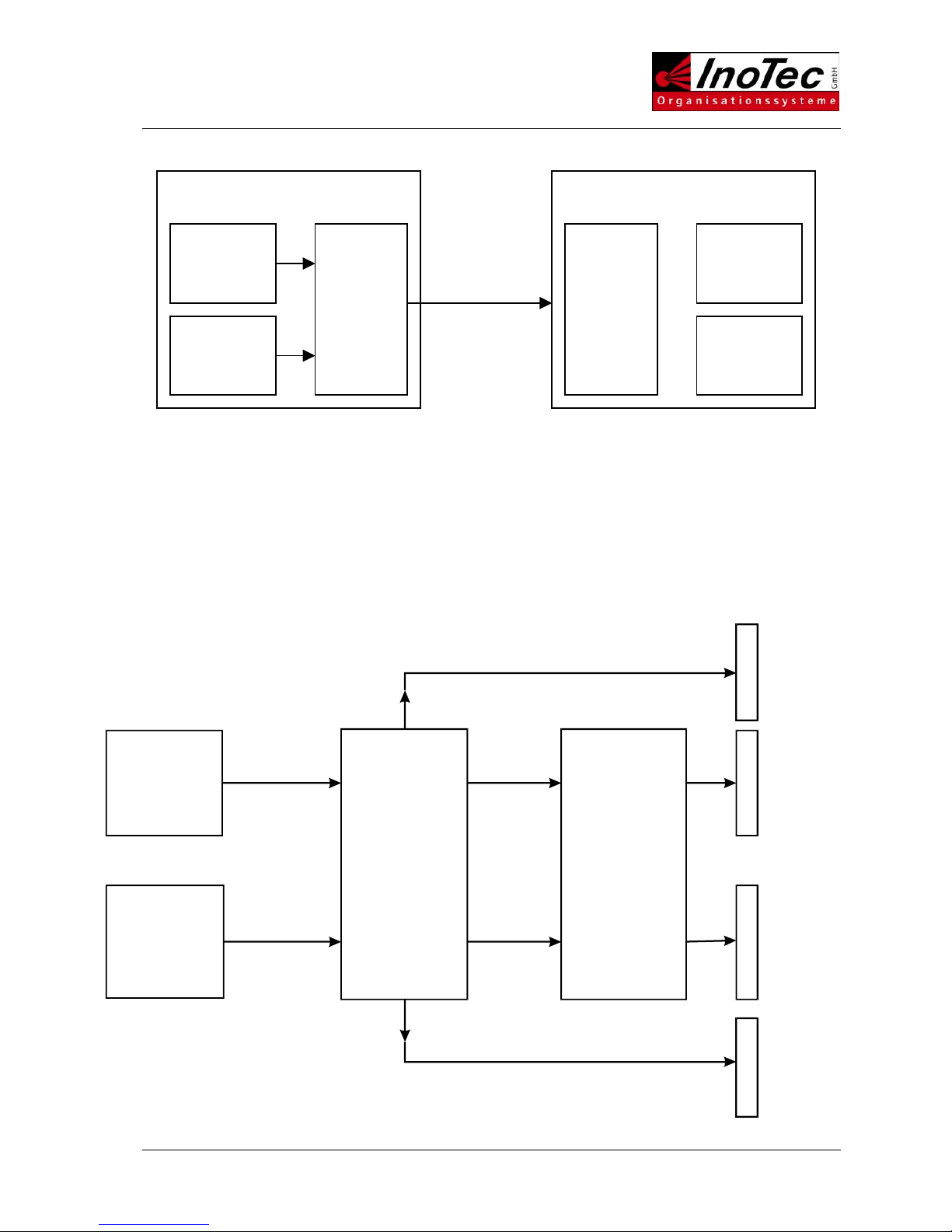

2.3 SCAMAX 2600 with Greyscale interface

For special application the SCAMAX 2600 can be fitted with a greyscale interface. The greyscale

interface passes image information in 8-bit form (256 grey levels) to the scan PC.

Scanner

module

front page

Scanner

module

reverse

page

Grey scale

interface

Controller

Board

Output video

8 bit grey scale

front page

Output video

8 bit grey scale

reverse page

8 bit

grey scale

8 bit

grey scale

8 bit

grey scale

8 bit

grey scale

Output

video bitonal

front page

Output

video bitonal

reverse page

Scanner S26/S40 Scan PC

Scanner

module 1

SMART

SCSI

Interface

Scanner

module 2

SCSI

Controller

TWAIN

or ISIS

Driver

Application

SCAMAX®2600/4000 Tech. Manual 06/2002 T-10

The scan module for the front page of the document transmits the image information in 8-bit format, i.e.

with 256 grey levels.

In the case of a duplex scanner the scan module for the back page simultaneously transmits the image

information in 256 grey levels as well.

The greyscale interface passes the greyscale image information for the front and back page via a

separate port to the scan PC.

At the same time the same image information is passed to the controller board. It converts the images to

bitonal (black&white) format for the front and back respectively and transmits it separately to the scan PC.

As can be seen in the drawing, one port each for bitonal and greyscale output exists for the front page.

These are connected to the PC’s scanner interface (dunord-Board). For the back page identical twin ports

exist. These are connected to the second scanner interface in the PC.

If the SCAMAX 2600 has a DTplus-Board fitted for each scan module that board comes with an

integrated greyscale interface. Should greyscale images be required it is possible to fit a plug connection

on each board (special option) to lead to outside port to transmit the greyscale signal to the PC.

SCAMAX®2600/4000 Tech. Manual 06/2002 T-11

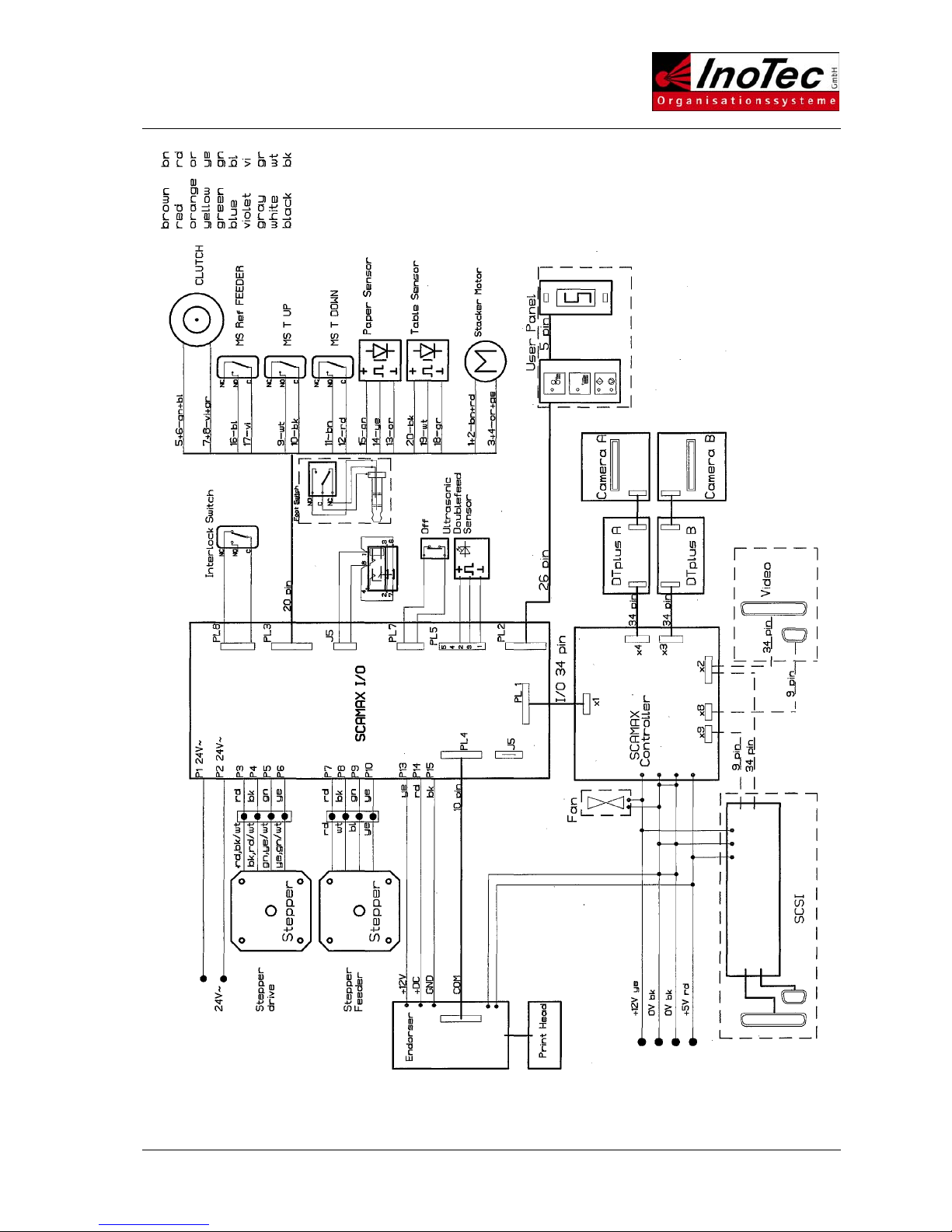

3 SCANNER COMPONENTS AND FUNCTIONS

The SCAMAX 2600/4000 scanner consists of the following main elements:

The paper transport system – it pulls sheets of paper into the scanner, transports them through the

machine and deposits them in the output hopper. It consists of input hopper, which is adjustable for single

sheet feed or stack feed, paper separation unit, transport mechanism and output hopper.

The illumination unit.

The optical system consisting of two mirrors plus a lens with colour filter.

The scan module 1, scanning the front of each document, is present in all SCAMAX scanners.

The scan module 2, scanning the back of each document, is only found in duplex models.

The controller board – controls all process in the machine.

The I/O board – converts TTL signals from the controller board into the signals required by the various

‚users’, such as motors. It also converts outputs from sensors, such as photocells and switches, into TTL

signals.

The operator panel – facilitates basic operation of the scanner, except for scan commands and internal

settings.

The power supply unit – supplies the necessary voltages for the entire machine.

The ultrasound double feed detector.

Optionally fitted elements are:

One DTplus board for each scan module, which significantly enhance images from difficult documents.

The greyscale interface.

The endorser - consisting of printer unit, endorser board and photocell. Used to print date, time, and so

on onto the back of each document during the scan process.

The following page shows a cross section of the SCAMAX 2600/4000 document scanner:

SCAMAX®2600/4000 Tech. Manual 06/2002 T-12

SCAMAX®2600/4000 Tech. Manual 06/2002 T-13

The principal of operation is as follows:

A single sheet or a stack of documents is placed in the input hopper. A photocell detects the presence of

document/s.

When the scan PC issues a scan command the machine pulls in the single sheet or top sheet of the stack

via the feed roller. The sheet travels through two guide plates till a rubber roller pair grips it. The sheet

reaches the scan area and is then grabbed by a second pair of rubber rollers. Subsequently, the sheet is

transport around a guide plate by yellow transport belts upwards and forward till it is deposited into the

output hopper.

In the scan area the sheet is illuminated by one or two fluorescent lamps, simplex or duplex. The lamps

are offset to each other to minimise ‚print-through’. The light reflected from each side of the sheet

contains the image information for the front and back respectively. Since the sheet is in continuous

motion each line is scanned in succession.

The reflected light hits a mirror that projects the light to a second mirror. The second mirror projects the

light to the lens, which sits in front of the CCD array.

The CCD converts the light containing the image information into an analogue electrical signal, which is

digitised and possibly binarised in the next processing step before being transferred to the PC.

The following page shows an electrical block diagram:

SCAMAX®2600/4000 Tech. Manual 06/2002 T-14

SCAMAX®2600/4000 Tech. Manual 06/2002 T-15

3.1 CCD-Linear-Camera

The CCD linear camera consists of a lens unit mounted on an aluminium plate and a CCD linear sensor

with associated electronics components fixed in a metal housing, which is attached to the aluminium

plate.

The document to be scanned is illuminated in the scan area. The CCD linear sensor captures the

reflected light containing the image information, after it has been refracted by two mirrors and passed

through the lens.

CCD stands for Charge Coupled Device. It is an electronic component containing capacitor elements

arranged in parallel. The capacitors convert the amount of light received into electrical current, the voltage

generated being proportional to the amount of light detected. An analogue-to-digital converter translates

the charge for each pixel into an 8-bit digital value.

This process takes place at very high speed, the clock speed being 20 MHz. This means that each

second an enormous amount of image information is read and output, i.e. 20 megapixels for bitonal and

60 megapixels for colour (20 for each channel red, green, blue).

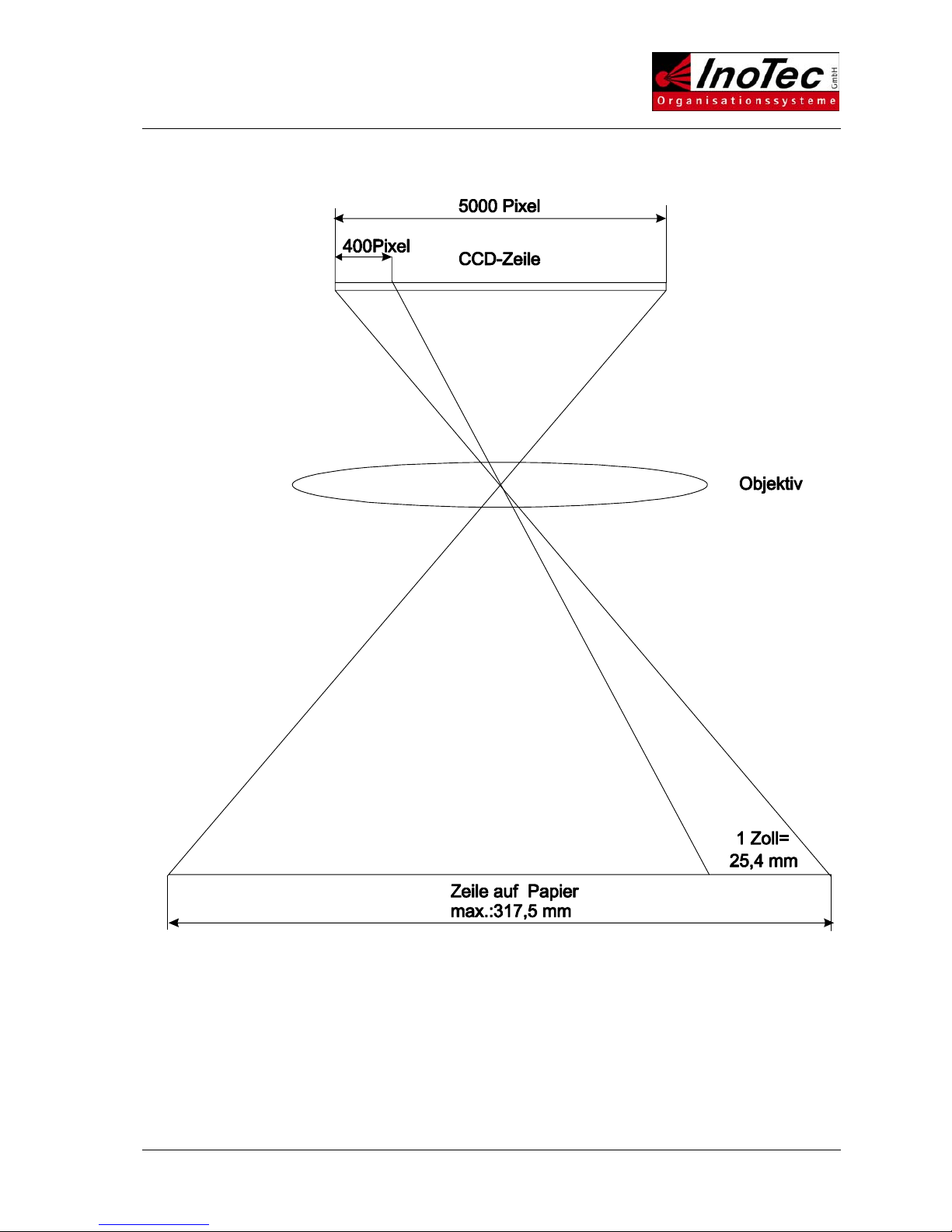

The CCD used has 5000 light sensitive pixel elements. This number is sufficient to scan an A4 page in

portrait mode (3,700 pixel) or an A3 in portrait mode (4,670 pixel) at an optical resolution of 400 dpi (dots

per inch).

It is necessary to set the optical reduction in such a way that a width of 1 inch (25.4 mm) covers exactly

400 pixels on the CCD chip (see illustration next page).

For lower resolutions the pixel elements shown in the table below are deactivated:

400 dpi X X X X X X X X X X

300 dpi X X X X X X X X

240 dpi X X X X X X

200 dpi X X X X X

The scan speed (paper transport speed) is automatically adjusted according to the resolution selected.

200 dpi requires only half the number of lines, thus the paper can be transported at double the speed.

SCAMAX 2600 SCAMAX 4000

Resolution in dpi Paper transport speed in m/min. Paper transport speed in m/min.

200 29,3 27,5

240 24,4 X

300 19,6 18,3

400 14,7 13,8

SCAMAX®2600/4000 Tech. Manual 06/2002 T-16

Illustration of optical reduction

SCAMAX®2600/4000 Tech. Manual 06/2002 T-17

The reading of the CCD linear sensor and conversion into digital values described above takes place on

two channels. One channel each for odd and even pixels. With colour two channels are used for each

colour.

A shielded ribbon cable is connected to the CCD board (two for colour), which provides the connection to

the controller board and for colour also to the video interface.

Both mechanical and electronic adjustments are accomplished by using the service program.

3.1.1 Camera types

Two different types of CCD linear cameras are used for the SCAMAX®2600/4000 scanners.

SCAMAX®2600:B&W CCD linear camera Type 0

B&W CCD linear camera Type 3

SCAMAX®4000: Colour CCD linear camera Type 2

CCD linear camera Type 0

CCD linear camera Type 3 CCD linear camera Type 2

SCAMAX®2600/4000 Tech. Manual 06/2002 T-18

3.1.2 Camera Faults

The service program is used to determine whether a camera is faulty. The program can display the

camera status. If the camera status is shown as OK it is possible that the camera sends wrong data or no

data at all. This fact would be shown by an unexpected curve formation, heavy noise or absence of a

channel. If a problem is diagnosed it will not be immediately obvious whether it is caused by the camera

board and/or the CCD sensor. Therefore, several solutions present themselves. In the majority of cases

an exchange of the camera board will yield the result desired. This methodology has the advantage of

retaining the optical alignment of the camera.

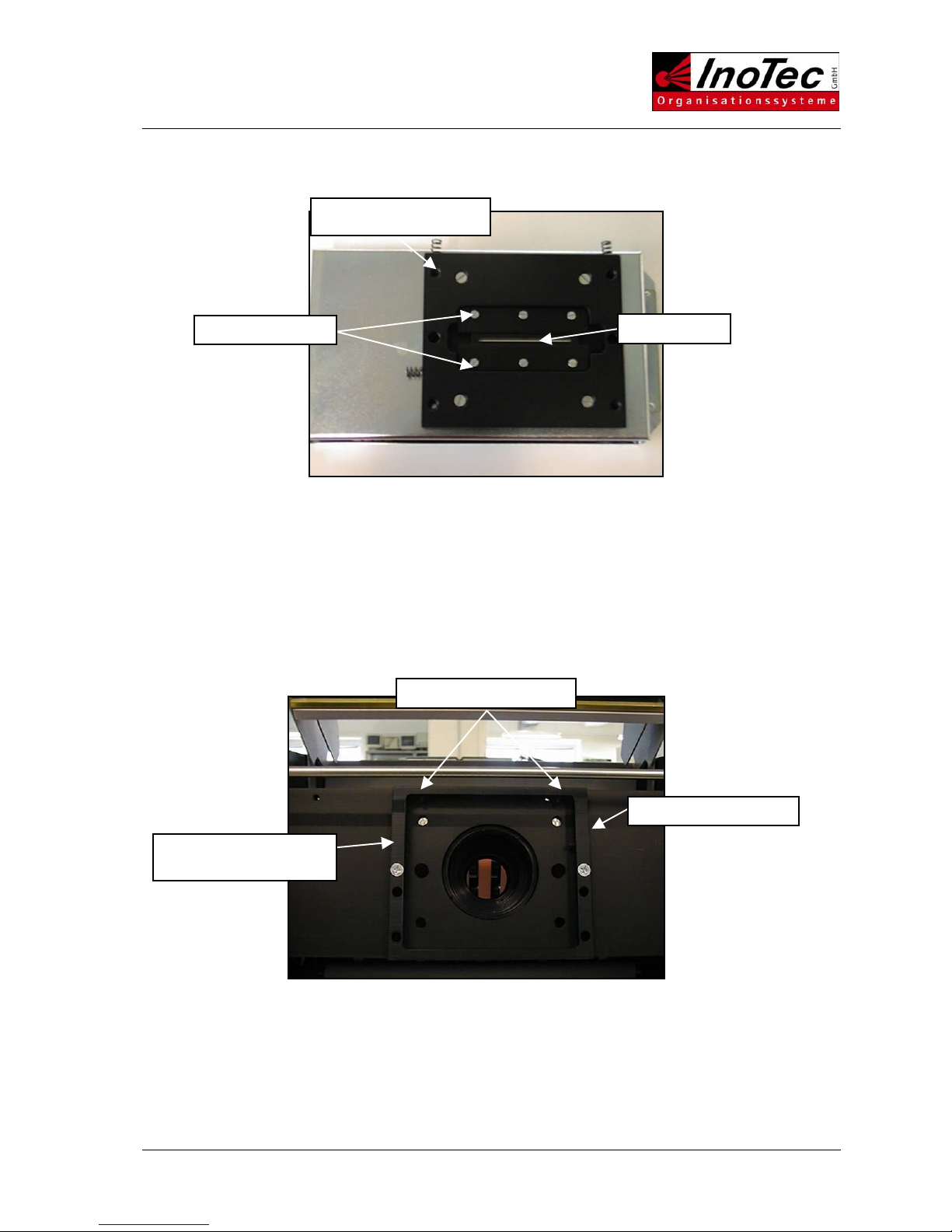

3.1.2.1 Changing Camera Board Type 2+3

Switch off Scanner!

All activities have to undertaken in accordance with current ESD regulations!

Remove the two screws of the EMV camera housing and lift lid.

Pull the post connector from the board (1x for SCAMAX®2600 and 2x for SCAMAX®4000) and un-screw

the four plastic nuts.

Using a pair of pliers pull the board backwards out of the housing by the earth straps. Ensure the board is

pulled squarely out of the housing; otherwise the CCD sensor's contact pins will be bent.

Carefully insert the new board and fasten using the plastic nuts.

Front Back

Camera-EMV-Housin

g

Earth straps Plastic nuts

SCAMAX®2600/4000 Tech. Manual 06/2002 T-19

Replace the post connector and switch the scanner on. The next step is to set CCD sample delay, which

calculates and adjusts run time differences of the various components, using the service program. To set

the CCD sample delay insert a sheet of white calibration paper in portrait mode into the scanner and

transport it past the roller pair. Press the "D" key and follow the menu instructions. When finished insert

the sheet in landscape mode and perform a white calibration ("M" key).

If the service program's camera signal display does not show an improvement re-insert the original

camera board and exchange the CCD sensor as described under 1.1.2.3 instead.

3.1.2.2 Changing Camera Board Type 0

The difference to the procedure described under 1.1.2.1 is that the camera type 0 has two boards

mounted on top of each other. The board having the potentiometers is mounted on the CCD board, it can

simply be pulled off. The CCD board is fastened with four nuts (M3) and have to be unscrewed prior to

removal of the board. When fitting the new boards ensure that they sit squarely one on top of the other.

The camera signals are to be adjusted as described under 1.1.2.5.

3.1.2.3 Changing the CCD Linear Sensor

All activities have to undertaken in accordance with current ESD regulations!

To change the CCD sensor it is necessary to remove the entire camera unit (consisting of: board. EMV

housing, board mounting plate and CCD sensor) from the scanner. Unscrew the fixing bolts (M4x10) and

remove the EMV housing with board mounting plate.

Front

Fixing bolts

Back

SCAMAX®2600/4000 Tech. Manual 06/2002 T-20

Unscrew the IC support plates and mark the position of the CCD sensor on the board mounting plate.

Plug the new CCD sensor into the IC socket on the board and align to the previously marked position.

CAUTION! Check polarity.

Fasten IC support plates. The new CCD sensor must be absolutely free from dust and grease. Clean it.

Insert the complete camera unit into the adjustment frame, ensuring the springs are forward. Check that

springs are not bent. Compress the springs sufficiently to ensure the board mounting plate seats properly

behind the set-screws. Fasten fixing bolts, then undo them again a quarter of a turn. The camera should

now be movable within the adjustment frame.

Set-screw ( C )

Set-screws (A+B)

Camera adjustment

frame

CCD sensor

Board mounting plate

IC support plates

This manual suits for next models

1

Table of contents

Other InoTec Scanner manuals

Popular Scanner manuals by other brands

Colortrac

Colortrac SMARTLF SCAN User instructions

Canon

Canon imageFORMULA DR-1210C Brochure & specs

Brother

Brother DS-620 user guide

Fujitsu

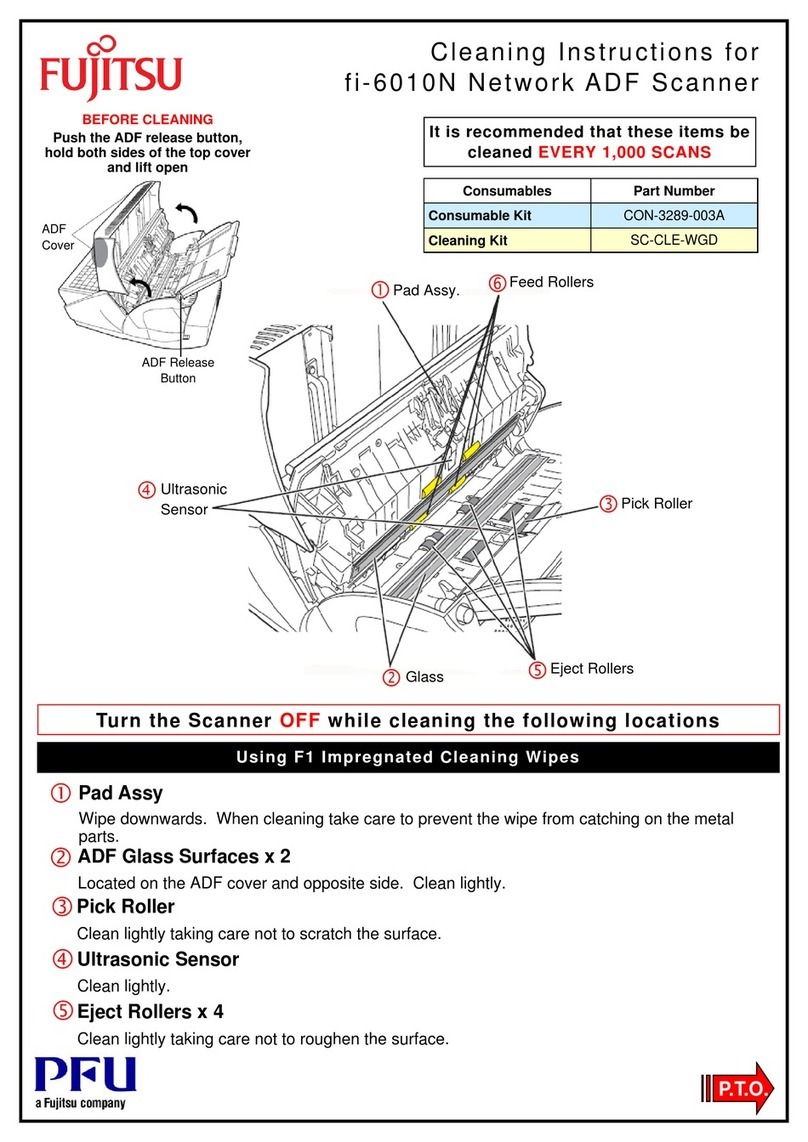

Fujitsu ScanSnap iScanner fi-6010N Cleaning instructions

Scanivalve

Scanivalve DSA3217-PTP Series Operation and service manual

Microtek

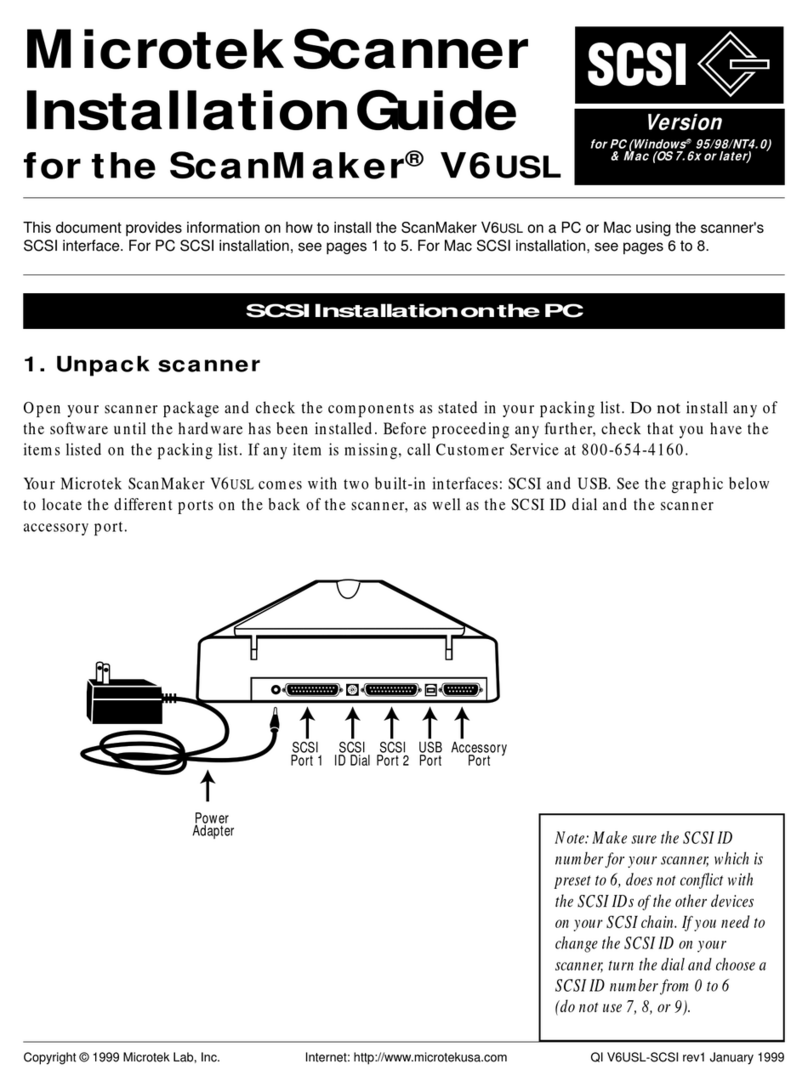

Microtek ScanMaker V6USL installation guide