DMTA-20006-01EN, Rev. B, February 2014

Table of Contents

iii

Table of Contents

List of Abbreviations ........................................................................................ v

Labels and Symbols ........................................................................................... 1

Important Information — Please Read Before Use ..................................... 3

Intended Use .......................................................................................................................... 3

Instruction Manual ................................................................................................................ 3

Instrument Compatibility ..................................................................................................... 4

Presence of Visual Interferences or Phantom Spots ......................................................... 7

Safety Symbols ....................................................................................................................... 8

Safety Signal Words ............................................................................................................... 8

Note Signal Words ................................................................................................................. 9

Safety ....................................................................................................................................... 9

Warnings ............................................................................................................................... 10

CE (European Community) ............................................................................................... 10

WEEE Directive .................................................................................................................... 10

Warranty Information ......................................................................................................... 11

Technical Support ................................................................................................................ 11

Introduction ...................................................................................................... 13

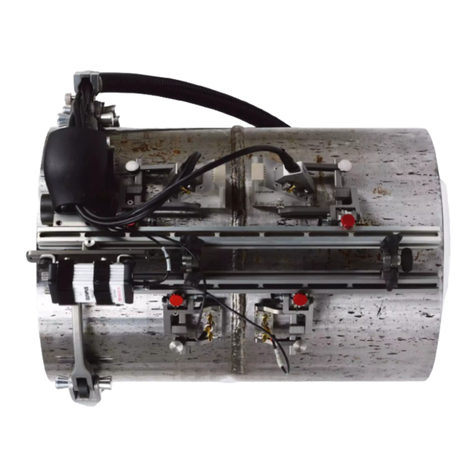

1. COBRA Scanner Description .................................................................. 15

1.1 Scanner Components ................................................................................................ 16

1.2 About the Setup Templates ..................................................................................... 18

1.3 Required Tools for Scanner Setup .......................................................................... 20

2. Setup and Operation ................................................................................. 21

2.1 Removing the Probe ................................................................................................. 21

2.2 Installing the Probe ................................................................................................... 22