Inshore 380N User manual

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

1

R29965

SERVICE MANUAL

INSHORE 380N

LIFEJACKET

Survitec House, Lederle Lane, Gosport,

Hants. PO13 0FZ, England.

Tel: +44 (0) 1329 820000 Fax: +44 (0) 1329 236218

email: crewsa[email protected]

Web: www.crewsaver.com

1

R29965

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

2

No.

Issue 2

Description

Reference to Venturi Vacuum System

added (sections 6.1.2, 8.1.2 and Parts List)

Cylinder now has Netlon sleeve fitted (section 8.1)

Back pressure testing of the operating head added

Date

November 2016

Service Bulletins and Amendments Register

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

3

Index

Section 1

1.1 Introduction

1.2 Product Description

1.3 Data Sheet

1.4 General Features

1.5 Donning Instructions

Section 2

2.1 Service Station Guidelines

2.2 On Receipt Inspection

2.3 General Care

2.4 Servicing Tools

2.5 Service Record Sheet

2.6 Servicing Tool Kit

Section 3

3.1 Unpacking the Lifejacket

Section 4

4.1 Cleaning & laundering

Section 5

5.1 Inspection

Section 6

6.1 Testing

Section 7

7.1 Repairs

Section 8

8.1 Assembly

8.2 Packing instructions

Section 9

9.1 Replacement parts

Scope

This manual covers the servicing of the Inshore 380N lifejacket without any current

derivatives.

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

4

1.1 Introduction

1.2 Product Description

1.1.1. This Service Manual will be published on the Crewsaver website (www.crewsaver.com). Click on PARTNER

AREA/LOGIN at the top of the screen. Personnel who have been trained in the servicing procedures for this

lifejacket will be issued with a Username and Password to enable them to access the download section.

Each manual carries an Issue Number and records of issue are logged by Crewsaver to ensure that the

service network maintains correct and up to date servicing information. Emails will be sent regarding any

new Issues. Periodically service bulletins may be issued which will be published on the Crewsaver website

(www.crewsaver.com). Emails will also be sent. It is the service station's responsibility to regularly check the

website for any new bulletins and to ensure inclusion within the servicing manual. The service bulletin

register at the front of the Manual should be completed.

1.1.2. The information referenced in each section, follows a standard servicing procedure by which the inspection

should take place.

1.1.3. This servicing manual details information to enable regular maintenance and servicing of the lifejacket to

help prolong the life of the product and ensure it functions correctly.

1.1.4. The manual should be used as a reference document following training in servicing procedures instructed by

Crewsaver approved personnel. The manual also details the equipment and parts needed for correct

maintenance to be performed.

1.1.5. Servicing must be carried out annually at a service station authorised by the manufacturer.

1.1.6. Regular servicing is to be carried out by qualified personnel trained by Crewsaver and holding a valid

servicing certificate. Certificates are valid for a period of 3 years.

1 yr

1.2.1. The Inshore 380N is a single chamber Level 275 PFD (Inflatable lifejacket), designed, tested and developed

in collaboration with the RNLI, ensuring it is suitable for rescue boat crews of inshore lifeboats or advanced

powerboat users.

1.2.2. The lifejacket is CE approved to BS EN ISO 12402-2.

1.2.3. The lifejacket is easy to don.

1.2.4. The lifejacket has 90N of inherent buoyancy provided by closed cell foam. In addition a further 290N of

buoyancy can be achieved by means of a single chamber inflated by CO . The chamber is fitted with an oral

2

tube to ensure that full buoyancy can be achieved upon or after inflation.

1.2.5. The lifejacket is inflated by a HR manual operating head fitted with a 60 gr. CO cylinder.

2

1.2.6. This lifejacket is fitted with an integral deck safety harness with a 2-hook safety line, a spray hood and a

water activated light. The lifejacket has a YKK QBR Zip closure system.

1.2.7 The outer cover is made from a hard wearing material.

1.2.8 This lifejacket has permanently fitted dual crutch straps and dual lifting beckets.

1

Section

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

5

1.3.1 Data Sheet

Features:

Inflatable Buoyancy

Inherent Buoyancy

Total Buoyancy

Buoyancy Category

Cover Colour

MCA (UK) Approved

SOLAS Approved

CE Approved

Cylinder size

Standard Automatic

Hammar Automatic

Manual Firing head

Manual Override

Oral inflation tube

Hard wearing cover

Whistle - fitted

Retro-reflective tape

Twin Lifting Becket - fitted

Light - fitted

Spray Hood - fitted

Dual Thigh straps - fitted

Integral Deck Safety Harness

Closure method

Inshore 380N Lifejacket

290N

90N

380N

275N

Red

-

-

X

60g

-

-

X

-

X

X

X

X

X

X

X

X

X

YKK QBR Zip

1

Section

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

6

1

Section

1.4.1 General Features - Inshore 380N

Centre buckle, D ring and Harness

2 hooks and harness

Flare pocket

Manual toggle

SS40 buckles to

Secure crutch straps

Stretcher loops

3 burst QBZ ykk zip

Cover has been ergonomically designed to

Create supreme shape and fit. Allows user full

and unobstructed Movement.

Approved to BS EN ISO12402-2

Neck padding to prevent lifejacket rubbing at back of neck.

One size fits all.

Foam padded for maximum comfort.

Velcro webbing end tidies for neat finish.

Side pocket

Centre zip

SPRAY HOOD

WHISTLE

SINGLE CHAMBER

290N BLADDER

8 PIECES REFLECTIVE TAPE

HR MANUAL OPERATING HEAD,

60 gm CYLINDER LOCATED AT

BACK

40mm CRUTCH STRAP

WEBBING WITH VELCRO

WEBBING TIDY

CREWSAVER WATER ACTIVATED LIGHT

TWIN LIFTING BECKETS

MOUTH INFLATION TUBE

FRONT OF CHAMBER

(TO DEFLATE THE CHAMBER

INVERT THE TUBE CAP)

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

7

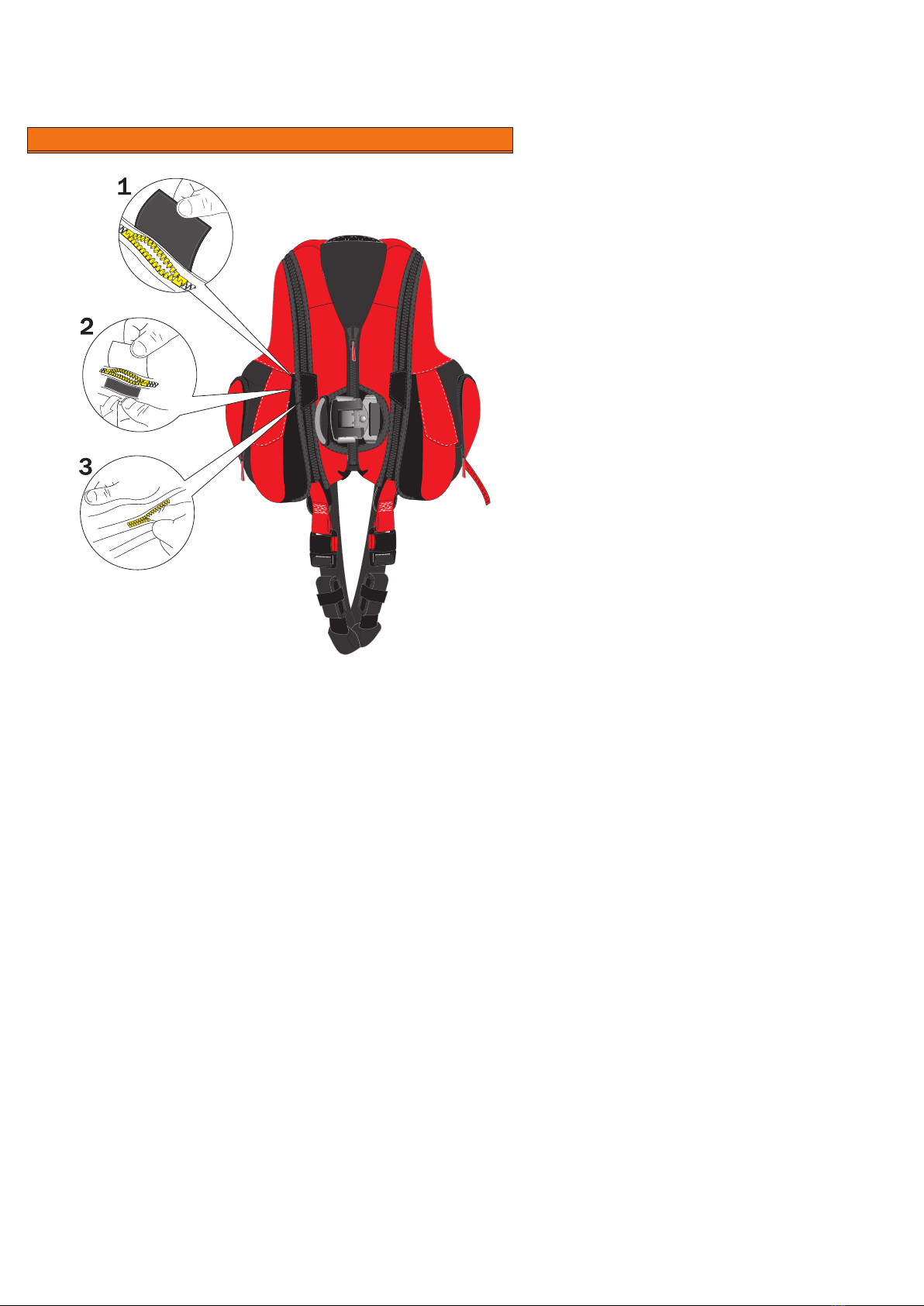

1.5.1 Donning Instructions - Inshore 380N

Section

1

Fasten centre buckle.

LLOYDS REGISTER

APPROVED,

AUTHORISED BY MCA

ADULT

43+KG

0191/#

Pull straps forward to

a tight but comfortable

tension.

Tighten straps to a tight

but comfortable tension.

Don life jacket like a waist coat Close centre zip

Fold excess waist webbing

into side slots. Pull lanyard to inflate lifejacket

Ensure crutch straps are fitted at all times

Fold excess webbing into

Velcro webbing tidy.

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

8

2.1.1 Service stations shall comply with the following as a minimum;

2.1.1.1 Servicing of Inflatable Lifejackets shall be carried out in a fully enclosed area only.

2.1.1.2 The area shall be well lit and protected from direct sunlight

2.1.1.3 The temperature and humidity shall be sufficiently controlled to ensure that the servicing of inflatable

Lifejackets may be carried out successfully.

2.1.1.4 The area shall be efficiently ventilated but free from draught

2.1.1.5 Sufficient tools (including specialist tools) shall be available to ensure Lifejackets may be

disassembled, tested and reassembled in accordance with this Manual. These shall include but not

limited to:

2.1.1.5.1 Manometers and pressure gauges

2.1.1.5.2 Oil free and dry air supply

2.1.1.5.3 Scales for weighing Gas Cylinders

2.1.1.5.4 Crewsaver Service tool kit (See 2.6). This is recommended but similar calibrated devices

may also be used.

2.1.1.6 Stock of materials and components to allow efficient servicing with readily available replacement parts

to ensure a prompt service for the customer.

2.1.1.7 Only personnel trained and certified in accordance with Crewsaver requirements are approved to

carry out Servicing and Maintenance. They must be holders of a valid Certificate issued by

Crewsaver.

2.1.1.8 The service station shall be of an approved standard.

2.1.1.9 Procedures shall be introduced to ensure that service bulletins, Manuals and replacement parts are

obtained from Crewsaver.

2.1.1.10 Subsequent to initial approval and thereafter the service station shall be subject to regular surveillance

by Crewsaver.

2.1.1.11 The service station must comply and have met all QA criteria in the Crewsaver servicing protocol file.

2.2.1 On receipt of the Lifejacket(s), check the state of the packaging before opening and notify the owner

and the company delivering the package of any defects or damage.

2.2.2 On opening the package, check the contents for their general condition and quantity.

2.2.3 Prepare Servicing Record Sheet.

2.2.4 Visually inspect the cover and inflation chamber for damage, abrasion, contamination etc. in

accordance with this manual.

2.2.5 Note replacements required on the record sheet.

2.2.6 Unless obvious damage is evident, test the Lifejacket in accordance with Section 6. If it is considered

that the damage found would cause the Lifejacket to fail the tests then corrective action shall be carried

out prior to testing.

2.2.7 Damaged areas shall be marked using wax based crayon only. Marks shall be made with a small circle

or

cross. Ballpoint, rollerball or other forms of ink shall not be used. If in doubt refer to Crewsaver for

guidance.

2.2.8 Repairs to the outer cover and the webbing are not permitted.

2.2.9 Repairs to welded components including the inflation chamber are expressly forbidden.

2.1 Service Stations

2.2 On Receipt Inspection

2

Section

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

9

2.3.1 The Lifejacket should be stowed in accordance with the manufacturer’s instructions

2.3.1.1 Lifejackets should be stowed in a dry compartment. Avoid high humidity, such as a car boot.

2.3.1.2 Lifejackets should have stowage facilities which are provided with a method to encourage

moisture removal.

2.3.1.3 Lifejackets should be stowed vertically, for example hung on hooks, in order that any trapped water

or condensation can drain away naturally.

2.3.1.4 Lifejackets should be rinsed in fresh water and dried thoroughly after use.

WARNING

Prior to sponging or washing remove automatic capsules from the firing mechanism. Allow to dry thoroughly

afterwards.

2.3.2 Contaminants such as oil or diesel fuel may be sponged off immediately with clean water and allowed

to dry naturally.

2.3.3 Mud can be removed with a stiff (not wire) brush when dry.

o

2.3.4 The outer cover may be hand washed in good quality mild detergent in cool water (40 C). Rinse well,

drip dry naturally in air.

2.3.5 Sponge the inflation chamber with pure soap solution only. Rinse in clean water immediately, inflate

and allow to dry naturally in air.

WARNING

Do not use proprietary cleaning fluids, thinners, spirits or similar substances.

2.3.6 In cases of severe contamination the unit shall be deemed beyond economic repair and the customer

advised to purchase a replacement lifejacket.

WARNING

Make sure you know how to use and fit this Lifejacket before an emergency occurs.

Always try and inflate the Lifejacket in the water. If already inflated, cross arms over the chest before jumping.

2.3.7 It is advised that personnel are familiarised with the operation of all Lifejackets and lifesaving

appliances.

2.3 General Care

2

Section

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

10

2.4 Lifejacket Servicing Tools

2.5 Lifejacket Service Record Sheet

2.5.1. An electronic copy of the sheet is available to aid reproduction (or copy next page).

2.5.2. Each lifejacket serviced should be recorded either individually or as a batch, showing the serial

numbers and the work performed during the service.

2.5.3. The service record sheet should be signed and a copy given to the owner certifying that the

lifejacket has been serviced.

2.5.4. All replacement parts should be noted - recording either the serial numbers of the component or

the expiry date.

2.5.5 The record sheet shown on the next page is a recommended version. Similar record sheets,

including the same information, may also be used.

2

Section

Fig. 2.4 Table of Tools Required

Crewsaver Servicing Tool Kit

A fine screw driver or tool suitable for removing gaskets

Boning tool

Roller

Brushes

Scissors or good quality trimming shears

“Chinagraph” pencil

Tailors chalk

Fine point indelible pen

1 off metal calibrated metre stick

Scales to weigh gas cylinders 0-1000gram (+1/-1 grams)

Adaptor/tee piece for testing inflation chambers.

Manometer 0-500Mbar

Timing Device

Thermometer 0-40ºC

Clean and dry air supply

1 off ball pein hammer

450mm wide bag sealer (3mm element)

Crewsaver Venturi Vacuum System

Back pressure test unit

Suitable large surface area for the work to be carried out

Description Type

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

11

2

Section 2

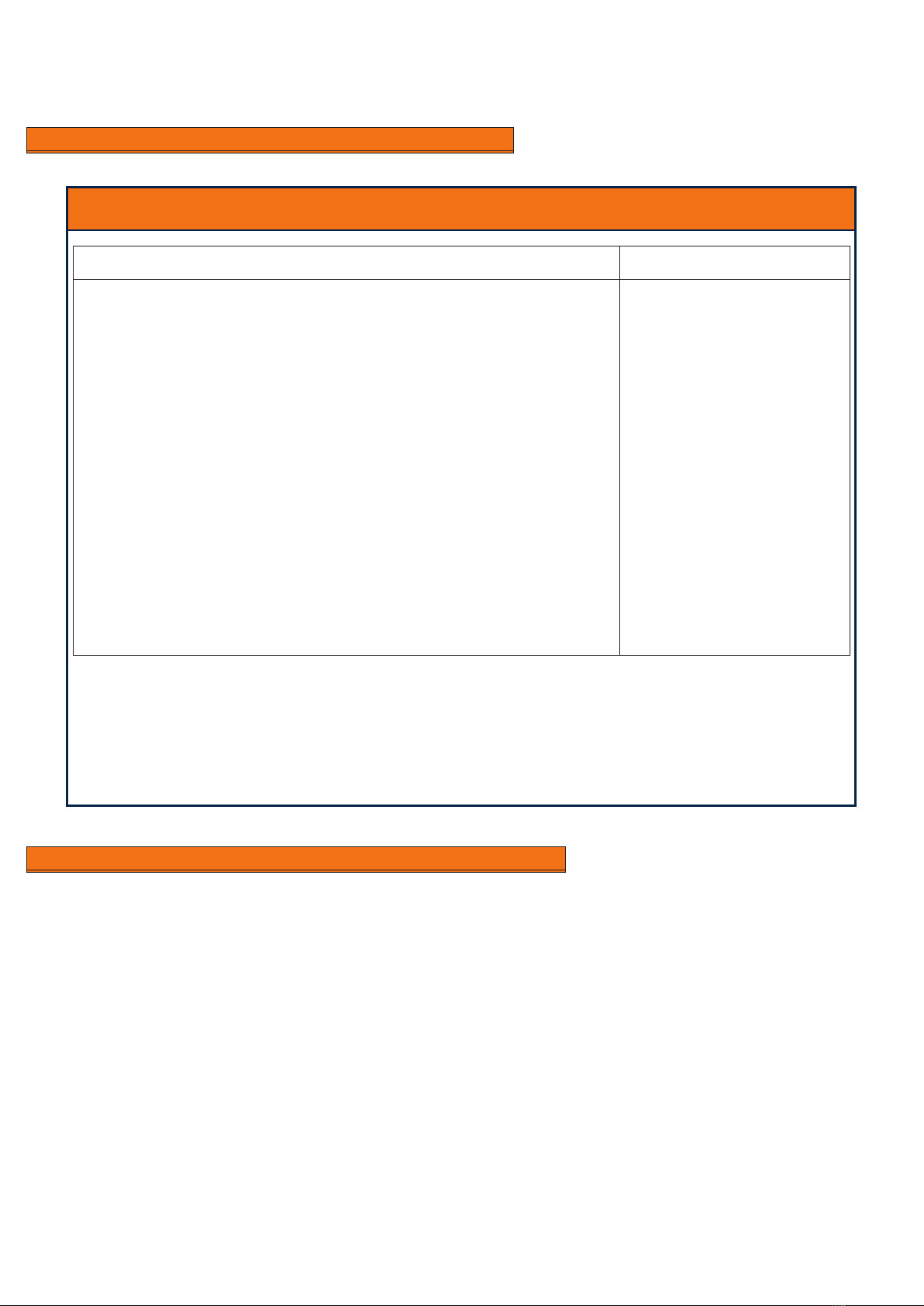

LIFEJACKET SERVICING SCHEDULE

SERVICED BY:

CERTIFICATE NUMBER:

VESSEL

W/O Number:

LAST SERVICED BY DATE OF LAST SERVICE

SERIAL NUMBER/S:

RQ

CHAMBER INSPECTION COMMENTS

GENERAL CONDITION

MATERIAL

WELDS

WEBBINGS

RETRO TAPE

WHISTLE

ORAL TUBES

RELIEF VALVES

MANIFOLDS

Schrader VALVES

CYLINDERS

LIGHT

CYALUME POCKET

BUDDY LINE

RQ

INFLATION MECHANISM COMMENTS

OPERATING

MECHANISM

CORD

AUTOMATIC CAPSULE

WASHERS

RETAINING NUT

RETAINING CLIP

TOGGLE

RQ

SPRAY HOOD COMMENTS

FABRIC

ATTACHMENT

VELCRO

REPAIRED ITEMS (COMMENTS)

TYPE

CUSTOMER

RQ

WEBBINGS COMMENTS

WAIST BELT / HARNESS

BACK STRAP

LIFTING BECKET

CROTCH STRAP

BUCKLES

STITCHING

ON

OFF

RELIEF VALVE TEST RESULTS FRONT

CHAMBER

OPEN

CLOSE

REAR

CHAMBER

DATE:

RQ

COVER COMMENTS

MATERIAL

VELCRO

ZIP

PLB POCKETS

PRESSURE TEST RESULTS

FRONT

CHAMBER

REAR

CHAMBER

TIME

TEMP. ON OFF

R29965R29965

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

12

2

Section 2

2.6 Lifejacket Servicing Tool Kit

Cylinder Torque Strap

UML Mk5 Auto Socket

Manometer

Valve Extraction Tool

Pressure Measuring

Adaptor

Inflation Adaptor

Turned Socket

Calibrated Socket Driver

(Tighten Cylinder)

Calibrated Socket Driver

(Remove & Replace Locking

Nuts For UML & HR)

Calibrated Torque Driver

(Schraeder Valve)

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

13

3.1 Unpacking the Inshore 380N

WARNING: All defects should be noted onto the service record sheet.

3.1.2 Following unpacking refer to:

a.) Manual Operation: Fig 3.2 - Halkey Roberts operating head removal.

3.1.2.1.2 Carefully remove the inflation cylinder by unscrewing it from the operating

mechanism. Retain for further Inspection. Refer to Section 5.

3.1.2.1.3 Remove Operating Mechanisms (and upper and lower manifold gaskets) by

unscrewing the retaining nut on the top of the inflation mechanism. Retain for further

Inspection. Refer to Section 5.

3.1.3. Remove light and battery. Place to one side for further inspection. Refer to section 5.

3.1.4 Remove Safety Line and place to one side for further inspection. Refer to Section 5.

3.1.5. For Cleaning. Refer to Section 4.

3.1.6. Carry out visual inspection. Refer to section 5.

3

Section

OPENING THE LIFEJACKET COVER

1. Open the velcro tab.

2. Pull apart the zip, opening the zip via

the 3 quick burst elements, holding the

cover either side.

3. Once the zip has opened insert your

finger and slide it around the Lifejacket.

Undo the zip all the way around the

outside of the lifejacket. The Lifejacket

cover should now be open and the

inflation chamber visible.

Fully separate the zip. Both sides of the

zip should be apart, with the zip slider

free to move back around the lifejacket

to the start.

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

14

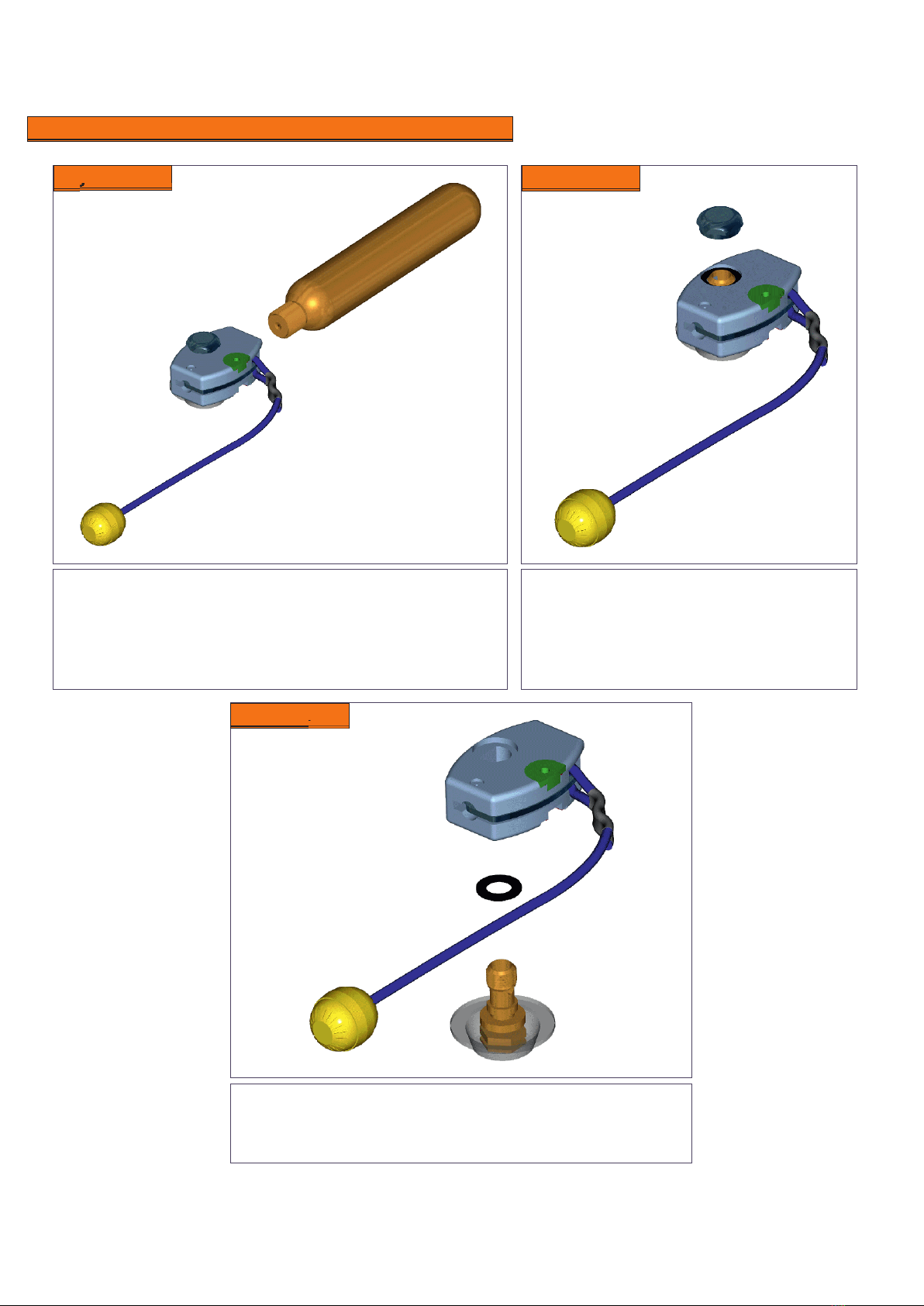

Fig. 3.2.2Fig. 3.2.1

Unscrew the 60 gram cylinder from the manual firing head. Check

to see if the cylinder has been used.

NOTE: This should be performed by check weighing. If under the

min. weight as displayed on the cylinder body, discard in a safe

manner.

Unscrew the valve retaining nut from the top of

the firing head, using a 9/16” socket or spanner.

Check for corrosion, discard if corroded.

Remove the top sealing gasket/ washer and

discard. This must be replaced with a new part

upon reassembly.

Fig 3.2 Halkey Roberts Operating Head

Fig. 3.2.3

Remove the operating head from the manifold which is welded to

the inflator fabric. Remove the bottom gasket / sealing washer and

discard. This must be replaced with a new part upon reassembly.

Please Note: The operating head may not match the images above, but the processes are always the same.

Section

3

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

15

4.1 Cleaning Lifejackets

4.1.1 The current standard cover of the Inshore 380N is made from a polyester fabric with a polyurethane

coating that can be cleaned with care. In the event that contamination is such that the materials are

inherently damaged refer to section 7.

4.1.2 For all types of cover, mud can be removed with clean water and the zip can be cleaned with a stiff (not

wire) brush when dry.

4.1.2.1 Contaminants such as oil or diesel fuel may be sponged off immediately with clean water and

allowed to dry naturally.

4.1.2.2 Mud can be removed with a stiff (not wire) brush when dry.

4.1.2.3 Covers may be hand washed in good quality mild detergent in cool water (40°C). Rinse well,

air drip dry.

4.1.3 Sponge the inflation chamber with PURE SOAP SOLUTION ONLY. Rinse in clean water immediately,

inflate and air dry.

WARNING: Do not use proprietary cleaning fluids, thinners, spirits or similar substances.

4

Section

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

16

5.1.1 Visually inspect the cover material for wear, abrasion, pulled threads, contamination, cuts and holes.

5.1.2 If necessary the cover may be washed. Refer to Section 4.

5.1.3 Repairs to the outer cover are not permitted.

5.1.4 Carefully examine the zips and the slider for wear, broken teeth or slider and worn or fraying tape.

5.1.5 If it is considered that the cover is so badly damaged that the lifejacket is no longer serviceable, the

customer shall be advised and offered a replacement lifejacket.

NOTE: Due to the construction of this lifejacket no individual cover is available for replacement, therefore

the lifejacket as a whole must be replaced.

5.2.1 Visually inspect the inflation chamber material for wear, pulled threads, contamination or signs of

mistreatment .

5.2.2 Visually inspect all welds.

5.2.3 Visually inspect all webbings in accordance with Section 5.8

5.2.4 Visually inspect the whistle and its attachment to the lifejacket for mistreatment, defects, and fraying of

the cord and its attachment.

5.2.5 Test Lifejacket in accordance with Section 6.

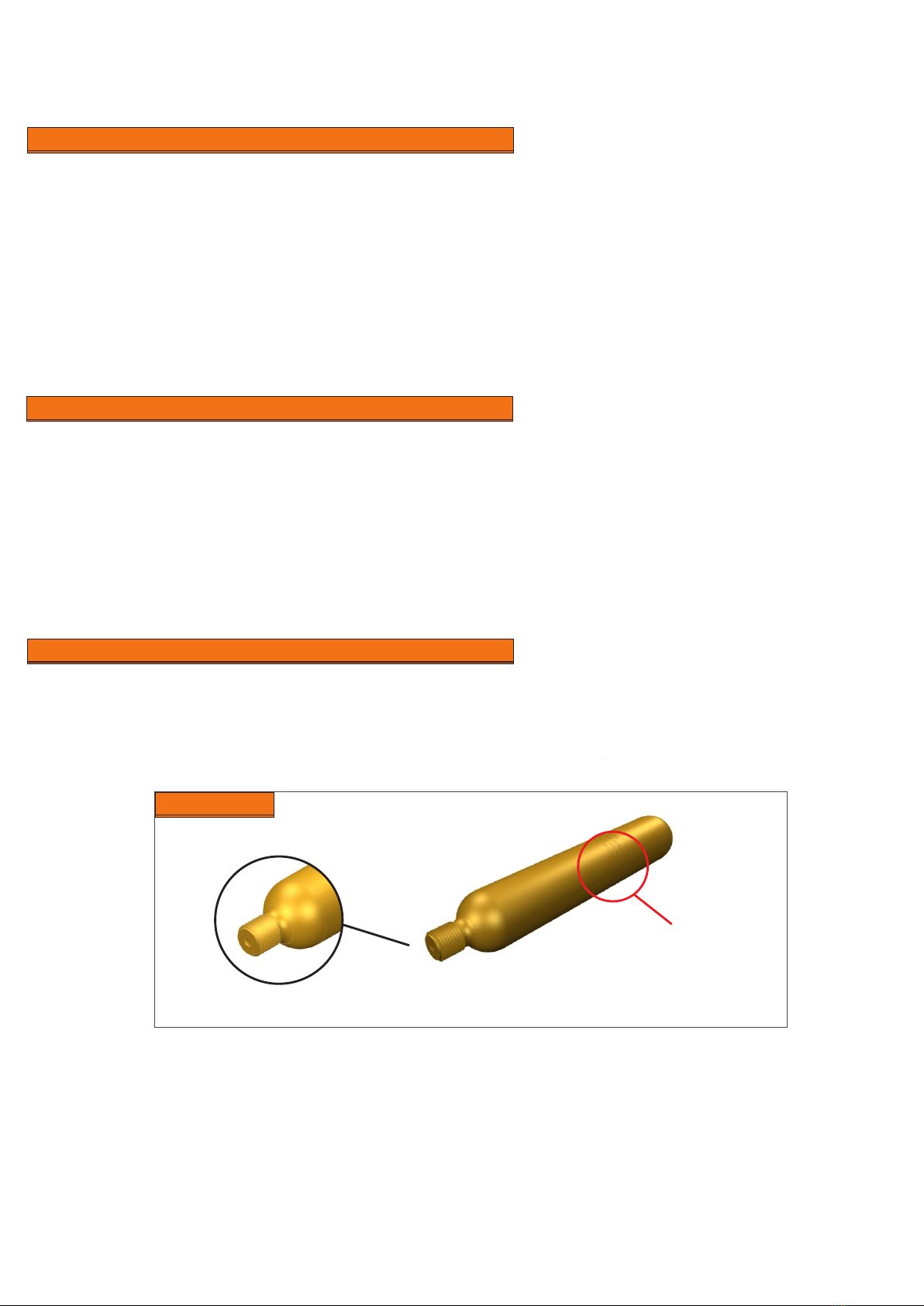

5.3.1 Visually examine:

5.3.1.1. For Corrosion in accordance with the procedure detailed overleaf. (All cylinders corroded with

red rust or with visible pitting must be replaced).

5.3.1.2. Pierced or damaged piercing disc.

5.3.1.3. That the cylinder has the correct gas charge - 60 grams CO2

5.3.2 Check Min Weight of Cylinder against that marked on the barrel.

Remedial Action: If any of the above conditions are found to be incorrect the cylinder shall be replaced. See

Section 9.

5.1 Outer Cover Inspection

5.2 Inflation Chamber Inspection

5

Section

5.3 Gas Cylinders

60 GRAMS CO2 NOMINAL

MIN GR. WT. 245.16G

ISI/38200 AUSTRIA 07/08

DO NOT HEAT

Fig. 5.3

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

17

5

Section

PROCEDURE FOR THE INSPECTION AND SERVICING OF MANUAL HEADS AND CYLINDERS WITH LEVELS OF

CORROSION

5.3.3 INITIAL INSPECTION

Unscrew the cylinder from the automatic or manual head. If corrosion is present it will be seen as one of the following:

a) A white/grey powdery deposit on the cylinder and in the thread recess of the head.

b) A red rusty surface to the cylinder.

5.3.4 PROCEDURE FOR WHITE/GREY POWDERY DEPOSIT

5.3.4.1 All CO cylinders showing signs of white rust and no pitting are

2

considered fit for purpose. If the white/grey deposit is seen then both the

cylinder and head can be reused after cleaning. Brush out the threads

with a stiff bristled nylon brush (M.E.C. Reference Br1)

Cylinder showing white rust on thread

5.3.4.2 Blow out the threaded recess of the head and check that there are no significant particles or bristles from the brush

across the sealing washer in the base of the recess. Check that the sealing washer is not damaged, either from

cleaning or use, and will provide a good seal. Replace if damaged.

5.3.4.3 Check that the head operates freely.

5.3.4.4 If any white/grey powdery deposit is present on the body of the cylinder within the areas shown in Section 4 then it

should be brushed or wiped off.

5.3.4.5 Re-assemble the cylinder to the manual or auto head.

5.3.5 PROCEDURE FOR RED RUSTY SURFACE

Cylinder showing red rust

5.3.5.1 If a red rusty surface is seen on the cylinder this means that the protective

zinc coating has been penetrated and the steel is corroding.

5.3 Gas Cylinders (cont.)

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

18

5

Section

5.3.6. PROCEDURE FOR ZINC/SUPER ZINC COATING

2

5.3.6.1 All CO cylinders showing signs of wear and loss of Zinc/Super Zinc coating larger than 1cm are considered unfit

2

for purpose.

2

Acceptable wear - less than 1cm

2

Acceptable wear - less than 1cm

Not acceptable wear - Reject. DO NOT USE

Not acceptable wear - Reject. DO NOT USE

5.3 Gas Cylinders (cont.)

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

19

5.4.1 Visually inspect for damage.

5.4.2 Test in accordance with Section 6.

Remedial Action: These items are not repairable. Refer to Section 9 for replacement part.

5.5.1 Visually inspect the Operation of the Manual Mechanism for:

5.5.1.1 Operation of the Manual lever. This shall move easily and freely.

5.5.1.2 Operation of the firing pin cam action. Similarly this shall be a smooth action when

the lever is operated.

5.5.1.3 Firing Pin centre discharge hole clear.

5.5.1.4 Activation cord for frays and damage.

5.5.1.5 Moulded body for cracks and damage. Special attention to be given to the areas

around the operating lever/body connection pin.

Remedial Action: In the event that the Operating Mechanism fails any of the above inspection procedures, the

complete unit shall be replaced. No Repairs are allowed. Refer to Section 9 for the part number of the relevant

replacement part.

5.4 Oral Valves

5

Section

5.5 Inflation System

5.6 Safety Line

5.6.1 Examine the Safety Line for any damage to the webbing or the stitching. If necessary remove any fluff from the

webbing. Check that there is no rust on the hooks. Check the operation of the self locking hooks and spray with

WD40 if necessary. Check that both of the hooks are facing the same way.

Remedial Action: No repairs are allowed. In the case of damage being found, return the Lifejacket to Crewsaver.

5.7.1 Remove the foam panels from the jacket by unfastening the velcro fastenings on the inside faces of the front

and back of the jacket. Check for any deterioration against the templates provided.

Remedial Action: No repairs are allowed. In the case of damage being found, return the Lifejacket to Crewsaver.

5.7 Foam Panels

Date: November 2016

Issue No: 2

Crewsaver - Servicing Manual : Inshore 380N Lifejacket

Page

of 31

20

5.8.1 Visually inspect for damage:

5.8.1.1. Fraying

5.8.1.2. Pulled Threads

5.8.1.3. Broken Stitches

Remedial Action: No repairs are allowed. In the case of damage being found, return the Lifejacket to Crewsaver.

5.9.1 Check that the single point release buckle latches and unlatches correctly. Check that the two

screws are flush with the surface and do not affect the latching operation of the buckle. DO NOT test

the tightness of the screws using a conventional screwdriver as this may cause the thread to strip in

the plastic saddle. If the tightness has to be checked it must be done with a torque screwdriver set to

15 lbf/in.

Remedial Action: No repairs are allowed. In the case of damage being found, return the Lifejacket to Crewsaver.

5.10.1 Check all Markings and Labelling are clear and legible.

Remedial Action: No repairs are allowed. In the case of damage being found, return the Lifejacket to Crewsaver.

5

Section

5.8 Webbings

5.9 Buckles

5.10 Labelling/Markings

5.11 Lights

R29965

5.11.1 This lifejacket is fitted with the Crewsaver CSL water activated light.

5.11.1.1 Check the expiry date of the light. Upon expiry the light should be removed by prising off

the plastic security clip. Take care not to damage the jacket. A new light should then be

fitted.

5.11.1.2 Inspect the light for any signs of damage. If there are chips or cracks the light must be

replaced.

5.11.1.3 Check that the light is securely attached to the lifejacket.

5.11.1.4 Ensure that the water activated switch is in the Auto-on position as shown below.

5.11.2 To test this unit to ensure the light is working correctly, immerse the water-activated switch in water.

The light should flash. Remove the light from the water and dry it. The light should stop flashing. If

the light does not flash when immersed in water the unit has expired and must be replaced.

5.10.3 These lights are not repairable; if the light fails inspection it must be replaced.

Expiry date

printed on end

Water activated switch in Auto-on

position (Earlier models)

Water activated switch in Auto-on

position (Later models)

Table of contents