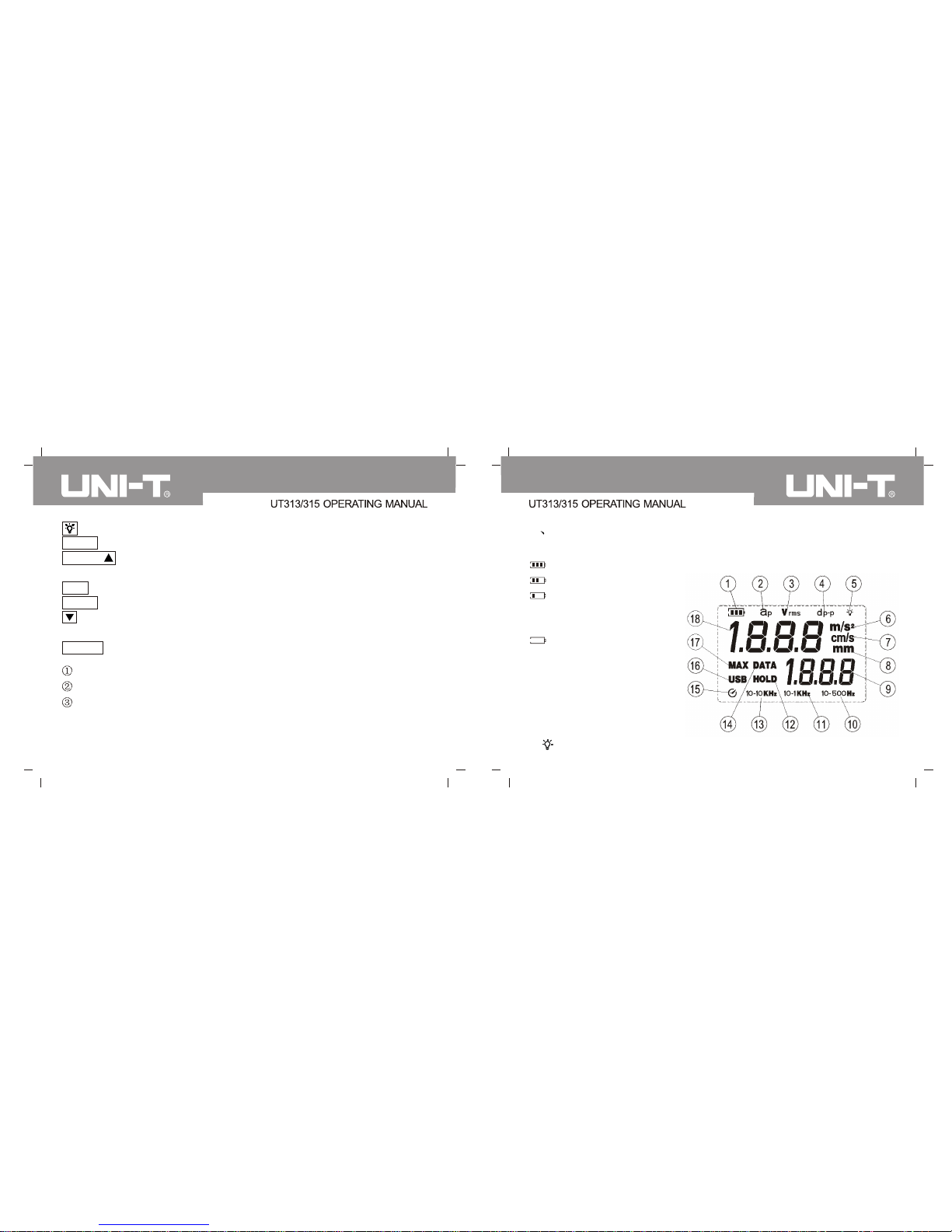

7 8

6. M/s2: acceleration unit indicator

In velocity measurement, LCD display the velocity unit m/s

7. cm/s: velocity unit indicator

8. mm: displacement unit indicator

9. Data record number display area

10. 10-500Hz: 10Hz-500Hz indicator

11. 10-1kHz:10Hz-1kHz indicator.

12. HOLD: reading hold measurement

13. 10-10kHz: 10Hz-10kHz indicator

14. DATA: data storage indicator

16. USB: USB indicator

17. MAX: maximum value measurement indicator

18. Measurement data value display area

15. : Automatic power-off function indicator

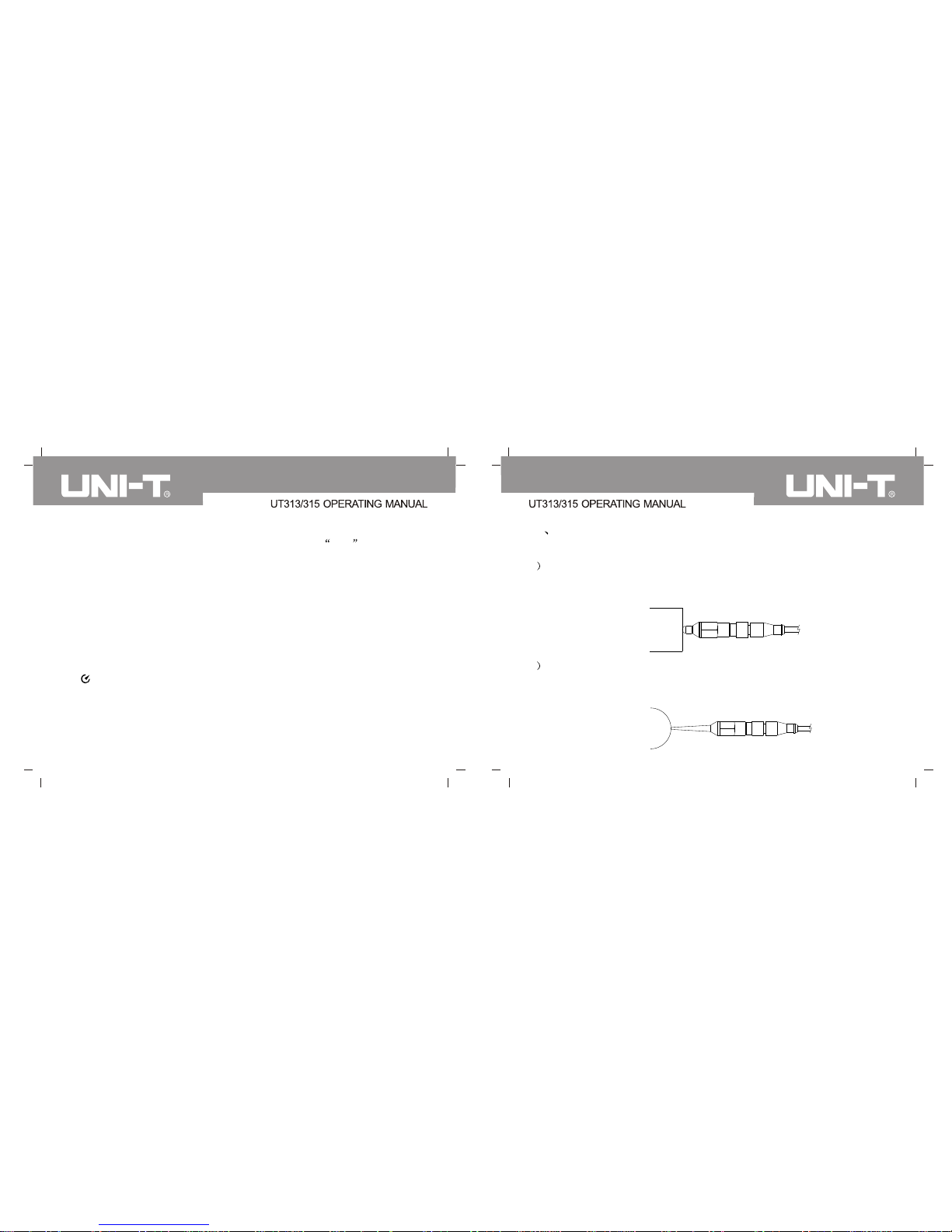

VI Select test method

Please select test method based on real status, four statuses:

1 Use short(s) probe to measure: it is installed with the machine and

applicable to wide scope vibration measurement; it can acquire effective

response numerical value, as shown in the following illustration

2 Use long (L) probe to measurement: it is an accessory in a package,

mainly used in rather narrow or special object area, with quick response,

as shown in the following illustration