Instrumentation Systems & Services MicroSpeed 196 User manual

MSMAN32C

MicroSpeed

196

I.

INTRODUCTION

The MicroSpeed 196 is a closed-loop motion control device, designed to operate as a

stand-alone Master, controlling a single AC, DC, or servo-type variable-speed drive

of any horsepower; or as a Follower control in more complex multi-motor drive

systems. The MicroSpeed 196 takes the place of the manually operated speed

potentiometer by providing the speed reference voltage to the variable speed drive

(0 to

±l0Vdc

typically). The Speed Set Point is entered via the front panel keypad

or remotely over the RS422 link. By continually comparing the feedback frequency

with the desired set point, the set point is accurately maintained.

HOW TO USE THIS MANUAL

This manual is designed in sequential order, from basics to the highest level of

MicroSpeed 196 programming. The deeper you read into each section, the less relevent

the options may be to your application. If this is the case, glance at the topics, to ensure

that you don’t miss useful information, then go to the next section. Each section begins

with the basics, and then leads into more complicated levels of programming. Everyone

who uses this manual should at least study the sections through Section V,

“Programming Master Mode”,

then skip to the sections required for your application.

It is, however, important to read Section IX,

“Tuning the Microspeed

196”.

This

section is the key to the control’s performance.

Master

Mode

AC

or

DC

Drive

Motor

with

Encoder

Ring

Kit

Follower

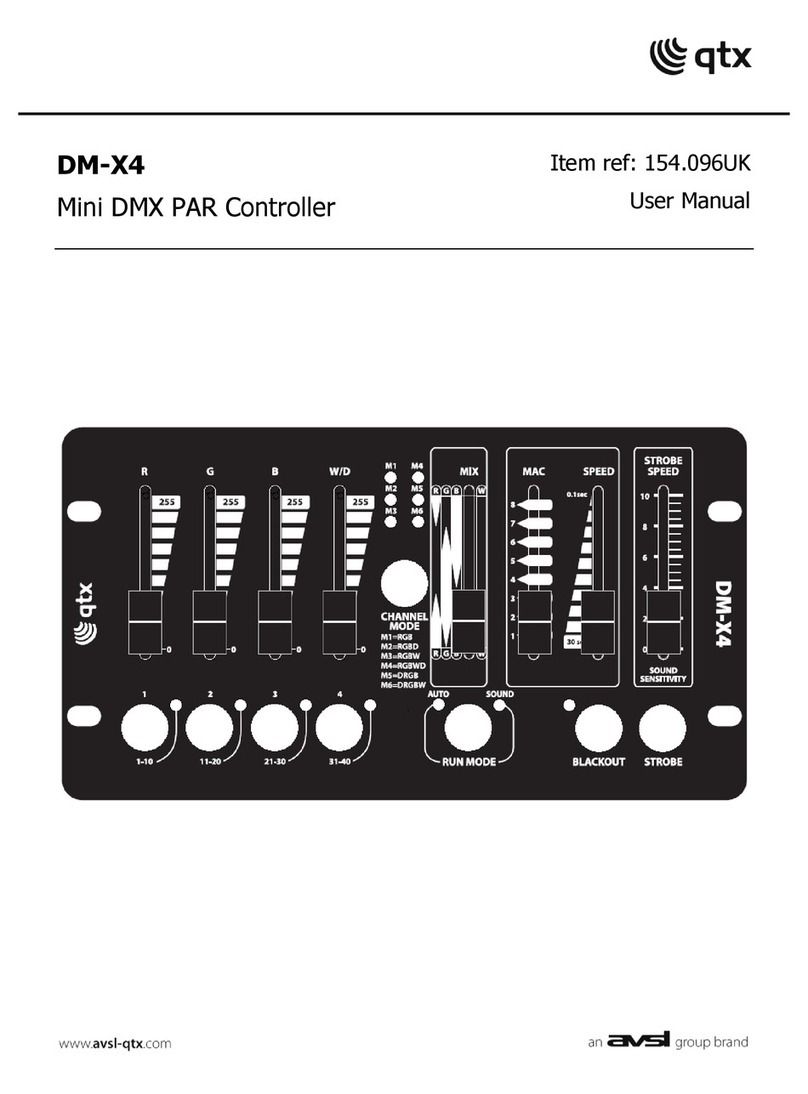

II.

MicroSpeed

188

l

Layout

Diagram 1

MicroSpeed

196

Back Panel Terminals:

Follower Mode

Dimensions:

In Inches

Panel Cutout

III.

Wiring the

MicroSpeed

196 and I/O Functions

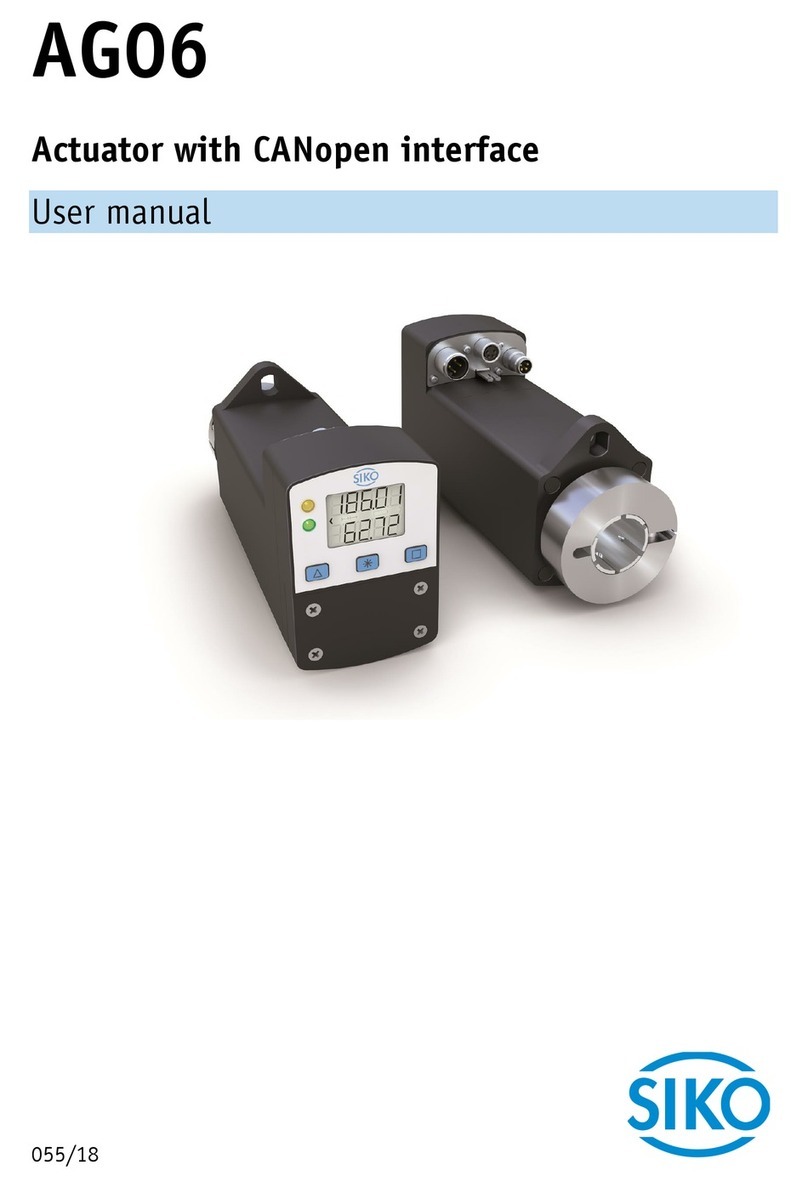

Diagram 2

MicroSpeed

196 Connections:

N.O. Momentary

N 0. Momentary

N 0

SUSTAINED

4

N.0

Sustained

N 0.

SustaIned

N

0

Sustained

N 0.

Sustained

et

Point

3 &4 Enable

N

0. Sustained

N 0 Sustained

t

Point

1(3)/Set

point

2(4) Status and

Alarm Outputs

50Vdc

Maximum

250mA

Maximum

.3

Watts Maximum

I

Common

Proper

Wiring Methods

-

Shielded cable is required for all signal wires connected to

the MicroSpeed 196, except for the AC input power. The shields should be tied on one

end only. Tie shields to the earth ground or common terminals provided on the

MicroSpeed 196. Important: Never use shielded cable with unused conductors.

Unused conductors act as antennas and will corrupt your signals. Attempting to send

one signal down two wires, or grounding extra conductors will not prevent this from

happening.

Power

Connection

-

Power to the MicroSpeed 196 is

115Vac

(standard) or 230Vac

(optional), and is switch selectable. Power input to the MicroSpeed 196 should be as

clean as possible, so that the control circuitry is not exposed to spikes or other noise.

Noise immunity is built into the unit; however, care should still be taken. Terminal

locations for power are as follows:

TB2-22

=

Line

(L1)

TB2-23

=

Neutral (L2)

TB2-24

=

Chassis Ground

3

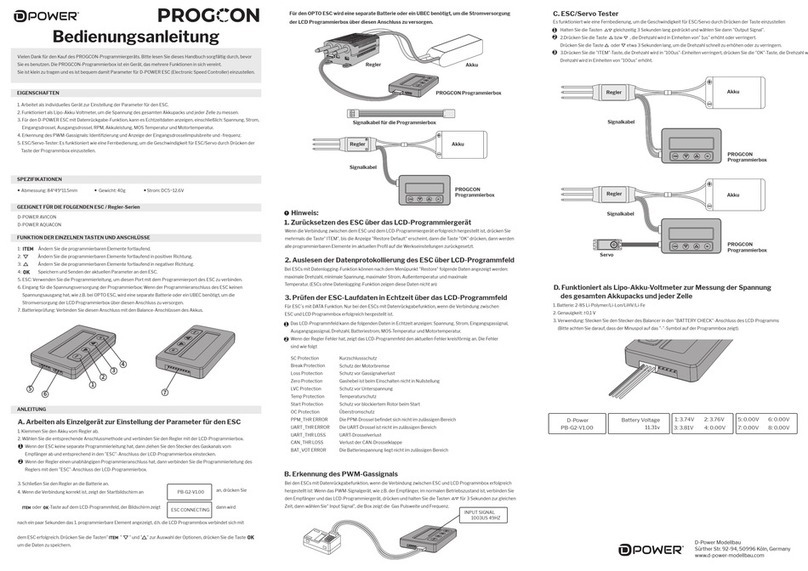

How to Change to 230Vac Power

Diagram 3

Microspeedd196 Power Board

Connection to Drive

-

The connection to the drive must be a shielded, twisted-pair

cable. The

Isolated Command Output

is connected to the input terminal on the

drive that is normally connected to the wiper of the speed potentiometer. The isolated

common terminal on the MicroSpeed 196 is connected to reference common on the

drive. Terminal locations are as follows:

TB2-2

=

Isolated Command Output

TB2-3

=

Isolated Common

EXTERNAL START/STOP SWlTCHES:

Run

-

The

Run

input functions as a motor start, causing the MicroSpeed 196 to

ramp the motor speed to the selected set point. Typically, a

N.O. Momentary

switch is wired from

TB1-21

(Run

input) to common.

Stop

-

The

Stop

input functions as a motor stop, causing the MicroSpeed 196 to ramp

the motor speed down to zero. This also must be activated to clear a no feedback shut-

down error. Typically, a N.C.

Momentary

switch is wired from

TB1-22

(Stop

input)

to common.

IMPORTANT: If an external Stop switch is NOT used, jumper TB1-22 to TB1-23

(factory

installed).

Single Contact Run/Stop

-

To control the Run/Stop function with a single contact,

jumper

Run

to

Stop

(TB1-21

to

TB1-22)

and switch to common (Open =

Stop,

Closed =

Run).

When Run/Stop is used in this way, the front panel key

pad

RUN

a

nd

STOP

keys are disabled, and the

E-Stop

must be a N.C.

Maintained

contact.

E-STOP

-

The Emergency Stop input functions as an immediate stop. This function is

provided only on the terminal strip. The E-Stop should be used in emergency

situations only, because it overrides all other functions. Typically, a N.C.

Momentary

switch

is wired from terminal

TB1-24

(E-Stop)

to common.

IMPORTANT:

If

an external

E-Stop

switch is not used, jumper

TB1-24

to

TB1-23

(factory

installed).

Jog

-

The

Jog

input accelerates the motor to the programmed speed and stops the

motor when the contact is opened. (See “Section VII,

Programming-Jog Mode”

for

details.) Typically,

an

N.O. Momentary

switch is wired from TB1-19 (Jog) to common.

4

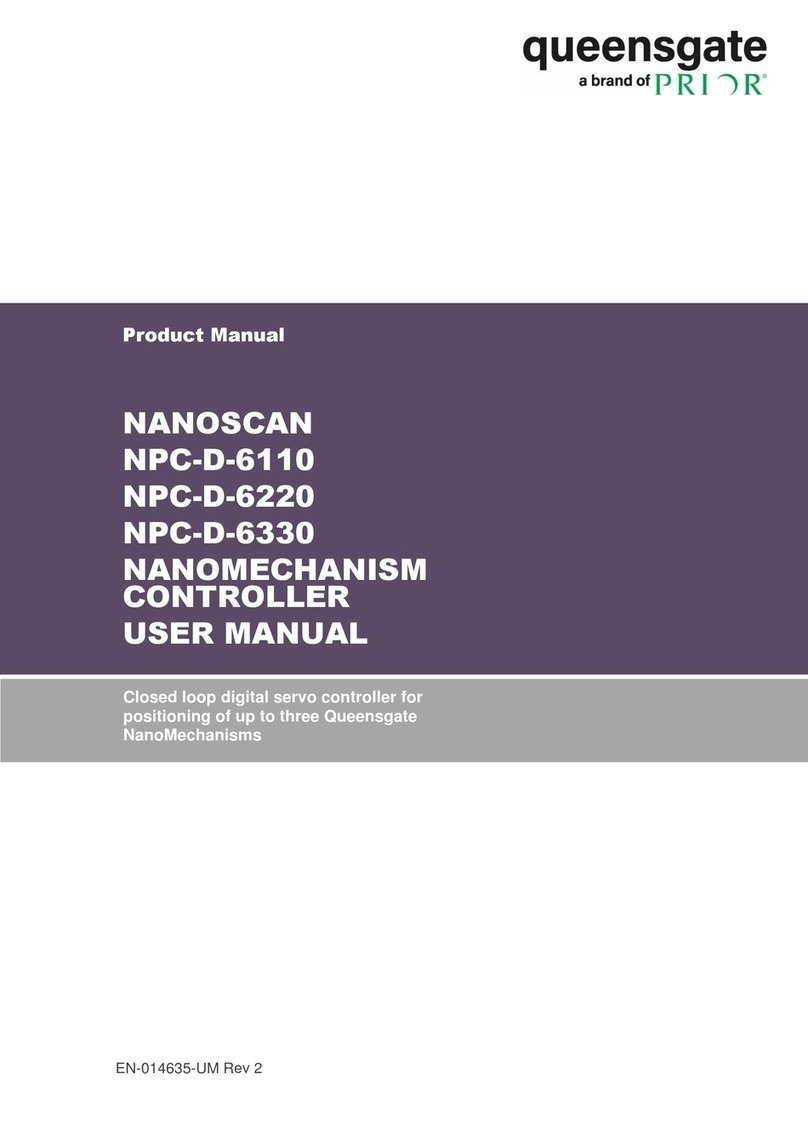

Diagram 4

Sensor Inputs, Switch Inputs:

Sensor Input

()

+12v

Switch Input

l

+12v

TBl-1

TB1-2,3,4

4

10K

1

10K

TB1l

-5

‘)

+12V

2

2.2K

Sensor Connections

-

The

MicroSpeed

196 can accept: NPN Open Collecter,

3-wire (factory standard configuration); PNP Open Collecter, 3-wire; Magnetic pick-up,

2-wire; and Logic Level inputs. All sensors should have shielded cable with no unused

conductors.

The supply terminal

(+12

Vdc unregulated) when using powered sensors (NPN or PNP)

for

Feedback, Lead,

or

Auxiliary

signals is terminal

TB1-1.

The common terminal for all sensor connections is terminal

TB1-5.

The

Feedback Signal

input is terminal

TB1-2.

The

Lead Signal

input is terminal

TB1-3.

The

Auxiliary Signal

input is terminal

TB1-4.

Note: When sharing signals, never use more than one pull-up resistor. See Diagram 4

for switch locations. See table below for sensor configurations.

Table 1

SENSOR SWITCH SETTINGS

Feedback Sensor Lead Signal

12 11 10 9

Auxiliary Input

8 7 6 5 4 3 2 1

NPN Open Collector OFF OFF OFF ON OFF OFF OFF ON OFF OFF OFF ON

PNP Open Collector

OFF OFF ON OFF

OFF OFF ON OFF OFF OFF ON OFF

Zero Crossing

ON ON ON

OFF ON ON ON OFF ON ON ON OFF

Logic Level

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

NPN Open Collector;2.2K

pull-up to

+12v,

trigger point at

2.5V

PNP

Open Collector;

2.2K

pull-down to common, trigger point at 2.5V

Zero Crossing

(Mag);

100mV

minimum peak, trigger point at 50mV

Logic Level;

trigger point at 2.5V

5

EXTERNAL CONTROL INPUTS:

The external control inputs give the operator control over the operating parameters of

the

MicroSpeed

196. These parameters include:

Master/Follower

modes;

Keypad

Lockout; Forward/Reverse

(positive or negative voltage output);

Closed/Open

Loop

modes;

and Local/Remote.

Note: All external control inputs should be Sustained, Normally Open switches, or

hardwired.

Master/Follower

-

This input tells the MicroSpeed 196 to operate independently (as

a Master), or to follow the lead signal of another device (feedback from a lead motor

or a generated signal from a PLC). The MicroSpeed 196 only reads this input while

stopped in the Ready mode. Wiring of the

Master/Follower

input is as follows:

TB1-15

(Master/Follower)

to common (Open =

Master;

Closed =

Follower).

Keypad Lockout

-

This input disables selected entries from the front panel keypad of

the

MicroSpeed

196, as defined by programming the

Keypad Lockout Selection

variable. Use of this function is highly recommended Wiring of the Keypad

Lockout

input is as follows:

TB1-12 (Keypad Lockout)

to common (Open=Keypad

Avail

able;

Closed

=

Key

pad Lockout).

Forward/Reverse

-

This controls the voltage polarity of the

Isolated Command

Output. Forward

is a positive voltage.

Reverse

is a negative voltage. The polarity

will change immediately when the switch is closed or opened. Wiring of the

Forward/

Reverse

input is as follows:

TB1-13 (Forward/Reverse)

to common (Open

=

Forward;

Closed =

Reverse).

Closed/Open

Loop

-

This enables or disables the PID control. In Open Loop mode,

the feedback is ignored, so control is extended to providing a particular command

output voltage only, with no correction to maintain a set point. Wiring of the

Closed/

Open

Loop

input is as follows:

TB1-18

(Closed/Open

LOOP)

to common

(Open =

Closed Loop,

Closed =

Open Loop).

Local/Remote

-

This input controls the point of information entry to the MicroSpeed

196. In Local mode, commands for all functions and programming are taken from the

front panel keypad and terminal strip. In Remote mode, all programming and speed

commands must come over the RS-422 link. (Refer to “Section XII, the

Serial

Communications”

for more information.) Wiring of the

Local/Remote

switch is as

follows:

TB1-10

(Local/Remote)

to common (Open=

Local;

Closed =

Remote).

SETPOINT CONTROL INPUTS:

There

are eight set points that can be programmed into memory (four master Speed Set

Points, and four follower Ratio Set Points). These eight set points allow the operator to

use different speeds upon start-up, and to alter speed by toggling from one set point to

another. The speed change will follow the ramp profile programmed for

Accel

and

Decel.

Two switches control which programmed set point is active. The two inputs are:

Set

Point 3

&4

Enable,

and

Set Point

1(3)/Set

Point 2(4).

6

Active Set Point

Set Point

1(3)1Set

Point

2(4)

Set Point 3

&

4

Enable

Set Point 1

Open

Set Point 2 Closed

Open

Set Point

3

Open Open

Set Point 4 Closed

Closed Closed

Set Point 3

&

4 Enable

-

Wiring of the

Set Point 3

&4

Enable

input is as

follows:

TB1-9

(Set

Point

3

&

4 Enable)

to common (Open = Set Points 1

&

2 Enabled;

Closed = Set Points 3

&

4 Enabled).

Set Point

1(3)/Set

Point

2(4)

-

Wiring of the

Set Point

1(3)/Set

Point

2(4)

input

is as follows:

TB1-16

(Set Point

1(3)/Set

Point

2(4))

to common (Open

=

Set Point

l(3); Closed = Set Point

2(4)).

Scroll Up/Scroll

Down

-

These inputs are used to make small changes to the active

set point while running. The high and low alarm outputs can be tied to these inputs,

preventing operators from running too fast or too slow. N.O.

Momentary

contacts

should be used when wiring the

Scroll

Up/ScrollDown

inputs. The terminals are:

Scroll Up = TB1-6; Scroll Down = TB1-8.

WIRING

STATUS AND ALARM OUTPUTS:

The status and alarm outputs provide a completed circuit when a programmed result

occurs. (See

“Status and Alarm Outputs”

in Section VIII,

“Programming Operational

Variables”).

The outputs are Open Collector NPN transistors, rated for

5OVdc,

250mA

and .3-watt maximums.

These outputs are intended to be used with the Microspeed 196 inputs, relays, LEDs,

etc. Power to the output circuits should be wired parallel with the

Diode Protect

(TB2-20)

terminal if inductive loads are driven, to avoid damage to the output

circuitry. (See Diagram 5: “Wiring Status and Alarm Outputs ”).

Diode Protect

(TB2-20)

-

This is a protection circuit (back EMF diode). Input power

from the power supply should be wired in parallel with this terminal.

Drive Enable

(TB2-16)

-

This output can be actuated under one of the three program-

mable conditions.

Drive Enable

is used to give the MicroSpeed 196 control over the

Run/Stop

command on the drive, or on other MicroSpeed units.

L

OW

Alarm

(TB2-19)

-

If the shaft speed drops below this programmed setting, the

output will conduct in order to actuate a load.

High Alarm

(TB2-17)

-

If the shaft speed goes above this programmed setting, the

output will conduct in order to actuate a load.

Deviation Alarm

(TB2-14)

-

This output is active in the Follower mode. If the

follower shaft is ahead or behind the Master exceeding the value programmed, the

output will actuate the load.

Ramp Complete

(TB2-13)

-

This is a nonprogrammable output. This output is

actuated when the Speed Set Point selected is reached (Master mode only).

Zero Speed

(TB2-11)

-

This is a nonprogrammable output. This output is actuated

when there is no feedback present, i.e., when the motor or shaft rotation has stopped,

or feedback is lost, due to an external problem.

7

Diagram 5

Wiring Status and Alarm Outputs:

8

IV.

PROGRAMMING

l

GENERAL

Alphanumeric Display:

Displays Current Operating

Mode or Identifies the Variable

Being Programmed

ems and

SetPoints

Operating Information Entries into

Exit the

ENTERINGANDALTERINGSETPOINTS:

Memory

Change

Var’ab’e

Mode

Diagnostic Tests

Set

Point

-

The

set

point can be adjusted to any speed (or ratio) by pressing SET

POINT,

entering a new speed using the number keys, and pressing

ENTER.

This

changes the programming of the current set point (Set Point

1,2,3,4

or Ratio

1,2,3,4).

The motor will immediately ramp to the new setting. If you wish to change a

non-selected set point, press

SET POINT,

then press the

UP

or

DOWN

arrows until the

desired set point is displayed, and enter the new set point.

Note: Decimal locations

are fixed

via programmable variables, and are not entered when

changing setpoints.

The front panel

LED displays will indicate which

set

point

is active.

SET POINT

=

ACTIVE

LIGHTS ON SET POINT

1

1

22

1&2

3

NONE 4

Using the Arrow Keys to Alter Set Points

-

Minor adjustments to the set point

can be made by pressing the

UP

or

DOWN

arrows while the system is running. If an

UP or DOWN

arrow key is pressed, the active set point will increase or decrease. The

rate of this change will increase if the key is held.

Programming

THE VARIABLES:

The

MicroSpeed 196 is programmed by entering data into a menu of variables. Only the

variables that affect operation of the unit as it relates to the application must be

programmed. Upon power up, the MicroSpeed 196 will display

READY

on the alpha-

numeric display. This indicates that the

MicroSpeed

196 is ready for operation or program-

ming. To program a variable, press

VAR

on the front panel keypad. The alphanumeric

display will prompt for a variable number, and the numeric display will indicate

two

zeros (00), which will reflect the variable number entered. Enter the desired variable

number and press

ENTER.

If you are unsure of the variable, the

UP and DOWN

arrows

on the keypad will allow you to scroll through the menu of variables. As you

9

scroll, the numeric display will indicate the number of the variable, and the alpha-

numeric display will name the variable. Press

ENTER

when the desired variable is

displayed.

When the variable to be programmed is accessed, enter data using the numeric keys, and

then press

ENTER.

Note: A decimalpointcannot

lead an

entry; the decimal

placemust be preceded

by a zero (0).

After

ENTER

is pressed, the display will ask for another variable number. If there is no

other variable data to be entered, press the

VAR

key to return to the

READY

mode.

List

of Variables:

Reference Variables

-

These variables tell the MicroSpeed 196 how to

control the motor, and can be changed in READY mode only:

01 Maximum RPM

02

User Units at Maximum RPM

03

Feedback Pulses per Revolution

04 Maximum Lead RPM (Follower)

05

Lead Pulses Per Revolution (Follower)

23 User Unity Ratio (Follower)

Operational Variables:

06 Jog Speed in User Units

07 Acceleration Time

08

Deceleration Time

10

User Unit Label

11

Keypad Lockout Selection

21

Display Selection

22

Follower Display Selection

29

Jog Ramp Selection

Control Loop Variables-These variables tell the control how to correct for

speed errors:

09

Maximum Lead Wind-up (Follower)

12 Gain-P

13 Reset-l

14 Rate-D

Status and Alarm Outputs:

15 High Alarm

16 Low Alarm

17 Deviation Alarm (Follower)

18 Drive Enable

Auxiliary Mode Variables- Allows for a third frequency, i.e., dancer

systems, to trim the Follower mode ratio:

24 Auxiliary Mode Selection

25 Auxiliary Reference Frequency

26 Auxiliary Gain Percentage

27 Auxiliary Trim Selection

28 Auxiliary Input Delay

10

V.

PROGRAMMING

l

MASTER MODE

Program the following variables when using the MicroSpeed 196 in any mode. (These

are the only required variables if the MicroSpeed 196 will be used exclusively in

Master

mode.) After programming the variables, go to Section IX

“Tuning the

Microspeed

196.“Then, after all programming and tuning is complete, go

to

“Appendix A,” and record your entries.

Variable 01

-

Maximum RPM

-

This number represents the revolutions

per

minute of the shaft on which the feedback sensor is mounted, when the

MicroSpeed 196 is running the motor at maximum operating speed.

Note:

The

drive system must be able to run 10% faster than the

value

programmed

into

Variable

01

(maximum

rpm.)

Variable 02

-

User Units at Maximum RPM

-

This number will set up the

MicroSpeed 196 to translate rpms to units of production that are more appropriate

to the user, such as “Feet per Minute,”or “Gallons per Hour,” etc. The Speed Set

Points and the linear tach display will then be relative to the operation. To use this

variable, first determine the value of the user units at maximum rpm. If the rpm

of

the monitored shaft is desired, enter the same value as Variable 01. Otherwise, you

must calculate the user unit at the speed entered into Variable 01. Or you can enter

the same value as Variable 01, run at that speed, measure the actual units, and then

enter the measured value. Use Variable 10 to program the alphanumeric display to

show the appropriate user unit, i.e.,

PPM,

GPM, GPH, etc. (see Section VIII,

“Programming Operational Variables" in

this manual for details and

the list of display options.

Variable 03

-

Feedback Pulses Per Revolution

-

This is the number of digital

pulses produced by the feedback sensor on the monitored shaft for each shaft

revolution.

Note: Variable 03 will not accept decimals, the entry must be a whole number.

Example 1

-

The feedback sensor in this case is a Ring Kit at 60 ppr, mounted on the

motor shaft. The rated motor speed is 1750 rpm, but the operation only requires

1500 rpm. The desired display is

rpm.

Then Variable 01 would be 1500, Variable 02

would be 1500, and Variable 03 would be 60.

Example 2

-

In this case, the feedback sensor is a 600 ppr encoder, mounted on a

intermediate downstream shaft. The speed of this shaft is not known, but we do know

we want a maximum line speed of 200 feet per minute. Enter the PPR value (600 PPR)

into variable 03. Then go into diagnostic

9

(explained in section

IX:

“Calibrating the

Isolated

Command Output through the Drive" and

slowly ramp up the system speed

until 200 ft./min. is obtained. The display will read out the rpm value needed for

Variable 01. In this example, 623 rpm. Now leave Diagnostic 9, and enter 623 into

Variable 01, and 200 into Variable 02. Adjust the Output Span Potentiometer as

shown in Section IX for proper operation.

11

VI.

PROGRAMMING

l

FOLLOWER MODE

The Microspeed 196 in the Follower mode mirrors a lead frequency input, and can be

scaled by the Ratio Set Point. The lead frequency is typically generated from a digital

transducer on another shaft. The initial relationship between the lead and follower is set

up in Variables 01 through 05. This relationship will be referred to as the Unity

Ratio.

First, program the Microspeed 196 Variables 01

-

03 per the Master mode instructions.

Then, program the Lead Input to set up the Unity Ratio. The MicroSpeed 196 maintains

both velocity and rotational control so that the cumulative following error is zero. A set

point ramp, cessation of the lead frequency, or a

STOP

command, will set the follower

error count to zero.The

ACCEL

and

DECEL

variables are active only when the Ratio

Set Point is changed by a value greater than 10% of the Unity Ratio, or by a

STOP

command.

Note: Follower control operates best when the lead and follower frequencies are relatively

equal. Example: When a lead frequency is 200 Hz, and the follower frequency is 2000 Hz,

one lead pulse controls 10 follower pulses. This situation can result in unstable follower

operation.

Variable 04

-

Maximum Lead RPM

-

This is the maximum rpm of the lead motor,

or of the shaft being monitored by the transducer that is producing the lead frequency

signal. The relationship of the Maximum Lead RPM (Var 04) at the User Unity Ratio

(Var 23) set point will result in the motor speed running at Maximum RPM (Var 01).

Variable 05

-

Lead Pulses per Revolution

-

This is the number of pulses per

revolution generated by the transducer that is producing the lead frequency.

Note: When generating the lead

signal

from

a non-rotational source and only Hz. is known,

enter 60 into Variable 05

(lead PPR).

Th

en enter thefrequency into Variable 04

(Max. Lead RPM).

Variable 23

-

User Unity Ratio

-

This variable allows the Ratio Set Point to be

programmed in User Units in the Follower mode (such as turns/foot). It is also used as

the Unity Ratio value in the ratio tach display mode. When this value is entered into the

Ratio Set Point, the follower motor will run at the relationship programmed into

Variables

01-05.

Note: Variable 23 (User Unity Ratio) is applied when the operation is based on units

other than time (i.e. threads/inch vs. cuts/minute). If your operation has a time based

relationship, then leave Variable 23 at the default value.

Example: Assume that the Unity Ratio between the Lead and Follower in a ball screw

thread-cutting operation results in 50.00 threads per inch being cut by the follower

machinery at its fastest rate. The lead motor turns at 1000 RPM with 60 PPR. The

follower motormust turn at 1500rpm with 60ppr. The variables would be programmed

as follows: Var 01 & 02 = 1500, Var 03 = 60, Var 04 = 1000, Var 05 = 60, and

Var 23 = 50.00.

Entering a Ratio Set Point of 50.00 will always produce 50 threads per inch. Changing

the Ratio Set Point to 25.00 will halve the follower motor speed in relation to the lead

motor and produce 25 threads per inch.

12

VII.

PROGRAMMING

l

JOG MODE

When the

Jog

function is initiated and held, the MicroSpeed 196 will accelerate to

the speed programmed in Variable 06. Variable 29 enables you to follow the accel/

decel times (Variables 07 and 08) or to bypass the ramp times.

Variable 06

-

Jog Speed in User Units

-

Enter the desired

jog

speed in user units,

then press

ENTER.

Variable 29

-

Jog Ramp Selection

-

This variable allows the operator to select the

following jog ramp profiles:

0000 = No

Ramp Time

0001 = Ramp on Decel

0010 = Ramp on Accel

0011 = Ramp on Accel and Decel

PROGRAMMING

l

OPERATIONAL VARIABLES

Variable 07

-

Acceleration Time

-

When the acceleration time is accessed, the alpha-

numeric display will read

AcelTime.

Enter the time in seconds desired for acceleration

from 0V (motor stop) to maximum output. The smallest unit of time is

l/10

second.

Variable 06

-

Deceleration Time

-

When the deceleration time is accessed, the alpha-

numeric display will read

DcelTime.

Enter the time in seconds for deceleration from

maximum output to 0V (motor stop). The smallest unit of time is l/10 second,

Variable 11

-

Keypad Lockout

-

When Variable 11 is accessed, the alpha-numeric

display will read

Key Lock.

Each zero represents a different section of the keypad that

can be independently “locked.” The section of the keypad that is locked is determined by

placing a 1 (one) in the appropriate location. Any section or combination of sections can

be locked. (See chart below for lockout positions and descriptions.) After all program-

ming and tuning is complete, activate the lock out by installing a jumper on

TB1-12

to

TBl-11.

Note: It is recommended that you “lock out” your variables, so that the MicroSpeed 196

cannot be inadvertently reprogrammed.

Positions: 0 0 0 0 (Unlocked)

VAR

key and

2nd Func

Key

Up and Down

Arrows

Run, stop and jog Keys

DISPLAY:

Variable 21

-

Display Selection

-

This Variable allows the user to select the

information that will be displayed on the Numeric display. Mode 0000 is commonly used

in normal operation, while modes 0001 through 0007 are typically used during setup or

troubleshooting only. When Variable 21 is selected, the alphanumeric display will read

Display#.

To

select the numeric display mode during operation, enter a number from the

following list:

0000

=

Tachometer in User Units

0001

=

Feedback Frequency in Hertz or Kilohertz

0002

=

Lead Frequency in Hertz or Kilohertz (Follower)

0003

=

Auxiliary Frequency in Hertz (Auxiliary Mode)

0004

=

Follower Error in Number of Pulses

0005

=

Total Output in DAC Bits (0 to 4094)

0006

=

Output Error in DAC Bits (-999 to 4094)

0007 = Alarms (a “1” Indicates the Alarm Is Active)

1000

=

Zero Speed

0100

=

High Alarm

0010

=

Low Alarm

0001

=

Deviation Alarm

Variable 22

-

Follower Display

-

When the MicroSpeed 196 is in the Follower

mode, the numeric display can be used as a linear tachometer (displaying actual speed

in user units), or it can be used to display the ratio that the Follower is maintaining to

the lead (i.e. the unit would read 1.000 when the follower was running at a 1:1 ratio to

the lead). When Variable 22 is selected, the alphanumeric display will read

Tach

Sel.

To select between the two follower display options, enter one of the following numbers:

0000

=

Linear Tachometer in User Units (Units from Variable 02)

0001

=

Ratio Tachometer in User Ratio Units (Units from Variable

23)

Variable 10 -User Unit Label

-

This variable allows the user to select what the

alphanumeric display will display during normal operation -when the display is in Tach

in User Units mode. The default label is

RPM.

To program Variable 10, enter the code

that corresponds to the desired user unit label from Table

3

below.

Table 3

-

User Unit Labels

0-

RPM

1

-

FPM

2-

GPM

3

-

REV/SEC

4-

REV/MIN

5-

REV/HR

6

-

INCH/SEC 7

-

INCH/MIN

8

-

INCH/HR

9

-

FEET/SEC 10

-

FEET/MIN11

-

FEET/HR

12

-

YARD/SEC

13

-

YARD/MINN

14

-

YARD/HR

15

-

MM/SEC 16

-

MM/MIN

17-

MM/HR

18-

CM/SEC

19-

CM/MIN

20

-

CM/HR

21

-

MET/SEC

22

-

MET/MIN

23

-

MET/HR

24

-

OZ/SEC25

-

OZ/MIN

26-

OZ/HR

27-

GAL/SEC

28-

GAL/MIN

29-

GAL/HR

30

-

ML/SEC

31

-

ML/MIN

32-

Ml/HR

33

-

LIT/SEC

34

-

LIT/MIN

35

-

LlT/HR

36

-

HERTZ

37

-

KHERTZ

38

-

MHZ

39

-

BOT/SEC

40

-

BOT/MIN

41

-

BOT/HR

42

-

CAN/SEC

43

-

CAN/MIN

44

-

CAN/HR

45

-

LBS/SEC

46

-

LBS/MIN

47

-

LBS/HR

48

-

TURN/SEC49

-

TURNIMIN50

-

TURN/HR

51

-

THRD/SEC

52

-

THRD/MIN53

-

THRDIHR

54

-

PART/SEC

55

-

PART/MIN

56

-

PARTSIHR

57

-

Percent%

58

-

RATIO%

65

-

Customized

15

Diagnostic 0

-

Custom User Unit Labels:

If

the choices presented in Variable 10 do not provide the display that is needed, a

Custom User Unit Label can be created, for both Master and Follower modes if the

MicroSpeed 196 will be used in both modes. When programming the MicroSpeed 196

custom display, the Master/Follower input must be in the appropriate position.

Note: The Custom User Unit Label has two preprogrammed labels; one for Master

Mode, defaulted to “RPM”, and one for Follower Mode, defaulted to

“Ratio %

“.

The following characters are available in the User Unit display:

ABCDEFGHIJKLMNOPQRSTUVWXYZ0123456789/*t-_and”blank.”

Use the following steps to program the desired display:

Enter Diagnostic 0 by pressing

2ND Func

and then the 0 key.

The alphanumeric display will show eight underscore characters:

--------’

Press the

?

(up arrow) or 1(down arrow) key to scroll through the

list of characters until the desired character for the first position is displayed.

Press the Enter key. This will lock the character into that position and move to the

next character on the eight character display. Repeat steps B and C until all eight

characters have been selected and entered.

After the rightmost character has been entered you will exit Diagnostic 0 and return

to the

READY

mode.

Note:

Pressing

2nd

Func

at

any time will cause an

exit

from

Diagnostic 0 and

will return the MicroSpeed 196 to the READY mode.

5.

To display your custom user unit label during operation, set variable 10 to 65 (The

preprogrammed user unit labels in Variable 10 are still available by setting Variable

10 to the desired display number.

To clear the previously programmed label, re-enter to

Diagnostic 0

(See Step 1 above

for instructions.)

16

STATUS AND

ALARM

OUTPUTS:

Variable 18

-

Drive Enable

-

This output is designed to give the MicroSpeed 196

control of the

Run/Stop

input on the controlled drive or other MicroSpeed 196’s,

based on the conditions it is monitoring.

Drive Enable

is actuated when

RUN or JOG

is pressed, and is deactivated automatically when

E-Stop

is pressed, or upon loss of

power, thus disabling the drive.

Drive Enable

will perform one of the following

options when a normal

STOP

command is

given.

The following options can be entered into Variable 18:

Variable 18

-

0001

The

Drive Enable

output waits for the Command Output

Voltage to reach 0V (zero) before disabling the drive.

Variable 18

-

0002

The

Drive Enable

output waits for the Command Output

Voltage to reach 0V (zero) and for the Feedback frequency to reach

OHz

(zero)

before disabling the drive.

Variable 18

-

0003

The

Drive Enable

output immediately disables the drive upon a

STOP command, and the Analog Output goes to zero (0) immediately.

Note: Disabling the drive prevents any motor creep or other unwanted motor movement

when the motor is stopped.

Variable 15

-

High Alarm

-

This output is activated if the speed of the monitored

shaft exceeds the value programmed. When

High Alarm

is accessed, the alphanumeric

display will read

“Hi Alarm”.

Enter the speed in user units above which the High

Alarm output will be activated.

Variable 16

-

L

OW

Alarm

-

This output is activated if the speed of the monitored

shaft drops below the level of the number entered in this variable. When the

L

OW

Alarm

is accessed, the alphanumeric display will read

“L

O

Alarm”.

Enter the speed

in user units under which the

L

OW

Alarm

output will be activated.

Variable 17

-

Deviation Alarm

-

This output is active in the Follower mode only,

and is programmed in revolutions of the follower feedback sensor. No decimal points

are allowed in this entry. The output will activate if the follower feedback sensor

deviates ahead or behind the lead shaft exceeding the programmed revolutions.

IX.

Tuning the

MicroSpeed

196

Calibrating the Isolated Command Output to the Drive:

1.

Program the MicroSpeed 196 variables.

Note: Variable 03

PPR

must be programmed.

2.

Select the proper polarity of the Command Output Voltage using the Forward/

Reverse Input. (Open = Positive; Closed = Negative)

3.

Access Diagnostic 9 (Digital Potentiometer) by pressing 2nd Function key, then

the 9 key. The alphanumeric display will read Pot % 00.

4.

Adjust the Zero Offset potentiometer (located on the back of the MicroSpeed 196 )

clockwise (or counterclockwise if reverse is selected), until the motor begins to

creep, then back off until it stops creeping.

5.

Press and hold the

1‘

(up arrow) key until the alphanumeric display reads

Pot % 90. The numeric display will be showing motor speed in RPM. Adjust the

Output Span potentiomete

r

(

CW

increas

es,

ccw

dec

rea

ses) until the rpm displayed

in the numeric display is equal to the maximum rpm programmed in Variable 01.

Note: The drive and motor are set up to run at maximum speed while the MicroSpeed

196

is

providing

90% Command Outputs, so that 10% Command

Authority

will be

available to compensate for slowdown caused by loading, etc., when the motor is

running at maximum set point.

6.

Press and hold the

DOWN

arrow key until the alphanumeric display reads

Pot % 00.

7.

Press

2ND FUNC

to exit the

Digital Potentiometer

mode.

FUNCTION AND TUNING OF THE PID VARIABLES:

The PID Variables make up the difference between the Expected Analog Output and

the Required Analog Output. The Expected Analog Output is based on a linear

relationship of 0

-

90% Command Output equal to 0

-

100% of the maximum speed

entered into Variable 01. The Required Analog Output is the actual Command Output

necessary to maintain the correct speed. A 0

-

100% Command Output is equal to

0

-

4094 DAC bits,

IMPORTANT!

Higher values in the PID Variables result in a faster correction time

and a tighter motor speed control. If the difference between the Expected Output and

the Required Output is extreme, the MicroSpeed 196 will begin changing its output in

the wrong direction, before the increasing error allows the PID Variables to overcome

this. Therefore, adjusting the output to the drive is very important.

PID VARIABLES:

Variable 12

-

(P) Proportional (or Gain)

-

Gain is the most active and important

tuning Variable. The Gain correction takes place every

.0l

seconds. A higher value

entered in this Variable (a number between 1 and 100) results in a faster change in the

Command Output to correct for error and, therefore, tighter motor control.

17

18

In the Master mode, the correction amount is based on the formula:

In Master Mode, the correction is limited to 25% of the total output per 10 msec cycle.

In the Follower mode, the correction change is based on the formula:

Variable 13

-

(I) Integral (or Reset)

-

The

Integral

operates as a long term

correction. It will add or subtract one DAC bit based on a positive or negative error. If

the

Integral

error is set at 100, this will happen every 20 msec. Each whole number

below 100 will add 10 msec to the loop time this bit is added.

Variable 14

-

(D) Derivative (or Rate) -The Derivative

operates as a boost to the

Gain

(Variable 12). Its function is to reduce the time it takes to eliminate a large error.

In Master mode, it operates identically to the

Gain,

except it has only half the authority

to change the output. In Follower mode, it operates identically to the

Gain

with the

same authority, but is only active when the error is greater than one Follower Feedback

Sensor revolution.

Use

the following steps to tune the PID Variables:

Note: Before beginning PID tuning, be sure that the Command Output has been

calibrated to the drive, and that all

ACCEL

and

DECEL

adjustments on the drive have

been set to their minimum positions. Failure to make these adjustments will degrade the

accuracy of the control.

1.

2.

3.

4.

5.

6.

Set Variable 13 (I) and Variable 14 (D) to zero (0).

Start the motor and set the speed to run at the most common operating speed.

Begin increasing the

Gain

(Variable 12) until instability (over and undershooting)

occurs. At this point, decrease the

Gain

until the motor stabilizes. The motor should

now be operated at different speeds throughout the operation range to ensure

stability.

Begin adding

Integral

(Variable 13) into the control loop. Keep increasing this

number until the motor begins to hunt above and below the Set Point, then back off

the number until the hunting stops.

Derivative

(Variable 14) can then be activated. Again, increase the value until

instability occurs and then back off. The most common value is usually from

50

-

100% of the value in the

GAIN

variable.

Run the the motor at all operating speeds to ensure stability. If instability

occurs,

retune the PID parameters at the unstable speed.

19

FOLLOWER MODE PID CONSIDERATIONS:

Variable 09

-

Max Lead Wind-Up

-

If you are speed matching and have very fast

master speed changes, or if you are bringing the Follower motor on-line with the master

motor already running, you may want to limit the maximum error accumulated. The

MicroSpeed 196 can be programmed to make up every revolution missed, up to 9,999,

or can be limited down to one revolution. Care must be taken, however, not to limit the

error count so low, that the MicroSpeed 196 cannot hold correct speed.

Note: Most applications should leave

Max. Lead Wind-Up

at the default value of

100.

Using

the

integral?

-

The MicroSpeed 196 in the Follower mode operates on a zero

error basis. For every master pulse, the MicroSpeed 196 will attempt to force a

corresponding follower pulse. The MicroSpeed 196 generates its expected analog

output based on the frequency of the lead motor. The

Gain

variable then uses error

pulses between the master and follower motor to lock the speeds together. Some phase

error between the shafts will occur. The degrees of phase error depends on the

Gain

number (Var 12) x pulses

per revolution, and the difference between the expected and

required output. If you are speed matching, a phase error is not a problem. If you need

the phases locked, you must add

Integral

to the PID loop.

Integral

(Var 13) will add

or subtract one DAC bit (out of 4095) at the programmed rate until the error count is

zero pulses.

Integral

will over or under-speed the motor for the required time period.

(This is not desirable if you are only speed matching.)

Softening the Master Motor

-

Every system (motor, drive, gearing, and load) has a

response time i.e., the ability of the system to respond to a change in speed command.

If we demand a change that is faster than a machine’s response time, we generate error.

Often when a follower motor’s speed is erratic (jumping or lagging), the only way to

correct this is to slow down the rate of change on the master motor. This includes the

ACCEL and DECEL rates, as well as the PID on the master control. Basically, this

allows the follower control’s PID Variables the time needed to overcome the delays in

the follower system. To slow down the PID response of the master

-

the MicroSpeed

196

-turn the

Derivative

to zero, increase the

Integral

and reduce the

Gain.

This will

slowly

correct the lead motor’s speed.

20

X.

AUXILIARY MODE

AUXILIARY

TRIM PROGRAMMING:

The

Auxiliary

input is used in the Follower mode to change the relationship between

the Master and Follower motor speeds, based on the input of a third frequency. This

frequency is commonly generated with Drive Control System’s AIFO-200 (analog-to-

frequency converter). The input to the AIFO-200 can be generated by a dancer pot, a

pressure transducer, or any other device with a

0-10V

or 4-20mA output.

In Auxiliary Trim mode, the

Auxiliary Frequency

input trims the final Follower motor

speed by adding or subtracting Auxiliary pulses to the Lead frequency, making the

Follower motor increase or decrease speed. The speed change is determined by the

following formula:

(Var 25) (Var 26)

Aux Freq

Input

Hz

-

1/2

Aux Ref Freq (Var 01)

xAux Gain x Max Feedback

1/2

Aux Ref Freq

(Var 25)

Multiply the Result by -1 if Var 27 is 0

The Auxiliary error count from this formula is summed in every

.02

seconds as long as

the lead motor is running. When the lead motor stops, the error count is returned to zero.

There are provisions for adding a delay on start-up, adjusting the amount of authority or

gain of the Auxiliary input, polarity change (increasing frequency decreases speed or

increasing frequency increases speed), and the frequency input programming.

Variable

24-

Auxiliary Mode Selection

-

0000 -Auxiliary

Input is disabled.

000l-

Auxiliary Trim mode is active.

Variable

25-

Auxiliary Reference Frequency

-

Enter the maximum frequency of

the auxiliary input. Zero trim correction is 50% of the programmed frequency; 9,999 Hz

maximum.

Variable

26-

Auxiliary Gain Percentage

-

This value is the percentage of maximum

speed (Variable 01) that can be corrected by the Auxiliary Trim mode. Enter 0 to 999%.

Variable

27-

Auxiliary Trim Selection

-

Entering 0000: Increasing the frequency

above 50% of the auxiliary reference frequency will decrease motor speed. Decreasing

the frequency will increase motor speed. Entering 0001

:

Increasing the frequency above

50% of the auxiliary reference frequency will increase motor speed. Decreasing the

frequency will decrease motor speed.

Variable 28

-

Auxiliary Input Delay

-

Delays the start of the Auxiliary Trim

function on startup. Enter the number of 10

msec

update cycles to wait. When ENTER

is pressed, the MicroSpeed 196 will insert a decimal point to display the delay in

seconds.

21

EXAMPLE:

In this application, (see Diagram 7, below) the MicroSpeed 196 is programmed to

control the wind-up (Follower) motor in a one-to-one relationship with the unwind

(Master) motor. Tension is controlled by a dancer arm. We will use 1000 rpm on the

encoders as the maximum speed of both the unwind (Master) and wind up (Follower)

reels. This would be entered into Variable 04

(Maximum Lead RPM)

and Variable 01

(Maximum RPM).

We will assume a 12-inch circumference on the nip rolls. Because

of this, we can enter 1000 into Variable 02

(User Units at Max RPM)

and the tach

will display ft/min. The PPR of the encoders is entered into Variable 03

(Feedback

PPR)

and Variable 05

(Lead PPR).

Enter the Ratio Set Point 1.000. The MicroSpeed

196 is now programmed to run in a one-to-one Master/Slave relationship. The machines

should now be operated, and PID tuning is completed.

The AIFO-200 has been programmed to provide a 0

-

2000 Hz output, based on a 0

-

10V

input signal from the dancer. 2000 is entered into Variable 25

(Auxiliary

Reference Frequency).

The MicroSpeed 196 will add correction whenever the

Auxiliary Reference frequency

is not

l/2

value. Set Variable 26

(Auxiliary Gain

Percentage)

at 10% to start with, and change Variable 24

(Auxiliary Mode

Selection)

to

1,

to enable the input as a trim function. Variable 27

(Auxiliary Trim

Selection)

will be set to 0. This gives a decrease in Follower motor speed, with an

increase in input frequency from the AIFO.

After starting the machine with the

Auxiliary

input active, (Variable 26)

Auxiliary

Gain Percentage

can be adjusted. Higher percentages result in tighter control;

however percentages that are too high will cause instability. It may also be desirable to

delay the Auxiliary trim on a start command. This allows the motors to get up to speed,

or above the low torque range, before adding extra correction changes. Use Variable 28

(Auxiliary Delay)

for this function.

Diagram 7

Typical Auxiliary Trim Mode Application:

AIFO

-

200

AC or DC Drive

MicroSpeed

196

22

XI.

DIAGNOSTIC TESTS AND

2ND

FUNCTION KEY

To access the Diagnostics and 2nd Functions, the unit must be in the “Ready” mode,

press

2ND FUNC,

then enter the number of the diagnostic test desired. To exit the

diagnostic test, press 2ND FUNC again.

Diag. 0

-

Custom User Label Programming

-

THIS IS NOT A TEST!

Refer to Section VIII,

“Programming the Display,

”

for information.

Diag. 1

-

Keypad Test

-

In this test, pressing each key on the front panel keypad will

result in the alphanumeric display showing the name of the key pressed. The numeric

display will show 0000 for keys that are not numbers, and will display the numeral (for

example: 1111, 2222, etc.) when the number keys are pressed. If any key does not

produce the proper display, that key may not be functioning. Contact the factory if this

occurs.

Diag. 2

-

Display Test

-

This test is to make sure that all of the LED segments on the

displays and all of the LED indicator lights are working correctly. During the test, the

Numeric display will scroll through all the numbers (i.e.

1111,

2222, 3333, etc.) and

will place the decimal point in each possible location. The alphanumeric display will

also display all of the numbers (i.e.

11111111,

22222222, etc.). The six LEDs on the

front of the unit indicating switch position and operating condition will light up one at a

time. If a segment is missing, or an LED indicator light fails, contact the factory.

Diag. 3

-

Input Switch Test -This

is a test for each of the remotely wired inputs.

Each possible input

(Local/Remote, Keypad Lockout,

Forward/Reverse,

etc.)

is represented by a 0 or a 1 on the alphanumeric display. The

E-Stop, Run, Jog,

and

Stop

inputs are represented by a 0 or a 1 on the speed display. Toggle the input to

check whether or not it is properly wired. When the digit corresponding to that input is

displayed as 0 the switch is Open, when it is displayed as 1 it is activated. E-Stop and

Stop

are 1 when opened and 0 when closed. Left to right, the eight digits on the alpha-

numeric display (00000000) correspond to the following inputs: Closed/Open Loop;

Master/Follower; Forward/Reverse; Keypad Unlocked/Locked out; Set Point

1(3)/2(4);

Set Point 3

&

4 Disabled/Set Point 3

&

4 Enabled; No Scroll/Scroll Down; No Scroll/

Scroll Up. Left to right, the four digits on the numeric display (0000) correspond to the

following command inputs: E-Stop; Run; Jog; Stop.

Diag. 4

-

Memory Test

-

This is an internal test by the micro-processor on its

memory locations. The alphanumeric display will show “Test ROM” for a few seconds,

then it will show either, “ROM ok” or “Fail.” If the test fails, contact the factory.

Diag. 5

-

Alarm Output Test

-

This is a test of the Status and Alarm outputs. In this

test, pressing a 1 through 6 on the keypad will result in completion of one of the Output

circuits. When in this diagnostic, the alphanumeric display will read “Output” until a

key (1 through 6) is pressed, then it will name the output being tested and the circuit

will be completed. A light wired into the circuit will illuminate, a relay will actuate, or

an alarm will sound, depending on how the circuit is wired. After an output is tested,

press the STOP button to turn the output off. To exit the Diagnostic, press the Stop, then

23

the 2ND FUNC key. The following numbers correspond to the following outputs:

1 =Ramp Complete; 2 = Zero Speed; 3 = High Alarm; 4 = Low Alarm; 5 = Deviation

Alarm; 6 = Drive Enable

Diag. 6

-

Communications Test

-

This test is used to test the RS422 hardware. To

perform the test, place a jumper wire between the Send and Receive lines at the terminal

(RXD- to TXD- and RXD+ to TXD+). The MicroSpeed 196 tests its communication

circuitry to make sure it is functioning. If it is, the alphanumeric display will read “Pass”

and the numeric display will name the node address. If it is not functioning properly, the

alphanumeric display will display “Fail.”

Diag. 7

-

Reset to Factory Programming -This

is Not a Test. Pressing

2nd

FUNC,

then accessing Diag. 7 will reset the programming in memory to the factory

defaults (see Appendix I for factory default settings). The alphanumeric display will read

“Reset”.

Diag. 8

-

Not Used.

Diag. 9

-

Digital Speed Pot

-

This function is explained in Section IX

“Calibrating

the Isolated Command Output to the Drive”.

It can be used as a test of the analog o

u

tput.

24

XII.

SERIAL COMMUNICATIONS

l

VIA RS422

USlNG THE REMOTE SERIAL lNTERFACE:

To control through the RS422 Serial Interface, the

Local/Remote Input

(TB1-10)

must be closed to common

(TB1-11).

This allows the MicroSpeed 196 to accept

commands over the RS422 link. The MicroSpeed 196 can be set up to only accept

commands over the RS422 link, or to allow some operator control as programmed with

Variable 30. All new set points and programming must come over the RS422 link,

except for speed changes with the scroll, or set point 1

-

4 switches. The

E-Stop

input

is also active in any mode of operation, and cannot be disabled.

Note: It is recommended that an optically isolated RS422 link be used between your

computer and the

MicroSpeed

196. Electrical noise will corrupt data on the computer,

causing it to send bad data, interpret data incorrectly, or lock up computer functions.

Prolonged exposure of your computer to electrical noise will destroy your computer!

Important: Remote setup Variables must be Setup from the keypad.

VARIABLE 19

-

NODE ADDRESS

-

Enter an address from 1

-

99. This address will

be used in the command format to talk to the MicroSpeed 196 with that specific

address. When using a global command (address 00) the MicroSpeed 196 with node

address 01 will be the only MicroSpeed 196 to answer the host computer, but all

MicroSpeed 196’s will respond to global commands. Never duplicate an address on the

same communications port.

VARIABLE 20

-

BAUD RATE

-

Enter the number (l-6) corresponding to the desired

operating baud rate. Each character has one start bit, eight data bits, one stop bit, and

no parity. 1 = 300

2 = 1200

3

=

2400

4 = 4800

5 = 9600

6

=

19200

VARIABLE 30 -EXTERNAL SWITCH ENABLE IN REMOTE MODE

-

This

variable allows the external inputs to be active during Remote mode. Entering a 1

enables the function. Entering a 0 disables the function. Default is 0000, or all functions

controlled by the RS422 link. Any combination of functions can be selected:

0001

=

Run, Stop, and Jog inputs enabled

0010

=

Forward/Reverse, Master/Follower, Closed/Open Loop,

Scroll up and Scroll Down inputs enabled

0100

=

Set Points

1,2,3&4

Enabled

1000

=

Keypad

RUN, STOP, and JOG enabled

25

Variable

48

-

Buffer Error

-

This variable is used to help diagnose communication

errors. If the variable displays a 1, then characters outside the Microspeed 196 protocol

format have been received by the MicroSpeed 196. If the variable displays a

2,

then

transmissions have been sent to the MicroSpeed 196 faster than it can process the

information and respond. The most recent error is kept in this variable until you set it to 0.

Diagram 8

RS422 Hook-Up

MicroSpeed

196’s

Host Device

26

COMMUNICATION PROTOCOL:

The communication protocol is a

13-character

command format. Each character has one

start bit, eight data bits, one stop bit, and no parity. The host sends messages in this

format and the addressed MicroSpeed 196 responds in the identical format. The time

from the end of the host message to the beginning of the MicroSpeed 196 message can

vary from 10 to 30 milliseconds, depending on the type of the host message. The

following diagram shows the command format.

0 1 2 3 4 5 6 7 8 9 10 11 12

stx device node node mess var# var# data data data data dec. etx

type addr addr type 10's 1's 1000's100's 10's 1's pt.

10’s 1’s

loc.

Char

# Description

ASCII

Value

Typical Keyboard

0

stx (start of transmission)

1

device type

2

node address (10’s digit) 30-39

3

node address (1’s digit)

4

message type

5

variable (10’s digit)

6

variable (1’s digit)

7

data (1000’s digit)

8

data (100’s digit)

9

data (10’s digit)

10

data (1’s digit)

11

decimal point location

12

etx (end of transmission)

02

03

30-39

30-33

30-39

30-39

30-39

30-39

30-39

30-39

30-34

03

hex

ctrl-B

hex 0

hex 0-9

hex 0-9

hex 0-3

hex 0-9

hex 0-9

hex 0-9

hex 0-9

hex 0-9

hex 0-9

hex 0-4

hex ctrl-C

DESCRIPTION OF CHARACTERS:

Character 0

-

stx

-

This character is used to indicate the start of a message. The

MicroSpeed 196 uses this character to open a new segment in the receive buffer.

Character 1

-

Device Type

-

Always a 0 for theMicroSpeed 196.

Character 2 and 3

-

Node Address (10’s and 1’s digits)

-

Used to select an

individual MicroSpeed 196 on the communications link. Corresponds to Variable 19 on

the MicroSpeed 196. Character 2 is the

10's

location and character 3 is the l’s location. A

node address of 00 is a Global Command. All MicroSpeed 196 units are affected

by a global command, but only address 01 will return a response to the host.

Character 4

-

Message Type

-

Tells what kind of message is being sent. This is also

the location at which the MicroSpeed 196 will indicate an error in a host communication.

Valid characters from the host are 0 (command), 1 (read variable), or 2 (write variable).

The MicroSpeed 196 will echo the host in this character location unless the host

communication message has an error; if this occurs, it will send back a 3 (error).

27

Characters 5 and 6

-

Variable Number (10’s and 1’s digits)

-

These are

variable number specifiers during read and write messages. In command messages, the

Character 6 (l’s) location specifies the type of command (start, stop, etc). In an error

response from the MicroSpeed 196, the error type is specified in Character 6.

Characters 7-10

-

Data Field

-These characters hold the data being passed between

the host and the MicroSpeed 196.

Ch#7

=

1000’s,

Ch#8

=

100’s,

Ch#9

=

l0’s,

Ch#l1 =

1’s.

Character 1

1-

Decimal Location

-

This specifies the location of the decimal point

in the data field.

Value Entered Decimal Location

0

X.XXX

1

XX.XX

2

XXX.X

3

XXXX.

4

XXXX (no decimal point)

Character 12

-

etx

-

This character signifies the end of the message transmission.

USING THE SERIAL PROTOCOL:

Global Messages

-

The global message is given using the

Node Address 00.

Only

Node 01

will return a response, but all Microspeed 196 units will act on the message.

Note: Global Read commands are not allowed and will prompt Node

01

to respond

with an error message.

Read a Variable

-

1

-

Select the Node Address (you cannot do a global read). Enter

the message type as 1

(Ch#4).

Enter the variable you wish to read into Characters 5 and

filled.

6. The MicroSpeed 196 will mirror the message string with the data and decimal field

Example:

Read Node 1, Variable 01, when Variable 01 = 1800

Message Sent

-

stx00ll0l00000etx

Message Returned

-

stx00ll0l18004etx

Write to a Variable

-

2

-

Used just like a read, only the message type is 2, and you

must fill the data field and decimal locator. A global write command is allowed.

Example:

Write Node 27, Variable 02, the Data 15.00

Message Sent

-

stx02720215001etx

Message Returned

-

stx02720215001etx

Command Messages

-

0

-

There are 9 different command messages that can be sent

to the MicroSpeed 196. Enter the 0 as the message type

(ch#

4) and the command type

(O-8) is entered into the character 6 location

var#

l’s).

28

MESSAGE

COMMAND

TYPE TYPE

0

0

0

1

02

0

3

04

05

06

0

7

08

FUNCTION

Start

Stop

E-Stop

Set to factory defaults.

Change set point (immediate change).

Load master set point (wait for execute).

Execute loaded master set point.

Load follower set point (wait for execute).

Execute loaded follower set point.

Example: Command All MicroSpeed 196 units to Stop

Message Sent- stx00000l00000etx

Message Returned- stx00l00l00000etx

Command Message Type Definitions:

Start - 0

-

Starts the specified MicroSpeed 196. If the front or back panel stop has been

enabled (with Var 30) and Stop is held, this command will be ignored.

Stop

-1

-Stops the specified MicroSpeed 196.

E-stop -

2

-

E-stops the specified MicroSpeed 196.

Set to Factory Defaults

-

3 -

Sets all variables, except Node Address (Var 19) and

Baud Rate (Var

20),

to the default values.

Set Point Changes:

Only the active set point can be changed via commands 4

-

8. To change a nonselected

set point, use the write message type. The decimal location is fixed by Variable 02 in

the Master mode or Variable 23 in the Follower mode. You cannot write to the active

set point’s variable while running.

Change Set Point

-

4

-

Changes the presently selected set point to the value sent.

Load Master Set Point

-

5

-

Allows for a new speed set point to be loaded, but not

executed. The value will be stored in Variable 49.

Execute Master Set Point -6

-

Moves the loaded speed set point into the active set

point (1

-

4),

and ramps to the new value.

Load Follower Set Point -7

-

Allows for a new ratio set point to be loaded, but not

executed. The value will be stored in Variable 49.

Execute Follower Set Point

-

8

-

Moves the loaded ratio set point into the active set

point (1

-

4),

and ramps to the new value.

Error Message

-

3

-

If the MicroSpeed 196 detects an error in a message, it will

respond with a 3 in the Character

#4

position. The type of error will be specified in the

Character

#6

position.

Error type

Problem

1

Parity

Error (Standard Definition)

2

Data Error (Data Outside of Range 1

-

9)

3

Global Read Error (Cannot Use the Address 00 During Read)

4

Etx Error (Etx Came Early, Late or Not At All)

5

Command Error (Reference Below)

Command Error

-

Any of the following conditions will give a command error:

.Message type out of range (O-2).

.Command type out of range (O-8).

.Variable value out of range.

.Write command sent to a protected variable while running.

.Command or write sent while in local mode.

.Load or execute new Master set point while in Follower mode.

.Load or execute new Follower set point while in Master mode.

REMOTE VARIABLES:

The Following variables are only available over the RS422 serial port:

49 -New

Set Point (Explained in Command, Changing Set Points

-

Monitor only)

50

-

Serial Status (Explained Below

-

Monitor Only)

51

-

Master or Follower Mode (O=Master,

1

=Follower)

52

-

Closed or Open Loop (O=Closed Loop, 1

=Open

Loop)

53

-

Forward or Reverse

(O=Forward,

1 =Reverse)

54

-

Master Set Point 1 in User Units

55

-

Master Set Point 2 in User Units

56

-

Master Set Point 3 in User Units

57

-

Master Set Point 4 in User Units

58

-

Follower Set Point 1 in User Ratios

59

-

Follower Set Point 2 in User Ratios

60

-

Follower Set Point 3 in User Ratios

61

-

Follower Set Point 4 in User Ratios

62

-

Display (Explained Below

-

Monitor Only)

63

-

Alarm Status (Explained Below

-

Monitor Only)

64

-

Spare for Future Use

65-

Spare for Future Use

Serial Status: Variable 50 -

Contains information on the present state of the

MicroSpeed 196. The data is returned in Characters 7

-

10.

Char

#7

(1000’s)

Char

#8

(100’s)s)

Operation status Local/Remote Char

#9

(10’s)

Active Set Point

0

=

E-Stop 0 = Local 1 = set point 1

1

=

Deceling 1 = Remote 2 = set point 2

2 = Stopping 3 = set point 3

3

=

Acceling

4 =Running 4 = set point 4

5 = Ready Mode

7 = No Feedback

8 = Digital Speed Pot Mode (Diag

#9)

29 30

Variable

62

-

Display

-

This variable will return whatever is

on the

numeric

display

of

the

MicroSpeed

196.

Refer to display variables

21

and

22

for information on

what

can be displayed.

SERIAL COMMUNICATIONS APPENDIX

Protected Variables in the Run Mode:

follower error-pulses, or the error output is being displayed.

No

te:

It is possible to receive a negative sign

in Character

#7,

(1000’sdata)

if the

Variable 63

-

Alarm Status

-

Refer to Display (Variable 21) for coding. This

wilt

return the status of the alarm outputs, per Variable 21, Option

7.

Var 01

Var 02

Var 03

Var 04

Var 05

Var 23

Var 51

Maximum Speed in RPM

User Units at Maximum Speed

PPR

Maximum Lead RPM

Lead PPR

User Unity Ratio

Master/Follower

The active set point will only change with a Change Set Point command.

A write command to the active set point while running will return an

error

message.

Possible Causes for No Communications.

The’unit does not act on or respond to messages sent.

1.

Check

Baud Rate

and

Address.

31

2.

Check wiring.

3.

Check Variable 48 for buffer communication errors.

4.

All 13 characters not sent.

5.

Check power to unit.

6.

Do a Diagnostic 6 communications test,

The unit acts on a message but does not return a response.

1.

Using global commands without Node 1 on line.

2.

3.

Not waiting long enough for response.

4.

The

MicroSpeed

196 transmit lines are open or shorted.

5.

More than one MicroSpeed 196 with the same node address.

Do a Diagnostic 6 communications test.

32

n

APPENDIX A

SPECIFICATIONS

Voltage

Fuse

115

Vac,

or 230 Vac, 50/60 Hz, 10

1/4

Amp. Fast Blow, 115

Vac./

1/8

Amp. Fast Blow, 23OVac.

Transducer Supply 12 Vdc, (unregulated) 250

mA

Max.

Transducer Input:

Wave Shape

Types

Square, Sine

Maximum Input Frequency

Internal Pull-Up

Trigger Levels

Analog Output:

NPN Open Collector

-

PNP Open Collector

-

Magnetic Pickup (Zero Crossing)

-

Logic Level

40 Khz

-

Master, 32 Khz

-

Follower

2.2

KQ,

Pull-up to 12 V

2.5 Vdc NPN, PNP, and Logic Level

50

mV

-

Zero Crossing (100 mv Peak Minimum Signal)

Type

Maximum Output

Current

Resolution

Optically Isolated 0 to

±15

Vdc

Adjustable from

±3

Vdc to

±15

Vdc

10

mA

Maximum

12-bit

D/A

Converter

Input Power:

External Control Inputs (Back Panel):

Sustained Contact Closures

Momentary Contact Closures.

Forward/Reverse

Closed Loop/Open Loop

Master/Follower

Keypad Unlocked/Keypad Locked

Set Points 1

&

3

/

Set Points 2

&

4

Set Points 3

&

4 Enable

Local Command/Remote Command

Scroll Up/12 Scroll Down

External Start/Stop Switches (Back Panel):

Momentary, N.O. Run

Momentary, N.C. Stop

Momentary, N.O. Jog

Momentary, N.C. Emergency Stop

Back Panel Transistor Outputs:

NPN, open Collector Drivers

(50 Vdc Max, 250

mA

.3

Watts Max.) High Alarm

Low Alarm

Ramp Compete

Zero Speed

Deviation

Drive Enable

Operational Specifications:

Accuracy

Respons

Modes of Operation

Preset Speeds

Accel/Decel Times

Processor

Speed Display

Alphanumeric Display

Function

LEDs

Diagnostics/2nd Function

Computer Interface

.01% of Speed Set Point (Master)

Zero Cumulative Error (Follower1

10-Millisecond Control Loop,Indivdually Adjustable

PID Gains

Master/Follower/Auxiliary Trim

4 Master, 4 Follower, 1 Jog

User Programmable from 0.1 to 600 Seconds

Intel 80C196TB

16-Bit

Micro Controller

4-Digit,

7-Segment LED,

.43-Inch

height

8-Character, 5 x 7 Dot Matrix,

.20-Inch

height

1 Run (Green)

1 Stop (Red)

1 Local (Amber)

1 Remote (Amber)

1 Set Point 1 (Amber)

1 Set Point 2 (Amber)

Diag. 0 Custom User Unit Display

Diag. 1 Keypad Test

Diag. 2 Display Test

Diag. 3 Input Test

Diag. 4 Memory Test

Diag. 5 Output Test

Diag. 6 Serial Interface Test

Diag. 7 Return to Factory (Programming Defaults)

Diag. 8 Not Used

Diag. 9 Digital Speed Potentiometer

RS422 Interface Standard, 300 to 19200 Baud,

13 Character String, 1 Start, 8 Data, No Parity, 1 Stop

Mechanical/Environmental Specifications:

Enclosure Material

KeyPad

Cold Rolled Steel

Tactile Feedback Membrane, Chemical Resistant,

Operating Temperature Splashproof

0°C

to

+50°C

Humidity

Panel Cutout

0

to

90%,

Non-Condensing

Weight 5.4-inch

Width x

2.7-inch

Height x 7.20-inchDepth

6 lbs.

Specifications Subject to Change Without Notice

35 36