12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | relevantsolutions.com/inteccontrols

Specifications subject to change without notice. | USA 160811 | Page 2of 34

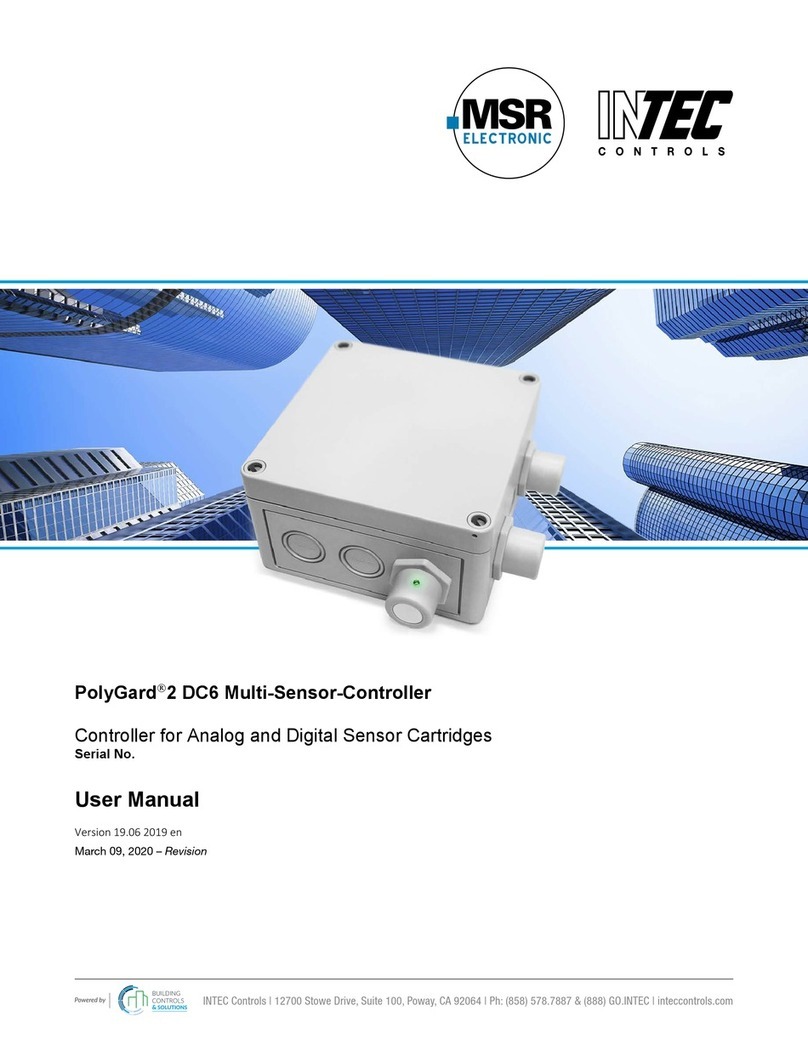

MGC2 – UserManual

PolyGard®is a registered trademark of MSR-Electronic GmbH

1 Application .......................................................................................................................................................4

2 Description .......................................................................................................................................................4

2.1 Normal Mode...............................................................................................................................................4

2.2 Alarm Mode .................................................................................................................................................4

2.3 Fault Mode .................................................................................................................................................. 4

3 Operating Instruction ...................................................................................................................................... 5

3.1 Description Keypad User Interface..............................................................................................................5

3.2 Setting / Change Parameters or Setpoints..................................................................................................5

3.3 Code Levels ................................................................................................................................................ 6

4 Menu Overview.................................................................................................................................................7

4.1 Fault Management ...................................................................................................................................... 8

4.1.1 Acknowledge a Fault.............................................................................................................................8

4.1.2 Error Memory........................................................................................................................................8

4.1.3 System Errors ....................................................................................................................................... 9

4.2 Status Alarm.............................................................................................................................................. 10

4.3 Status Relay.............................................................................................................................................. 10

4.3.1 Manual Operation of the Relays ......................................................................................................... 10

4.4 Menu Sensor Readings............................................................................................................................. 11

4.5 Menu Relay Parameter .............................................................................................................................12

4.5.1 Relay Mode......................................................................................................................................... 12

4.5.2 Relay Function Static / Flash .............................................................................................................. 12

4.5.3 Latching Mode .................................................................................................................................... 13

4.5.4 Horn Function ..................................................................................................................................... 13

4.5.5 External Operation of Alarm Relay ..................................................................................................... 14

4.5.6 Delay Mode of Alarm Relay ................................................................................................................ 14

4.6 Menu SP Parameter..................................................................................................................................15

4.6.1 Activate – Deactivate SP ....................................................................................................................16

4.6.2 Lock or Unlock SP .............................................................................................................................. 16

4.6.3 Selection Gas Type.............................................................................................................................17

............................................................................................................... 18

............................................................................................................................18

4.6.6 Threshold/Hysteresis .......................................................................................................................... 18

4.6.7 Delay for Alarm ON and/or OFF ......................................................................................................... 18

4.6.8 Control Mode Current or Average Value............................................................................................. 19

4.6.9 SP Fault Assigned to Alarm ................................................................................................................ 19

4.6.10 Alarm Assigned to Alarm Relay......................................................................................................... 19

4.6.11 SP Signal Assigned to Analog Output............................................................................................... 19

4.7 Menu Data Logger.....................................................................................................................................20

4.7.1 Data Logger Switch On/Off................................................................................................................. 20

4.7.2 Current Value......................................................................................................................................21

4.7.3 CV Log Rate ....................................................................................................................................... 22

4.7.4 Alarm Status ....................................................................................................................................... 22

4.7.5 Error Status......................................................................................................................................... 23

4.8 Menu System Parameter...........................................................................................................................24

4.8.1 Service Mode......................................................................................................................................26

4.8.2 Software Version................................................................................................................................. 26