Intellidyne IntelliCon-FA Specification sheet

OPERATING MANUAL and INSTALLATION INSTRUCTIONS for Form FA3300 build_198

IntelliCon®-FA

FORCED-AIR HEATING SYSTEM ECONOMIZER

Description

The IntelliCon®-FA is a patented microprocessor-based fuel-saving device for

forced-air (warm-air) heating systems. The controller reduces fuel consumption and

burner emissions by actively managing the burner, in conjunction with the

thermostat, to operate the furnace in a more energy efficient manner. The controller

indicates average theoretical savings. In addition, certain parameters are

programmable. All of the programmable parameters and savings values are stored

in memory that will not be lost in the event of the unit being turned off or a power

failure.

This unit is not intended for use on milli-volt or self-powered gas burner

systems.

Electric Ratings

Power input: 24,115,220 VAC ± 10%, 5 Watts max., 50/60Hz

Control circuit input: 24,115,220 VAC ± 10%, 0.1A max. Burden

Relay Contact: Form B, 10A @ 220 VAC (General Purpose)

Environmental Conditions

For Indoor Use

Maximum Altitude (2000M)

Rated Ambient Temperature 32 - 120˚F. (0 - 49˚C.)

Maximum Rh 90% non-condensing

Mains Supply Voltage Fluctuations ± 10%

Transient Over-Voltage Category (III)

Pollution Degree (2)

Operation

After installation, setting the switch on the unit to the ‘ON’ position activates the

control. The LCD display indicates the various ‘modes’ of operation of the control,

sensed temperatures, savings and economizer and burner run-times. The possible

messages and their explanation are:

The space temperature is satisfied and the thermostat is not calling for the furnace to

fire.

The thermostat is calling for the burner to fire and the controller is allowing the

burner to fire.

Note: A period (.) or colon (:) may be appended to the message.

.= The period signifies that the Discharge-Air Terminal Temperature has been

established.

:= The colon indicates that the Maximum Economizer Hold-Off timer has enabled

the burner.

The controller has turned the burner Off even though the thermostat is calling for the

burner to fire.

During normal operation, one of the above messages will be alternated with the

messages below.

OR

“DA TEMP = xxx˚” - The measured value of the furnace’s discharge-air temperature

is displayed in degrees F or C (see Programming section). This message will NOT

appear if the optional sensor is installed

“DA = xxx˚RA = xxx˚” - The measured value of both the discharge and return air

temperatures in degrees F or C (see Programming section). This message will only

appear if the optional sensor is installed (see “Sensors” section of these

instructions).

In the event that the unit detects a sensor fault, full control of the burner is returned

to the existing controls. The ‘Power/Normal’ indicator will blink, and the following

message will be displayed:

?? = DA and/or RA

If this message appears, see the instructions under Service and Troubleshooting.

The calculated average savings of burner cycles since commissioning of the

controller (A = Average).

Note: This message will indicate N/A until there is sufficient data to perform the

calculations.

Total hours of Economizer time. (maximum = 65,535.9 hours).

Total hours of Burner run-time. (maximum = 65,535.9 hours).

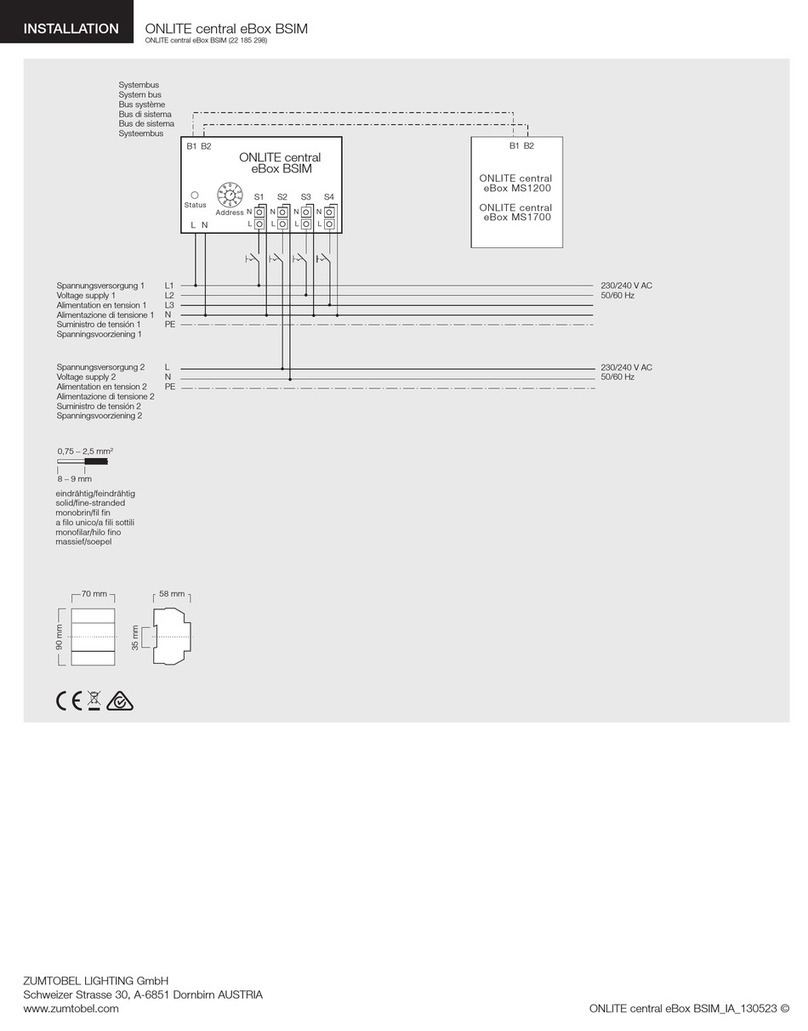

Installation

The controller is electrically installed in series with the burner control device as

shown in the wiring diagrams contained in these instructions. Check and determine

the voltages of the burner control circuit and power circuit prior to installation. FOR

SAFETY, POWER TO THE FURNACE MUST BE DISCONNECTED DURING

INSTALLATION.

Positioning

The unit must be protected from the elements and may be mounted on the

equipment either vertically or horizontally. The unit should be mounted directly on

the existing electric enclosure via the unit’s standard ½” electrical fitting or within the

enclosure using an accessory mounting bracket. For mounting in the elements, a

rain-tight mounting enclosure is available.

Wiring

All wiring and connections must comply with Local and National Electrical

Codes. The unit should be wired as shown in the wiring diagram(s) on the

reverse side. It is important to read all of the instructions. Ensure that POWER

TO THE UNIT IS OFF DURING INSTALLATION and that all unused leads are

individually taped/insulated.

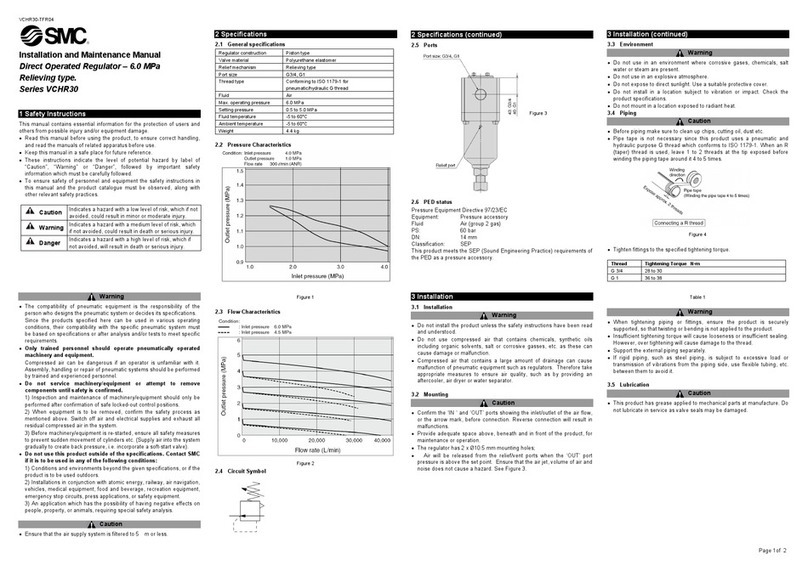

Sensors

Mount the discharge air sensor on the Furnace’s discharge air ductwork/plenum as

close to the furnace as possible but at least 18” from the heat-exchanger. Locate an

unobstructed area on the ductwork/plenum and (making sure there is nothing

behind it) drill a 5/8” dia. hole for the sensor to extend into the airflow. Attach the

mounting bracket to the duct using # 8 hardware. If the sensor is installed exposed

to the elements or mounted within the ductwork, the sensor must be installed using

the optional rain-tight enclosure kit which may be obtained from Intellidyne (part no.

4066). Make sure that the sensor is oriented according to the direction of airflow as

shown on the mounting diagram. Plug the sensor’s connector into the ‘Discharge

Air’ jack located on the side of the unit.

Additional economies can be realized through the use of a return air temperature

sensor. Mount the return air sensor on the Furnace’s return air duct in a similar

fashion to that of the discharge air sensor. Plug the sensor’s connector into the

‘Return Air’ jack located on the side of the unit.

The controller will not work without the discharge air sensor and will work

improperly if the plugs are in the wrong jacks. Use of the return air sensor is

optional but should be used whenever possible.

Checkout

Recheck wiring one last time and make sure that the temperature sensor(s) is

plugged into the proper jack(s). The sensors are only detected during power-up.

Set the controller to ‘Off/Bypass’ and restore power to the furnace. Note the

thermostat setting and then change that setting all the way down. Place the switch

on the controller to ‘On’. After a brief check of the electronics, the sensor(s) will be

detected and the green ‘Power/Normal’ indicator should light continuously. It is

important to verify recognition of the sensors by viewing the temperature reading(s),

on the display. If the installed sensor(s) are not detected, the unit will not function

properly. If the green indicator is blinking or if the display does not verify the

installed sensor(s), turn the unit ‘Off’ and check the sensor installation. After the

sensor-check, verify that the unit is in . If in , force a

heat call (burner to fire) by temporarily raising the thermostat all the way up and

verifying that the unit changes to mode and that the burner fires.

Make sure to return the thermostat to its’ original setting. This indicates that the

control is operating normally. If the unit did not change modes and the burner fire

when the thermostat was adjusted the unit is probably wired incorrectly.

Service and Troubleshooting

After Installation and Checkout, the controller requires no maintenance and will

provide years of trouble free operation. The unit may be disconnected at any time

by placing the slide switch in the ‘Off/Bypass’ position. In this position, the unit has

no effect on the system and the burner is controlled as it was prior to the controllers

installation. This allows service personnel to troubleshoot or work on the furnace

without the controller intervening.

If at any time the light on the front panel blinks continuously, a sensor is not

operating properly.

If the message is displayed the control

should be placed into the OFF/Bypass position.

If any of the above trouble conditions have occurred the control

has taken itself out of the circuit and returned full control to the

pre-existing controls. The Installer should be called for service.

STANDBY MODE

BURNER ENABLED

ECONOMIZING

DA TEMP = DA = xxx˚RA = xxx˚

CHECK ?? SENSOR

A SAV = xx.x%

ET HRS = xxxxx.x

RT HRS = xxxxx.x

STANDBY MODE

BURNER ENABLED

LINE SYNC FAILED SYSTEM BYPASSED

STANDBY MODE

Intellidyne LLC • 5507 Nesconset HWY STE10 PMB148 • Mount Sinai, NY 11766, USA • Email [email protected]

OPERATING MANUAL and INSTALLATION INSTRUCTIONS for Form FA3300 build_198

IntelliCon®-FA

FORCED-AIR HEATING SYSTEM ECONOMIZER

IMPORTANT - READ CAREFULLY

1. Failure to follow these instructions may result in damage to the

system or cause a hazardous condition.

2. Installer must be experienced, qualified, and in certain

locations, licensed to work on the system that this control is

being installed on.

3. After installation is complete, follow the check-out procedure as

provided in these instructions to confirm proper system

operation.

4. Intellidyne is not responsible for improper installation or any

damages that may result from improper installation.

5. Actual wiring may differ from that shown in the diagrams.

6. Equipment may have controls not shown.

7. Because the IntelliCon can operate with different voltages for

the power and control circuits, it has separate common wires

for these circuits. It is necessary that these wires are

connected to the proper commons or the unit will not function

properly. See the wiring diagrams contained in these

instructions for details.

IMPROPER VOLTAGE SELECTION MAY DAMAGE THE UNIT

AND VOID THE WARRANTY.

PROGRAMMING

The following parameters may be changed in the field by following these

instructions.

Pre-Purge time and Temperature indication in either degrees F or C.

It is very important that if there is any kind of a delay (more than ten

(10) seconds), from the time that the thermostat calls for the burner

to start and the burner actually starts, that this time delay value be

entered into the controller as a Pre-Purge time (e.g. actual pre-purge

timer, Flue Damper interlock, etc.). If there is a delay and the correct

value is not programmed into the controller, the savings calculations

will be incorrect.

ALL PROGRAMMING IS ACHIEVED BY INSERTING AND REMOVING A

TEMPERATURE SENSOR PLUGED INTO THE RETURN-AIR SENSOR

CONNECTOR, WHEN DIRECTED TO DO SO VIA THE DISPLAY ON

THE CONTROLLER. THE SENSOR MUST BE CONNECTED TO THE

CABLE OR THIS WILL NOT WORK!

YOU HAVE TEN (10) SECONDS TO RESPOND TO ANY OF THE

DISPLAY PROMPTS. THE 10 SECOND COUNTDOWN IS DISPLAYED

ON THE CONTROLLER’S LCD DISPLAY.

PROGRAMMING MAY BE STOPPED OR ABORTED AT ANY TIME BY

TURNING THE CONTROLLER OFF. ANY PARAMETERS THAT WERE

CHANGED WILL REMAIN CHANGED.

Entering Configuration Mode:

To enter configuration mode, the controller must be powered up without

any sensors connected. When prompted insert a sensor plug into the

RETURN-AIR sensor connector. To confirm, remove the plug when

prompted.

Any changes made to a programmable parameter will be confirmed

by indicating before advancing to the next

parameter.

This parameter will reset all of the programmable parameters to factory

defaults. It will not clear any of the accumulators.

This parameter will clear the Economizer and Burner Run-Time

accumulators.

This parameter indicates the pre-purge time currently programmed into

the controller (default value = 000 seconds). Next you will be prompted to

change by inserting the sensor plug within 10 seconds. If not inserted

within the 10 seconds the controller will advance to the next

programmable parameter (For Degrees F or C). If inserted you will be

prompted to force a burner call, typically done by increasing the set-point

of the thermostat, and then to remove the sensor plug when the burner

starts. When prompted to “FORCE A HEATING CALL” the controller will

wait indefinitely (NO 10 second time-out) for the CALL. So it is not

necessary to rush.

OR

The controller will prompt you to change to whatever value is NOT

currently selected (default value = F). For example, if the parameter is

currently set for degrees F, the only choice will be to change to degrees

C. This setting will alter how the indicated temperatures are displayed

when the controller is in operation.

This feature of the controller allows the user to set or limit the Maximum

Air Temperature being discharged from the unit. The allowable values are

90˚- 150˚F ( 32˚- 65 ˚C), AUTO, and DISABLED. To change this setting,

plug in the sensor when prompted. The indicated value will be what is

currently set in the controller (default = DISABLED). Next the controller

will count up until the maximum settable value is reached and then roll

over to the lowest. Remove the sensor when the desired value is

reached. It is recommended that this be set to Disabled. If you feel that

this must be changed, it should be discussed with technical support.

OR

This feature of the controller is to limit the maximum amount of time that

the controller is allowed to hold the Burner OFF. To change this setting,

plug in the sensor when prompted. The indicated value will be what is

currently set in the controller (default = 3 minutes). Next the controller will

count up until the maximum settable value is reached (10 minutes), then

“DISABLED”, and then will jump to the minimum settable value (1 minute).

Remove the sensor when the desired value is reached.

OR

This parameter controls whether or not the Economizer Time accumulator

is displayed. The controller will prompt you to change to whatever value is

NOT currently selected (default value = ON). For example, if the

parameter is currently set for “ON”, the only choice will be to change to

“OFF”. Note – the accumulator is active even if not displayed.

OR

This parameter controls whether or not the Burner Run-Time accumulator

is displayed. The controller will prompt you to change to whatever value is

NOT currently selected (default value = ON). For example, if the

parameter is currently set for “ON”, the only choice will be to change to

“OFF”. Note – the accumulator is active even if not displayed.

OR

This parameter controls whether or not the Average Savings accumulator

is displayed. The controller will prompt you to change to whatever value is

NOT currently selected (default value = ON). For example, if the

parameter is currently set for “ON”, the only choice will be to change to

“OFF”. Note – the accumulator is active even if not displayed.

OR

This is a special application feature that should NOT be used without

conferring with Technical Support (Default = OFF).

RESET DEFAULTS?

RESET TIMERS?

PREPURGE=xxx SEC

FOR DEGREES C FOR DEGREES F

DAT MAX = ??????

MAX ECON = xxx MIN MAX ECON = DISABLD

ECON TIMER OFF? ECON TIMER ON?

RUN TIME OFF? RUN TIME ON?

A

SAVING OFF? A SAVING ON?

LATCH MODE = ON? LATCH MODE = OFF?

**DATA SAVED**

Intellidyne LLC • 5507 Nesconset HWY STE10 PMB148 • Mount Sinai, NY 11766, USA • Email [email protected]

OPERATING MANUAL and INSTALLATION INSTRUCTIONS for Form FA3300 rev 5.4

IntelliCon®-FA

FORCED-AIR HEATING SYSTEM ECONOMIZER

TYPICAL 115/220V POWER & CONTROL -- FURNACE BURNER CIRCUIT

SEEWIRING NOTE

SWITCH

SHUTOFF

EMERGENCY

INDIVIDUALLY TAPE

POWER

COMMON

HOT

OR WIRE-NUT

THERMOSTAT

DROP

TEMP.

BLU=24V

SEEWIRINGNOTE

BRN=115/230V

WHT

LINE-VOLTAGE

THE WHITE TO THE 24V COMMON. THE BLACK AND VIOLET WIRES ARE NOT USED AND SEPARATELY TAPED)

(FOR 24V POWER & CONTROL THE BLUE WIRE WOULD BE CONNECTED TO THE 24V HOT,

COMMON

GRY=24V

TYPICAL 115/220V POWER / 24V CONTROL -- FURNACE BURNER CIRCUIT

SEE WIRING NOTE

OR WIRE-NUT

POWER

CONNECTION

BROKEN

HERE

EXISTING

BURNER

YEL

RED

GRY = 24V

SWITCH

COMMON

HOT

115/220V

24V

HOT

EMERGENCY

SHUTOFF

INDIVIDUALLY TAPE

OR WIRE-NUT

SEEWIRINGNOTE

WHT

BLU=24V

FOR 220V POWER USE VIO WIRE AND TAPE OFF BLK

FOR 115V POWER USE BLK WIRE AND TAPE OFF VIO

WIRING NOTE:

INDIVIDUALLY TAPE

BRN=115/230V

LOW-VOLTAGE

CONNECTION

THERMOSTAT

TEMP.

DROP

EXISTING

BROKEN

HERE

BURNER

RED

24V CALL

YEL

Fig. 1a Fig. 1b

The IntelliCon Model FA must be connected as shown when a Riello burner is used with a

24vac switching relay module. Connecting this way ensures that the FA Heating Economizer

is connected after the call for heat, but before the burner flame safeguard.

VIOLET

GREY

BLUE

YELLOW

B

W

W

R

T

T

Switching Relay Module

AL1008 24 Volt

TAPE OFF

INDIVIDUALLY

BROWN

Riello Burner

N

L

POWER SUPPLY

UNINTERRUPTED

BLACK

WHITE

RED

120vac

Connection

Break

Here

NOTE:

R C G Y W

Control

Thermostat

Transformer

OR

Power Supply

208/230 VAC

Single Phase

110/120VAC

Neutral

OR L2

L1

From

WHITE

BLUE

GREY

Unit

RED

Here

Connection

Break

INDIVIDUALLY

TAPE OFF

YELLOW

BROWN

BLACK

VIOLET

Riello Burner with 24vac Switching Relay Connections

Fig. 1c

Typical 24vac Power and Control Connections

Fig. 1d

WIRING NOTE: The IntelliCon unit has MULTI-VOLTAGE capability and has separate common wires for the Power

and Control circuits. It is necessary that these wires be connected to the appropriate commons for the circuit or the

unit will not function properly. Unused wires MUST be separately taped!

IMPROPER VOLTAGE SELECTION WILL DAMAGE THE UNIT and Void the Warrant

y

.

Intellidyne LLC • 5507 Nesconset HWY STE10 PMB148 • Mount Sinai, NY 11766, USA • Email [email protected]

OPERATING MANUAL and INSTALLATION INSTRUCTIONS for Form FA3300 rev 5.4

IntelliCon®-FA

FORCED-AIR HEATING SYSTEM ECONOMIZER

CURB

HEAT

EXCHANGER

ROOF

SUPPLY

AIR

DUCT

RETURN

AIR

DUCT

AIR

FLOW

AIR

FLOW

OPTIONAL

RETURN-AIR

SENSOR

SUPPLY-AIR SENSOR

SHOWN MOUNTED ON

DUCT, IN RAIN-TIGHT

ENCLOSURE.

CURB

ROOF

SENSOR SHOWN IN RAIN-TIGHT

ENCLOSURE SUSPENDED WITHIN

DUCT VIA CONDUIT ANCHORED AT

TOP. SENSOR MAY BE MOUNTED

EXTERNAL TO DUCT IF ACCESSIBLE.

HEAT EXCHANGER & FILTER

SHOWN FOR ILLUSTRATIVE

PURPOSES.

SUPPLY

AIR

DUCT

RETURN

AIR

DUCT

AIR

FLOW

AIR

FLOW

FILTER

OPTIONAL RETURN-AIR

SENSOR SHOWN MOUNTED

IN DUCT. MAY BE MOUNTED

IN PLENUM, IF NO O.A.

ECONOMIZER.

SENSOR

OPTIONAL

SURFACE OF THE DUCTWORK.

SENSORS MAY BE MOUNTED ON ANY

DUCT

RETURN AIR

AIRFLOW

DUCT

DISCHARGE AIR

FURNACE

AIRFLOW

TYPICAL TOP DISCHARGE RESIDENTIAL UNIT

SENSOR ORIENTATION TO AIRFLOW

AIRFLOW IN DUCT

TYPICAL DOWN-FLOW DISCHARGE

ROOF-TOP UNIT

TYPICAL SIDE OR END-FLOW

DISCHARGE ROOF-TOP UNIT

4004B, 4004C SENSOR MOUNTING

Note: This sensor is NOT air-flow direction sensitive

1. Drill a 1/4” hole in the duct away from temperature stratified air, coils or humidifiers. Insert the probe into the duct (A).

2. Drill two 1/8” pilot holes through the holes in mounting flange (B). Use two # 8 galvanized or stainless steel sheet-metal screws

and securely fasten the sensor to the duct. Do not over tighten.

3. We recommend mounting the sensor with the cable inlet facing down.

4. Run control wires through cable inlet (C) and attach wires to the quick connect terminals. The connections are not polarity or

p

osition sensitive. Attach cover to senso

r

.

4004C (507-6) 4004B (507-5)

Intellidyne LLC • 5507 Nesconset HWY STE10 PMB148 • Mount Sinai, NY 11766, USA • Email [email protected]