IntelligentAg RECON SPREADSENSE User manual

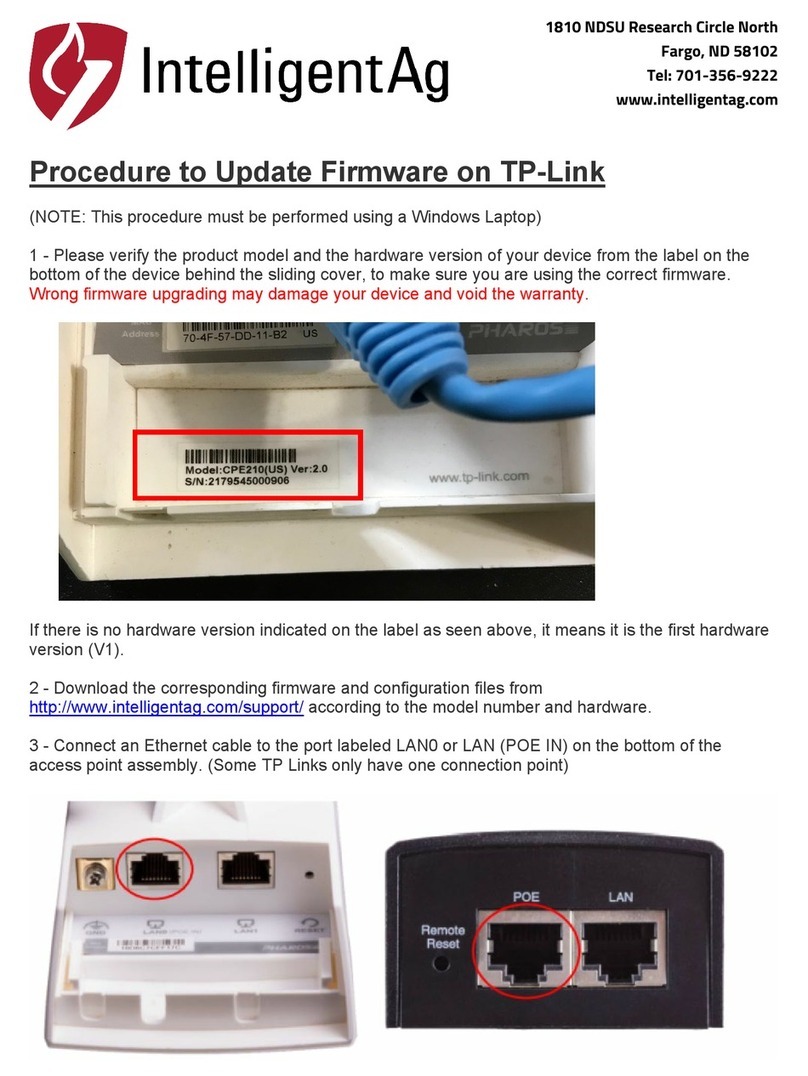

INSTALLATION MANUAL

Document revision: 1.7

Last revised: April 25, 2023

Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 2 of 32

Recon SpreadSense®

Installation Manual

© 2017-23 Intelligent Agricultural Solutions. All Rights Reserved.

Recon SpreadSense® Installation Manual. All content within is copyrighted by Intelligent

Agricultural Solutions and may not be reprinted without permission.

The content of this manual is furnished for informational use only, is subject to change without

notice, and should not be construed as a commitment by Intelligent Agricultural Solutions.

Intelligent Agricultural Solutions assumes no responsibility or liability for any errors or

inaccuracies that may appear in the content contained in this guide.

Patent pending. Recon, SpreadSense®, Intelligent Agricultural Solutions, Intelligent Ag™,

Intelligent Ag Monitoring Solutions, IAS, and the IAS logo are trademarks or registered

trademarks of Intelligent Agricultural Solutions. iPad is a registered trademark of Apple Inc.,

registered in the U.S. and other countries. App Store is a service mark of Apple Inc. All other

trademarks are property of their respective owner.

Intelligent Agricultural Solutions, 1810 NDSU Research Circle North, Fargo, ND 58102 USA.

Visit us online at intelligentag.com/support

Questions? E-mail us at info@intelligentag.com

Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 3 of 32

Table of Contents

1. Getting Started.....................................................................................................................5

1.1. About Recon SpreadSense®.....................................................................................5

1.2. Compatible Floaters...................................................................................................5

1.3. Required Tools and Equipment..................................................................................5

1.4. Installation Overview..................................................................................................6

2. Installing Flow Sensors........................................................................................................7

3. Installing ECUs ....................................................................................................................9

4. Connecting Auditory Tube to ECUs....................................................................................13

5. Connecting Harnessing......................................................................................................14

5.1. Installing ECU Wiring Harnesses.............................................................................14

5.2. Installing Gateway Harness.....................................................................................14

5.3. Connecting Cab Harness.........................................................................................14

6. Installing the Gateway........................................................................................................15

7. Installing Wi-Fi Antenna .....................................................................................................18

8. Installing the iPad and SpreadSense® App........................................................................21

8.1. Installing the iPad Mount..........................................................................................21

8.2. Downloading the SpreadSense® App......................................................................22

8.3. Connecting to the Gateway......................................................................................22

8.4. Configuring the System............................................................................................22

9. Daily Maintenance..............................................................................................................23

Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 4 of 32

Record of Revision

Revision

Number

Change Description

Revision

Date

Inserted

By

1.0

Initial release

11/29/17

AAL

1.1

Added alternate gateway mounting instructions and

clarified some steps

6/21/18

AAL

1.2

Updated with new hardware

9/19/18

AAL

1.3

Removed incompatible system, added new hose

clamps, updated ECU install instructions, added

system maintenance

1/02/19

AAL

1.4

Added new compatible machines, gateway model,

and harnessing

2/05/20

AAL

1.5

Added new compatible machines, auditory tubing

5/17/22

AAL

1.6

Updated Intelligent Ag logo

1/17/23

AAL

1.7

Updated ECU image in diagrams, removed round u-

bolt from gateway instructions

4/25/23

AAL

Getting Started Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 5 of 32

1. Getting Started

1.1. About Recon SpreadSense®

Recon SpreadSense is the industry’s first blockage monitor for floaters. Utilizing the same

acoustic technology developed for other Recon monitoring systems, Recon SpreadSense

provides reliable real-time blockage detection. Acoustic sensors installed on the back of each

deflector listen to the material flow and send sound pulses through auditory tubes, similar to a

stethoscope. The data is collected by the Electronic Control Unit (ECU), which displays the

information on an iPad® in the cab. If there’s a blockage anywhere in the system, you’ll know.

For instructions to use and configure SpreadSense, see the Recon SpreadSense Operator’s

Guide (Intelligent Ag™document number 600890-000015) from the SpreadSense app’s Guides

screen.

For installation videos, current documentation, and iPad and software requirements, visit

intelligentag.com/support.

1.2. Compatible Floaters

Recon SpreadSense can be installed on the following floaters:

•Case Titan 810 Flex-Air

•Case FA 1030

•John Deere F4365 AB485

•RBR Enterprise 810 Flex-Air

•RoGator AirMax Precision

•Salford 6700 AB200DS

•Salford 6700 AB320DS

•TerraGator AirMax Precision

1.3. Required Tools and Equipment

You will need the following tools and equipment to install Recon SpreadSense:

•Standard wrench and socket sets

•Cordless drill with 5/16 driver and/or flathead screwdriver

•Cleaning rags

•Two flathead screwdrivers, WD-40, rag, brake cleaner (if removing flow sensors)

WARNING: Do not use a high-pressure washer on electronic components.

Getting Started Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 6 of 32

1.4. Installation Overview

ESTIMATED INSTALL TIME: 6 hours

Recon SpreadSense® is installed through the following steps:

□Install flow sensors

□Install ECUs

□Connect auditory tubes to ECUs

□Connect harnessing

□Install gateway

□Install Wi-Fi antenna

□Install iPad and SpreadSense app

NOTE: Detailed wiring diagrams are found in Appendix B.

Installing Flow Sensors Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 7 of 32

2. Installing Flow Sensors

Flow sensors detect when product is impacting the deflector.

Part name

Part number

Quantity

Sensor

153510-000085

1/deflector

Auditory tube

353070-000478

1/sensor

Alcohol wipes

356070-000063

varies

Installation Location

Mount flow sensors on each deflector. See Appendix A for sensor placement diagrams.

Installing the Flow Sensors

1. Refer to Appendix A for sensor placement diagrams for your floater.

2. Clean the deflector with alcohol wipes (356070-000063). If there is a lot of dirt, clean the

deflectors with a cleaning rag first.

3. If it is below 60°F (15°C), apply heat to the underside of the deflector. The sensor

adhesive will not stick in cold temperatures.

4. Remove the protective backing from the sensor (153510-000085).

5. Align the sensor with the deflector according to the sensor placement diagrams in

Appendix A, with the port for the auditory tube pointing up. Firmly push the sensor onto

the deflector with about 75 lbs. of force to ensure a good seal.

6. Verify that the flow sensor is firmly adhered to the deflector by pulling on the sensor. If it

comes loose, re-install the sensor with more force.

7. Connect an auditory tube (353070-000478) to the sensor.

Figure 1: Connecting auditory tubes

8. Repeat the steps above for each deflector.

WARNING: Use caution when folding and unfolding the booms. Failure to properly fold

booms may cause damage to your sensors and other components of the

SpreadSense® system.

Installing Flow Sensors Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 8 of 32

Removing Flow Sensors

If you need to replace a sensor, contact Intelligent Ag™for a replacement adhesive disk. Then,

follow the instructions below.

1. Push a screwdriver between the sensor adhesive and the deflector. Lift the sensor

slightly until there is enough room to push the other screwdriver further under the

sensor. Pry the sensor gently until it comes off of the deflector.

2. Completely cover the sensor and deflector with WD-40 and let it soak for 3 to 5 minutes.

3. Use a rag to clean the sensor and deflector until there’s no adhesive left. You may need

to scrape larger pieces off with a screwdriver.

4. Spray and wipe the deflector with a cleaning solution such as brake cleaner to remove

any additional residue.

5. Remove the protective backing from the replacement adhesive disk and adhere it to the

bottom of the sensor.

6. Reinstall the sensor on the back of the deflector using the instructions in Installing the

Flow Sensors on the previous page.

Installing ECUs Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 9 of 32

3. Installing ECUs

WARNING: Do not use a high-pressure washer on electronic components.

The Electronic Control Units (ECUs) communicate the flow measurement data received by the

flow sensors to the gateway.

Part name

Part number

Quantity

ECU

153510-000045

8-10*

Hose clamp

356060-000246

2 per flat plate ECU

Flat-plate ECU bracket

353070-000135

6-8*

C-channel ECU bracket

353070-000139

2

Rubber mount

353070-000239

2 per ECU

3/8"-16 locknut

356060-000094

2 per ECU

3/8"-16 x 2.5" bolt

356060-000237

2 per ECU

1.25" OD washer

356060-000239

4 per ECU

*See Appendix B for installation drawings for your system.

Installation Location

Mount ECUs on the booms and middle implement plate.

Installing the ECUs

The ECUs use two different types of mounting brackets: a flat-plate ECU bracket and a

C-channel ECU bracket. Refer to Appendix B to determine where to use each bracket.

Figure 2: ECU installation locations

Installing ECUs Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 10 of 32

Installing ECUs with the Flat-Plate Bracket

Figure 3: Installing flat-plate bracket ECUs

1. Refer to Appendix B to determine the installation location for the ECUs that use the flat-

plate bracket (353070-000135).

2. Align the flat-plate ECU bracket (353070-000135) with the bottom of the ECU (153510-

000045). Secure the ECU to the bracket using bolts (356060-000237), washers

(356060-000239), rubber mount back (353070-000239), and locknuts (356060-000094),

as shown in Figure 3.

3. Position the bracket onto the machine using the auditory hoses to help guide placement.

Thread the hose clamps (356060-000246) through the bracket and secure the ECU to

the boom.

NOTE: Make sure that when the boom is folded up, the ECU connectors point

downward so that they do not collect water. This might mean rotating the bracket and

ECU on the machine.

NOTE: If the hose clamp won’t fit around larger structures, connect two hose clamps

together to make a larger hose clamp.

4. Repeat the steps above for each flat-plate ECU.

Installing ECUs Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 11 of 32

Installing ECUs with the C-Channel Bracket

Figure 4: Installing C-channel bracket ECUs

1. Refer to Appendix B to determine the installation location for the ECUs that use the

C-channel bracket (353070-000139).

Twist the locknut (356060-000094) onto the bolt (356060-000237) and screw it upwards until it

reaches the head of the bolt, as shown in the left image of

2. Figure 4.

Align the ECU (153510-000045) with the bracket as oriented in the right image of

3. Figure 4. Secure the ECU to the bracket using the bolt/locknut, washers (356060-

000239), and rubber mount back (353070-000239).

4. Position the bracket onto the machine using the auditory hoses to help guide placement.

Tighten the bolt head to secure the bracket to the machine.

NOTE: Make sure that when the boom is folded up, the ECU connectors point

downward so that they do not collect water. This might mean re-installing the ECU on

the bracket so that the ECU faces the other direction.

Figure 5: Installed C-channel bracket ECU

5. Screw the nut downward to secure the ECU to the bracket.

Installing ECUs Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 12 of 32

6. Repeat the steps above for each C-channel ECU.

Connecting Auditory Tube to ECUs Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 13 of 32

4. Connecting Auditory Tube to ECUs

Auditory tubes allow sound to be transmitted from the sensor to the ECU.

Part name

Part number

Quantity

Auditory tube

353070-000478

1/sensor

Figure 6: Auditory tubes connected to an ECU

Connecting Auditory Tubes to ECUs

1. Remove the caps from the ECU ports that you will be using. Refer to the diagrams in

Appendix B for the number of sensors per ECU.

2. Connect the loose end of the auditory tube to an ECU port. You can connect it to any

port, but we recommend connecting auditory ports in numeric order to make

configuration in the app easier.

3. Repeat the steps above for all sensors.

Securing Auditory Tubes

IMPORTANT: Do not cut or shorten auditory tubing. This could cause inaccurate readings.

Secure loose auditory tube with zip ties and verify that the tubing is NOT:

•Kinked

•Impeding product flow

•Coiled too tightly

•At risk of getting pinched when the booms are folded

•Compressed by zip ties

Connecting Harnessing Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 14 of 32

5. Connecting Harnessing

Refer to Appendix B for wiring diagrams for the steps below.

TIP: Start with harnessing on leftmost and rightmost side of the booms and work toward the

center. Then, work on harnessing toward the cab.

NOTE: The gateway uses the tractor's key switch for proper operation. Make sure that the key

switch is wired to the key switch terminal of the 3-pin power outlet in the tractor cab.

Part name

Part number

Quantity

CAN termination plug

153510-000051

2

Cab harness

353050-000054

1

Gateway harness

353050-000055

1

10' ECU harness

353050-000025

varies

20' ECU harness (810 Flex-Air only)

353050-000027

2

Power/CAN split harness

353050-000028

1

Cable ties

356070-000079

varies

5.1. Installing ECU Wiring Harnesses

1. Connect S3 of a 10’ ECU harness (353050-000025) to each ECU.

NOTE: If installing on an 810 Flex-Air, use S3 of two 20’ ECU harnesses (353050-

000027) to connect to the two middle ECUs.

2. Connect S1 of each ECU harness to S2 of the nearest ECU harness to form a daisy

chain on each boom. Do not connect S1 of the two centermost ECU harnesses until the

next step.

3. Connect S2 and S3 of the Power/CAN Split harness (353050-000028) to S1 of each of

the two centermost ECU harnesses.

4. Insert a CAN termination plug (153510-000051) into the two unused S2 ends of the

outermost ECU harnesses.

5.2. Installing Gateway Harness

1. Connect S2 of the Gateway harness into S1 of the Power/CAN Split harness (353050-

000028).

NOTE: S3 and S4 of the Gateway harness are connected in Section 6.

5.3. Connecting Cab Harness

1. Connect S1 of the Cab harness (353050-000054) into the convenience outlet of the cab.

2. Connect S2 of the Cab harness to S1 of the Gateway harness (353050-000055).

Installing the Gateway Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 15 of 32

6. Installing the Gateway

The gateway is a computing platform that sends ECU data to the iPad through the Wi-Fi

antenna.

Part name

Part number

Quantity

Gateway 260

153010-000085

1

1/4” flat washer

352012-000002

8

Gateway mounting bracket

353070-000079

1

3/8" locknut

356060-000094

4

U-bolt

356060-000152

2

3/8" washer

356060-000239

4

1/4" nut

356060-000241

4

1/4” x 2-1/2” screw

356060-000303

4

Installation Location

Mount the gateway between the cab and bins. The mounting location must be at least 8 inches

(20 cm) away from the operator to ensure safe operation.

NOTE: Your gateway may look different than the one pictured below.

Figure 7: Gateway mounting location

Installing the Gateway Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 16 of 32

Installing the Gateway

We recommend mounting the gateway to a beam between the cab and bin. If you don’t have a

beam to mount to, use the Alternate Installation instructions.

Standard Installation (mounted to a beam between the cab and bin)

Figure 8: Installing the gateway

1. Position the gateway (153010-000085) on the mounting bracket (353070-000079). The

gateway can be mounted on the bracket in any direction, but the connectors should not

face up when the bracket is mounted on the beam.

2. Secure the gateway to the mounting bracket using the provided screws (356060-

000303), washers (352012-000002), and nuts (356060-000241) as shown in Figure 8.

3. Mount the gateway to the beam using u-bolts (356060-000152). Secure with washers

(356060-000239) and locknuts (356060-000094).

Installing the Gateway Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 17 of 32

Alternate Installation (mounted directly to bin)

WARNING: Do not drill into structural framework.

1. Position the gateway (153010-000085) in a mounting location between the cab and the

bin. The connectors should not face up.

2. On the bin, mark the location of the four mounting holes shown in Figure 9. Remove the

gateway and drill out the holes using a 5/16 inch or 8 mm drill bit.

3. Secure the gateway to the sheet metal using the provided screws (356060-000303),

washers (352012-000002), and nuts (356060-000241) that are typically used to secure

the gateway to the bracket.

Figure 9: Gateway mounting holes

Connect Gateway Harness to Gateway

1. Connect S3 of the Gateway harness into Port A of the gateway.

2. Connect S4 of the Gateway harness into Port B of the gateway.

Installing Wi-Fi Antenna Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 18 of 32

7. Installing Wi-Fi Antenna

The Wi-Fi antenna sends information from the SpreadSense® system to the iPad.

Part name

Part number

Quantity

SMA cap

251015-000139

2

SMA terminator jack

251015-000272

1

Wi-Fi antenna

252005-000010

1

Antenna bracket

353070-000083

1

3/8" locknut

356060-000094

4

U-bolt

356060-000152

2

3/8" washer

356060-000239

4

Installation Location

Mount the Wi-Fi antenna on the bin between the cab and bins. Mount it at least 2 feet (60 cm)

away from the operator and at least 8 inches (20 cm) from the gateway to ensure safe

operation.

If you don’t have a beam behind the cab, find a beam within 6 feet of the cab that has line of

sight to the cab.

Figure 10: Wi-Fi antenna mounting location

Installing Wi-Fi Antenna Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 19 of 32

Installing the Wi-Fi Antenna

Figure 11: Mounting the Wi-Fi antenna

1. Thread the Wi-Fi antenna (252005-000010) cables through the hole in the mounting

bracket (353070-000083) and through the nut. Tighten the nut to secure the antenna to

the bracket. Do not over-torque.

2. Mount the bracket on a beam behind the cab using u-bolts (356060-000152), washers

(356060-000239), and locknuts (356060-000094). If you don’t have a beam behind the

cab, find a beam within 6 feet of the cab that has line of site to the cab.

3. Connect the Cellular Main and Wi-Fi/BT antenna cables to the gateway.

Figure 12: Gateway connectors

4. Cap the 433 MHz antenna cable with the SMA terminator jack (251015-000272). Zip-tie

the cable to the other cables.

5. Cover connectors 5 and 6 with the provided caps (251015-000139).

Installing Wi-Fi Antenna Recon SpreadSense®Installation Manual

600840-000046, rev 1.7 Page 20 of 32

Routing Loose Harnessing

Coil any loose harnessing around a hydraulic line or existing electrical wire and ensure that

harnessing will not get pinched when you fold the booms up. Secure all harnessing to the

implement using cable ties (356070-000079).

Table of contents

Other IntelligentAg Control System manuals

Popular Control System manuals by other brands

Hobym Observatory

Hobym Observatory TiTaN TCS Opeation Manual

Conrad

Conrad Steelmate operating instructions

LIFE home integration

LIFE home integration Probo 60 R manual

Beninca

Beninca LADY manual

Raven

Raven SBGUIDANCE SMARTRAX MD installation manual

Fagor

Fagor CP-G905 Installation, Usage and Maintenance Instructions