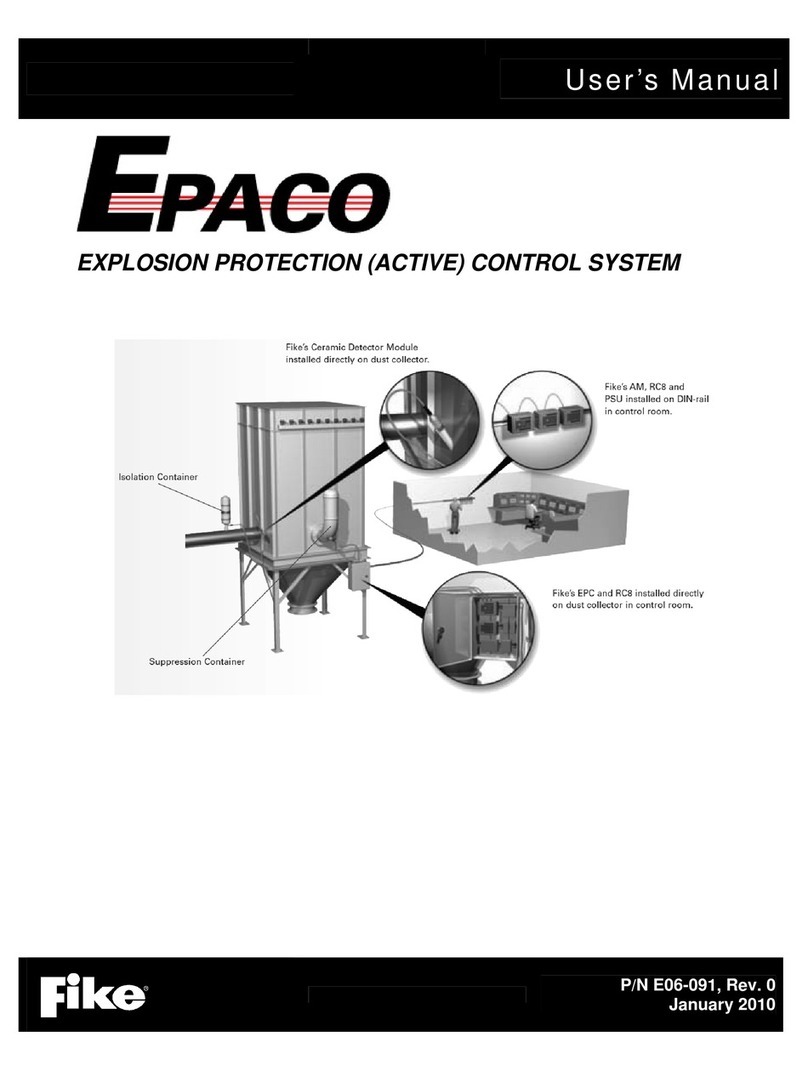

Mid-tech TASC-6100 User manual

Midwest Technologies, Inc. of Illinois

Springfield, IL 62703

TASC-6100

LIQUID/GRANULAR

APPLICATION CONTROL SYSTEM

USER GUIDE

PN - 98-05018

R2

Software Version 1.30

%Rate

DISPLAY SELECTOR

Speed

Area Width

Distance

Fan RPM

Test

Speed

PSI/Prime

Total Applied

Product Vol. Appl. Rate

OFF SET- UP DEC.

ON OPERATE INC.

123 4567 89

BOOMS

Scan

TASC-6100

Rate Controller

MID-TECH

MIDWESTTECHNOLOGIES, INC.

®

MPH

Alt.-Rate

Standard Rate

OFF

CE & STANDARD VERSION

II

CHANGE LOG

DATE: DATE CODE: PAGES AFFECTED: SW VERSION

4/24/98 98114 New Manual(TASC-6100 w/Fan RPM) 1.20

10/1/98 98114 A-4 (No Revision Change) 1.20

5/15/00 00060 All - New Format/SW, CE Console 1.30

2/20/00 01110 Corrected graphic, updatedlogo & 1.30

warranty, cleaned up text

II

98-05018

R2

CE&STANDARD V ERSION

TASC 6100

III

98-05018

R2

TASC 6100

CE&STANDARD V ERSION

TABLE OF CONTENTS

CHANGE LOG II

TABLE OF CONTENTS III

LIST OF ILLUSTRATIONS V

HOW TO USE THIS MANUAL VI

CHAPTER 1 SWITCHES AND CONTROLS 1-1

CONSOLE SWITCHES AND INDICATORS 1-1

POWER SWITCH 1-1

MODE SELECTOR SWITCH 1-1

INC / DEC SWITCH 1-2

BOOM SECTION “ON/OFF” INDICATORS 1-2

RATE SWITCH 1-2

DISPLAY SELECTOR SWITCH 1-2

IMPLEMENT STAT U S INPUT 1-6

GROUND SPEED OVERRIDE SWITCH (GSO) 1-7

CHAPTER 2 CALIBRATION 2-1

SELECTING THE A PPLICATION PROGRAM 2-1

SELECTING ENGLISH OR METRIC, UNITS 2-1

UNITS FOR EACH DISPLAY SELECTOR SWITCH POSITION 2-2

UNITS FOR EACH DISPLAY SELECTOR SWITCH POSITION 2-2

CHANGING UNITS 2-2

LIQUID/GRANULAR COMMON SETUP ITEMS 2-3

SETTING A PPLICATION RATES 2-3

SETTING THE % RATE CHANGE 2-3

SETTING BOOM WIDTHS 2-4

DISTANCE CALIBRATION - GROUND SPEED SENSOR 2-5

SETTING THE HOLD/CLOSE RESPONSE OFTHE FLOW CONTROL VALVE 2-7

SETTING THE GROUND SPEED OVERRIDE (GSO) VALUE 2-9

PRODUCT VOLUME (FULL LOAD VALUE) 2-10

RESETTING A CCUMULATORS 2-11

OPERATING UNDER EXTERNAL RAT E COMMANDS 2-11

LIQUID ONLY SET-UP2-12

SETTING THE CORRECTION FACTOR 2-12

FLOW SENSOR CALIBRATION 2-12

GRANULAR ONLY SET-UP2-20

SETTING THE PRODUCT DENSITY 2-20

SETTING THE FAN TACH CAL.# 2-20

RATE SENSOR CALIBRATION 2-21

SETTING AUTO POWER DOWN TIME 2-24

CHAPTER 3 OPERATION 3-1

NORMAL START-UP AND OPERATION 3-1

CHANGING A CTIVE BOOM SECTIONS 3-2

CHANGING APPLICATION RAT E 3-2

ALTERNATE A PPLICATION RATE 3-2

% RAT E CHANGE 3-2

PRIMING THE MAIN PUMP AND BOOM 3-3

RAPID UNLOAD USING THE CONVEYOR 3-4

GROUND SPEED OVERRIDE (GSO) 3-5

IV

98-05018

R2 TASC 6100

IVCE&STANDARD V ERSION

CHAPTER 4 MAINTENANCE 4-1

FLUSHING AND CLEANING 4-1

CONTROL CONSOLE 4-1

GROUND SPEED SENSOR 4-2

FLOW A ND PRESSURE SENSOR 4-2

CONVEYOR RATE SENSOR 4-3

FLOW CONTROL V ALVE 4-3

WIRING HARNESS 4-3

CHAPTER 5 TROUBLE SHOOTING - ERROR MESSAGES 5-1

LIQUID ERROR MESSAGES 5-1

GRANULAR ERROR MESSAGES 5-5

CHAPTER 6 EMERGENCY OPERATION 6-1

GROUND SPEED SENSOR FAILURE 6-1

FLOW CONTROL VALVE FAILURE 6-2

FLOWMETER OR PRESSURE SENSOR FAILURE 6-4

APPENDIX A - SYSTEM DIAGRAMS A-1

APPENDIX B - SYSTEM OVERVIEW B-1

HOW THE TASC 6100 CONTROLS APPLICATION RAT E B-2

TASC 6100 SYSTEM COMPONENTS B-3

AUTO TIP CONTROL B-7

EXTERNAL RATE CONTROL B-7

APPENDIX C - GLOSSARY/TABLES C-1

GLOSSARY C-2

USEFUL FORMULAS C-4

ENGLISH/METRIC CONVERSION C-4

MISCELLANEOUS NOTES C-6

CALIBRATION NUMBERS C-6

V

98-05018

R2

TASC 6100

CE&STANDARD V ERSION

List of Illustrations

FIG. 1-1. TASC CONSOLE SWITCHES AND INDICATORS 1-1

FIG. 1-2. DISPLAY SELECTOR FUNCTIONS - OPERATE MODE 1-3

FIG. 1-3. DISPLAY SELECTOR FUNCTIONS - SET-UPMODE 1-4

FIG. 1-4. TASC 6100 DEFAULT VALUES - LIQUID STANDARD MODE 1-8

FIG. 1-5. TASC 6100 DEFAULT VALUES - LIQUID PRESSURE MODE 1-9

FIG. 1-6. TASC 6100 DEFAULT VALUES - GRANULAR MODE 1-10

FIG. A1 - TYPICAL FLOW/PRESSURE BASED WIRING DIAGRAM A-2

FIG. A 2. TYPICAL FLOW/PRESSURE BASED PLUMBING DIAGRAM A-3

FIG. A 3. TYPICAL TASC 6100 GRANULAR SYSTEM WIRING DIAGRAM A-4

FIG. A 4. TASC 6100 W/AUTO TIP CONTROL WIRING DIAGRAM A-5

FIG. A 5. SERVICE FORM A-6

FIG. B-1 TASC 6100 SYSTEM DATA FLOW B-2

FIG. B-2. TASC 6100 CONSOLE B-3

FIG. B-3. GROUND SPEED RADAR B-4

FIG. B-4. FLOWMETER B-5

FIG. B-6. 100 PULSE SENSOR B-5

FIG. B-5. PRESSURE SENSOR B-5

FIG. B-7. FLOW CONTROL VALVE B-6

FIG. B-8. BOOM CONTROL SWITCHBOX B-7

FIG. B-10. DATA LINK B-7

FIG. B-9. AUTO TIP CONTROL BOX B-7

VI

98-05018

R2 TASC 6100

CE&STANDARD V ERSION

This manual is designed to provide you with the basic

information needed to set up and operate the Mid-Tech®

TASC 6100 control system. Actual procedures may vary

somewhat, depending on the configuration of your system.

When you see "Mitch", he is pointing out special information

that you should be aware of, regarding safety, preventing

console damage, an easier way to perform an operation, etc..

Below is a listing of the chapters in this manual, along with a

brief description of the information found in each chapter.

Chapter 1 - Switches and Controls - Lists each control switch,

on the face of the console, and gives a brief description of its

use.

Chapter 2 - Calibration and Setup - Takes you, step by step,

through the calibration of each sensor providing input to the

console, and entering other information the console needs to

perform the functions you require.

Chapter 3 - Operation - Briefly describes how to initiate the

application operation.

Chapter 4 - Trouble shooting - Lists possible causes and

remedies for the error codes that appear on the TASC display

if the console detects a problem.

Chapter 5 - Maintenance - Covers the basic maintenance

needed to keep your system operating at peak performance.

Chapter 6 - Emergency Operations - Suggests ways to operate,

under reduced accuracy, in the event of a major fault.

Appendix A - Sample system wiring and plumbing diagrams.

Appendix B - System Overview - Describes the major compo-

nents of the TASC system and their individual functions in

application control.

Appendix C - Glossary/Tables

Back Cover - Quick Start/Quick Set Up Guides

HOW TO USE THIS MANUAL

Mid-T

Mid-T

ech

ech

1-1

98-05018

R2

TASC 6100

Switches

& Cont.

CE&STANDARD V ERSION

%Rate

DISPLAY SELECTOR

Speed

Area Width

Distance

Fan RPM

Test

Speed

PSI/Prime

Total Applied

Product Vol. Appl. Rate

OFF SET- UP DEC.

ON OPERATE INC.

123 4567 89

BOOMS

Scan

MID-TECH

MIDWEST TECHNOLOGIES, INC.

TASC-6100

Rate Controller

®

Alt.-Rate

Standard Rate

OFF

123

4

6

5

-Ac

Flow

Gal./

Several switches and indicators serve as the

interface between the operator and the Mid-

Tech control system.

CONSOLE SWITCHES AND INDICATORS

This section shows the location of each switch

and indicator found on the TASC 6100 control

console and discusses its function in both the

Operate and Setup modes.

POWER SWITCH

The power switch (see #1 in Fig. 1-1) controls power

to the console. The CE console has an "Auto Power

Down" feature which

powers the console off

after a operator selectable

time has elapsed. The

console has a nonvolatile

memory so it "remembers"

the constants and data

previously entered, even

with the power removed.

NOTE: The “Auto Power Down Feature is only

available on the CE version of the console (CE

designation label on back of console).

MODE SELECTOR SWITCH

The Mode Selector switch (see #2 in Fig. 1-1)

switches between the OPERATE and SET-UP modes

of the control console. This switch must be in the

“OPERATE” position when applying product. The

“SET-UP”position is used for entering set-up

information into the console. In the SET-UP Mode an

“Err”message appears if a position which can not be

programmed is selected.

CHAPTER 1 SWITCHES AND CONTROLS

Fig. 1-1. TASC

Console Switches and

Indicators

1-2

TASC 6100

98-05018

R2

CE&STANDARD V ERSION

INC / DEC SWITCH

The Increase/Decrease (INC/DEC) switch (see #3 in

Fig. 1-1) is used, in both the OPERATE and SET-UP

modes, to adjust the values appearing in the display.

BOOM SECTION “ON/OFF” INDICATORS

The boom section On/Off indicators (see #5 in Fig. 1-

1) indicate which boom sections the operator has

selected. When a boom is turned on, its indicator is lit.

There are a maximum of nine boom sections available.

RATE SWITCH

The Rate Selector switch (see #6 in Fig. 1-1) is a three

position switch that allows the operator to select

either a pre-selected standard rate, an alternate rate, or

stop the application.

DISPLAY SELECTOR SWITCH

The Display Selector (see #4, Fig. 1-1) is used to

choose which of the console functions is displayed on

the screen and is available for setting by the operator.

Display Selector - Operate Mode (Liquid)

(See Fig. 1-2)

Speed: The current vehicle speed.

Area: Area Accumulator #1. The total area treated

since the counter was last reset.*

Fan RPM: Not used in liquid mode.

Product Vol: Amount of product aboard the vehicle.

Value counts down as the product is applied and

alarm sounds when 10 % of the full load is left.**

1-3

98-05018

R2

TASC 6100

Switches

& Cont.

CE&STANDARD V ERSION

INC.

567 89

MID-TECH

®

MPH

123

BOOMS

OFF DEC.

4

CH

®

OFF

ON

MIDWEST TECHNOLOGIES, INC.

SET- UP

OPERATE

567 89

MPH

123

BOOMS

OFF DEC.

4

OFF

MIDWEST TECHNOLOGIES, INC.

Rate Controller

TASC-6100

%Rate

DISPLAY SELECTOR

Speed

Area Width

Distance

Fan RPM

Test

Speed

PSI/Prime

Total Applied

Product Vol. Appl. Rate

Scan

%Rate

DISPLAY SELECTOR

Speed

Area Width

Distance

Fan RPM

Test

Speed

PSI/Prime

Total Applied

Product Vol. Appl. Rate

Scan

SET- UP

OPERATE

% Rate: The percent

of programmed

application rate

at which the

system is apply-

ing product.***

Application Rate:

Displays the

target application

rate when the

ground speed is

zero or all booms

are OFF.** The

actual application

rate is displayed

here once

application has started.

Total Applied: The total volume of product applied

since the last time the counter was reset, as

measured by the pressure sensor or flow meter.*

Impl. Width: The active boom width, (total of all

boom sections turned ON).

Distance: The total distance traveled since the last

time the counter was reset.

PSI/Prime: Used to open the control valve during

product pump priming, for fast unload, and to

display boom pressure when operating in pressure

based mode.

Test Speed: The speed the console uses for stationary

tests of the sprayer.**

Scan: The display scans Speed, Area #1, Product

Vol., Application Rate, Total Applied, and Fan

RPM, stopping at each position for approximately

two seconds before automatically cycling to the

next.

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

Fig. 1-2. Display Selector

Functions - Operate Mode

1-4

TASC 6100

98-05018

R2

CE&STANDARD V ERSION

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

INC.

567 89

MID-TECH

TASC-6100

Rate Controller

®

MPH

123

BOOMS

OFF

%Rate

DISPLAY SELECTOR

Speed

Area Width

Distance

Fan RPM

Test

Speed

PSI/Prime

Total Applied

Product Vol. Appl. Rate

Scan

DEC.

4

ON

SET- UP

OPERATE

%Rate

DISPLAY SELECTOR

Speed

Area Width

Distance

Fan RPM

Test

Speed

PSI/Prime

Total Applied

Product Vol. Appl. Rate

Scan

MIDWEST TECHNOLOGIES, INC.

SET- UP

OPERATE

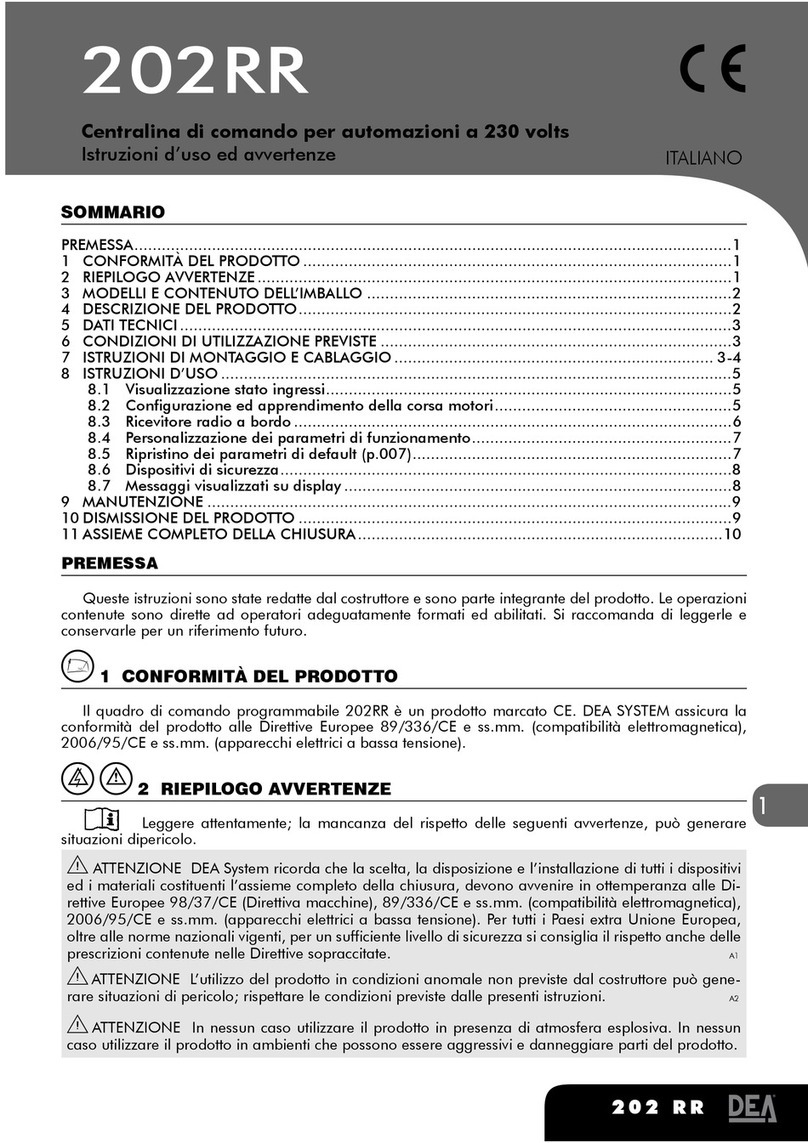

Display Selector - Setup Mode (Liquid)

(See Fig. 1-3)

Speed: Ground speed

override (GSO) value.**

Area: Area Accumulator

#2. The total area treated

since the counter was last

reset.*

Fan RPM: The current fan

RPM. calibration number.

Since not used in liquid

mode, can be set to zero to remove the fan

RPM reading from the scan feature.**

Product Volume: Used to set the full load value of the

vehicle.**

% Rate: The percent rate change value (the percent

by which the programmed application rate can be

changed with each activation of the INC/DEC

switch).**

Application Rate: Psi mode - A flow sensor cal. #

correction factor that allows for corrections due to

differences in product viscosities without changing

the base cal. #. STnrd and rEFLO modes - ERR, No

function in this mode.

Total Applied: The pressure sensor or flow meter

calibration number. NOTE: Must have all booms

ON when in REFLOW Mode.**

Width: Individual boom section widths. The display

cycles through the individual boom sections, in

order, unless a particular boom switch is activated

and the boom master switch is ON.**

Distance: The current distance calibration number.**

PSI/Prime: The current console operating mode.**

Test Speed: The current test speed.**

Scan: ERR, No function in SETUP mode.

Fig. 1-3. Display Selector

Functions - Set-Up Mode

1-5

98-05018

R2

TASC 6100

Switches

& Cont.

CE&STANDARD V ERSION

Display Selector - Operate Mode (Gran.)

(See Fig. 1-2)

Speed: The current vehicle speed.

Area: Area Accumulator #1. The total area treated

since the counter was last reset.*

Fan RPM: The current speed of the fan (spinners).

Product Vol.: Amount of product aboard the ve-

hicle.**

% Rate: The percent of programmed application rate

at which the product is being applied.***

Application Rate: Displays the target application rate,

when the ground speed is zero or all booms are

OFF. ** Once application begins, the actual

application rate is displayed here.

Total Applied: The total volume applied since the

accumulator was last reset, as measured by the rate

sensor.*

Impl. Width: The active spread width, (total of all

spreader sections turned “ON”).

Distance: The total distance traveled since the last

time the counter was reset.

Prime: Used to open the control valve. It can be used

in the granular application to unload the vehicle at

its maximum discharge rate.

Test Speed: The speed the console uses for stationary

tests of the spreader.**

Scan: The display scans Speed, Area #1, Product

Volume, Application Rate, Total Applied, and Fan

RPM (if Fan RPM Cal # not set to zero). The

display stops at each position for approximately

two seconds before automatically cycling to the

next.

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

1-6

TASC 6100

98-05018

R2

CE&STANDARD V ERSION

Display Selector - Set-Up Mode (Gran.)

(See fig. 1-3)

Speed: Ground Speed Override (GSO) value.**

Area: Area Accumulator #2. The total area treated

since the counter was last reset.*

Fan RPM: The current fan RPM calibration

number. This cal # can be set to zero to remove the

fan RPM reading from the scan feature.**

Product Volume: Used to set the full load capacity of

the vehicle.**

% Rate: The percent rate change value (the percent

by which the programmed application rate can be

changed with each activation of the INC/DEC

switch).**

Application Rate: Product density.**

Total Applied: The rate sensor calibration number

[spreader constant].**

Width: Individual boom section widths.**

Distance: The current distance calibration number.**

Prime: The current console operating mode.**

Test Speed: The current test speed.**

Scan: Err, No function in the SETUP mode.

IMPLEMENT STATUS INPUT

An external “Implement Status”input can be

used to override the TASC control. The

input must present a positive voltage (+12.0

VDC) on the boom interface cable sense line. As long

as this condition is present, the control console

operates normally. If the voltage is interrupted, the

control console automatically stops applying. At the

same time, the control console will either "HOLD" or

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

1-7

98-05018

R2

TASC 6100

Switches

& Cont.

CE&STANDARD V ERSION

"CLOSE" the control valve, depending on the

response selected by the operator. (See Page 2-7).

This feature allows the operator to control the

operation of the control valve through the normal

operation of the vehicle. The implement status input

can be used to sense the ON/OFF condition of the

main vehicle pump switch, a separate Master switch,

or, an external switch sensing an implement "UP"/

"DOWN" condition.

GROUND SPEED OVERRIDE SWITCH (GSO)

If your TASC system includes an optional MID-

TECH®Boom Control Switch Box, the GSO

switch is already installed. An optional, externally

mounted, GSO switch can be used to temporarily

operate the vehicle using a pre-selected GSO mini-

mum speed rather than the actual speed registered by

the ground speed sensor. The override feature is used

to allow the vehicle to reach the application rate

quickly when starting from a complete stop or to

maintain a good application pattern when the vehicle

is moving at very low ground speeds. It can also be

used to allow the operator to flush or empty the tank

of a sprayer, or empty the bed of a spreader, from the

cab, with the vehicle stopped.

The control console operates normally as long as the

GSO switch condition is open (OFF). Whenever the

override switch is closed (ON) and the actual ground

speed is less than the GSO Speed, the control console

automatically uses the GSO Speed to control applica-

tion rate. As soon as the switch reverts to its normally

open (OFF) condition, or the actual ground speed

increases above the preset GSO speed, the control

console will adjust the rate based on the actual ground

speed.

CAUTION: Controlling application rates based on

a GSO Speed is not as accurate as using the actual

ground speed. When GSO is being used and the true

ground speed is less than the GSO speed", the

console sounds an alarm and the display flashes a

"Too Slow" message to warn the operator of over

application.

Mid-T

Mid-T

ech

ech

Fig. B-8, in Appendix B,

shows a “Boom Control

Switch Box” which incorpo-

rates the Implement Status

Switch and the GSO function

into one switch. The “OFF”

position provides a Status

Switch “OFF” condition,

“AUTO” furnishes Status

Switch ON, and “GSO”

activates the GSO function.

Other methods of controlling

these functions are also

available. This switchbox

also includes an individual

ON/OFF switch for each

boom section.

1-8

TASC 6100

98-05018

R2

CE&STANDARD V ERSION

SOFTWARE VER. 1.30

LIQUID STD MODE

Preset #1

TASC 6100, DISPLAYED VALUES WHEN IN

Area

Speed

Scan

Test Speed

Fan RPM

Product Vol.

% Rate

Application Rate

Total Applied

Impl. Width

Distance

PSI/Prime

-----

100

10.0/12.0

10.0

Default values shown in upper left of boxes.

OPERATE

Hold increase switch to drive valve OPEN

Use INC/DEC switch to change up or down

Use INC/DEC switch to change up or down

Use DEC switch to zero display

Use INC switch to set full load,

INC/DEC to change

Use DEC switch to zero display

Use INC/DEC switch to change up or down

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

99362

TASC 6100, DISPLAYED VALUES WHEN IN

Area

Speed

Scan

Test Speed

Fan RPM

Product Vol.

% Rate

Application Rate

Total Applied

Impl. Width

Distance

PSI/Prime

C

1

2

3

4

5

6

7

8

9

960

120

200

320

200

120

0

0

0

0

1000

Stnrd L

Err

Default Custom

0.0

10

500

71.0

10.0/

7.0

Default values shown in upper left of boxes.

Use the INC/DEC switch to change values.

SET-UP

DEC sets to granular

INC sets to liquid

Ground Speed Override

Full Load Amount

Rate Change Increment

Rate Sensor Cal#

Distance Sensor Cal#

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

SOFTWARE VER. 1.30

LIQUID STD MODE

Preset #1

1.00

Correction factor

2.00

Fig. 1-4. TASC 6100 Default Values

- Liquid Standard Mode

1-9

98-05018

R2

TASC 6100

Switches

& Cont.

CE&STANDARD V ERSION

SOFTWARE VER. 1.30

LIQUID PSI MODE

Preset #1

TASC 6100, DISPLAYED VALUES WHEN IN

Area

Speed

Scan

Test Speed

Fan RPM

Product Vol.

% Rate

Application Rate

Total Applied

Impl. Width

Distance

PSI/Prime Ps---

100

10.0

10.0

Default values shown in upper left of boxes.

OPERATE

Hold increase switch to drive valve OPEN

Use INC/DEC switch to change up or down

Use INC/DEC switch to change up or down

Use DEC switch to zero display

Use INC switch to set full load,

INC/DEC to change

Use DEC switch to zero display

Use INC/DEC switch to change up or down

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

99362

TASC 6100, DISPLAYED VALUES WHEN IN

Area

Speed

Scan

Test Speed

Fan RPM

Product Vol.

% Rate

Application Rate

Total Applied

Impl. Width

Distance

PSI/Prime

C

1

2

3

4

5

6

7

8

9

960

120

200

320

200

120

0

0

0

0

1000

PSi

Err

Default Custom

0.0

10

500

10.0/12.0

10.0

7.0

Default values shown in upper left of boxes.

Use the INC/DEC switch to change values.

SET-UP

DEC sets to granular

INC sets to liquid

Ground Speed Override

Full Load Amount

Rate Change Increment

Rate Sensor Cal#

Distance Sensor Cal#

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

SOFTWARE VER. 1.30

LIQUID PSI MODE

Preset #1

1.00

Correction factor

2.00

Fig. 1-5. TASC 6100 Default Values

- Liquid Pressure Mode

1-10

TASC 6100

98-05018

R2

CE&STANDARD V ERSION

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

SOFTWARE VER. 1.30

GRANULAR MODE

Preset #1

TASC 6100, DISPLAYED VALUES WHEN IN

Area

Speed

Scan

Test Speed

Fan RPM

Product Vol.

% Rate

Application Rate

Total Applied

Impl. Width

Distance

PSI/Prime

-----

100

200/250

10.0

Default values shown in upper left of boxes.

OPERATE

Hold increase switch to drive valve OPEN

Use INC/DEC switch to change up or down

Use INC/DEC switch to change up or down

Use DEC switch to zero display

Use INC switch to set full load,

INC/DEC to change

Use DEC switch to zero display

Use INC/DEC switch to change up or down

99362

TASC 6100, DISPLAYED VALUES WHEN IN

Area

Speed

Scan

Test Speed

Fan RPM

Product Vol.

% Rate

Application Rate

Total Applied

Impl. Width

Distance

PSI/Prime

C

1

2

3

4

5

6

7

8

9

720

360

360

0

0

0

0

0

0

0

1000

Stnrd C

Err

Default Custom

SOFTWARE VER. 1.30

GRANULAR MODE

Preset #1

0.0

10

10750

1630.0

10.0

7.0

Default values shown in upper left of boxes.

Use the INC/DEC switch to change values.

SET-UP

DEC sets to granular

INC sets to liquid

Ground Speed Override

Full Load Amount

Rate Change Increment

Rate Sensor Cal#

Distance Sensor Cal#

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

65.0

Density

2.00

Fig. 1-6. TASC 6100 Default Values

- Granular Mode

2-1

98-05018

R2

CE & StandardVersion

TASC 6100

Setup

& Cal.

CHAPTER 2 CALIBRATION

NOTE: PLEASE READ THROUGH THE FOLLOW-

ING SECTIONS COMPLETELY BEFORE YOU

BEGIN CALIBRATION!

Specific information about your applicator (i.e.

application rates, boom widths, test speed, etc.)

must be programmed into the control console and

the flow/rate and ground speed sensors must be calibrated

before the system is ready to use. The calibration and set

up procedures are not difficult but must be followed

precisely in order to get the maximum possible accuracy

out of the system.

SELECTING THE APPLICATION PROGRAM

8erify that the proper console application pro

gram is selected.

To view the program currently selected, set the Mode switch

to Setup and the Display Selector to PSI/Prime.

To change programs, hold the INC. switch up to set LIQUID

and cycle between standard, reflow, and pressure. Hold the

DEC. switch down to set GRANULAR and cycle between

standard and split drive. The display changes about every

ten seconds. The program being displayed, when the INC./

DEC. switch is released, is the program selected. If you have

a question about which application to use, check with your

dealer or call MID-TECH Customer Service.

SELECTING ENGLISH OR METRIC, UNITS

The control console is capable of displaying either

US or Metric units of measure.

Mid-T

Mid-T

ech

ech

Pump L PSi(bAr) is LIQUID PRESSURE application (normal pressure based spraying)

Pump L STnrd is STANDARD LIQUID application (normal flow based spraying)

Pump L rEFLO is LIQUID REFLOW application (for use on some European sprayers)

Pump C STnrd is standard GRANULAR application (single conveyor spreaders)

Pump C SPLit is GRANULAR SPLIT DRIVE application (dual conveyor spreaders)

2-2

TASC 6100

98-05018

R2

CE&STANDARD V ERSION

CHANGING UNITS

A. Set the console switches to the following positions:

1. Power ON

2. Mode Selector OPERATE

3. Display selector Speed

The display shows the current speed units.

B. Hold down the INC./DEC. switch for approximately

5 sec. The display alternates between MPH (US) and

KPH (Metric). Release the switch when the mode

that you desire is being displayed.

DISPLAY SELECTOR

Speed

Area Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Fan RPM

BOOMS

123456789

% Rate

A-1 A-2

A-3

B

UNITS FOR EACH DISPLAY SELECTOR SWITCH POSITION

(Liquid Mode)**

POSITION US METRIC

Speed Miles/Hour (mph) Kilometers/Hour (kmph)

Field Area Acres (acre) Hectares (ha)

Total Area Acres (acre) Hectares (ha)

Product Vol. US Gallons (gal.) Liters (l)

Appl. Rate US Gallons/acre (gpa) Liters/Hectare (l/ha)

Total Applied US Gallons (gal.) Liters (l)

Impl. Width Inches - Feet (in., ft.) Meters (m)

Distance Feet - Miles (ft.-miles)* Meters - Kilometers (m-km)*

Test Speed Miles/Hour (mph) Kilometers/Hour (kmph)

UNITS FOR EACH DISPLAY SELECTOR SWITCH POSITION

(Granular Mode)**

POSITION US METRIC

Speed Miles/Hour (MPH) Kilometers/Hour (KPH)

Field Area Acres (Ac) Hectares (-Ha)

Total Area Acres (Ac) Hectares (-Ha)

Product Vol. Pounds (lb) Kilograms

Appl. Rate pounds/Acre (lb/Ac) Kilograms/Hectare (-Ha)

Total Applied Pounds-Tons (lb -Tons) Kilograms-Metric Tons

Impl. Width Inches-Feet (In.-Ft.) Meters (Meters)

Distance Feet-Miles (Ft.)* Meters-Kilometers (Meters)*

Test Speed Miles/Hour (MPH) Kilometers/Hour (KPH)

Prod. Density Pounds/Cubic Ft. (Cu Ft.) Kilograms/Tenths Meter3(Meters Cu)

* No units displayed after roll over of feet to miles or meters to kilometers

** Items in parenthesis are the abbreviations that appear on the screen.

2-3

98-05018

R2

CE & StandardVersion

TASC 6100

Setup

& Cal.

Setting the APPLICA-

TION RATE to 0.0 will

turn off the flow

control function.

DISPLAY SELECTOR

Speed

Area Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Fan RPM

BOOMS

123456789

% Rate

A-1 A-2

A-3

B

Alt.-Rate

Standard Rate

OFF

A-4

DISPLAY SELECTOR

Speed

Area Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Fan RPM

BOOMS

123456789

% Rate

A-1 A-2

A-3

B

Alt.-Rate

Standard Rate

OFF A-4

LIQUID/GRANULAR COMMON SETUP ITEMS

SETTING APPLICATION RATES

The TASC 6100 system is designed to maintain a

constant, pre-selected application rate. In order for

the control console to do this, the operator must

enter the desired application rate. Two, switch selectable,

rates can be pre-programmed into the console.

Standard Rate

A. Set the console switches to the following positions:

1. Power ON

2. Mode Selector OPERATE

(APPLICATION RATE IS SET IN THE OPERATE MODE!!!)

3. Display Selector Application Rate

4. Rate switch Standard Rate

The display shows the current application rate.

B. Use the INC./DEC. switch to set the desired rate.

Alternate Rate

C. Set the console switches to the following positions:

1. Power ON

2. Mode Selector OPERATE

(APPLICATION RATE IS SET IN THE OPERATE MODE!!!)

3. Display Selector Application Rate

4. Rate switch Alt.- Rate

The display shows the current application rate.

D. Use the INC./DEC. switch to set the desired rate.

SETTING THE % RATE CHANGE

This feature allows the operator to change the

application rate “ON THE GO”with a simple

actuation of the INC./DEC. switch. The amount of

change each switch actuation makes is proportional to

the value programmed into this position, (e.g. 20 =20%

2-4

TASC 6100

98-05018

R2

CE&STANDARD V ERSION

change in the target rate). For example, with the applica-

tion rate set to 10.0 gallons per acre, a single actuation of

the INC. switch causes the system to control flow at the

rate of 12.0 gallons per acre (10.0 + 20% = 12.0).

A. Set the console switches to the following positions:

1. Power ON

2. Mode Selector SET-UP

3. Display Selector % Rate

The display shows the current % change value.

B. Use the INC./DEC. switch to set this number to the

desired % change value.

SETTING BOOM WIDTHS

The MID-TECH control console is designed to

automatically compensate for changes in the swath

width, caused by turning boom sections on or off.

To accurately respond to changes in swath width, the

console must know the length of each boom section. Use

the following procedure to set boom section widths.

A. Set the console to the following positions;

1. Power ON

2. Mode Selector SET- UP

3. Display Selector Impl. Width

4. Boom switches OFF

(or Master switch)

The display cycles through each boom position (1

through 9) and displays its current width in inches

(meters).

B. As each boom position appears on the display, use

the INC./DEC. switch to set the display to the

number of inches (meters) covered by that boom.

Repeat for each section.

C. Set all unused boom sections to a width of zero “0”

inches (meters). This insures that accidentally

turning a boom switch ON doesn’t affect the control

console. (An ERROR 0 Boom # will then result if an

unused boom gets accidentally turned on)

DISPLAY SELECTOR

Speed

Area Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON OPERATE INC.

Scan

Product Vol.

Fan RPM

BOOMS

123456789

% Rate

A-1 A-2

A-3

B

DISPLAY SELECTOR

Speed

Area Impl. Width

Distance

Test

Speed

PSI/Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Fan RPM

BOOMS

123456789

% Rate

A-1 A-2

A-3

B, C, D, E

E

MASTER

ON

OFF

MI

A-4

E

Table of contents

Popular Control System manuals by other brands

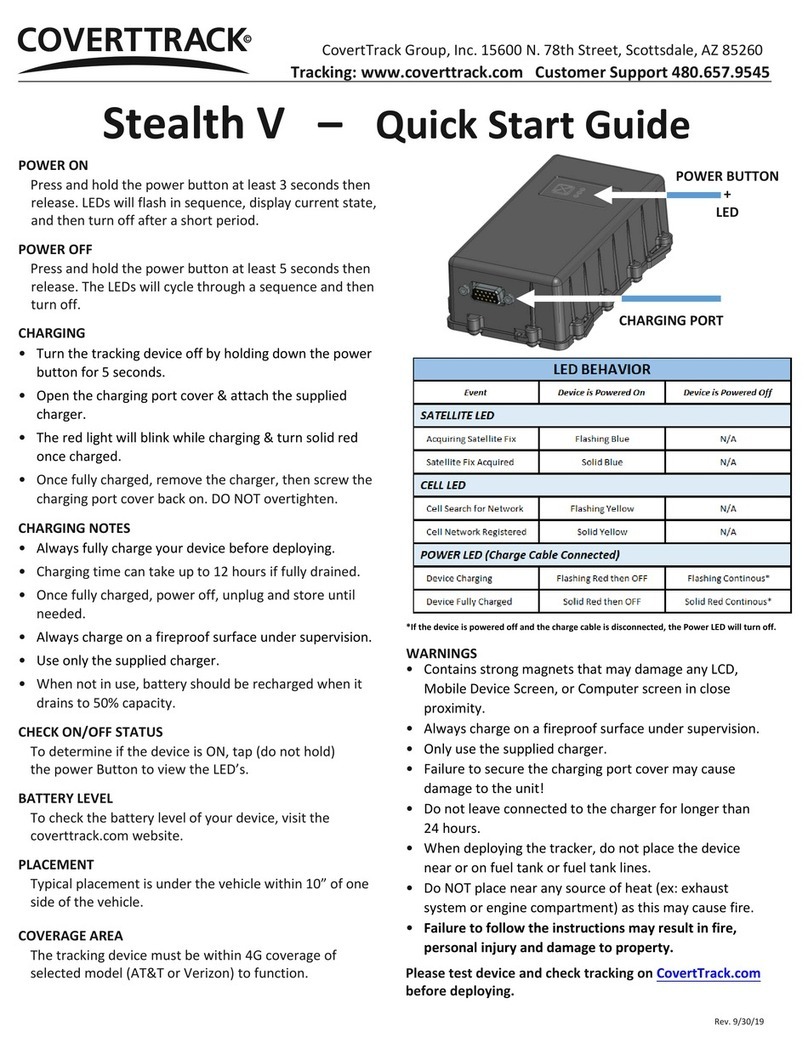

COVERTTRACK

COVERTTRACK Stealth V quick start guide

Siemens

Siemens SIMOTION P320-3 manual

Amco Veba

Amco Veba S Operator's manual

Whelen Engineering Company

Whelen Engineering Company CanTrol Basic with Traffic Advisor Installation & operating guide

SALUPO

SALUPO MULTIPLUS 2 Instruction and installation manual

Siemens

Siemens SINUMERIK 840D sl Programming manual