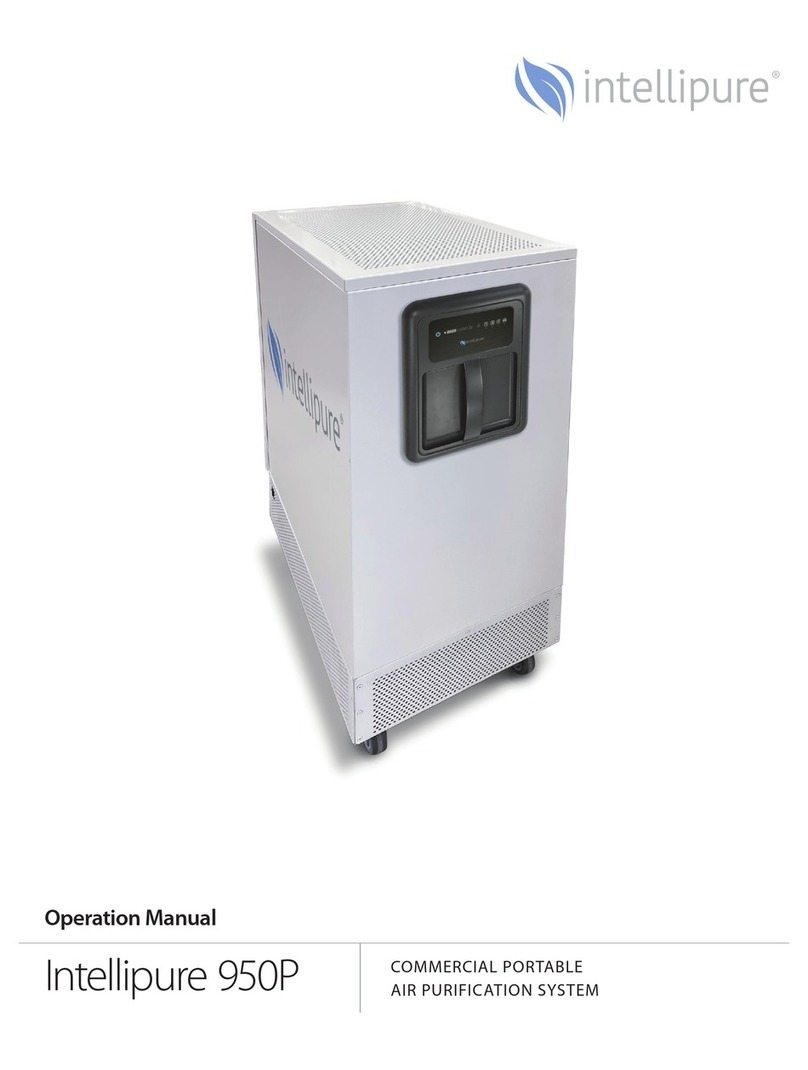

Intellipure 950P User manual

Installation Manual

950P

PORTABLE AIR CLEANING SYSTEM

2015 #10065

950P

PortableAirCleaningSystem

Installation and Operation Manual

Intellipure’s DDFSTechnology (Disinfecting Filtration System)surpassesallothertypesoffiltration.This

revolutionary technologytrapsmicroorganismssuchasbacteria,moldandviruses,reducesbioburdenandinhibits

microorganism’s growth through Microbiostatic condition, resulting in the most powerful indoor air purification in the

world.

SPECIFICATIONS

•

12gaugealuminumconstruction

•

ButterflyLatchbackdoorforaccess

•

High-memory sponge neoprene door

gasketstoensuredoortofilterseal

•

Aluminum filter track design for 2”

standardprefilterandatrackforHigh

EnergyGridFrame

•

Apolypropylenefinsealonthemainfilter

tracktoeliminatefilterairbypass

•

Designedforcontinuousoperation

•

Op

e

r

a

t

e

s

a

t

120/

22

0

V

,

5

0

/

6

0

H

z

,

4.4

/

2

.

2a

m

p

FEATURES

•

High Air Flow Capacity

–delivershighCFMwithlow

energy consumption

•

Wattage

•

MobileDesign–builtin3.5”safetylockswivelcasters,fullwidth

handle for easy movement

•

Multiple Fan Speeds

–fourfanspeedsforeaseofcontrol

•

99.99% DFS Filtration Efficiency

–downtoasizeof0.007microns

•

IndependentAirflow/DistributionControl–tofacilitate

placement anywhere in the space

•

Patented V-Bank Filter

–increases surface area and provides

higher dust loading capacity

•

Three times longer filter span

–comparedtoconventional

HEPA Filtration –Lower Maintenance Cost

•

HousingDesign

–5052paintedmarinegradealuminum,provides

a100%sealaroundthefilter

•

Ease of Maintenance

–quickreleasefilteraccessfromtheback

sideoftheunit.

•

Optional

V-

bankVOCFilter(70lbs–AdsorbentBlend)

HydratedPhoto

Catalytic Oxidation (HPCO) Odor-TVOC

Cartridge

Low

Medium

High

Turbo

334 m3/hr

660 m3/hr

1000 m3/hr

1500 m3/hr

210 CFM

415 CFM

630 CFM

950 CFM

Low

Medium

High

Turbo

50 watts

90 watts

172 watts

450 watts

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

©Intellipure 2015

#10065

3

© Intellipure 2015

Part Number: #10065

Copyright: © 2015 All rights reserved.

Address: Intellipure, Inc.

3420 Maple Ave.

Pulaski, NY 13142

Phone No: 1-315-298-2904

1-800-843-3860

Fax No: 1-315-298-6992

Email: info@Intellipure.com

LIMITED WARRANTY

This one year Limited Warranty applies only to the repair and replacement of any manufactured or supplied part of

this product which, upon inspection by Intellipure authorized personnel, proves to have failed in normal use due to

defects in material or workmanship. A return authorization must be obtained before any product is shipped to the

manufacturer for warranty repair and all transportation charges must be prepaid all work must be performed by a

Intellipure authorized technician. The sole responsibility of Intellipure under this Limited Warranty is, at its sole

discretion, to either repair or replace a duly registered product (or defective part thereof) with the same

comparable model within a reasonable period of time, subject to the following exclusions, limitations, statutory

rights, and warranty claim procedures. This Limited Warranty is exclusive, and Intellipure expressly disclaims all

other or additional warranties, whether written or oral, expressed or implied, including, but not limited to,

warranties of merchantability, workmanship, or fitness for a particular purpose.

Exclusions:

A. This Limited Warranty does not apply, or is void, as to any product or part damaged by (1) accident, misuse,

abuse, or lack of reasonable care or normal maintenance; (2) installation or operation under conditions other

than those recommended by Intellipure; (3) subjection of the product to any but the specified voltage;

(4) servicing or disassembly by unauthorized personnel; (5) defacing the serial number; or (6) modifying the

original factory assembled unit in any way.

B. THIS LIMITED WARRANTY DOES NOT APPLY TO SHIPPING CHARGES FOR PRODUCT SHIPPED TO OR

FROMTHEFACTORYORDESIGNATEDSERVICECENTERINCONNECTIONWITHWARRANTYCLAIMSNOR

DOESITAPPLYTOANYDAMAGESOCCURRINGDURINGSUCHSHIPMENT.

C. This Limited Warranty does not apply to labor for installation, removal, re-installation, and/or travel or shipping

expenses and related expenses.

This Limited Warranty does not apply to replaceable filters.

Limitations:

Intellipure shall not be liable for property, incidental, and/or consequential damages of any kind and, unless otherwise

prescribed by applicable state law, Intellipure shall not be liable for personal injury resulting from malfunctions,

defects, misuse, improper operation or installation, or alteration of an Intellipure product or any part thereof. The

exclusive remedy for a breach of this Limited Warranty is the repair or replacement of the defective product. In no

case, shall liability under any other remedy prescribed by law exceed the purchase price of the product.

Warranty Claim Procedure:

This information is provided as a guide regarding warranty claim procedures for Intellipure air purification systems.

1.

Determine model number from the label on the unit.

2.

For technical support, warranty information, warranty parts or replacement parts, call Intellipure and a

representative will help you troubleshoot and diagnose the problem. Warranty matters involving products sold

through a manufacturer representative should be directed to the appropriate representative.

3.

Important: Do NOT return anything without a Return Authorization.

4.

All returned parts are quality tested. If the returned part is found not to be defective, you may be invoiced for the

new part.

The following is a history of the Instruction Manual

for

950P Portable Air Cleaning System Initial Printing

................ 7/2015

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

© Intellipure 2015

#10065

5

© Intellipure 2015

Safety Precautions

SAFETY PRECAUTIONS

Personnel, who will operate this system, or those who will perform maintenance thereon, must be given all

manuals and other instructions regarding safe operation of the filtration system.

This manual contains general recommendations, but specific requirements may apply to individual

installations. Such requirements are outlined in federal, state, and local codes. Compliance with

applicable codes and strict adherence to these installation instructions are the sole responsibility of the user.

This symbol will be used throughout this manual to indicate safety checkpoints.

Failure to heed these warnings and notices may result in damage to the unit and/or

injury or death topersonnel.

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

© Intellipure 2015

#10065

7

© Intellipure 2015

TableofContents

Safety Precautions .......................................................................... 5

Receiving and Unpacking................................................................9

Receiving.........................................................................................9

Storage ............................................................................................9

Unpacking and Inspection.............................................................10

System Overview ........................................................................11

Unit Description..............................................................................11

Component Description.................................................................12

Installation Procedures.......................................................13

Power Requirements .....................................................................13

Location Determination..................................................................13

System Operation...........................................................................15

Electrical Connection..................................................................................15

To Turn On the Unit.....................................................................................15

To Turn Off the Unit.....................................................................................15

Maintenance ...................................................................................17

Prefilter Replacement ....................................................................17

VOC PostFilter Replacement........................................................17

V-Bank Main Filter Replacement......................................................18

Cleaning the Unit ...........................................................................19

Parts List........................................................................................20

Troubleshooting............................................................................. 21

DFS Troubleshooting Guide...........................................................22

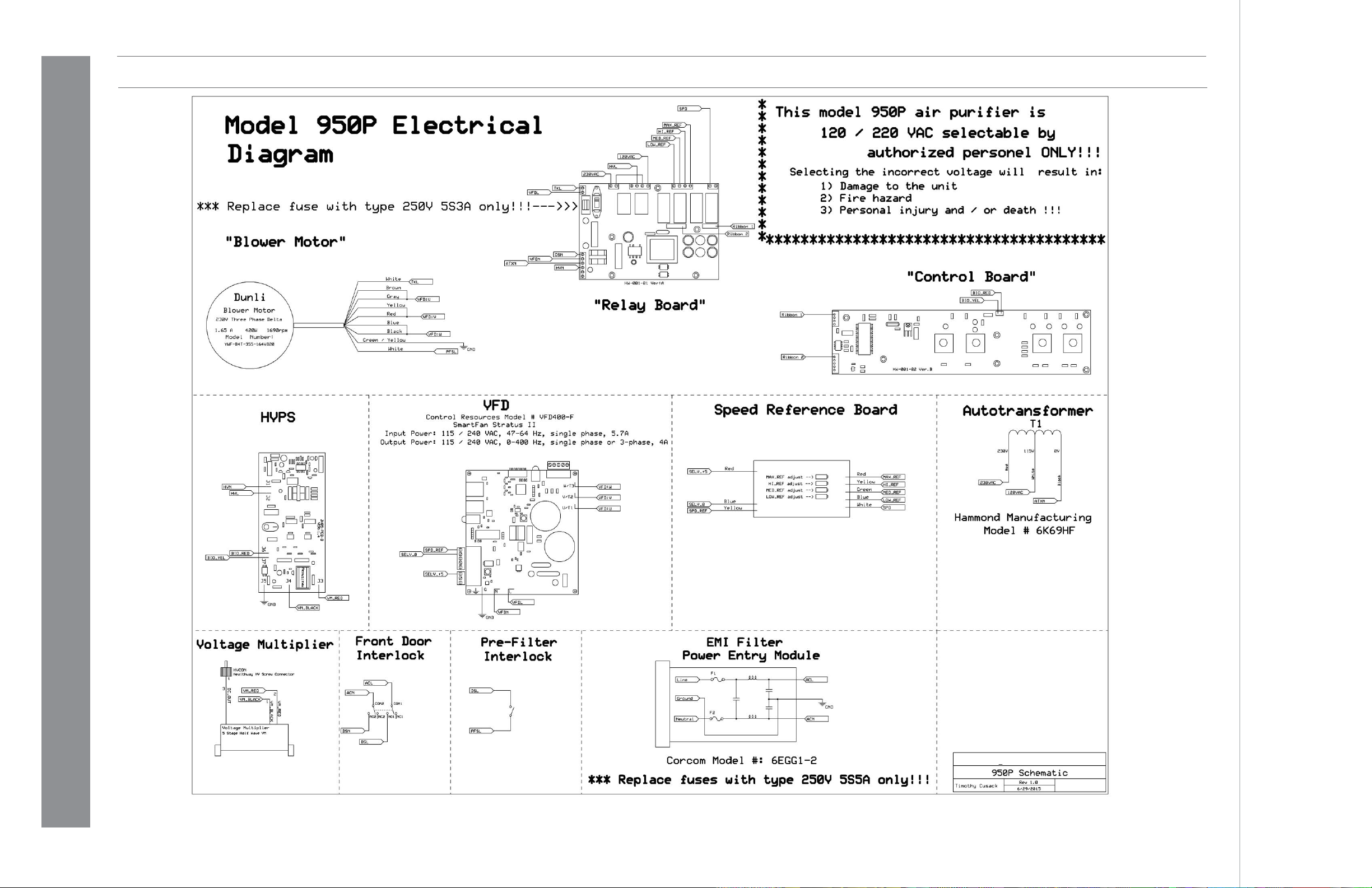

Figures and Schematics.............................................................1-1

950PSchematic.............................................................................1-1

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

© Intellipure 2015

#10065

9

© Intellipure 2015

System Overview

ReceivingandUnpacking

RECEIVING

Your unit has been car fully packed to avoid damage in shipping and storage. Equipment is prepared for

shipment in accordance with the Uniform Freight Classification. It is thoroughly inspected at the factory and

barring damage in transit, should be received in good condition.

When a freight carrier signs the Intellipure bill of lading, the carrier accepts the responsibility for any

subsequent shortages or damage evident or concealed. Inspection by the carrier of damage evident or

concealed must be requested. Evident shortage or damage should be noted on the carrier’s delivery

document before signature of acceptance. Claims must be made against the carrier by the purchaser.

Filtration systems are shipped as fully assembled filter units.

STORAGE

Store it in a dry place protected against moisture, dust, physical damage, weather, corrosion and excessive heat.

Must install the V-Bank Main Filer before running the unit.

For long term storage, unit must be turned on and run at low speed for 8 hours

every 6 months to recondition the capacitors in the VFD.

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

10

© Intellipure 2015

#10065

11

© Intellipure 2015

ReceivingandUnpacking System Overview

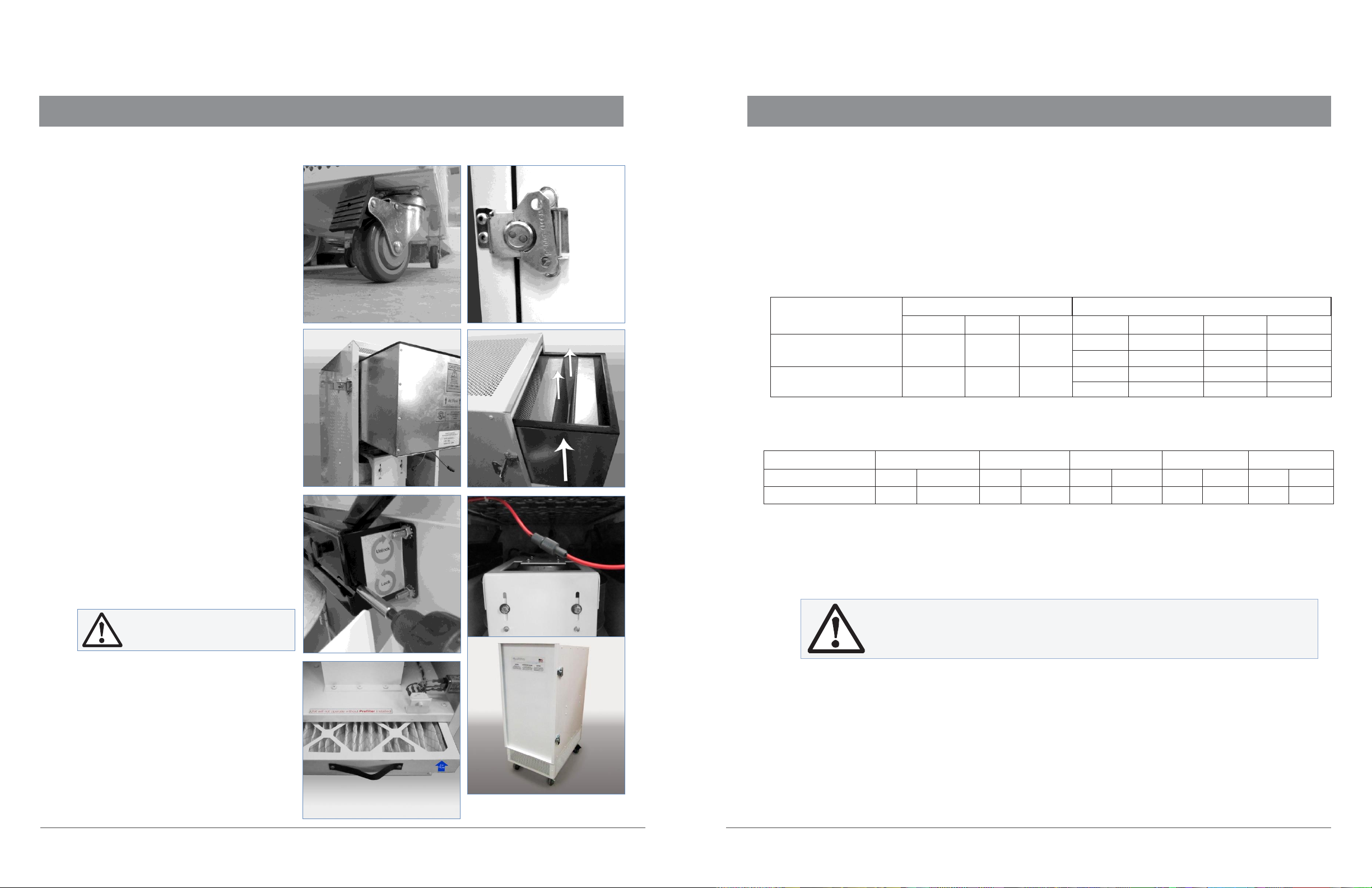

UNPACKING AND INSPECTION

To prevent damage during shipping, the V-

Bank Main Filter and High Energy Grid

Assembly are packaged separately from

the main unit.

To un-crate, remove the strapping, box tops

and additional wrappings around the unit

and V-Bank Main Filter and High Energy

Grid Assembly.

Inspect for damages not previously evident.

Lock the (2) front wheels to secure the

unit. (fig-A)

Remove the Filter Access Door located in

the back of the unit using the four butterfly

latches located on the sides of the unit.

Lift the latch wings (4) and turn

counter-clockwise to open. (fig-B)

Filter Access Door removal may require a

firm pulling effort.

Slide the V-Bank Main Filter and High

Energy Grid Assembly into the unit. Take

note that the labels will be facing outward

with the airflow arrow pointing upwards.

(fig-C) (fig-D)

Using the Magnetic Bit Holder provided,

alternate tightening the left and right

Scissor Locking Mechanisms located near

the motor plate in the filter. (fig-E)

Connect the High Voltage Lead. (fig-F)

Ensure the Prefilter is firmly seated.

The unit will not run if the Prefilter is

not installed correctly. (fig-G)

Return the Filter Access Door. Lift the

latch wings (4) and turn clockwise

to close. (fig-H)

UNIT DESCRIPTION

The 950PAir Cleaning System is a high performance system that utilizes patented award winning

Disinfecting Filtration System technology. DFS technology electrically enhances a low efficiency, high flow,

low-pressure drop filter to high efficiency while retaining the low pressure drop and longer life advantages of

the base filter material. This technology has also been shown to inhibit bacteria growth onthe filter.

The 950PPortable DFS Air Cleaning System is available in the following models:

Model

Power Requirement

Air Flow Capacity

V

Hz

Phase

Low

Medium

High

Turbo

950P

120

50/60

1

334 m3/hr

660 m3/hr

1000 m3/hr

1500 m3/hr

210 CFM

415 CFM

630 CFM

950 CFM

950P

220

50/60

1

334 m3/hr

660 m3/hr

1000 m3/hr

1500 m3/hr

210 CFM

415 CFM

630 CFM

950 CFM

Height

Width

Depth

Weight

Ship Wt

950PUnit

44in

1,118mm

18in

457mm

28in

711mm

155 lb

70 kg

254 lb

116 kg

V-Bank VOC Filter

57in

1,448mm

18in

457mm

28in

711mm

81 lb

37 kg

fig-B

fig-D

fig-F

fig-A

fig-C

fig-E

Do not over-tighten the

Scissor Lock Clamps.

fig-G

fig-H

Please confirm your model number and follow the instructions for that model. The

electrical power requirements for each individual unit are on the data plate label

adjacent to the electrical connections. These requirements supersede all other

inferences to power requirements.

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

12

©Intellipure 2015

#10065

13

©Intellipure 2015

SystemOverview

Installation Procedures

COMPONENT DESCRIPTION

The 950P Portable DFS Air Cleaning System integrates the system components into a single, portable unit:

the Prefilter, V-Bank Main Filter and the High Energy Grid are accessible from the back service door. The unit

is also remotely controllable by using a remote control. The fan inlet screen is located on the bottom side of

the unit and provides protection from loose items being drawn into the fan and thus damaging the unit and

the internal components.

Electrical controls are located on the front of the unit. It consists of the Main Power ON-OFF switch with a

Blue LED to indicate HVPS power status, Blower Speed Status and Blower Speed Control Switch.

Replacement Filters

Efficiency

Replacement Period*

Prefilter

MERV-8 (30% Efficiency)

1-2 times per year

VOC Post Filter

Formaldehyde > 99%

Benzine > 99%

Toluene > 99%

1/2” Filter: 2 times per year

Optional V-Bank: once a year

DFS V-Bank

Main Filter

99.99% Efficient

(down to .007 microns)

once a year

*Replacement period depends on the level of pollution in the environment

POWER REQUIREMENT

The power requirements are as follows:

*Electrical disconnects may also be required - check local electrical codes

Model

Power

FLA

Power Usage

Max Start-up

V

Hz

Phase

AMPS

WATTS

950P

120

50/60

1

4.44

590

950P

220

50/60

1

2.21

560

LOCATION DETERMINATION

The 950P is designed as a portable floor model. Place the air purifier anywhere in the room; being careful

not to block air from “entering” the intake grill, or “exiting” the top grill cover.

Do not place the air purifier where drapes or other objects block airflow.

For best performance, it is recommended to place the air purifier at least two (2) feet from walls and

other obstructions.

Place the unit on a flat and level surface to allow continuous airflow to the bottom intake and out the top

outlet grill.

Do not run power cord under carpeting or near heaters, registers, radiators, stoves or fireplaces. To avoid a

tripping hazard, keep the power cord away from traffic areas.

Never operate the air purifier in areas where combustible gases or vapors are present or any other

flammable materials.

Do not operate unit using an extension cord.

The filter unit will not turn on without the Prefilter installed and firmly seated.

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

© Intellipure 2015

#10065

15

© Intellipure 2015

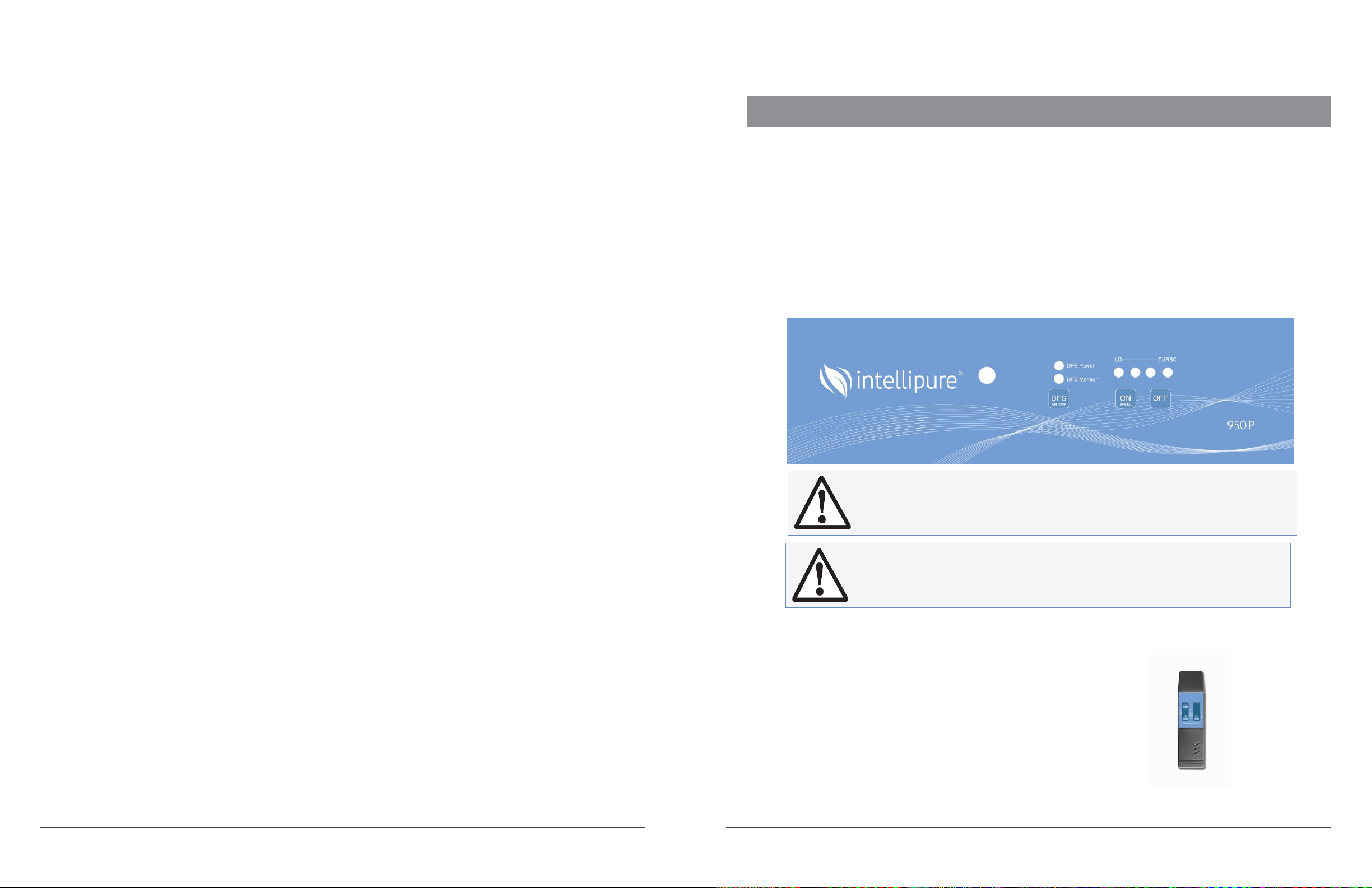

System Operation

ELECTRICAL CONNECTION

Inspect power cord for damage before plugging in.

The outlet must be grounded.

TO TURN ON THE UNIT

Plug the unit in. Turn on the ON/SPEED located on the front of the unit, the power indicator should

illuminate, indicating the power is on, the Blue LEDS indicating blower speed and DFS function should also

come on. (fig-I)

TO TURN OFF THE UNIT

To turn off the unit, simply turn off the main switch located on the front of the unit.

Do not connect power to the unit until the High Energy Grid wires have been

checked for proper connection. (Refer to page 10)

fig-I

LO

TURBO

®

950P REMOTE

Each unit is also equipped with a Remote Control. (fig-J)

The Remote has 3 buttons:

fig-J

ON/SPEED Turns the unit on and controls the speed of the fan.

OFF Turns the unit off

FS Turns the FS on andoff

®

Disconnect power to the unit before servicing. Moving Parts inside.

Wait 30 seconds after turning the unit off before opening the Filter Access

Door.

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

© Intellipure 2015

#10065

17

© Intellipure 2015

Maintenance

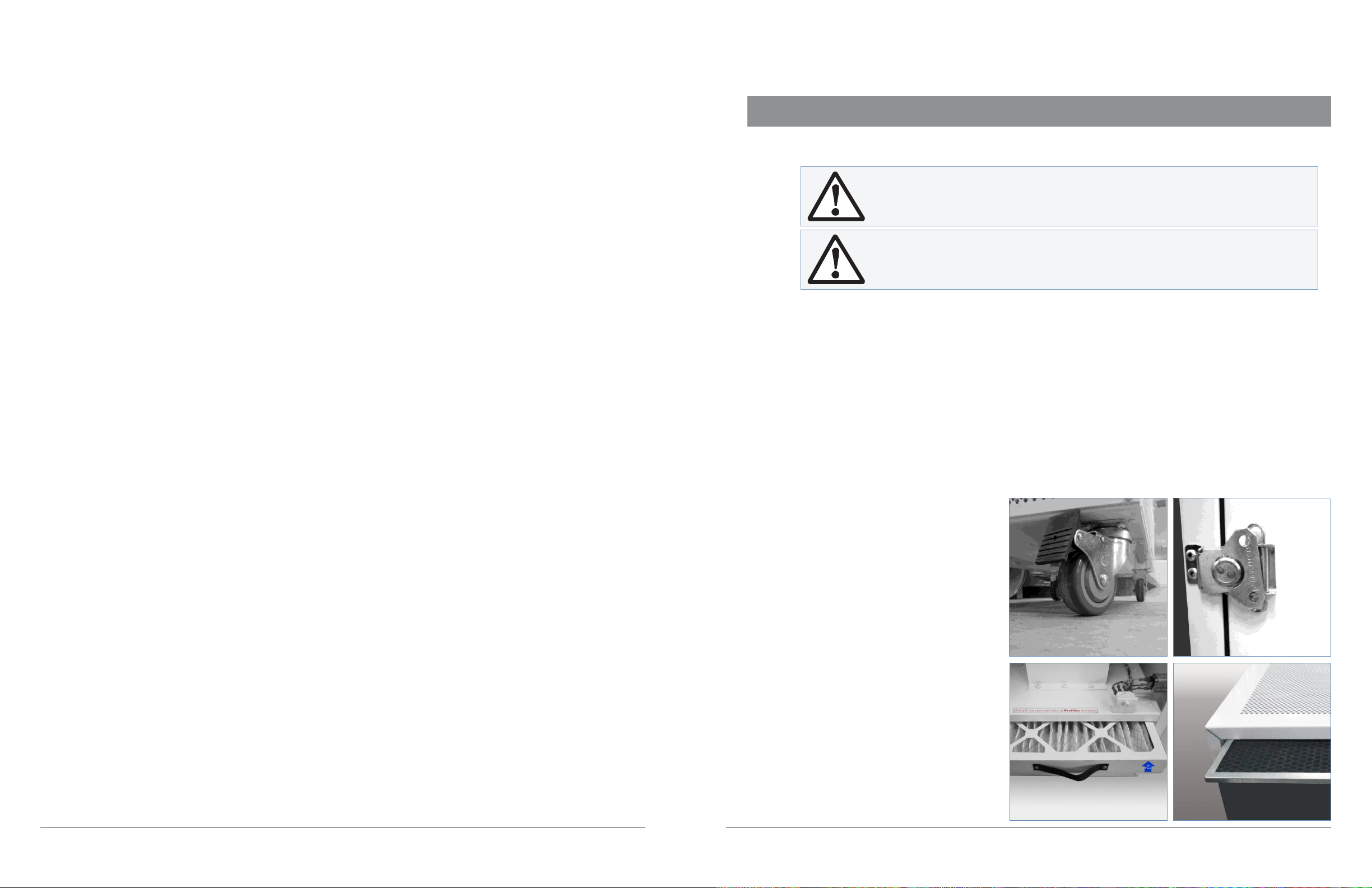

PREFILTER REPLACEMENT

Lock the (2) front wheels to secure the unit. (fig-1)

Remove the Filter Access Door located in the back of the unit using the four butterfly latches located on the

sides of the unit. Lift the latch wings (4) and turn counter-clockwise to open. (fig-2)

Filter Access Door removal may require a firm pulling effort.

Simply slide the Prefilter out of the filter channel located in the bottom of the unit. (fig-3)

To install a new Prefilter, slide the Prefilter back in the channel. Pay attention to the Flow Direction Arrow on

the Prefilter, the arrow should point upwards towards the Supply/Outlet End of the unit. (fig-3)

Ensure the Prefilter is firmly seated. The unit will not run if the Prefilter is not installed correctly.

Return the Filter Access Door. Lift the latch wings (4) and turn clockwise to close. (fig-2)

VOC POST FILTER REPLACEMENT

Lock the (2) front wheels to secure

the unit. (fig-1)

Remove the Filter Access Door located in

the back of the unit using the four butterfly

latches located on the sides of the unit. Lift

the latch wings (4) and turn

counter-clockwise to open. (fig-2)

Filter Access Door removal may require a

firm pulling effort.

Simply slide the VOC Post Filter out of

channel located in the top of the unit. (fig-4)

To install a new VOC Post Filter, slide

the VOC Post Filter back in the channel.

Return the Filter Access Door. Lift the

latch wings (4) and turn clockwise

to close. (fig-2)

When replacing filters use only Intellipure certified filters. Intellipure filters are

designed for high voltage operation. Use of non-Intellipure filters can behazardous

to personnel and equipment voiding the warranty.

Always unplug the unit and wait a minimum of 30 seconds before

touching the unit.

fig-2

fig-3

fig-4

fig-1

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

18

© Intellipure 2015

#10065

19

© Intellipure 2015

fig-6

fig-5

Maintenance

Maintenance

V-

BANK MAIN FILTER REPLACEMENT

Lock the (2) front wheels to secure the unit. (fig-1)

Remove the Filter Access Door located in the back of the unit using the four butterfly latches located on the

sides of the unit. Lift the latch wings (4) and turn counter-clockwise to open. (fig-2)

Filter Access Door removal may require a firm pulling effort.

Using the Magnetic Bit Holder provided, alternate loosening the left and right Scissor Locking Mechanisms

located near the motor plate in the filter. Make sure the Scissor Locking Mechanisms are fully opened. (fig-5)

Disconnect the High Voltage Lead from the High Energy Grid. (fig-6)

Using a firm pull, remove the V-Bank Main Filter and High Energy Grid Assembly out of the filter access

opening. (fig-7)

Inspect and clean the inside of the unit.

Refer to page 19 for proper instructions.

Separate the High Energy Grid from the

V-Bank Main Filter by removing the

six screws (4 corners and 2 in the center)

in the V-Bank Main Filter. (fig-8)

Replace the V-Bank Main Filter.

Secure the V-Bank Main Filter to the bottom

of the High Energy Grid by using the

six screws (4 corners and 2 in the center)

in the V-Bank Main Filter.

Slide the V-Bank Main Filter and HighEnergy

Grid Assembly back into the unit. Pay

attention to the Flow Direction Arrow on

the Prefilter, the arrow should point

upwards towards the Supply/Outlet end

of the unit. (fig-9)

Using the Magnetic Bit Holder provided,

alternate tightening the left and right

Scissor Locking Mechanisms located

near the motor plate in the filter.

CLEANING THEUNIT

Depending on contamination level, this procedure should be conducted about once a year or during each

filter change or if an electrical problem occurs.

Remove the V-Bank Main Filter and High Energy Grid Assembly

Refer to page 18 for proper instructions.

To clean the wires, use a fiber free swab, either dry or moistened with distilled or deionized water, clean

along the length of each wire, spring clip, and ceramic insulator.

Clean the inner surfaces of the High Energy Grid material using a lint cloth moistened with distilled or

deionized water.

Clean the High Energy Grid surface by vacuuming between the wires using a small vacuum attachment or

by using a lint free cloth, either dry or moistened with distilled or deionized water. Take care to avoid leaving

large fibers snagged on the wires, control grid, or other components of the High Energy Grid.

Make sure that any contaminant that falls to the bottom of the filter unit is removed.

In extreme cases, it may be necessary to remove the wires from the springs attached at each end to the power

distribution bars, thus allowing complete access to the inside of the High Energy Grid assembly for cleaning

as previously described. It is recommended that the manufacturer be contacted for detailed instructions

should this step appear necessary.

Vacuum the bottom of the filter seal plate section and of the filter unit to remove any particles dislodged during

cleaning. Reinstall the High Energy Grid, V-Bank Main Filter and Filter Access Door as previously instructed.

Reconnect the High Voltage Lead.

Ensure the Prefilter is firmly seated.

The unit will not run if the Prefilter is

not installed correctly.

Return the Filter Access Door. Lift the

latch wings (4) and turn clockwise

to close. (fig-10)

fig-9

fig-10

Do not over-tighten the

Scissor Lock Clamps.

Do not use alcohol or cleaners that may damage acrylics, plastics or aluminum.

fig-7

fig-8

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

20

© Intellipure 2015

#10065

21

© Intellipure 2015

Maintenance

Troubleshooting

PARTS LIST

Intellipure recommends that the following spare parts be available on-site at all times.

Order all parts by contacting:

Phone No: 1-315-298-2904

1-800-843-3860

Fax No: 1-315-298-6992

Email: info@Intellipure.com

For additional troubleshooting assistance refer to the DDFS Troubleshooting Guide on the following page or

contact Intellipure International:

Phone No: 1-315-298-2904

1-800-843-3860

Fax No: 1-315-298-6992

Email: info@Intellipure.com

Service should only be done by a qualified factory trained technician.

Problem Description

Recommended Action

Blue LED (FS) is OFF - Fan is running

1.

Check the High Energy Grid for broken, loose

or disconnected wires and debris. If the

problem persists then refer to the

FS Troubleshooting Guide.

2.

If the problem persists, then call for assistance.

Fan motor not running

1.

Check whether the unit is running on the required

supply voltage and confirm the status of the fuses.

2.

If problem persists, then check for disconnected

wires or connectors inside the unit including all low

voltage control connections.

3.

If the problem persists, then call for assistance.

Blue LED (FS) is OFF - Fan is not running

1.

Check whether the unit is running on the required

supply voltage and confirm the status of the fuses.

2.

If the problem persists, check the prefilter and

prefilter safety interlock.

3.

If the problem persists, then call for assistance

Description

Part Number

Prefilter

FT-101-2

V-Bank Main Filter

1200-VB-92

1/2” Carbon Post Filter

950P carbon filter

High Energy Grid

TC-019

High Energy Grid Wires

NZ-023

High Energy Voltage Lead Wires

NZ-026

1/2” S.S. Spring

NZ-004

Airdecon Pure 2 H.V. Extension Cable

950P HV ext cable

230V 3 Prong Cord

10-916

Standoff

7047

Multiplier

NZ-025

355-230-3ph motor

4065

115/240v VFD

EC-083

120v Power Supply

2010

230-120 Step-Down Transformer

EC-033

Electronics Assembly:

Relay, Ribbon, Control Panel

LED Light Wires

4045

EMI Filter w/ Fuse 5amp

NZ-033

Interlock Switch Single-Pole

2034

Interlock Switch Two-Pole

2009

Airdecon Pure 2 Remote

4051

2-7/8 Magnetic Bit Holder

HA-115

Optional

Part Number

Airdecon Pure 2 VOC Filter Assembly

950P-VOC

1200- VB VOC

1200-VB-VOC

950P Portable AirCleaningSystem

950P PortableAirCleaningSystem

#10065

22

© Intellipure 2015

#10065

23

© Intellipure 2015

Troubleshooting

Troubleshooting

DFS TROUBLESHOOTING GUIDE

Refer to pages 17 and 18 to view figures

Symptom: The unit has been turned on but the High Voltage Power Supply Indicator Light (DFS) is OFF

Probable cause #1: Short in High Energy Grid (foreign debris, loose wires, loose electrical connection)

Confirmation:

Step 1: Disconnect power to unit and lock the (2) front wheels to secure the unit. (fig-1)

Step 2: Remove the Filter Access Door located in the back of the unit using the four butterfly latches

located on the sides of the unit. Lift the latch wings (4) and turn counter-clockwise to open. (fig-2)

Step 3: Disconnect the High Voltage Lead from the High Energy Grid. (fig-6)

Step 4: Safely secure the male end of the High Voltage Lead to ensure that the High Voltage Lead cannot

contact the blower wheel.

Step 5: The following steps should be done with extreme care and the person(s) performing this

test should ensure that unauthorized personnel cannot come in contact with dangerous moving

parts and high voltages.

Defeat Safety Interlock: Ensure the Prefilter is firmly seated. The unit will not run if the Prefilter is not

installed correctly.

Step 6: Return power to the unit and put the unit into run mode. Observe the status of the High Voltage

Power Supply Indicator Light (DFS). If the light is now functioning the problem is in the High

Energy Grid.

Disconnect power to the unit and follow these steps:

(A)

Using the Magnetic Bit Holder provided, alternate loosening the left and right Scissor

Locking Mechanisms located near the motor plate in the filter. Make sure the Scissor Locking

Mechanisms are fully opened. (fig-5)

(B)

Ensure the High Voltage Lead is disconnected from the High Energy Grid. (fig-6)

(C)

Using a firm pull, remove the V-Bank Main Filter and High Energy Grid Assembly out of the

filter access opening. (fig-7)

(D)

Separate the High Energy Grid from the V-Bank Main Filter by removing the six screws (4

corners and 2 in the center) in the V-Bank Main Filter. (fig-8)

(E)

Inspect the High Energy Grid and its wires, they should be free from debris and evenly

tensioned. Loose wires can cause arcing or cause the protection circuit to trip.

(F)

Inspect the “V” sections of the V-Bank Main Filter and ensure that it is free of metal debris,

excess dirt or hair etc…

(G)

Secure the V-Bank Main Filter to the High Energy Grid by using the six screws (4 corners

and 2 in the center) in the V-Bank Main Filter.

(H)

Stand the V-Bank Main Filter and High Energy Grid Assembly up and inspect the gasket on

the seal side of the Assembly. Replace the gasket if it is damaged

DFS TROUBLESHOOTING GUIDE CONT.

(I)

Slide the V-Bank Main Filter and HighEnergyGridAssemblybackintotheunit.Pay attention to

the Flow Direction Arrow on the Prefilter, the arrow should point upwards towards the

Supply/Outlet end of the unit. (fig-9)

(J)

Tighten the right and left Scissor Locking Mechanism.

(K)

Repeat Step 5 from aboveand place the unit in runmode to confirmthe problemhas been resolved.

Conclusion: If the High Voltage Power Supply Indicator Light stays off this indicates a faulty Voltage

Multiplier. Disconnect power from the unit and replace the Voltage Multiplier. Repeat Step 5

from above and place the unit in run mode to confirm the problem has been resolved.

Probable Cause #2: Faulty Voltage Multiplier / Faulty High Voltage Power Supply (DFS)

Confirmation:

Step 1: Disconnect power to unit

Step 2: Open the Electrical Panel located behind the front panel of the unit. You will need to remove the

(14) screws holding the front panel in place.

Step 3: Locate the Voltage Multiplier above the electrical components on the left side. The Voltage

Multiplier is a gray, rectangular device with red and black wires at one end and a single red wire

at the opposite end. (fig-11)

Step 4: Disconnect the red wire of the Voltage Multiplier from the “J3” terminal of the High Voltage

Power Supply (HVPS). Stay clear of this terminal while testing and Do Not attempt to

re-connect the terminal with power applied to the unit.

Step 5: Re-connect power to the unit

Step 6: Place the unit in “run” mode and observe the status of the High Voltage Power Supply Indicator

Light (HVPS1)

Conclusion: If the High Voltage Power Supply Indicator Light stays off with no Voltage Multiplier attached

there is a fault in the High Voltage Power Supply. Disconnect power from the unit and

replace the High Voltage Power Supply.

If the High Voltage Power Supply

indicator light is on with no Voltage Multiplier attached the fault is

either in the High Energy Grid or in the Voltage Multiplier.

Variable Frequency Drive

High Voltage Power

Service should only be done by a qualified factory trained technician.

Voltage Multiplier

fig-11

950P Portable DFS Air Cleaning System

950P-220

#10065

©Intellipure 2015

1-1

950P

©Intellipure 2015 #10065

Other manuals for 950P

1

Table of contents

Other Intellipure Air Cleaner manuals