4

LED Indicators

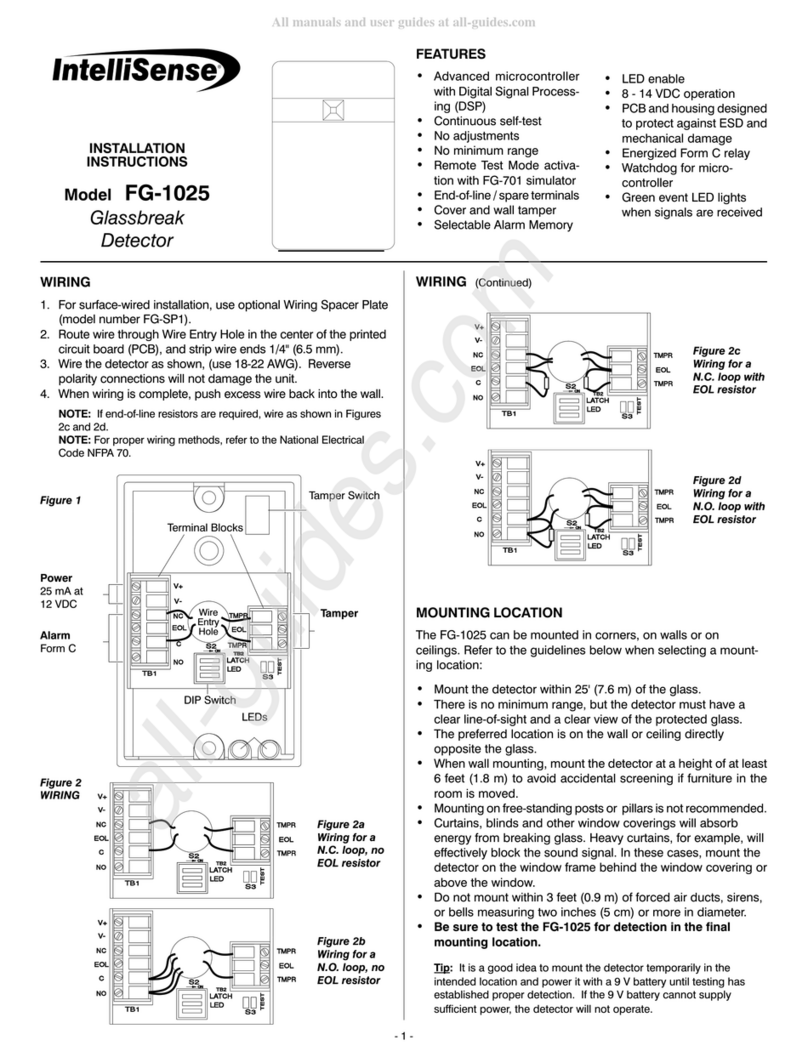

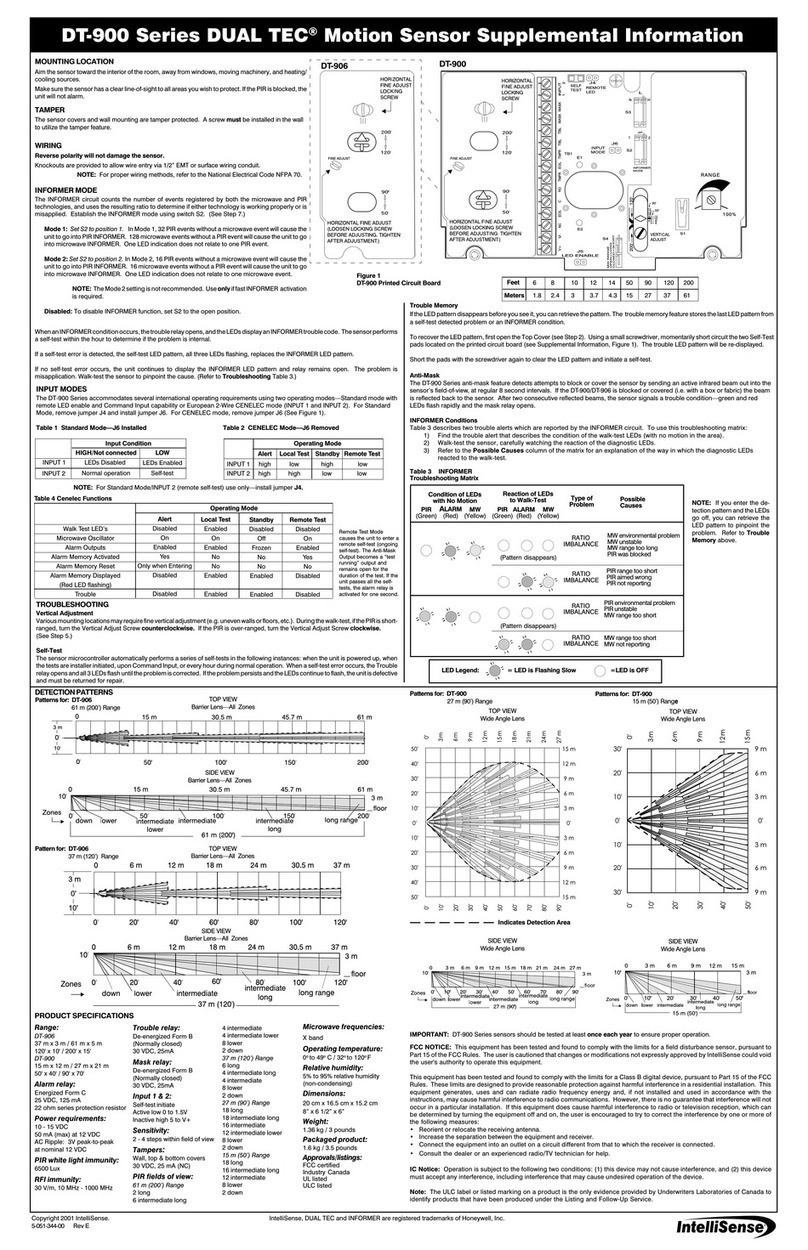

The two LEDs shining through the front cover are used to

indicate the detector's operational status. The following table

summarizes the LED operation when the LEDs are enabled.

FCC Notice: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance with the instructions may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures: 1) Reorient or relocate the receiving

antenna, 2) Increase the separation between the equipment and receiver, 3) Connect the equipment into an outlet on a circuit different from that to which the receiver is connected. The installer can also consult

an experienced radio/television technician for additional suggestions, if necessary.

In addition, a booklet on interference, prepared by the Federal Communications Commission, is also available for reference. Order "Inter ference Handbook" from the U.S. Government Printing Office,

Washington D.C. 20402, stock no. 0004-000-00450-7.

Copyright 1997 C&K Systems, Inc.

All Rights Reserved

http://www.cksys.com

5-051-436-00 Rev C

C&K is a registered trademark of C&K Components, Inc.

IntelliSense is a registered trademark of C&K Systems, Inc.

3M is a registered trademark and Scotchtint is a trademark of 3M Corporation.

Hardglass is a registered trademark of CHB Industries.

Normal, no event OFF OFF

Normal, event detected Flicker OFF

Normal, break detected OFF ON

Power-up self-test ON, one second ON, one second

Trouble detected Flash ON/OFF Flash OFF/ON

Test mode, no alarm Flash once per second OFF

Test mode, event detected Flicker OFF

Test mode, alarm Flash once per second ON

Condition Green LED Red LED

Self-Tests

The FG-1008 automatically performs a series of self-tests

during power-up, and continuously. If any self-test fails, the

detector will signal trouble by flashing the LEDs alternately

once per second. Protection will continue if possible. If the

trouble condition clears, the LEDs will return to the normal

state. Always return the detector for repair if there is any

indication of trouble, even if the trouble is temporary.

SPECIFICATIONS

Range:

8’(2.4m) maximum

No minimum range

Alarmrelay:

Form A, 250 mA maximum

25VDCmaximum

Alarm duration:

5 seconds (unaffected by alarm

LED latching)

Tamperswitch:

Cover tamper 25 mA maximum

24VDCmaximum

Powerrequirements:

8 - 14 VDC; 17 mA typical at

12VDC, 30 mA max.;

AC Ripple: 4 Volts peak to peak at

nominal 12 VDC

Operating temperature:

32°to120°F(0° to49°C)

Storage:-4°to122°F(-20°to50°C)

RFIimmunity:

30 V/m, 10 MHz - 1000 MHz

ESDimmunity:

10 kV, Discharges of either polarity

toexposed surfaces

Magneticcontact:

Makegap 0.9” minimum

Break gap 2.2” maximum

Dimensions:

Glassbreakhousing:

4-9/16”x15/16”x1-1/4”

(11.6 cm x 2.3 cm x 3.2 cm)

Magnethousing:

4-9/16”x15/16”x1/2”

(11.6 cm x 2.3 cm x 1.3 cm)

Weight:

2.9 oz., (81 g)

packaged product: 3.8 oz., (108 g)

Accessories:

FG-701 Glassbreak Simulator

Approvals/listings:

FCC verified

UL listed

POWER-UPSELF-TESTS

• RAMTest:Write&read allRAMlocations

withone’s &zero’s

• ArithmeticTest:Verifycorrectresultsfor

CPUarithmetic

• LogicTest:Verifycorrect resultsfordata

comparisons

• ClockRate Test:Checkclock frequencyby

measuringexternaltimeconstants

• ActiveAnalogCircuit Test: Injectsignals

intoanalog channelstocheck gains,filters,

A/D,andinterrupts

CONTINUOUSSELF-TESTS

• Watchdog:Supervises

microcontroller

• ROMChecksum:Firmware ROM

checksumverified

• RAMTest:Write& readRAM

locationswith one’s &zero’s

• LogicTest:Verifycorrectresultsfor

datacomparisons

• PassiveAnalogCircuitTest:Verify

analoginputs are withinnormal

bounds

Protected glass:

Minimum size for all types is 11" (28 cm) square; Glass must be framed in

the wall of the room or mounted in a barrier of 36" (0.9 m) minimum width.

1Laminated and sealed insulating glass types are protected only if both plates of the

glass are broken.

2For glass coated on the inner surface with 3M ScotchtintTM type RE35NEARL or Hardglass®

Security Film.

IMPORTANT: The FG-1008 must be connected to a UL listed power supply or UL listed

control unit capable of providing a minimum of four hours of standby power.

THICKNESS

Type Minimum Maximum

Plate 3/32" (2.4 mm) 1/4" (6.4 mm)

Tempered 1/8" (3.2 mm) 1/4" (6.4 mm)

Laminated11/8" (3.2 mm) 9/16" (14.3 mm)

Wired 1/4" (6.4 mm) 1/4" (6.4 mm)

Coated21/8" (3.2 mm) 1/4" (6.4 mm)

Sealed Insulating11/8" (3.2 mm) 1/4" (6.4 mm)

NOTE: The content of this manual has been

revised. For your convenience, dashed lines have

been added to the margins of this document to

note the locations of the changes.