InterApp DESPONIA User manual

1/14

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

1. Introduction

2. Intended Use

3. Conguration

4. Safety information

5. Transport and storage

6. Installation

7. Functional tests

8. Operation and maintenance

9. Troubleshooting

10. Further information

11. Declaration of incorporation

Original Installation instructions with operating instructions and technical documentation.

In accordance with:

• Pressure Equipment Directive 2014/68/EC

• Machinery Directive 2006/42/EC

• Standard EN 161

• Gas Appliances Regulation 2016/426/EC (GAR)

2/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

1. Introduction

This manual is intended to support the user during the installation, operation and maintenance of the buttery

valves models Desponia® and Desponia® plus in accordance with the EN 161.

The “warning” and “caution” notes must be strictly followed. Not following the advice might

result in damages of various severity levels for the operators and the place of installation of

the valves, and the warranty may be invalidated.

The buttery valves according EN 161 are always supplied from the factory with a pneumatic actuator and accessories to

assure the closing of the valve when de-energized and other technical features according the EN 161.

The valves are class A and Group 2 according the EN 161.

Buttery valves models Desponia® and Desponia® plus by themselves, are no equipment according to article

1 of the directive 2014/34/EU (ATEX). In potentially explosive areas, the user is obliged to identify dangerous

ignition sources, perform a risk analysis of the entire system and initiate the necessary preventive measures.

Therefore, the use of conductive versions might be necessary.

Electrical and mechanical actuators as well as accessories are subject to a separate conformity analysis

according to ATEX. The user is responsible to consider all the safety instructions for applications in explosion

hazardous areas.

Additional safety instructions for the proper selection the InterApp valves materials and their use in explosion

hazardous zones are listed in the document "interapp-buttery-valves-for-use-in-potentially-explosive-

atmospheres-XXX.pdf", which can be downloaded from www.interapp.net

Note: The valve tted with actuator and accessories may not be used as an automatic shut-off valve for

domestic cooking appliances burning gas in accordance with standard EN 30.

2. Intended use

Buttery valves models Desponia® and Desponia® plus in accordance with the EN 161 are intended to shut-

off or regulate uids of various natures, including those mentioned in the EN 161 standard and the Gas

Appliances Regulation 2016/426/EC (GAR). After installation the valves in the piping system, please ensure the

temperature and pressure limits of the valve are always kept.

The technical datasheets of the Desponia® and Desponia® plus valves, show the different limits in temperature

and pressure of the different materials.

In the valve labels (example provided on page 5), PS and TS, show the limits of pressure and temperature

to according the EN 161 standard and complement the data provided by the technical datasheets. The

information is based on neutral liquids only, so please contact InterApp if you need additional information for

other liquids.

If the valve is operated outside it limits of Pressure and temperature, personal damage and

to the equipment might occur.

Please avoid cavitation and water hammer, which can cause a failure of the valve, with

personal and equipment damages.

3/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

3. Conguration

Buttery valves according EN 161 are always supplied from the factory with a pneumatic actuator and

accessories to assure the compliance with the EN 161.

Please consult our technical department to obtain the technical datasheet "EN 161 buttery valves selection"

that includes the possible combinations of actuators and accessories for the valves according the EN 161.

The different parts that could be included are:

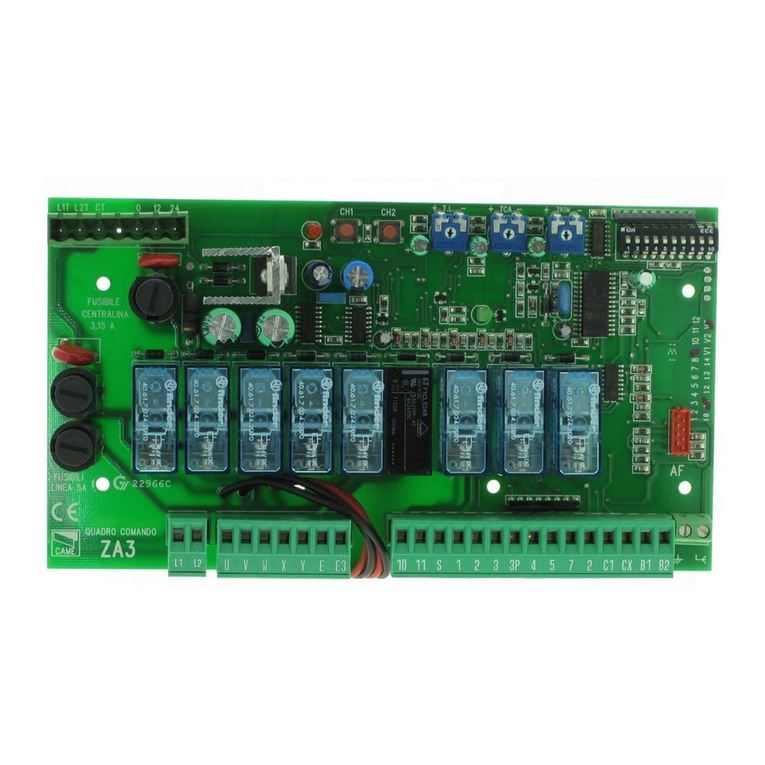

Single acting pneumatic actuators

Model: PTB - XXX -YY

Where XXX denotes the size of the actuator and YY the ange connection to the buttery valve.

The pneumatic actuators have their own manuals, which will be attached together with this manual, when

ordering the valves.

Solenoid valve

Model: 331N03 - XXX

Where XX denotes the different voltage and current possibilities. According the EN 161 cl 6.6 the input signal

has to be 0-20 mA to ensure a safe shutdown, 4 mA trip signal is not allowed.

The solenoid valves have their own manuals, which will be attached together with this manual, when ordering

the valves.

Quick exhaust block

Model: SENR-207-01

Other optional equipment

Limits switches can be provided together with the valves, and they do not affect the behaviour of the assembled

unit or its capacity to close in the required time when the actuator is de-energized.

Due to the required cycling operations only proximity switches shall be used. Please consult our Technical

department for further information.

Rated ow:

DN 20º 30º 40º 50º 60º 70º 80º 90º

50 2 7 15 28 45 68 88 100

65 3 11 24 48 85 138 180 210

80 8 22 50 83 134 230 312 360

100 15 35 70 130 225 410 585 650

125 28 70 135 230 360 600 920 1050

150 33 95 205 320 580 980 1410 1620

200 60 175 355 580 910 1600 2450 2800

250 132 340 590 940 1480 2550 3950 4480

Kv values m3/h opening angle of the valve

Ambient temperature: As shown on the label -20ª up to +60ªC.

Opening and closing time: Less than one second for all sizes between DN 50 up to DN 250

Limit switch box

(optional)

Single acting

pneumatic actuator

Desponia® or Desponia® plus

buttery valve

Quick exhaust block

Solenoid valve

4/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

4. Safety information

Buttery valves are intended to be installed in a piping system, so the same regulations and safety measures

that apply to the complete system, must be applied to the valve. In this manual, additional safety instructions

related to the buttery valve are contained.

General safety information

• In the piping system, the common ow speeds in permanent operation are not exceeded.

• If abnormal operational conditions such as vibrations, cavitation, erosion, solids in the medium, are present,

they have been discussed with InterApp.

• At operating temperatures that result in hot or cold valve parts (incl. add-ons) and therefore might cause

dangers, the installation must take into account protective measures against accidental touching.

• That any actuator that is installed on the valve not by InterApp are adjusted to the valve, and all the safety

measures have been considered.

• Only expert personnel operate and service the valve.

Safety instructions to the operators

Buttery valves are intended to be installed in a piping system, so the same regulations and safety measures

that apply to the complete system, must be applied to the valve. In this manual, additional safety instructions

related to the buttery valve are contained.

InterApp does not assume any responsibility, so therefore the operator must ensure when operating the valve

that:

• The valve is only used properly as intended.

• The piping system has been laid professionally and is checked regularly.

• The valve is professionally connected to the piping.

Particular hazards

Before the valve is removed from the piping system, ensure that the pressure in the system

is completely relived from both sides of the valve. Do not attend to unscrew the valve of

the pipes with pressure, failure to follow this recommendation can cause damages to the

personnel and the equipment.

Please notice that some residues could remain in the inner of the valve and that they might

be dangerous for people or the environment. Therefore, the buttery valve has to be handled

with the corresponding caution.

For valve to be installed at the end of line, please always follow the instructions on chapter

6. Never attempt to unscrew or operate the valve without relieving the pressure.

Do not remove the actuator of the valve, while the valve is still under pressure.

Lifetime for safe function

Verify the external tightness of the valve at suitable intervals, and if leakage is detected please proceed to

uninstall the valve and replace the liner.

The liners are suitable for the following frequency of operations without replacement:

Nominal Size DN Number of cycles without

service operations

50 <= DN <= 80 100.000

80 < DN <= 150 50.000

150 < DN <= 250 25.000

5/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

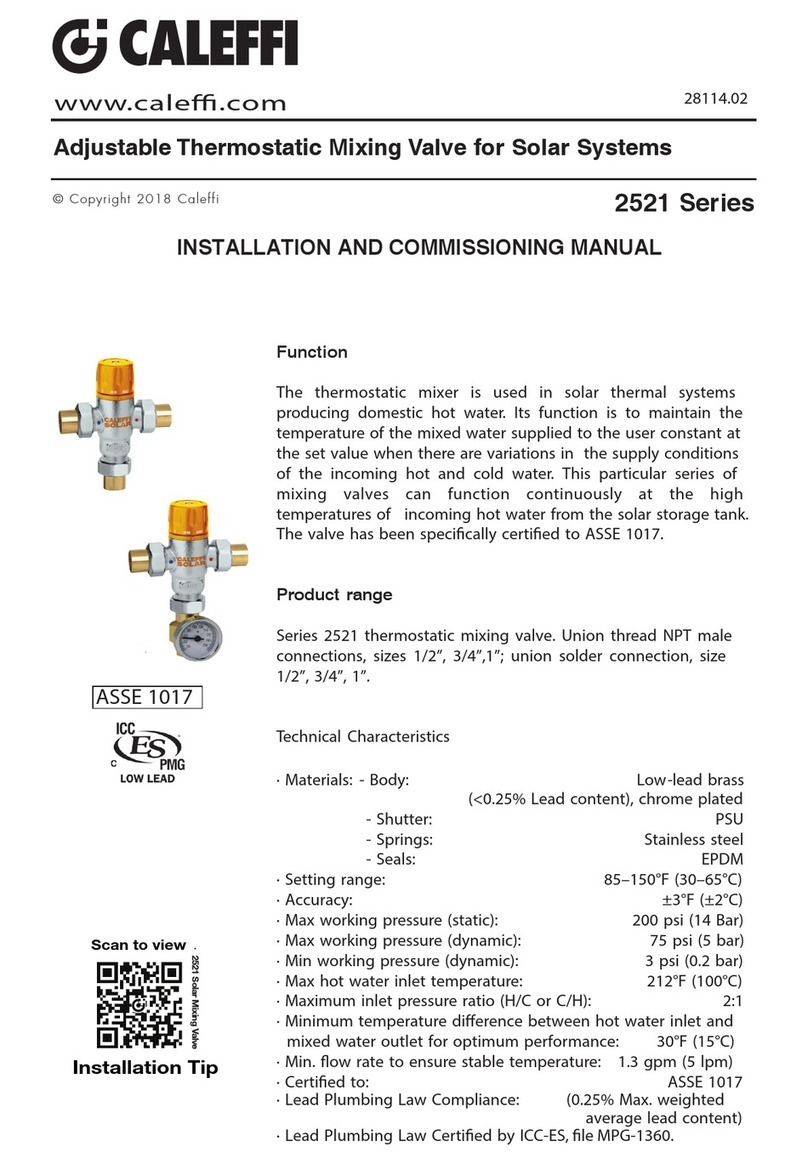

Label Details Explanation

Manufacturer InterApp

Conformity ID and number CE marking and notied body as per EU directives

Valve class (VC) Class A

Ambient temperature (AT) -20 – 60 ºC (according EN 161 certication)

Nominal size DN and number (in mm)

Maximum pressure PS – maximum allowable pressure in bar at room

temperature

Maximum Temperature TS –Allowable temperature in Celsius (for clean neutral

uids)

Valve type and codication

D1XXX / D3XXX /

Sequence of alphanumeric characters that identify the

valve. See the valve datasheet for an explanation of

the same

Body Material BOD → Material used for the body

Shaft Material SH → Material used for the shaft

Disc material DIS → Material used for the disc

Reference number A set of numbers that identify the production order,

therefore establishing the date of manufacture

Marking and labelling

InterApp valves carry a label with the following information:

1

5. Transport and Storage

Special care should be taken when handling, storing and transporting the buttery valves Desponia® and Desponia®

plus. Local regulations as well as the necessary safety measure must always be observed.

The buttery valves must be kept in the original packaging up to the installation.

InterApp buttery valves Desponia® and Desponia® plus should always be stored free from dust and humidity. The

valve is supplied with the disc in a slightly open position and should remain so until the installation is completed.

(Fig.1).

Special care should be taken when handling, storing and transporting the buttery valves Desponia®

and Desponia® plus. Local regulations as well as the necessary safety measure must always be

observed.

The buttery valves must be kept in the original packaging up to the installation.

InterApp buttery valves Desponia® and Desponia® plus should always be stored free from dust and

humidity. The valve is supplied with the disc in a slightly open position and should remain so until

the installation is completed. (Fig.1).

6/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

6. Installation

Introduction

To guarantee the benets of the InterApp buttery valves Desponia® and Desponia® plus,

proper procedures and compliance with the installation instruction are essential. The

installation has to be carried out according to the state of the art and only by qualied

personnel. InterApp reserves the right to decline responsibility for damage or premature

failure if the recommendations contained in this instruction are not being followed. Consult

the corresponding valve datasheet concerning the installation of a valve at the end of

the line. Dimension, material and application range of the buttery valves Desponia® and

Desponia® plus are according to the technical documentation.

The weight of the buttery valves Desponia® and Desponia® plus is shown on the technical datasheets.

Due to its weight, special care should be taken during the installation of the valves, and the use of lifting devices,

ropes, slings, etc. should always be contemplated.

For these operations the end user and personnel should wear the necessary protection equipment as per the

local regulations and follow the local safety regulations.

Storage

InterApp buttery valves Desponia® and Desponia® plus should always be stored free from

dust and humidity.

The valve is supplied with the disc in a slightly open position and should remain so until the

installation is completed. (Fig. 1).

Buttery valves supplied with a single acting spring closing pneumatic actuator should be

stored with disassembled actuator, this to avoid a lasting deformation of the liner.

The actuator should be mounted only after the installation of the valve in the piping.

Precautions to be taken prior to installation

Please make sure that the valve intended for installation is suitable for the service conditions

prevailing. The responsibility about the used uids (corrosion resistance, pressure,

temperature, etc.) lies by the user of the plant.

Call your supplier or InterApp if you need any assistance.

Please consider that turbulences (i.e. created by piping bow) generate hydro dynamic forces

increasing the operating torque of the valve. We recommend installing the valve minimum

5 x DN after pipe ttings.

For the installation of valves in horizontal pipelines, we recommend installing the valves with

their shaft in a horizontal position.

Please ensure that the lower edge of the disc opens with the direction of the ow. This

prevents deposition of slurries and contamination in the shaft sealing area. (Fig. 2)

Check before installation:

Positioning

Never use gaskets nor grease. (Fig. 3)

Gaskets

7/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

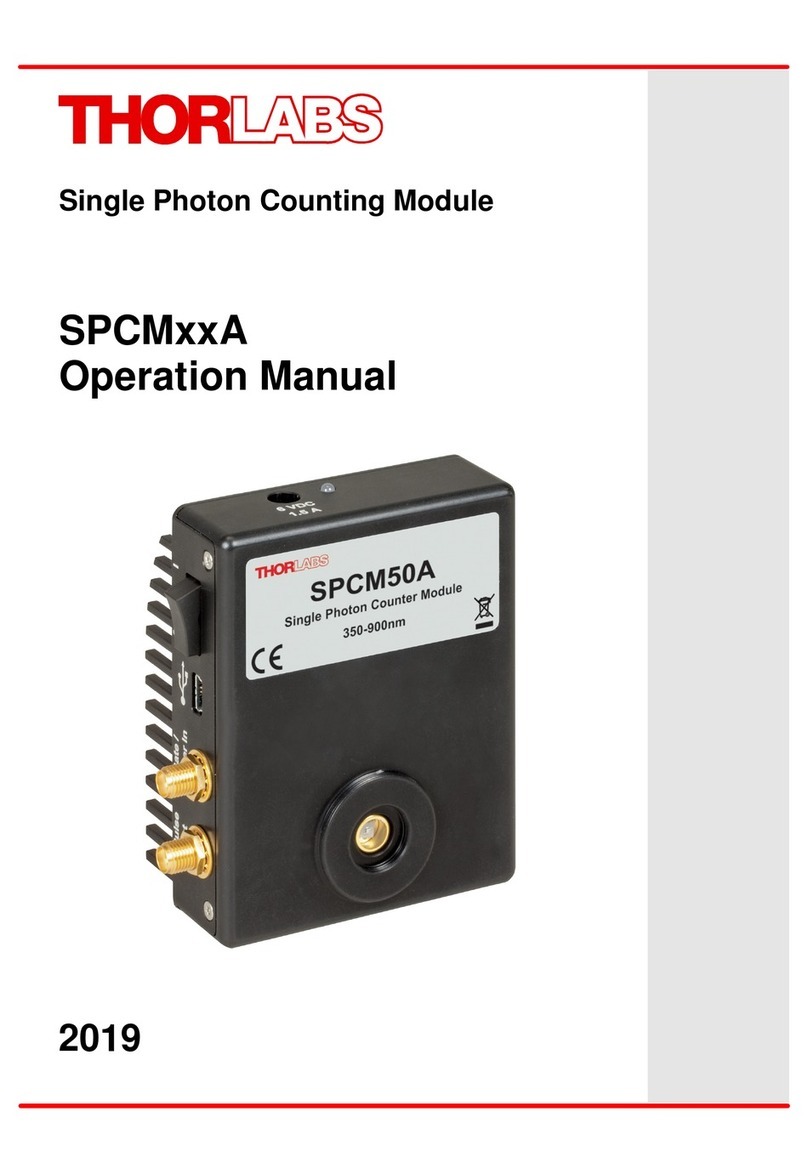

1245

3

7 86

Installation

Flange facings must be smooth and clean. Rust, welding scores, rests of paint, dirt, etc.

must be removed in order to prevent damage of the valve gasket.

Desponia® and Desponia® plus buttery valves, in wafer style design, are suitable for

installation between DIN PN10/16 or ANSI150 anges. For the installation of valve between

anges of other standards consult InterApp or its authorized distributors.

The valve should not be mounted in pipes, where the actual bore diameter is less than the

nominal bore dimension of the valve. In that case, spacer rings should be tted between

anges and valve to prevent damage to the disc on opening. (Fig.4)

The valve should never be installed between anges which are not parallel to each other.

Make sure that pipes and valves are installed concentric. The disc of a misaligned valve

may be damaged. (Fig.5). Furthermore, it is inadmissible to carry out any welding on the

piping while the valve is between the anges. This would destroy the liner of the valve.

The anges have to be spread in order to ease the installation of the valve and the disc must

be partially open (Fig. 6).

Misspreaded anges may damage or roll the liner outside the body anges.

Set all stay-bolts by keeping the disc slightly open and do not tighten the nuts (Fig. 7).

By tightening the stay-bolts when the disc is closed, the liner will be compressed in a wrong

position. An excessive closing torque and leakage will result. Open completely the disc (Fig.

8). Ensure that the piping is aligned. Tighten diagonally opposite the nuts.

8/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

PN 6 PN 10 PN 16 ANSI 150

A A A A

DN C n M x L nM x L nM x L nUNC x L [Inch]

25 30 4 M10x80 4M12x90 4M12x90 4UNC 1/2"-13 x 3"

32 30 4 M12x80 4M16x100 4M16x100 4UNC 1/2"-13 x 3 1/4"

40 33 4 M12x90 4M16x100 4M16x100 4UNC 1/2"-13 x 3 1/2"

50 43 4 M12x100 4M16x110 4M16x110 4UNC 5/8"-11 x 4"

65 46 4 M12x100 4M16x110 4(8) M16x110 4UNC 5/8"-11 x 4 1/2"

80 46 4 M16x110 8M16x120 8M16x120 4UNC 5/8"-11 x 4 1/2"

100 52 4 M16x120 8M16x120 8M16x120 8UNC 5/8"-11 x 5"

125 56 8 M16x120 8M16x130 8M16x130 8UNC 3/4"-10 x 5"

150 56 8 M16x120 8M20x140 8M20x140 8UNC 3/4"-10 x 5 1/4"

200 60 8 M16x130 8M20x150 12 M20x150 8UNC 3/4"-10 x 5 1/2"

250 68 12 M16x140 12 M20x160 12 M24x170 12 UNC 7/8"-9 x 6 1/4"

300 78 12 M20x160 12 M20x170 12 M24x180 12 UNC 7/8"-9 x 6 3/4"

350 78 12 M20x160 16 M20x170 16 M24x190 12 UNC 1"-8 x 7 1/4"

400 102 16 M20x190 16 M24x200 16 M27x220 16 UNC 1"-8 x 8 1/4"

A

C

B B

PN 10 PN 16 AISI 150

B C B C B C

DN C n M x L nM x L nM x L nM x L n

UNC x L [Inch]

n

UNC x L [Inch]

450 113 16 M24x240 8M24x60 16 M27x280 8M27x80 8

UNC 1 1/8"-7 x 9"

12

UNC 1 1/8"-7 x 3 1/2"

500 126 16 M24x250 8M24x60 16 M30x310 8M30x90 8

UNC 1 1/8"-7 x 10"

16

UNC 1 1/8"-7 x 4"

600 153 16 M27x290 8M27x70 16 M33x360 8M33x100 8

UNC 1 1/4"-7 x 11 1/2"

16

UNC 1 1/4"-7 x 4 1/2"

700 165 20 M27x310 8M27x70 20 M33x340 8M33x90 8

UNC 1 1/4"-7 x 12"

24

UNC 1 1/4"-7 x 5"

800 190 20 M30x340 8M30x80 20 M36x370 8M36x90 8

UNC 1 1/2"-6 x 16 1/2"

24

UNC 1 1/2"-6 x 7"

900 203 24 M30x360 8M30x80 24 M36x390 8M36x90 8

UNC 1 1/2"-6 x 17"

28

UNC 1 1/2"-6 x 7 1/2"

1000 218 24 M33x380 8M33x80 24 M39x420 8M39x100 8

UNC 1 1/2"-6 x 18"

32

UNC 1 1/2"-6 x 8"

1100 218 28 M33x380 8M33x80 28 M39x420 8M39x100 8

UNC 1 1/2"-6 x 18 1/2"

36

UNC 1 1/2"-6 x 8"

1200 254 28 M36x440 8M36x90 28 M45x490 8M45x120 8

UNC 1 1/2"-6 x 20 1/2"

40

UNC 1 1/2"-6 x 9"

1400 280 32 M39x480 8M39x100 32 M45x520 8M45x120 8

UNC 1 3/4" x 23"

44

UNC 1 3/4" x 10"

1600 318 36 M45x600 8M45x140 36 M52x680 8M52x180 -

-

-

-

Wafer U-section body

DN

32 40 50 65 80 100 125 150 200 250 300 350 400 450 500 600 700 800 900 1000 1200 1400 1600

Dmin

19 32 35 53 74 93 119 147 198 247 297 340 384 425 490 585 680 790 880 980 1175 1348 1560

Dopt

34 42 53 68 83 103 128 153 202 253 303 345 395 453 505 605 696 810 900 997 1195 1387 1602

Dmax

47 57 68 87 104 126 154 174 226 277 328 370 421 462 514 617 715 817 918 1019 1225 1430 1640

Dmin Minimum diameter of the ange enabling to move the disc (in case of a perfectly centred valve).

Dopt Diameter of the ange for optimal mounting.

Dmax Maximum diameter of the ange.

Flange inside diameter

The InterApp buttery valve has to be mounted between anges without gasket. It has

bidirectional tightness. Consult the corresponding valve datasheet concerning the installation

of a valve at the end of the line. It is centred by stay-bolts or by screws. The diameter of the

ange should be in accordance with the stated values Dopt, Dmin, Dmax.

Wafer + U-section body DN 450 - 1600

BStay bolt with 2 nuts + Cbolt

Wafer + U-section body DN 25 - 400

ABolt with nut

Bolting

9/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

C

1

2

3

LUG type DN 50 - 600

CBolt

n = number of bolts for one valve

Body type Picture Mounting end of line DN Max. working

pressure

Wafer D1

-- not allowed -- --

Lug D3

--

possible without counter ange DN 25 -

600

valve PN 16 = 10 bar,

valve PN 10 = 6 bar

with anges on both sides DN 25 -

600

nominal pressure of the

valve

Flanged D4

1

only with counter ange using passing through bolts DN 150 -

1600

nominal pressure of the

valve

2

possible without counter ange; use at face ange

only and valve with special code -081, for anges PN

10 and PN 16 only. All other ange ratings on request

DN 700 -

1600

valve PN 16 = 10 bar,

valve PN 10 = 6 bar

3

Flanged installation using at face anges and

valve with special code -081

DN 700 -

1600

nominal pressure of the

valve

Mounting the valve at the end of a line

When installing of the valve at the end of a line please note:

Fluid Only neutral liquids, temperature 10 - 80°C

Body material Ductile iron GGG 40 / EN-GJS-400-15, carbon steel 1.0619 or stainless steel 1.4408

Flange bolting Tightening torque values according to the supplier of the bolting you are using

10/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

Disposal:

Please notice that some residues could remain in the inner of the valve and that they might be

dangerous for people or the environment. Therefore, the buttery valve has to be handled with

the corresponding caution. After its use, the buttery valve has to be disposed of according to the

state of the art and under consideration of the environment.

Cleansing of the piping:

When cleansing the piping system, it is very important to assure that the cleaning products and

devices are harmless for the valve. Not convenient products and devices might destroy the valve.

Removal:

When removing the valve from the pipe please take care not to damage the disc and the liner of

the valve.

7. Functional Tests

Pressure tests on the valves has already been done by InterApp.

When putting the piping system in operation for the rst time, please follow the local regulations and the necessary

safety measures of the whole system.

In order to remove potential debris located in the piping system, prior to the normal operation of the same, it is

recommended to ush the piping system.

Prior starting to use the installation, we recommend making a function test. Therefore, the valve must be opened

and closed at least once in order to check that the disc doesn’t touch the anges and that the valve is tight

through the passage and toward outside.

To make the pressure test of the piping system with the valves installed, please observe the following:

• Valve Open: The pressure test must not exceed the value of x 1,5 PS (Ps is shown on the label)

• Valve Closed: The pressure test must not exceed the value of x 1,1 PS (Ps is shown on the label)

8. Operation and Maintenance

Please notice that uid residues inside the buttery could be dangerous for humans and

the environment. The buttery valve must be handled accordingly and be cleaned carefully

prior to the maintenance.

Normal operation

Please notice that uid residues inside the buttery could be dangerous for humans and

the environment. The buttery valve must be handled accordingly and be cleaned carefully

prior to the maintenance.

Maintenance is made at the own risk of the user. Maintenance on a Desponia® must be

executed by trained staff only. Only original spare parts are to be used.

The frequency of replacement of the wear parts, is highly dependent on the uid, cycles, operating conditions,

etc.

The user should include in its maintenance program a chapter for inspecting the valves to check the wear parts

and change them if necessary.

In the next paragraph the spare parts are identied. Please contact InterApp to obtain the specic codes and

additional information for the spare parts.

Maintenance

Introduction

11/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

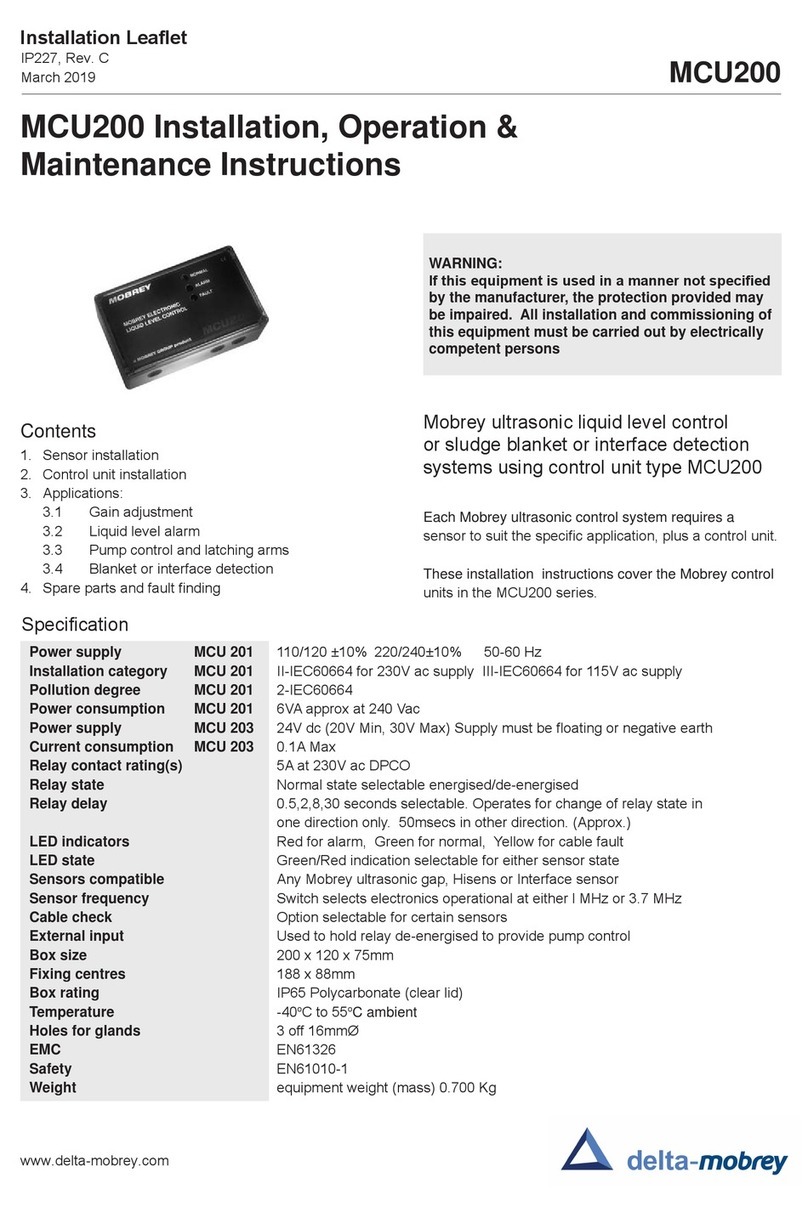

5

1

2

3

64

3. Disassembly:

3.1 Make sure there is no overpressure trapped inside of the valve prior disassembly.

3.2 Open the valve completely.

3.3 Remove the actuator.

3.4 Unlock screws and remove the retaining washer

3.5 Remove the shaft (either by using an extractor or by tightening the square of the shaft in a vise).

3.6 Remove the disc.

3.7 Loosen the liner at a point, squeeze until it is heart-shaped and then remove the liner.

4.1 Clean all parts. Use, if possible, a silicone spray or like ease the handling.

4.2 Ensure that the bigger hole of the liner is on the top side of the valve (the shaft diameter on the upper side is

bigger than this on the lower side).

4.3 Insert the heart-shaped liner. Set the upper part facing the shaft hole (use the shaft to centre the liner), let the

liner expand and adapt with the body.

4.4 Replace the disc. Ensure that the square is at the lower part (opposite the top of the valve). Take care not to

damage the liner.

4.5 Introduce the shaft through the liner and the disc, by rotating the disc in an alternated movement to ease the

operation.

4.6 Properly align the axis of the shaft square with the axis of the disc. Completely insert the shaft, evacuating air

from the lower shaft housing (slightly lift the liner using a screwdriver).

4.7 Remount the actuator.

4. Reassembly:

Before using the valve in a piping system, if it is required to make a tightness test (e.g. EN 12266-

1) or similar as well as a function test. Afterwards, put the disc in a slightly open position, so that

the disc edge doesn’t surpass the ange surface. This position must be kept until the valve is

being installed.

Parts list

1Body

2Disc

3Shaft

4 Liner*

5O-ring*

6Retaining washer +

2x Screws*

Before removing the valve from the pipe consider that dangerous uids might leak. Corresponding measures of

precaution must be applied.

When removing the valve from the pipe please take care not to damage the disc and the liner of the valve.

2.1 Do not close the valve completely.

2.2 Loosen all bolts and remove the valve.

2.3 Use ange spreaders and remove the valve

2. Valve removal from the line:

*Spare parts

1. Parts of a DESPONIA®, DESPONIA® plus

12/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

9. Troubleshooting

Fault Action

Leak at the

piping ange

connection of the

valve

1. Tighten the ange bolts. Please follow the recommendations of the bolt’s supplier

being used.

2. If the medium leaks even after tightening the bolts: remove the valve from the pipe

and observe the instructions mentioned in paragraph 7 of this manual.

3. Ensure that the pipe anges are aligned and the ange surface is smooth and clean.

4. If still the leaking persists, check for damages in the liner. Order replacement parts

from InterApp.

Leaking from the

shaft of the valve

1. Repair needed. Repair shaft sealing system. Remove the valve from the pipe and

observe the instructions mentioned in paragraph 7 of this manual

2. Order replacement parts from InterApp and contact us for further instructions.

The valve does

not open or close

1. If the valve carries an actuator, please check if the supply pressure is high enough

and the corresponding documentation of the actuator.

2. If the valve is manually operated, please check for the following possibilities:

• If foreign media is present → Please ush the piping.

• Operating pressure to high → Operate the valve with its corresponding allowable

pressure.

3. If still the problem persists, please check for damages on the valve. Remove the valve

from the pipe and observe the instructions mentioned in paragraph 7 of this manual.

4. Order replacement parts from InterApp and contact us for further instructions.

Leakage between

disc and liner

1. Please check that the valves have been correctly installed. Follow the instructions on

paragraph 6.

2. If the valve is correctly installed, and the leakage still occurs, disc/liner might be

damaged. Contact InterApp for spare parts and further instructions.

Other

malfunctions

1. If the valve is damaged, please contact InterApp for further instructions and spare

parts ordering.

10. Further Information

Technical datasheets, drawings, other documents and further advice can be obtained from:

Additional further information can be obtained from: www.interapp.net

InterApp Valcom S.A.

Calle Almenara, s/n.

Carretera Nacional A-1, KM 31.1 (Salida 30),

(Polígono Industrial Sur)

28750 San Agustín del Guadalix, Madrid, Spain

13/14www.interapp.net

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

11. Manufacturer´ Declaration in accordance with EC directives

The manufacturer InterApp Valcom S.A.

Calle Almenara, s/n. Carretera, Nacional A-1, KM 31.1 (Salida 30), (Polígono Industrial Sur)

28750 San Agustín del Guadalix, Madrid, Spain

declares InterApp Buttery valves:

• Desponia®

• Desponia® plus

With the following valve congurations:

• Manually operated valves

• With electric or pneumatic actuator

• Bare shaft for later assembling of an actuator

That these products* meet the requirements of the following Directives:

Pressure Equipment Directive – 2014/68/EC [valid if Article 4 Paragraph 1.c) or Article 4 Paragraph 3 apply]

The valves conform to this directive with the Conformity Assessment Procedure:

For Category I and II Module A2.

For Category III Module B and Module C2

Notied Body for the Inspection: TÜV Rheinland Ibérica, Inspection, Certication & Testing, S.A

Notied body Nº: 102

The instructions for the valves and the relevant instructions for the actuators shall be observed.

Machinery Directive 2006/42 EG:

1. The products are not a complete machine within the meaning of the European Machinery. Directive 2006/42. They are considered as

“partly completed machinery” as per Article 1, paragraph 1.(g) of the directive.

2. If they are installed in a pipe system on any other complete system, the entire system is then considered a complete machine within the

meaning of the European Machinery Directive 2006/42.

3. This declaration is the declaration of incorporation of partly completed machinery as it is laid out on ANNEX II, paragraph 1.B of the

European Machinery Directive 2006/42

4. For the necessary customer risk analysis, the table included in this declaration lists whether and how the requirements of the European

Machinery Directive 2006/42 in relation to the valve and actuator unit are fullled.

5. The operation instructions of the valves and the relevant instruction of the actuators shall always be observed.

6. The relevant technical documentation has been compiled in accordance with part B of Annex VII, and the person responsible to make

these documents available to the national authorities, by email and in electronic format is Mr. Alberto Nieto, Quality manager of InterApp

Spain, and located in Calle Almenara, s/n, San Agustín del Guadalix - 28750 -Madrid - Spain

For conformity with the above directives it shall be observed by the user:

1. The user shall observe the “correct valve destination“ as dened in the “operating manual for buttery valves“ which can be accessed

from our webpage “www.interapp.net” and shall observe all notices contain in this document that may be relevant for the use. Failure to

follow these notices and advices, will invalidate this declaration.

2. This partly completed machinery must not be put into service until the nal machinery into which it is to be incorporated has been de-

clared in conformity with the provisions of all the relevant European directives, by a person or institution responsible, where appropriate.

3. The manufacturer InterApp Valcom has made and documented the necessary risk analysis – the responsible person for making available

this information is Mr. Alberto Nieto from InterApp Valcom S.A, Spain.

San Agustín del Guadalix, April 2020 Alberto Nieto - InterApp Valcom S.A

This declaration of conformity and operating instructions have been generated electronically and are legally binding without signature

* The declaration of incorporation and all the different documentation of the actuators, observes the compliance of the actuators with the

different relevant directives

Standards applied [buttery valves]

EN 593:2009+A1:2011

EN 13774:2013

EN ISO 12100-1:2004/A1:2010

Industrial valves - Metallic buttery valves

Valves for gas distribution systems with maximum operating pressure less than or equal to 16 bar [valid

only for valves used in gas distribution systems and limited to the conguration certied for this purpose]

Safety of machinery - Basic concepts, general principles for design

Product documentation

Product datasheets, catalogue, drawings

Quality management system

ISO 9001:2008

InterApp Valcom S.A. declares that the following basic requirements according to ANNEX I of the Machinery Directive (2006/42/EC), are

applied and fullled

[Paragraph]

14/14 OPER_INT_MAINT_Desponia_Desponiaplus_accEN161_2017

© 2020 InterApp AG, all rights reserved

www.interapp.net en

The technical data are noncommittal and do not assure you of any properties. Please refer to our general sales conditions. Modications without notice.

DESPONIA®, DESPONIA®plus - Operation Installation and Maintenance Manual

1.1.2 a) b) c) d) See operating manuals and related documentation. The protective measures for personnel are the same as the

ones where the product will be installed

1.1.2 e) No specic tools are needed

1.1.3 The materials in contact with the media are identied in the product datasheet, the order conrmation and in the

valve label. The user must make a risk analysis.

1.1.5 Relevant instructions and information are given in the operating manuals and related documentation

1.2 Responsibility of the user following the instructions of the actuator.

1.3.1 See operating manual and handling instructions.

1.3.2 For the parts under pressure, through the declaration of conformity according 2014/68/EC. For the functional parts,

ensured through the intended use.

1.3.3 Fullled through design and assembling process

1.3.4 Fullled

1.3.7, 1.3.8, 1.3.9

and 1.4

Ensured through the intended use. Maintenance and servicing operations are never allowed with the valve under

pressure and/or connected to the control system.

1.5.1, 1.5.2, 1.5.3

and 1.5.4 Responsibility of the user. See operating manuals and related documentation of the actuators.

1.5.5 Responsibility of the user when the products are installed in its destination. See warnings and intended use of the

operating manual.

1.5.7

In potentially explosive areas, the user is obliged to identify dangerous ignition sources, perform a risk analysis of

the entire system and initiate the necessary preventive measures. If Ex-protection is required is must be stated in

the order. See also document "interapp-buttery-valves-for-use-in-potentially-explosive-atmospheres-XXX.pdf",

which can be downloaded from www.interapp.net

1.5.8 It is the responsibility of the user to verify the hydrodynamic conditions of the media line and establish the noise limits

1.5.13

Valves are installed in piping systems, which can carry dangerous uids. The user is responsible to ensure a

correct installation of the valves for which information is given in the operation and installation manual and ensure

the intended use.

1.6.1 and 1.6.5 See operating manual.

1.7.3 According to the manuals for the valves and the actuators.

1.7.4 Fullled through the manuals.

InterApp Valcom S.A. declares that the following basic requirements according to EN ISO 12100, are applied and fullled

Scope The risk analysis has been done considering the products a “partly completed machinery”.

The basis for the analysis of the buttery valves is the product standard EN 593 (Industrial valves - Metallic buttery

valves). For the actuators, please refer to their own documentation.

For the risk analysis, our long experience supplying the above-mentioned valves + actuators, has been taken into

account, with the result of the different instructions and warnings contained in the Manuals.

It is mandatory that for fullling the requirements of the clauses 4 to 6 of the ISO 12100, the user must make a

risk analysis of the actuator+valve installed and taking into account all details of the nal application. This type of

analysis cannot be done by InterApp Valcom S.A.

Machine limits The limits of the “partly completed machinery” have been dened according the “intended use”

Hazard Identication The hazards mentioned in the standard ISO 12100, have been identied for the complete risk assessment. Hazard

related to dismantling, decommissioning and scrapping are not under the responsibility of InterApp Valcom S.A.

Risk estimation A risk estimation has been carried out, with the “intended use” for the products as a prerequisite.

Risk evaluation A risk evaluation has been carried out.

Risk reduction By means of; Inherent safe design measures and Information for use contained in the manual

Documentation of

risk assessment

and risk reduction

InterApp Valcom S.A. has the documentation that demonstrates that the ISO 12100 procedure has been followed

and the consequent results.

This manual suits for next models

1

Table of contents