3

Type 2080

Inhalt

1 OPERATING INSTRUCTIONS ................................................................................................................5

1.1 Symbols........................................................................................................................................5

1.2 Denitionoftheterm“device” ....................................................................................................5

2 INTENDED USE ......................................................................................................................................6

3 BASIC SAFETY INSTRUCTIONS ...........................................................................................................7

4 GENERAL NOTES...................................................................................................................................8

4.1 Contactaddress...........................................................................................................................8

4.2 Warranty .......................................................................................................................................8

4.3 InformationontheInternet..........................................................................................................8

5 STRUCTURE AND FUNCTION...............................................................................................................9

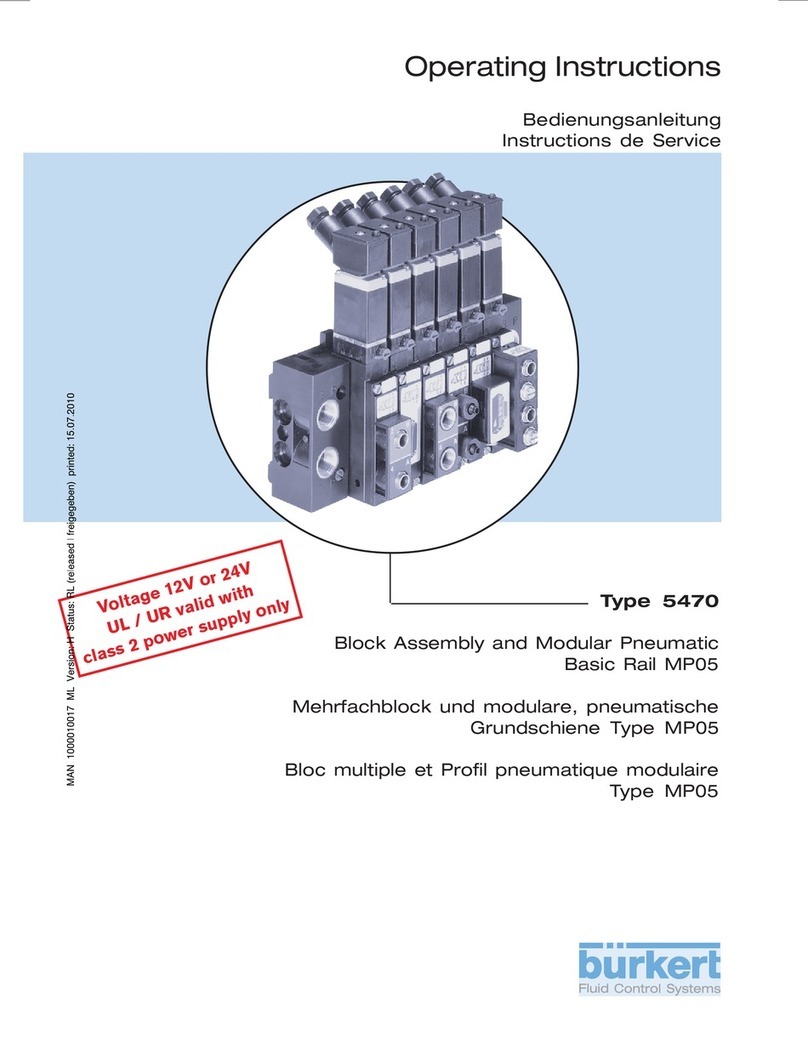

5.1 Modularity ....................................................................................................................................9

5.2 Design...........................................................................................................................................9

6 TECHNICAL DATA ................................................................................................................................10

6.1 Operatingconditions .................................................................................................................10

6.2 Restrictions ................................................................................................................................10

6.3 Conformity..................................................................................................................................10

6.4 Standards ...................................................................................................................................10

6.5 PTdiagram .................................................................................................................................10

6.6 Mechanicaldata.........................................................................................................................11

6.7 Fluidicdata.................................................................................................................................11

6.8 Actuatorversions .......................................................................................................................11

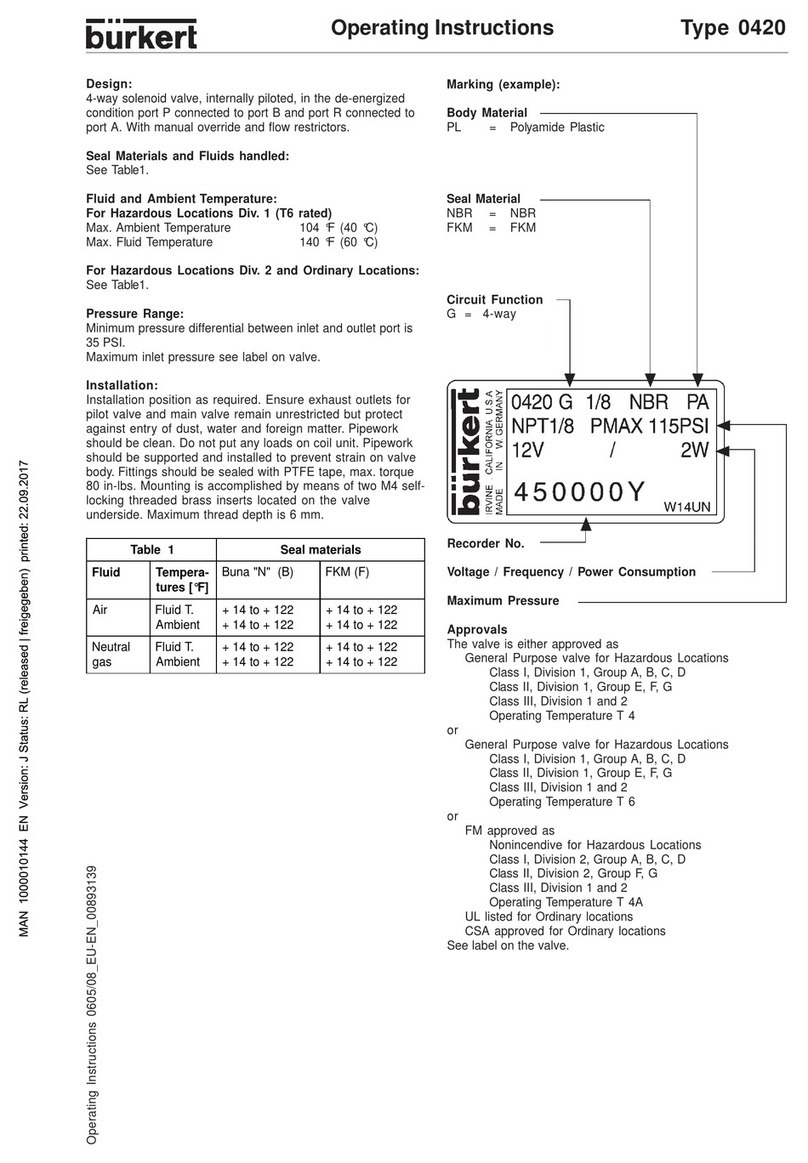

6.9 Typelabel(example) ..................................................................................................................12

7 INSTALLATION......................................................................................................................................13

7.1 Fluidicinstallation ........................................................................................................................... 13

7.1.1 Installation position.....................................................................................................13

7.1.2 Prior to installation......................................................................................................13

Type 2080

English