©2017 United Technologies Corporation 2 / 2 P/N 466-5276 • REV C •ISS 14FEB17

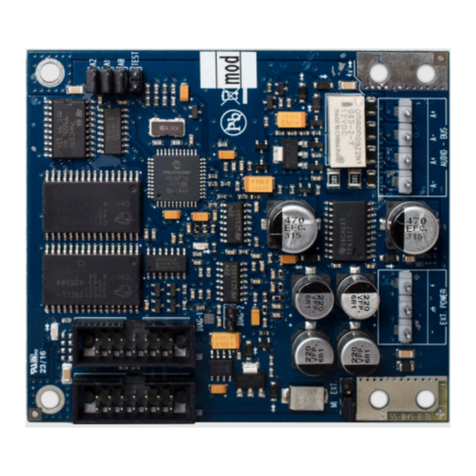

Blinks when sending data to control panel

Blinks when receiving data from control panel

Blinks when valid packet received from sensor or keyfob

Blinks when valid packet received

A triple blink every second indicates module not enrolled, a

single blink every second indicates module is enrolled

UM-W7 Programming

Consult the UltraSync Modular Hub Reference Manual for programming the UM-W7.

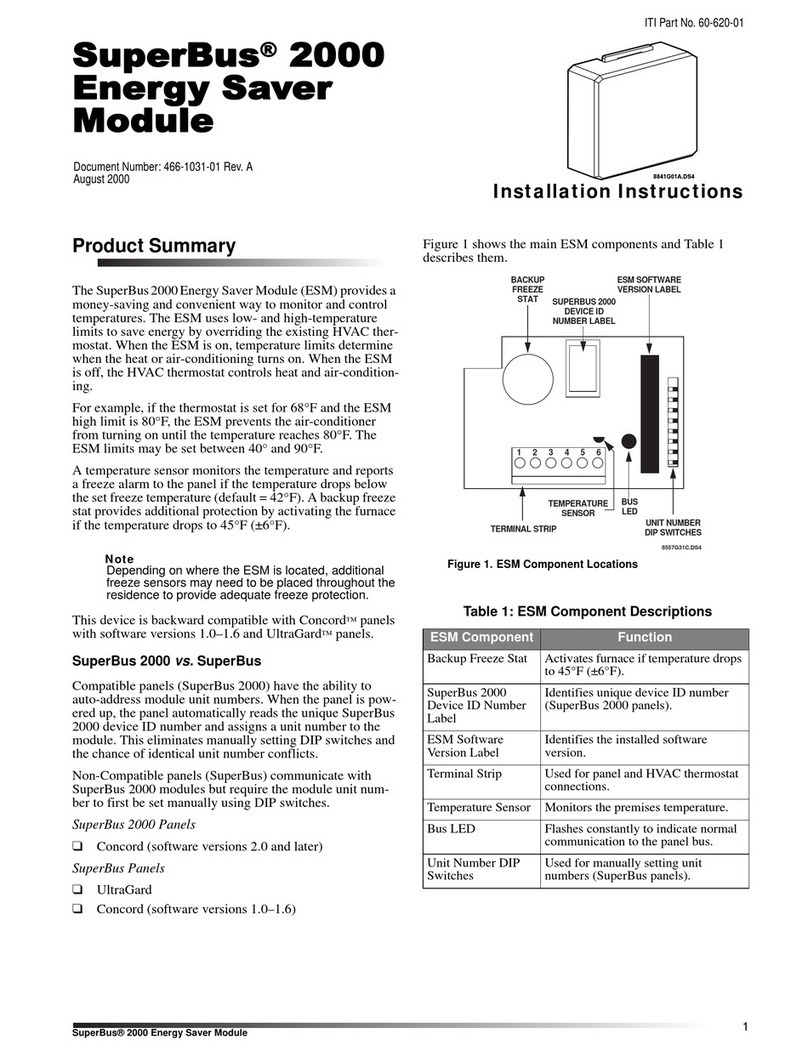

Note on Tamper

Two rubber push buttons provide front case and rear wall tamper.

To clear an Expander Tamper condition, both tamper inputs must be sealed. The

enclosure should be firmly mounted on a flat surface with the cover closed.

If either tamper input is open then an Expander Tamper condition will occur.

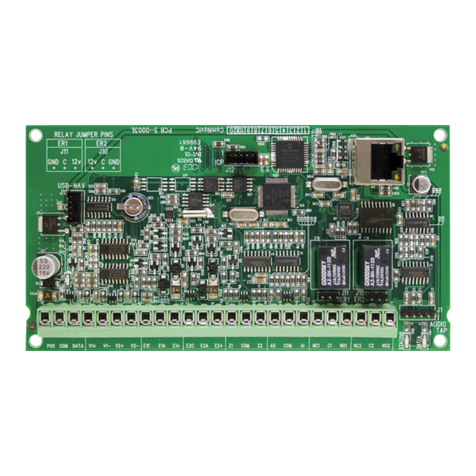

Note on Relay Modes

The receiver features one Single Pole Double Throw (SPDT) Form C relay.

The relay is connected to output terminal J6 with Normally Open and Normally

Closed connections for your convenience.

The red LED (D14) lights up when the relay is energized.

The relay can be configured in 3 different modes to support different applications.

Use jumper on J5 to select the mode suitable for your requirements.

Default is no jumper with relay in NC position.

No Jumper

Dry contact closure provided to output terminal. Maximum Load 30VAC @ 0.5A or

30VDC @ 1A.

Jumper between - and C

Buss Ground provided to output terminal @ typical 0V.Do not exceed relay rating

which is maximum load 30VAC @ 0.5A or 30VDC @ 1A.

Jumper between C and +

BUS Voltage is provided to output terminal @ typical 12-13VDC. Maximum Load @

12V is total panel current of 1,000 mA, this includes all connected devices such as

keypads, cellular module, sirens and expansion modules. Do not exceed relay rating.

Adding and Removing Wireless Devices

Refer to the UltraSync Modular Hub Reference Manual for adding and removing

wireless devices.

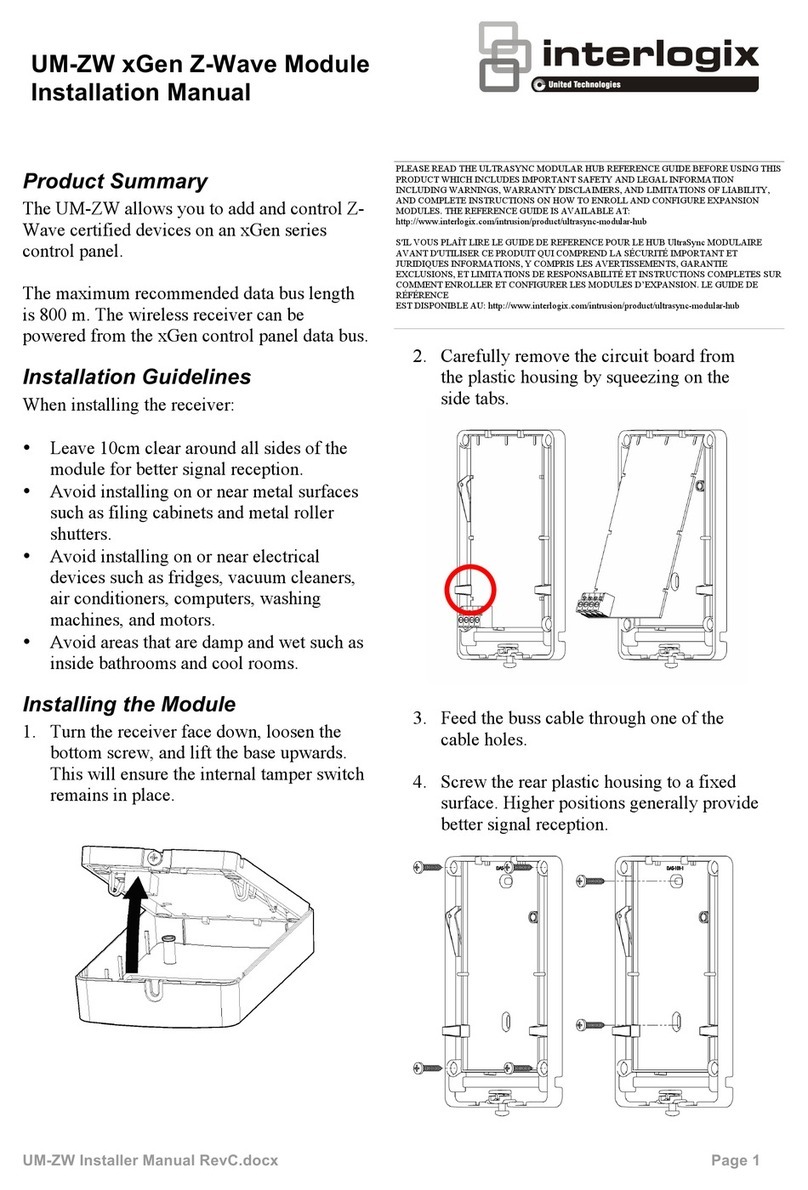

Completing Installation

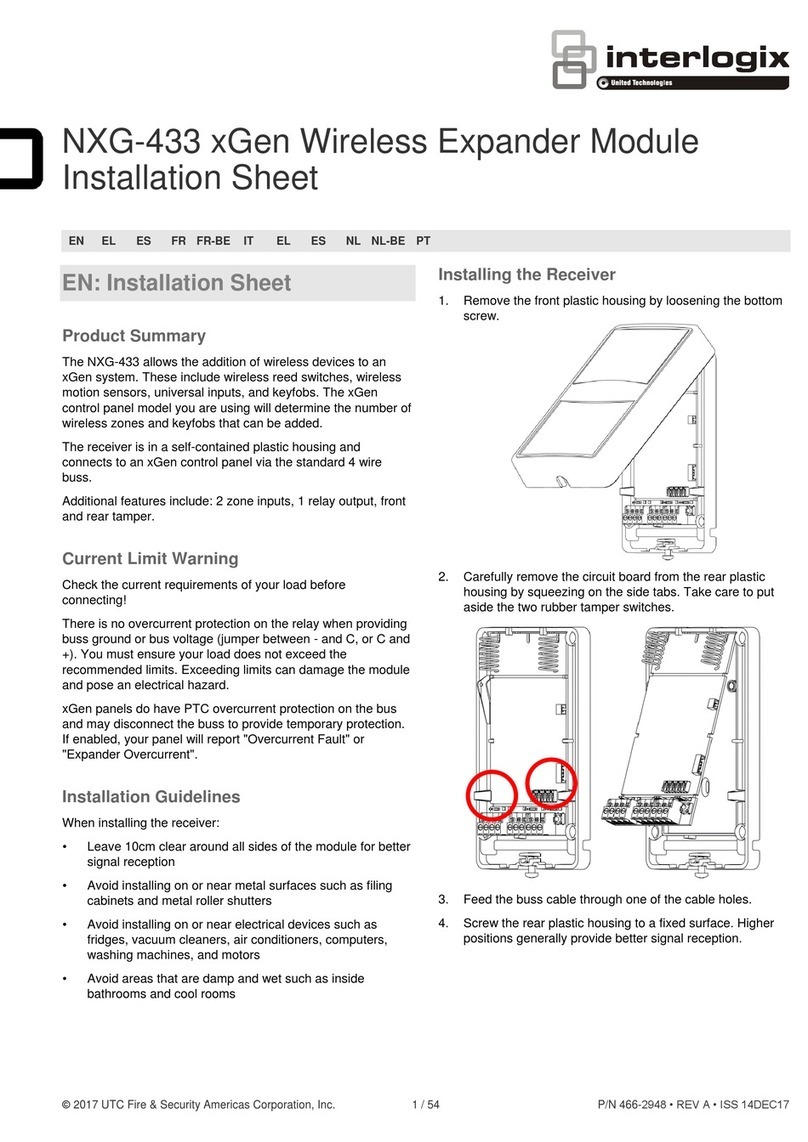

1. Re-install the front rubber tamper button if it was removed.

2. Re-install the front plastic housing and tighten the bottom screw

Warning:

CHECK THE CURRENT REQUIREMENTS OF YOUR LOAD BEFORE CONNECTING. THERE IS NO OVERCURRENT PROTECTION ON

THE RELAYS. YOU MUST ENSURE YOUR LOAD DOES NOT EXCEED THE RECEMMENDED LIMITS ABOVE. EXCEEDING LIMITS CAN

DAMAGE THE MODULE AND POSE AN ELECTRICAL HAZARD THAT COULD RESULT IN A FIRE OR CAUSE SERIOUS ELECTRICAL

SHOCK OR LOSS OF LIFE.

THE ULTRASYNC MODULAR HUB HAS OVERCURRENTPROTECTION ON THE BUS AND MAY DISCONNECT THE BUS TO PROVIDE

TEMPORARY PROTECTION. IF ENABLED, YOUR PANEL WILL REPORT “OVERCURRENT FAULT” OR “EXPANDER OVERCURRENT.”

REPEATED OVERCURRENT CONDITIONS CAN RESULT IN PERMANENET DAMAGE TO THE PANEL OR CONNECTED DEVICES.

Attention:

VERIFIER LES CONDITIONS ACTUELLES DE VOTRE CHARGE AVANT DE CONNECTER.

IL N'Y A PAS PROTECTION DE SURCHARGE SUR LES RELAIS. VOUS DEVEZ ASSURER VOTRE CHARGE NE DEPASSE PAS LES

LIMITES SUGGERER CI-DESSUS.

SUPERIEURE LIMITES PEUVENTENDOMMAGER LE MODULE ET POSE UN RISQUE ÉLECTRIQUE QUE POURRAIT CAUSER UN

INCENDIE OU ENTRAÎNER UNE GRAVE ÉLECTROCUTION OU DES PERTES DE VIE. LE HUB UltraSync MODULAIRE A DE LA

PROTECTION DE SURCHARGE SUR LE BUS DE COMMUNICATION POUR OFFRIR UNE PROTECTION TEMPORAIRE. SI ELLE EST

ACTIVÉE, VOTRE GROUPE PRÉSENTERA SON RAPPORT "SURINTENSITÉ" OU "EXPANDER SURVOLTAGE." CONDITIONS DE

SURINTENSITÉ RÉPÉTÉ PEUTENTRAÎNER UN ENDOMMAGEMENT PERMENANT AU PANNEAU OU A DES APPAREILS

CONNECTÉS.

Specifications

UltraSync Modular Hub systems

40 mA Average

65 mA Alarm/Maximum*

*If relay is inactive, calculation can be de-rated 25 mA per inactive relay. If

positive switching is utilized, additional current draw of connected load must be

included in power budget calculations.

Operating

temperature

range

Non UL/ULC installations

14° to 131°F

(-10° to 55°C)

UL/ULC installations

32° to 120° F

(0° to 49° C)

−30° to 120°F

(−34° to 60°C)

Non UL/ULC installations

up to 95% noncondensing

UL/ULC installations

up to 85% noncondensing

Product Dimensions

(W x H x D)

3.74” x 6.10 x 1.02”

95mm x 155mm x 26mm

Regulatory Information

Placed on the market by:

UTC Fire & Security Americas Corporation, Inc.

3211 Progress Drive, Lincolnton, NC, 28092, USA

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed andused in accordance with

the instruction manual, may cause harmful interference to radio communications.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This class B digital apparatus complies with Canadian ICES-3B.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada.

Contact Information

For contact information,visit us online at www.interlogix.com.

For technical support, see www.interlogix.com/support.

Copyright

Copyright © 2017 United Technologies Corporation. All rights reserved.

Trademarks

Interlogix is a registered trademark of United Technologies Corporation. Interlogix is part

of UTC Climate, Controls& Security, a unit of United Technologies Corporation.