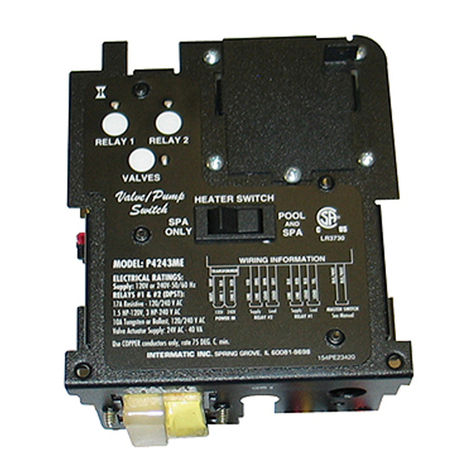

INSTALLATION - MODEL RC2343PT

1. Select the appropriate wiring diagram on Page 4

and prepare your installation layout. Make sure only

copper (solid or stranded) conductors are used,

properly sized and suitable for the installation. Each

equipment must have its own power disconnect and

must be grounded properly.

IMPORTANT: NEUTRAL MUST ALWAYS BE

CONNECTED TO THE WHITE LEAD OF THE

CONTROL.

2. Hang Air Switch on a flat vertical surface or other

support, using hardware suitable for the purpose.

Make sure the air button is within the range of the

Air Switch. NOTE: The optimum range of this Air

Switch is 100 feet. However, factors beyond control

of the manufacturer (like the size of the air pump,

the I.D. of the air hose, etc.) will determine the actual

distance between the mechanism and the air pump.

3. Prepare the necessary conduit runs, including one

for the air hose, terminate them at both ends and

pull-in the conductors as specified by the installation

layout.

4. Follow proper wiring diagram, make LINE, PUMP,

BLOWER and FREEZE PROTECTION (if applicable)

connections as shown. Make sure the installation is

securely grounded.

5. Make air hose connections. Remove compression

nut from Pulse Switch, feed air hose through

hole, connect hose to Pulse Switch and re-install

compression nut. Repeat procedure at Air Button

end of hose. Make sure connections are tight.

6. Check wiring, tightness of connections and

grounding. Close wiring compartment and test

installation.

7. Set timer, see instructions below.

OPERATION

2

TROUBLESHOOTING

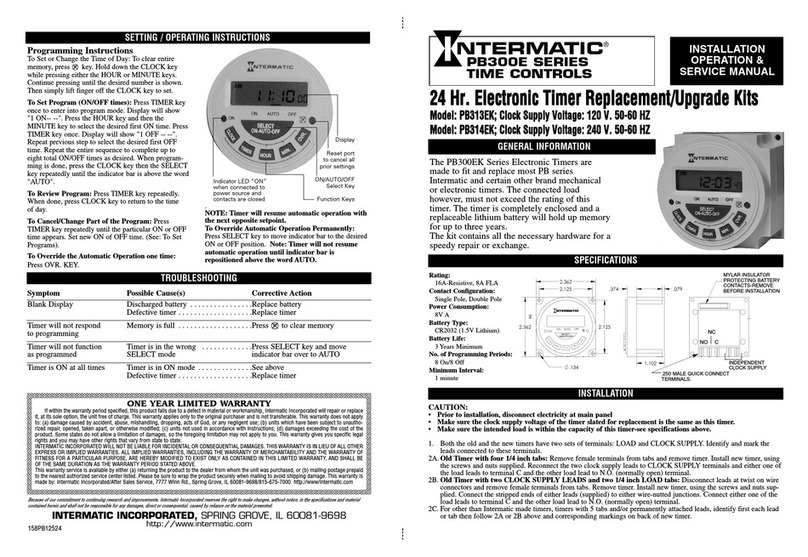

SYMPTOM CAUSE(S) CORRECTIVE ACTION

1. Pump will not operate or operates 1a. Air hose disconnected Check hose connections.

on low speed only. 1b. Defective air button Replace air button - see note 1.

1c. Water in air hose Blow-out air hose - see note 2.

1d. Defective pulse switch Replace pulse switch - see note 2.

1e. Defective relay Replace relay - see note 3.

1f. Air button is too far Install larger air button.

2. Pump will not turn off or operates 2a. Air hose disconnected Check hose connections.

on high speed only. 2b. Defective air button Replace air button - see note 1.

2c. Defective relay Replace relay - see note 3.

3. Pump turns on/off by itself. 3a. Defective pulse switch Replace pulse switch.

3b. Water in air hose Blow-out air hose - see note 2.

3c. Changing air pressure in air hose Reroute air hose.

TROUBLESHOOTING NOTES

A Pneumatic Remote Control (Air Switch) consists of an air button (air pump, transmitter), a pulse switch (air Sensor,

receiver) and a relay (either alternate action or stepper). The air button is connected to the pulse switch by the air hose.

By pressing on the air button at one end of the air hose, the increased pressure will momentarily close the contacts of

the pulse switch at the other end of the air hose, thus energizing the coil of the relay. The relay turns ON or OFF the

connected equipment.

1. An air button with ruptured seal or bellows inside, will not produce sufficient air pressure to operate the momentary

air switch and could lead to total break down.

2. Water in air hose will damage the pulse switch and it is caused by a faulty air button (see note 1 above) or

condensation. In either case, it must be drained and the cause found and corrected. To reduce condensation,

3. A defective relay is either due to contact or coil failure. Contact failure is caused by over-load or cross wiring and coil

failure is caused by 240 volt connected across the 120 V coil or permanently applied 120 V. (The relay is designed

for intermittent duty only). Permanently applied 120 V could be the result of water in the air hose (see note 2 above)

or a spa cover placed over (and depressing) the air button. In any case, the cause must be found, corrected and the

relay replaced.

3

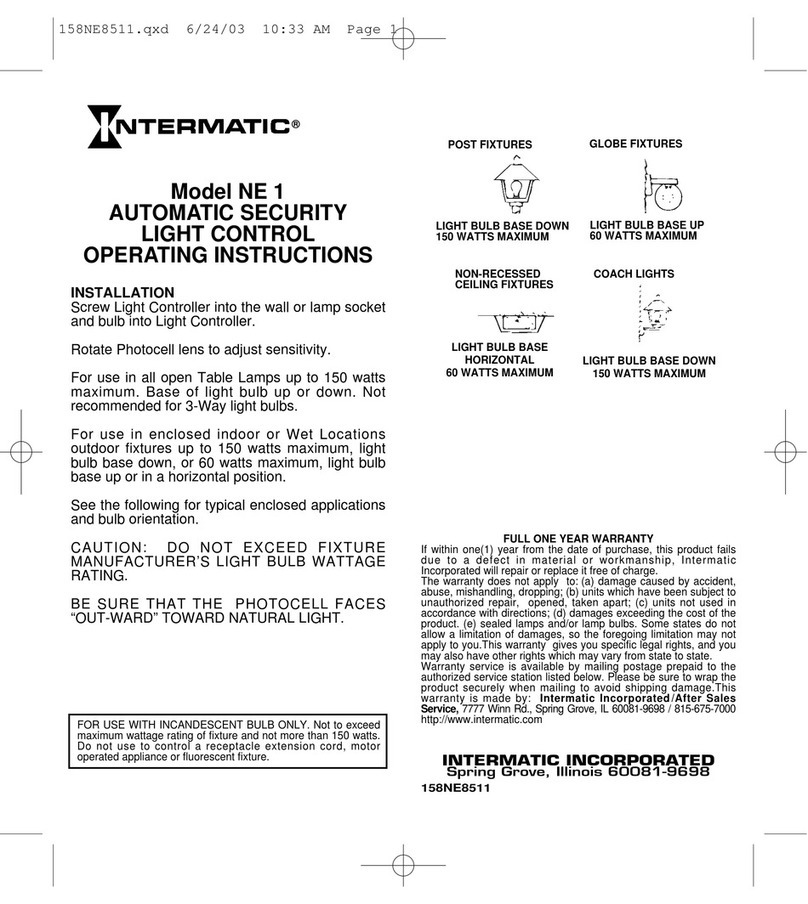

1. Insert ON (green) and OFF (red) trippers into

dial at desired ON and OFF times (Fig. 1).

Be sure trippers are firmly pressed against

dial surface and at least one space is left

between ON and OFF trippers (Fig. 2).

2. Turn dial clockwise one or more revolutions

until correct time of day is next to arrow in

center of dial (Fig. 3).

Manual Knob ON Tripper (Green)

OFF Tripper (Red)

1. The knob in the upper left corner of timer is for

operating the Filter pump manually when needed. By

turning it COUNTERCLOCKWISE, it will start or stop

the ltering/heating cycle ahead of the scheduled

start/stop time. Automatic operation will resume with

the next scheduled cycle.

2. Timer comes with two sets of trippers, allowing the

choice of two cycles per day. If only one cycle is

needed, the extra trippers may be stored on the dial

by placing SAME color trippers next to each other.

3. To suspend automatic operation, remove red and

green trippers from Dial and Store them in a convenient

place.

4. Additional trippers can be obtained by contacting an

Intermatic distributor or Intermatic Customer Service

at (815-675-7000 and asking for 156PB10398A tripper

kit (2 ON and 2 OFF trippers.)

Figure 1 Figure 2

Figure 3